3D printing has come a long way in just a few years. It was started as a tool for hobbyists, but now it is used in factories, hospitals, and labs worldwide. But there’s one question every maker, engineer, and manufacturer has to answer first: What plastic should you use?

Because not all plastics are the same. Some can resist high heat. Some bend without breaking. Others are light, strong, and cheap. The plastic you choose affects how your part looks, how long it lasts, and how well it works in the real world.

In this guide, we’ll walk you through the most famous plastics used in 3D printing today. You’ll see how they work, where they’re used, and why one must fit your project better than another.

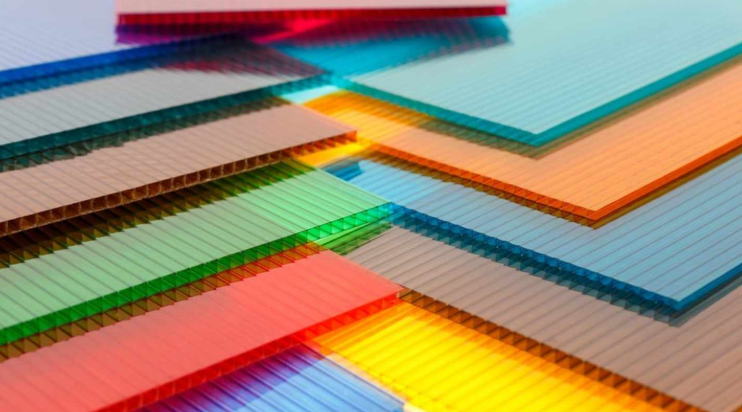

3D Printing Materials

Before examining product specifications, you should step back first. When choosing plastic materials, you must understand the behavior of your print during actual pressure conditions. For example;

Every plastic comes with trade-offs. You can print them perfectly, but their strength collapses under stressful situations. The material withstands chemicals but wears down when you subject it to rapid cooling. Beyond data sheets alone, you require additional information. You must choose plastics that fulfill your actual requirements because they will operate within your printer environment and workspace configuration.

Ask yourself this first: This material will function for the future in addition to its present-day abilities. Does the material need to remain stationary on display items? Does it need to operate inside machinery that moves? Does the material require Food and Drug Administration regulation? Should it pass an impact test? The answer shapes everything. When you print in 3D, the ideal plastic material becomes the one that seamlessly meets your specific requirements.

Once you have the proper mindset in place, we can examine top performers to see their achievements in actual practice.

Selecting suitable plastic materials demands more consideration than random name selection among the available options. Each material from this lineup represents years of testing that resulted in successful deployments across factories and retail stores and critical operational environments. Before loading your spool, you must understand these features, which set each material apart.

PLA Plastic

It is Best for beginners, fast prototyping, and low-heat environments

PLA has widespread popularity among 3D printing users. This material prints with clarity without bed issues while requiring no heated chamber. People who want rapid results along with hassle-free functionality should choose this material. PLA offers a biodegradable solution derived from renewable corn starch that works well for both visual models and concept parts.

But here’s the catch: it softens fast under heat. When placed in a hot car during sunny weather, your PLA prints could become deformed. PLA stands out as the best material for quick and straightforward printing despite its lower strength properties.

ABS Plastic For 3D Printing

It is Best for functional parts, high-heat applications, and post-processing

ABS material exhibits excellent toughness, the ability to resist impacts, and maintains stability at high temperatures. For enduring structures, including enclosures, brackets, and tools, ABS material stands out as the most suitable choice. The production materials used to make LEGO bricks, car interior components.

Here’s the trade-off: It’s challenging to print. To prevent warping, you will require both a heated bed and an enclosure. The fumes released during print time require ventilation equipment, which becomes mandatory. After proper setup, you will achieve parts that function effectively when pushed to their limits.

Polyethylene Terephthalate Glycol

It is best for: PETG provides durable prints and mechanical parts that demonstrate high chemical resistance.

The material properties of PETG unite the advantageous elements of ABS and PLA during printing. It prints in a way that resembles PLA while delivering superior strength, flexibility, and chemical resistance properties. It remains transparent while being food-safe and resistant to damage from regular use.

You can avoid using an enclosure, and the risk of warping remains very low. PETG requires careful monitoring of your retraction settings because it produces strings. PETG stands out as an excellent material option for durable functioning parts that will not break or warp.

TPU Plastic

It is best for flexible prints, wearables, gaskets, as well as shock absorption applications.

TPU changes the game. It stretches like a rubber yet maintains its durability across long periods of use. When you need to make phone cases or wearable items and waterproof seals through printing the TPU material (Thermoplastic Polyurethane) serves as your optimal solution. It demonstrates remarkable bending abilities while bouncing back without breaking.

If you use flexible filaments in a printer setup without TPU-ready extrusion, it can lead to kinks in your Bowden tubes while also causing jams. When you decrease print speed and properly calibrate your printer, TPU produces resilient, flexible components that will last.

Nylon Plastic

It is best for High-strength, industrial-grade parts, moving components

Nylon shows key features, including high strength while staying lightweight and demonstrating unusual flexibility. It is useful for creating functional prototypes, as well as hinges and gears, and wear-resistant parts. It has a shock absorber capability to fight against friction while maintaining its integrity during pressure situations.

Most people overlook the fact that nylon exhibits a strong preference for water exposure. The material draws moisture from the surrounding air, which ends up damaging printed objects. Dry it well before use. Print it hot and slow. After reaching proper calibration, nylon provides exceptional performance results.

PC Plastic for 3D Printing

It is Best for impact-resistant materials designed for high-temperature situations that also produce transparent components.

Polycarbonate is a beast. PC stands out as one of the most rugged 3D printing materials available on the market. The need arises for materials that handle both heat and pressure as well as pressure alone. Many aerospace professionals, along with automotive engineers, frequently choose PC as their material of choice.

The printing process requires high temperatures but generates easy warping and needs a fully enclosed printer environment. The setup complexity aside, PC withstands high impacts and heat while maintaining its durability in harsh conditions.

ASA Plastic

ASA suits outdoor applications with UV resistance properties and durability against weather impacts in printed materials.

ASA functions similarly to ABS, however, it operates outside. This material withstands UV rays, together with moisture and temperature changes, better than any other commonly used material. ASA works exceptionally well for outdoor structures and signs, and protective housings that face climate exposure.

HIPS 3D Printed Plastic

It is best for support structures alongside lightweight models, along with dissolvable supports

Users mix HIPS with ABS as support material during production. Limonene serves as a solvent, allowing the printing of intricate models having overhangs or enclosed sections.

Support material is not all it does not function as. The base material HIPS demonstrates high strength and lightness during independent printing operations. Therefore, it remains a popular choice for producing lightweight models, including drone components and small electronic displays.

PP 3D Print Product

It is best for hinges and produces lightweight components.

Polypropylene serves as the fundamental material in storage containers, car bumpers. HIPS provides flexibility and resists fatigue while sustaining exposure to various chemicals. Printing PVA proves challenging because the material shows weak bonding between layers and struggles with sticking to the build platform. New printing bed materials combined with modified resin formulas show promise in raising printing success rates.

The ability to flex and snap back in your design makes polypropylene (PP) suitable as a material solution for reusable lids and live hinges.

PVA (Polyvinyl Alcohol)

It is best for water-soluble supports, dual extrusion printing

When used as a dual-extrusion component, PVA demonstrates superior value, though it shines less independently. Customers can print their models with PLA or PETG while supporting their structure with PVA before dissolving the PVA support into water. No tools. No cleanup. Just clean the inner geometry.

The material requires expensive storage inside airtight containers. It absorbs moisture fast. The use of PVA in multi-material printing reduces post-processing time to enable complete freedom in design imagination.

The selection of a technique for printing plastic parts is equally important as the choice of material itself. Print technologies use different approaches to manage materials, which result in distinct outcomes regarding product strength, finish, production speed, and investment cost.

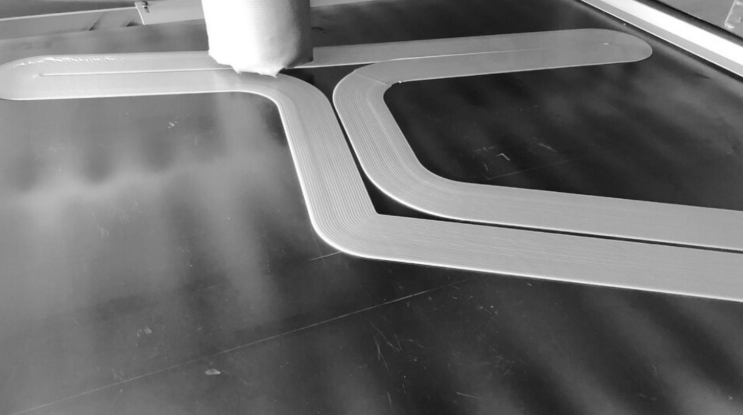

FDM 3D Printing

FDM stands as the principal technique for 3D printing. In this operation, a plastic filament melts to create thin layers, which build up sequentially. The technique allows budget-friendly, quick installations through its ability to work with multiple plastic materials, including PLA, ABS, PETG, and TPU.

What makes FDM practical:

But don’t expect perfect surfaces. Layer lines are visible. Overhangs need supports. The use of nylon or PC requires precise control over both temperature and humidity conditions.

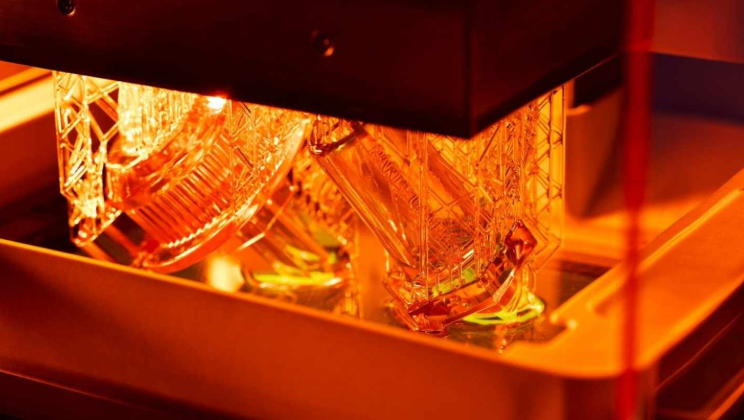

SLA 3D Printing

The laser technology of SLA uses liquid resin instead of filament to create the object through curing. Printing with this technology produces exact geometric models that require high levels of precision. Users often select dental aligners, casting molds, and finely textured prototypes from this technology.

Why choose SLA:

Most resin materials exhibit brittleness alongside UV and heat sensitivity. Resin printing necessitates gloves and alcohol, along with a post-cure setup for completion.

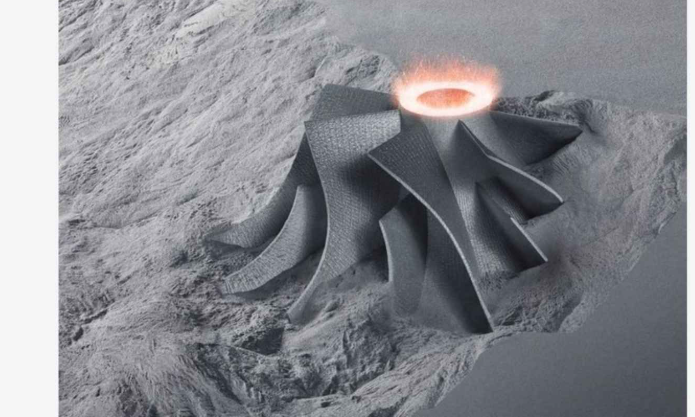

SLS 3D Printing

SLS is best for producing industrial components with complex geometries and high-strength requirements.

Selective Laser Sintering melts powdered plastic, such as nylon, using a laser to form solid layers. Support structures are unnecessary when using this process to create nested or interlocking parts. Aerospace and automotive industries, together with advanced product design facilities, utilize this technology.

SLS stands out because:

However, it’s not cheap. You will require an industrial printing machine to make this work. The surface shows slight graininess unless you implement post-processing methods.

MJF 3D Printing

MJF is the best fit for mass production while producing consistent strength and serving business-level applications.

MJF machines eliminate lasers by employing heat and fusing agents to create functional parts from powder material. The method provides prints with both shorter production times and enhanced inter-layer bonding.

Where MJF shines:

MJF has become the standard for healthcare and robotic applications since these industries value consistent product results. Among these technologies, it holds a position as one of the most expensive solutions.

DLP 3D Printing

Digital Light Processing functions as an SLA alternative that employs a digital light projector in place of a laser. This process delivers the whole layer curing at once to achieve higher speed. This production method has widespread dental applications and miniatures production, while also working for intricate parts.

DLP perks:

The same brittle nature exists in both SLA and these resins. Parts exposed to mechanical stress or impact are not suitable for DLP printing.

FJF 3D Printing

Emerging tech alert: FJF represents a recent additive manufacturing technology showing rapid expansion. Using plastic pellets instead of filament reduces costs significantly and speeds up production times for extensive parts.

Why it matters:

Most industrial and large-scale applications currently adopt this technology. You should consider this printing method if your projects require substantial volume production of sustainable prints.

Ask yourself three questions:

FDM serves as an optimal option for prototyping and budget-friendly functional part production. The best choice for visual models and ultra-fine details becomes SLA or DLP. Industrial-strength manufacturing needs SLS or MJF for batch production. You should examine FJF technology if you need to increase production numbers or minimize material expenses.

Each method offers unique benefits which prevent any one technology from working for all projects. The result becomes magical when you unite your printing technology with your selected plastic material.

Every project requires a different plastic material for the desired results. Here’s a quick guide to select the right plastic for your case;

Printing PLA constitutes the simplest operation among all plastic types. The material works well for creating fast draft versions and mockups, and visual elements. The print bed can easily keep PLA in place. It does not require extra equipment. These printers can produce fast prints without any problems.

But keep this in mind: PLA isn’t strong under heat. Meaning it becomes softer through exposure to hot car conditions or sunlight. Parts that experience high-touch frequency and stress should not be made with this material.

Your part requires strength to support weight or handle impacts, so PLA material should be avoided. The combination of toughness and heat resistance can be achieved by selecting ABS. Tool handles and car parts, and enclosures utilize this material.

PETG strikes a balance because its printing process is similar to PLA while delivering ABS-level strength. Nylon exceeds every other material in terms of strength. This material demonstrates the ability to bend while receiving impacts during harsh environmental conditions.

Just remember: these materials need more tuning. ABS needs an enclosed printer. Nylon performs best when it's dry and printed at high temperatures.

The material TPU shapes into a rubber-like substance with molded plastic properties. It works perfectly for creating phone cases and gaskets because these objects need to bend without breaking. TPU maintains stretchability while maintaining its initial form.

But it prints slower. A printer must support flexible filament technology to work. A printer with direct-drive extruders delivers superior performance than printers that utilize Bowden extruders.

ASA should be your material selection when your printed items will endure outdoor conditions, including signs and tools, and boxes. ASA stands as a sunlight and rain-proof plastic that operates like ABS but demonstrates superior tolerance to temperature variations. Exposure to sunlight will not cause TPU to fade or develop cracks.

PETG stands out as a material solution when you require parts to stand up against alcohol-based chemicals, cleaning agents, and oils. The food-safety compliance of PETG depends on checking the label information. The material appears in kitchen appliances such as water containers and tools.

However, the printing process requires special equipment, and standard beds struggle to adhere to these materials properly.

PVA dissolves in water. Dual-extruder printers using PLA as their material benefit significantly from PVA because of its compatibility. The printed piece with its support structure is created together before you immerse the part in water. But the PVA melts away.

So, the best method of use for HIPS matches ABS printing. Limonene serves as a special dissolving liquid for this material.

3D printing isn’t just about the printer; in fact, it’s all about the plastic behind the print. From flexible TPU to rugged ABS, each material brings its strengths and limits. The best choice depends on what your part will face: stress, heat, weather, or wear. Whether you're prototyping, producing, or perfecting a design, choosing the right plastic sets the foundation for success. Don’t just follow trends. Always try to match your material to your mission, and your print will do the rest.