In the ever-evolving landscape of automotive design, manufacturers are constantly seeking innovative ways to enhance performance, efficiency, and aesthetics. One of the pivotal contributors to this advancement is the utilization of specialized CNC (Computer Numerical Control) turning services. These cutting-edge machining processes have revolutionized the production of complex automotive components, pushing the boundaries of what's possible in vehicle manufacturing.

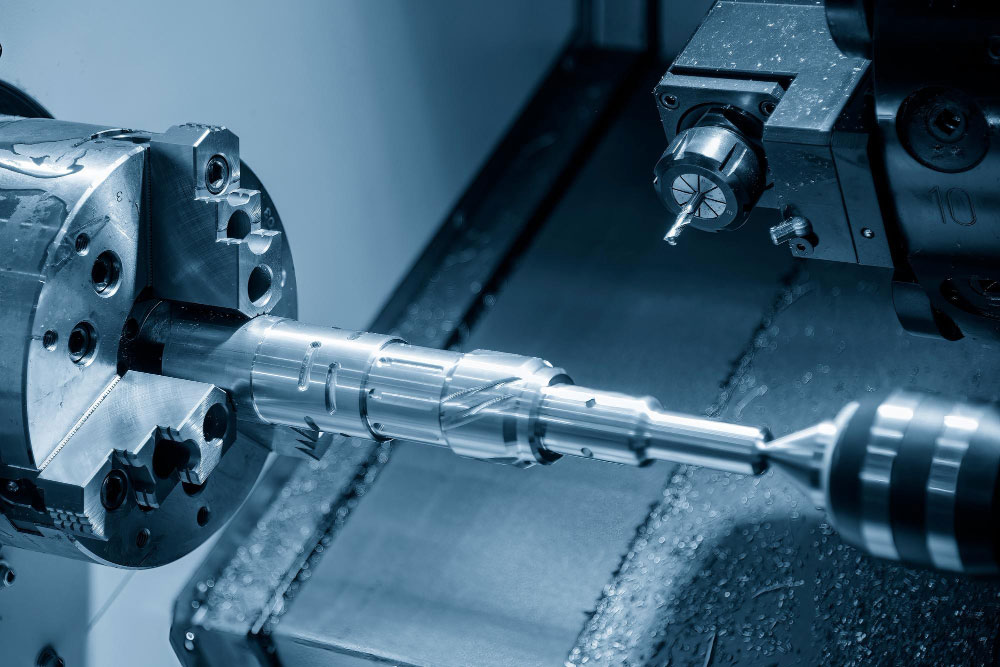

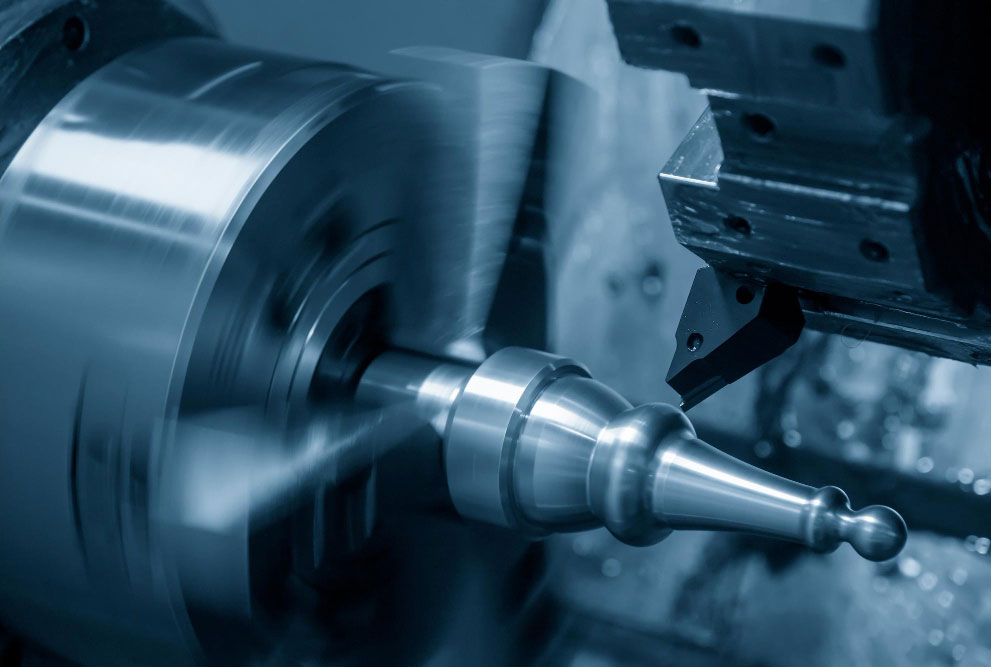

CNC turning is a precision machining process where a cutting tool, fed by a computer-controlled program, removes material from a rotating workpiece to create intricate parts and components. This technology allows for high levels of accuracy and repeatability, essential for the demanding specifications of the automotive industry.

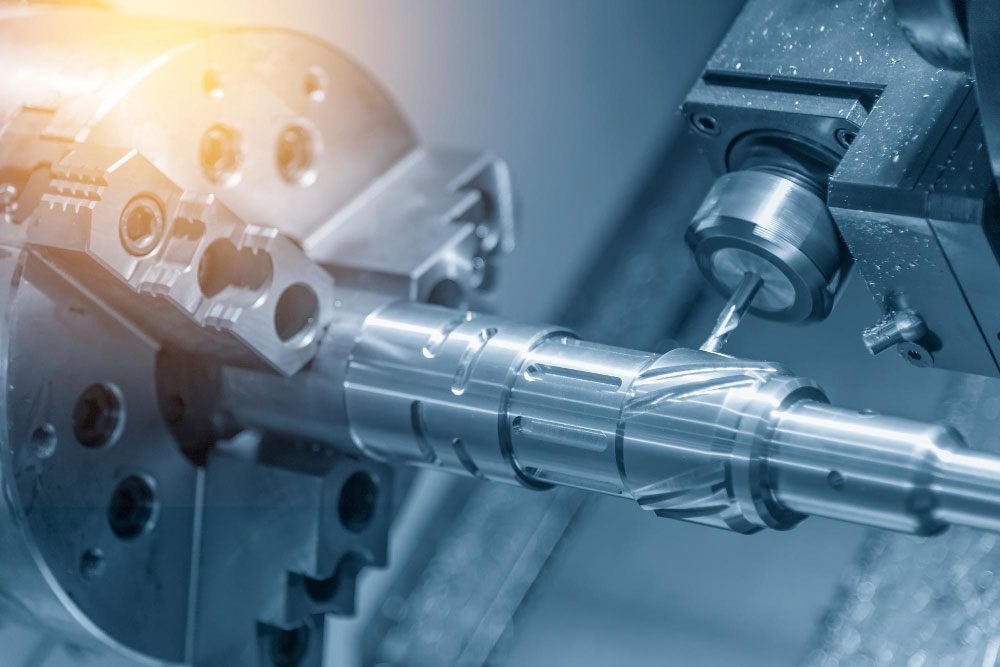

Specialized CNC turning services go a step further by offering advanced capabilities, such as multi-axis machining, high-speed operations, and the ability to work with a diverse range of materials—including metals, plastics, and composites. These services provide automotive designers and engineers with the flexibility to create complex geometries and tight tolerances that are often unachievable with traditional manufacturing methods.

The modern automobile is a marvel of engineering, composed of thousands of parts that must work seamlessly together. Specialized CNC turning enables the production of components with intricate designs, which are critical for the functionality and efficiency of today's vehicles.

For instance, in the production of engine parts like turbocharger shafts, piston pins, and crankshafts, CNC turning ensures each component meets exact specifications for optimal performance. The precision machining allows for the creation of complex features such as grooves, tapers, and threads, which are essential for engine efficiency and longevity.

Transmission systems rely heavily on precisely machined parts to function correctly. CNC turning services facilitate the manufacturing of gears, shafts, and other drivetrain components with the exacting tolerances necessary for smooth operation and power transmission.

With the automotive industry's push towards lightweight vehicles for improved fuel efficiency, materials like aluminum and carbon composites are becoming more prevalent. Specialized CNC turning can adeptly handle these materials, producing lightweight yet strong components that contribute to overall vehicle weight reduction without compromising safety or performance.

Quality and reliability are non-negotiable in automotive manufacturing. Specialized CNC turning services contribute significantly to these standards through:

The computer-controlled nature of CNC machines ensures that each part produced is consistent with the last, reducing the margin of error to virtually zero. This level of precision is crucial in automotive applications, where even minor deviations can lead to significant performance issues or safety concerns.

CNC turning machines can operate continuously with minimal human intervention, leading to faster production rates. This efficiency not only speeds up the manufacturing process but also allows for rapid prototyping, enabling designers to quickly test and refine components.

While the initial investment in CNC technology may be high, the long-term benefits include reduced labor costs and material waste. Automation minimizes the potential for human error, ensuring high-quality output and lowering the cost per unit in mass production scenarios.

As consumer demand shifts towards personalized vehicles with unique features, the ability to produce custom components becomes increasingly important. Specialized CNC turning services empower manufacturers to meet these demands by:

As automotive technology progresses towards electric and autonomous vehicles, the demand for precision-engineered components will continue to rise. Specialized CNC turning services will play a crucial role in this evolution by:

Specialized CNC turning services are at the forefront of enhancing automotive design and manufacturing. By offering unparalleled precision, efficiency, and the ability to handle complex and custom components, CNC turning is not just a manufacturing process but a catalyst for innovation in the automotive industry.

Manufacturers that leverage these advanced machining services position themselves to meet the challenges of today's market and the demands of tomorrow's technologies. As a result, vehicles become more efficient, reliable, and tailored to the evolving needs of consumers, all while maintaining the highest standards of quality and performance.

Whether it's in the pursuit of speed, efficiency, or sustainability, CNC turning stands as a cornerstone in the ongoing quest to push automotive design beyond conventional limits. The road ahead is shaped by these technological advancements, driving us towards a future where the possibilities in vehicle manufacturing are as limitless as our imagination.

If you're interested in learning more about how CNC turning can elevate your manufacturing processes or wish to discuss a specific project, feel free to contact us today.