Polishing is a surface finishing process that is frequently utilized in industrial manufacturing & storage systems to enhance the components' aesthetic appeal, dimensional accuracy, & functional performance. For the process to increase cleanliness, corrosion resistance, & mechanical dependability, the surface must be smoothed as well as polished through removing flaws, scratches, or inconsistent materials. Whether it's a precision-machined turbine's blade or a stainless-steel storage tank, polishing is vital for producing a product that meets both technical as well as aesthetic requirements.

We'll explore how polishing functions, different methods, material-specific factors, & the equipment, advantages, potential drawbacks that influence modern polishing procedures in this article.

During machining, casting, or shaping, polishing is a material removal method used to improve the surface smoothness and get the item ready for end use or other surface treatments such as coating or plating. It belongs to the more general heading of finishing operations, and also includes buffing, lapping, grinding, & superfinishing.

In technical terms, polishing involves employing bonded or loose abrasives to chemically or mechanically reduce surface roughness. According to the needs of the application, finishes on the surface with a roughness average (Ra) of 0.2 to 0.8 microns are typically the goal.

It's essential to distinguish polishing from:

Polishing is crucial in sectors such as precise storage systems, automobiles, healthcare equipment, & aerospace since it fills the gap between practical enhancement & esthetic refinement.

For the purpose to enhance surface smoothness, reflectivity, & functional qualities, polishing is a surface improvement process that uses controlled abrasion to remove minute layers of material. Given the material type & application, it may be done physically, chemically, or electrochemically. To ensure uniform quality and uniformity, the procedure typically adheres to a multi-stage, organized workflow.

The workpiece is thoroughly scrubbed to get rid of contaminants like coolants, oils, & grime before polishing starts. Any prior forming, grinding, or machining should be completed first. Descaling & degreasing are also standard preparation procedures for metallic parts.

Material hardness, needed polish, & desirable surface roughness (Ra) are all taken into account while choosing abrasives. The elements aluminum oxide, silicon carbide, cerium oxide, & diamond paste are instances of common abrasive types. For initial leveling, the sizes of grits vary from coarse (e.g., 60–100) for ultra-fine (e.g., 1200–3000) for mirrored polishing.

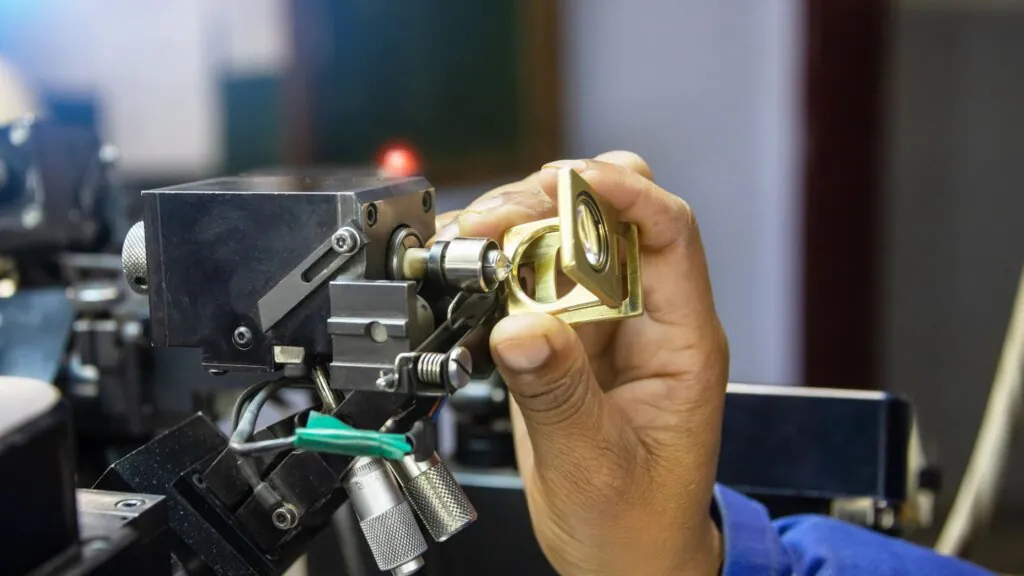

Rotating polishing wheels, belt sanders, orbital tools, and other flat lapping machines are employed for the actual polishing procedure. Properly regulating pressure, feed rate, & tool motion guards prevent deformation or surface warming. By soaking the workpiece in an electrolytic bath, an electric current lowers surface peaks by anodic disintegration, producing a clean, smooth finish without mechanical strain.

During the process, coolants or lubricants like water, oil emulsions, or polishing slurries are employed to reduce heat damage & friction. These additionally serve to keep the surface clean while getting rid of harsh residues.

To avoid cross-contamination, elements are cleaned in between polishing cycles, especially when switching to finer grits. High-precision manufacturing may utilize deionized water rinses or ultrasonic cleaning.

Optical microscopes, tactile tools, or profilometers are employed to inspect the final surface for flaws. Ra (the roughness average), Rz (an average of peak-to-valley height), & visual gloss metrics are a couple examples of evaluates used to quantify surface finish.

Even on complex geometries, manufacturers may get precise tolerances as well as consistent finishes with a variety of modern polishing methods, whether they are entirely CNC-controlled, semi-automated, and manual.

The characteristics of the material, required quality, manufacturing scale, and efficiency requirements, polishing methods might vary greatly. The most prevalent polishing techniques in industrial production are outlined below:

This traditional well-known technique uses abrasive wheels, belts, or pads to manually smooth out surface irregularities. The abrasive, which may vary from coarse grit to ultra-fine polishing pastes, may be applied both wet or dry. It is cheap and frequently used in metal finishing, but if left unchecked, it can cause heat distortion or minor scratches.

Applications include machine components, aluminum casings, & stainless steel tanks.

For the purpose of dissolving surface imperfections at the level of the micro, the workpiece is immersed in a chemical bath. It gives off a smooth, brilliant finish without a requirement for mechanical power. However, it necessitates rigorous control of exposure duration, temperature, & bath composition.

Applications include small-batch manufacturing, biomedical devices, or intricate components.

Anodically dissolved the component in an electrolyte is a highly accurate electrochemical method. At the level of the micron, the surface is made smooth by the preferential removal of material located in elevated spots. Additionally, it lessens bacterial adhesion and improves corrosion resistance.

Applications include semiconductor components, food-grade containers, & medical implants.

For high-performance items which require a very low roughness of the surface (Ra < 0.05 µm), this ultra-precision technique is used. Superfinishing removes surface waviness & produces a crosshatch pattern through applying low pressure to tiny abrasive stones.

Applications include shafts, gears, & bearings in the aerospace and automotive sectors.

The outermost layer of the surface is heated by laser beams before being solidified into a flawless finish. While this non-contact method requires costly equipment and safety precautions, it is very controlled and reduces manual effort.

Applications include hard-to-machine components including aerospace alloys.

This sophisticated technique produces highly uniform finishes for surfaces on intricate geometries through the use of magnetic abrasives that are modulated by a magnetic field.

Applications include surgical tools & turbine blades.

Flame polishing is primarily employed on thermoplastics, such as acrylic, to melt & smooth the surface by running a flame over it. Accurate flame control is necessary for avoiding distortions or burns.

Applications include optical components, laboratory apparatus, including plastic containers.

In manufacturing, choosing the appropriate polishing method is essential as it has an immediate effect on surface integrity, usability, and expenditure effectiveness. A variety of operational & technical aspects have to be assessed:

Manufacturers can choose the most effective and reliable polishing technique for their operations by creating a choice matrix with weights for each of these factors.

Although polishing can be applied to a wide variety of materials, the best surface quality and integrity is possible only by carefully matching the process to the mechanical & chemical properties of each material.

The hardness, thermal characteristics, as well as the surface quality of the material have to be taken into consideration when selecting abrasives, lubricants, & tools to perform effective polishing.

In numerous different sectors, polishing serves as vital to enhance the aesthetics & practical performance of industrial components. It could be used for much more than simply improving surface luster.

For both aerodynamic & aesthetic reasons, polishing is essential in the production of automotive. To get a mirror-like gloss, alloy wheels, body panels, & exterior trimmings are cleaned chemically or mechanically. To reduce wear as well as friction, engine & gearbox parts can also be superfinished.

To improve air flow dynamics & lower drag, aerospace parts such as turbine blades, shafts, as well as fuselage pieces are cleaned to strict requirements. Component lifetime & fatigue resistance are enhanced by superfinishing procedures.

Sterility, biocompatibility, including corrosion resistance are ensured when surgical tools, implants, & dental equipment are surface polished. Titanium & stainless steel should be polished by electropolishing in order to get rid of tiny cracks where germs may grow.

In addition to preventing bacterial accumulation and rendering cleaning easier, polish stainless steel surfaces in mixers, conveyors, & storage tanks additionally conform to hygiene standards like FDA and GMP guidelines.

Finished surfaces on racks, tanks, & transport containers in storage infrastructure give a clean, polished look, reduce material adhesion, & increase corrosion resistance.

Polishing improves industrial components both aesthetically as well as functionally. By reducing blemishes & imperfections, it enhances the surface's look & produces a glossy, reflecting surface. This renders sterilization and cleaning easier along with improving appearance. By eliminating tiny cracks where pollutants or moisture can gather, polishing additionally improves resistance to wear and corrosion. The method may significantly improve part longevity, especially in harsh environments like that found in the food production, chemical processing, & maritime sectors.

Polishing can be costly and laborious despite its advantages. Multiple passes, tiny abrasives, skilled workers, or automated equipment are frequently needed to achieve superior surface finishes. Investments in machinery can be expensive, particularly for CNC or electrical polishing installations. In addition, poor technique could end up in over-polishing, resulting in modifications to the part's dimensions or its structural strength due to too much material removal. Surface quality, tolerance requirements, and price effectiveness have to be carefully balanced.

The type of material, intended finish quality, & manufacturing scale all influence the tools as well as equipment used for surface polishing. Hand equipment such as polishing pads, abrasive sheets, & rotary polishers are frequently employed in manually or small-scale polishing. These instruments are suitable for small-batch production, minimal finishing, including fine detail work.

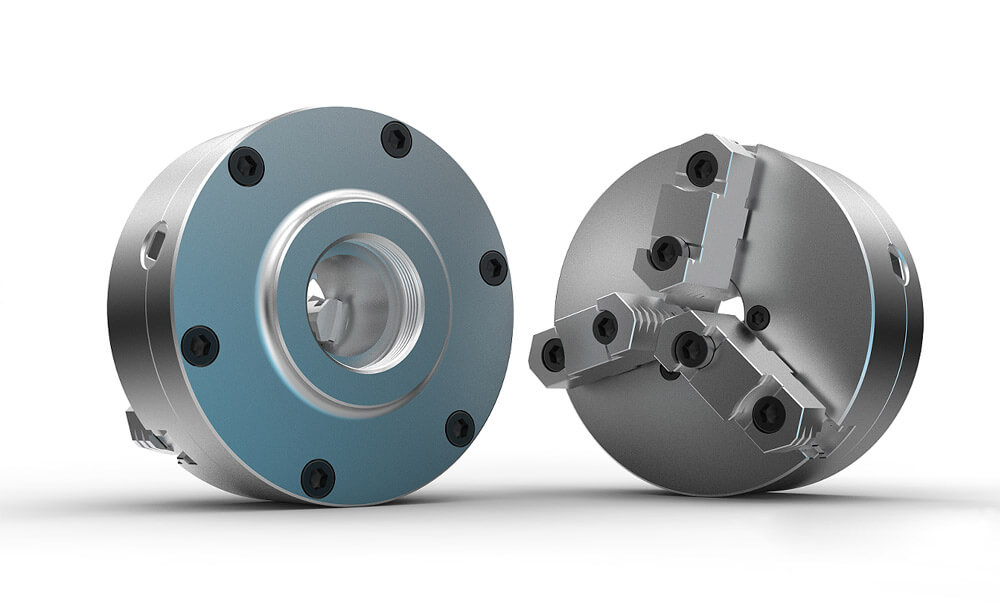

Mechanical polishing equipment can be helpful for circumstances requiring higher productivity or accuracy. This comprises:

Titanium, aluminum, and stainless steel belong to the materials that are polished utilizing chemical & electrochemical processes. Power supply, electrolyte baths, plus cathodes suited for particular aspect geometries are instances of electropolishing machinery.

Consumables that include buffing wheels, polishing pastes, abrasive compounds, & non-woven pads are additionally selected based on the hardness & finish level of the materials. Wearing appropriate safety equipment, including gloves, face shields, including ventilation systems, is essential for shielding personnel against exposure to heat, chemicals, as well as dust.

In an effort to control heat generation and decrease surface damage during extended polishing cycles, contemporary polishing systems may further include cooling or lubrication systems.

Although polishing continues to be an established surface finishing method used in a variety of industries, it's not always an especially useful or economical option, especially for parts that don't need a mirror shine or as function takes priority over aesthetics. Manufacturers have the option to use various surface treatments in such circumstances; each has distinct uses, production circumstances, & technological advantages.

Among the most popular alternatives is blasting. High-pressure abrasive particles are employed in procedures like sandblasting, bead blasting, & shot blasting to prepare, clean, or textured surfaces. The above methods are perfect for rapidly and evenly cleaning surfaces of metal of rust, paint, or scale. For steel as well as aluminum, where modest aesthetics are still crucial, bead blasting which employs fine glass beads offers a more velvety, satin-like surface finish.

A further viable choice is coatings, especially if ornamental or protective elements are required. Powder coating produces a long-lasting, corrosion-resistant finish by electrostatically depositing dry powder to a surface & heating it in order to cure it. It is often used for metal shelves, enclosures, & heavy-duty parts that are vulnerable to environmental damage. Anodizing, especially for aluminum components, hardens the outer layer and adds texture and color in addition to improving corrosion resistance. Whichever are the requirements of the end result, these coatings may entirely eliminate the requirement for polishing.

In modern industrial production, polishing is crucial because it enhances the surface quality, durability against corrosion, and visual appeal of a wide variety of components and materials. The selection of polishing methods may have a measurable impact upon performance, lifespan, & compliance with regulations, whether it is used to improve medical-grade equipment or polish aircraft turbine blades. However, depending on the demands of the project, it is equally critical to evaluate additional methods like blasting, coating, or grinding. Choosing a finishing approach that fits the end-use use, operating environment, & overall production goals is ultimately important in striking a balance between cost, functionality, & visual appeal.