In manufacturing, tooling directly shapes your production strategy. You don’t just choose tools, you actually define timelines and cost. For manufacturers, the difference between soft tooling vs hard tooling is crucial. It determines how fast you move and how far you scale.

Soft tooling provides you with flexibility in early-stage manufacturing. You reduce initial costs and speed up development cycles. It’s a practical choice for prototypes and low-volume production. But soft tools wear down faster and limit long-term use.

Hard tooling supports high volume. It offers high-precision manufacturing. You invest more upfront but gain production consistency. It’s ideal when parts require tight tolerances over long runs. For most established manufacturers, hard tooling secures product repeatability. In this guide, we will walk you through distinct aspects of soft and hard tooling.

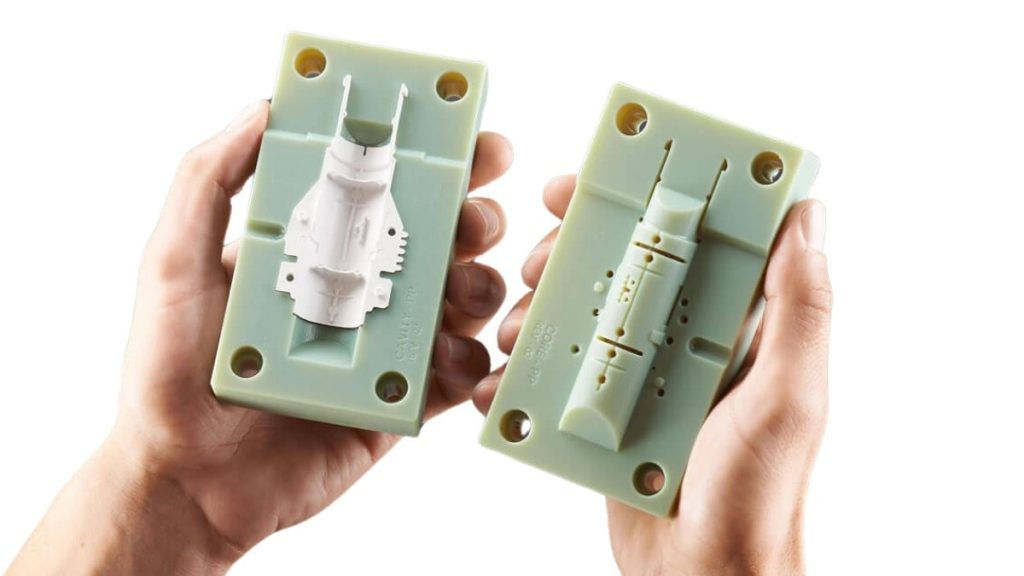

Soft tooling refers to temporary, low-cost manufacturing molds. It finds its primary application during prototype testing as well as when running initial pilot production. Usually, these toolings are made mainly of silicone, urethane, or aluminum materials. Before starting large-scale manufacturing, you can use these tools to evaluate component performance.

The key advantage of soft tooling becomes evident during urgent production demands. The tooling system allows quick product modification between different manufacturing stages with a shorter production processing duration. The tool proves its worth for validation tasks involving fit or form or function. However, it lacks durability when subjected to prolonged high-pressure manufacturing conditions.

Through this method you can accelerate your work flow while preventing significant expenditure on capital. On top, you can create and check few parts while operating under minimal risk conditions.

Here are the common benefits of soft tooling;

Soft tooling costs much less upfront. The production system requires basic materials together with simple equipment which reduces total expenses. Soft tooling serves as an excellent solution because of its cost-effective nature for product development at the prototype stage and initial low-volume production. Investments for large-scale production remain unnecessary before validating the functional design.

Soft tooling speeds up production. Your parts will be ready through the short timeframe of days instead of waiting for multiple weeks. The short production time enables quick completion of urgent work requirements. Prototyping needs quick solutions which soft tooling delivers effectively.

Soft tooling offers flexibility. Design adjustments with soft tooling become possible without requiring you to create a new start. Using this process enables you to adopt improvements at a low cost while keeping the process short. The process requires neither significant expense nor extended time duration to implement alterations.

The use of soft tooling minimizes potential risks in the prototyping stage. Testing design prototypes allows producers to avoid committing to mass manufacturing until they are fully satisfied. Your unsuccessful prototype will cost you very little since you did not spend too much money on it. Testing your product with soft tooling enables a low-risk assessment beforehand of product readiness for expansion.

Besides benefits, these tools also pose a few limitations. These are

Soft tooling tools have a shortened service life compared to hard tooling tools. Soft tool design has short-term use because it serves only for prototype creation and limited production batches. The materials experience rapid deterioration, which creates possible issues concerning product quality and time-based consistency.

Soft tooling tools do not achieve the same exactness which hard tooling tools provide. Soft tooling fails to reach necessary manufacturing standards when making complex designs or when working with tight tolerances. Part quality suffers in industries with high precision requirements during usage of soft tooling.

The tools made from soft materials cannot work effectively for large-scale production needs. The tool works adequately for small production runs, yet fails to manage the capacity or resistance levels that hard tooling can handle. High-volume manufacturing requires high-performance tools instead of switching to soft tools because they lack durability in these situations.

Soft tooling provides fewer alternative materials than hard tooling technology. The use of soft tooling becomes problematic in situations that require special qualities from materials. The availability of various materials through hard tooling operations makes it a superior choice for complex manufacturing needs.

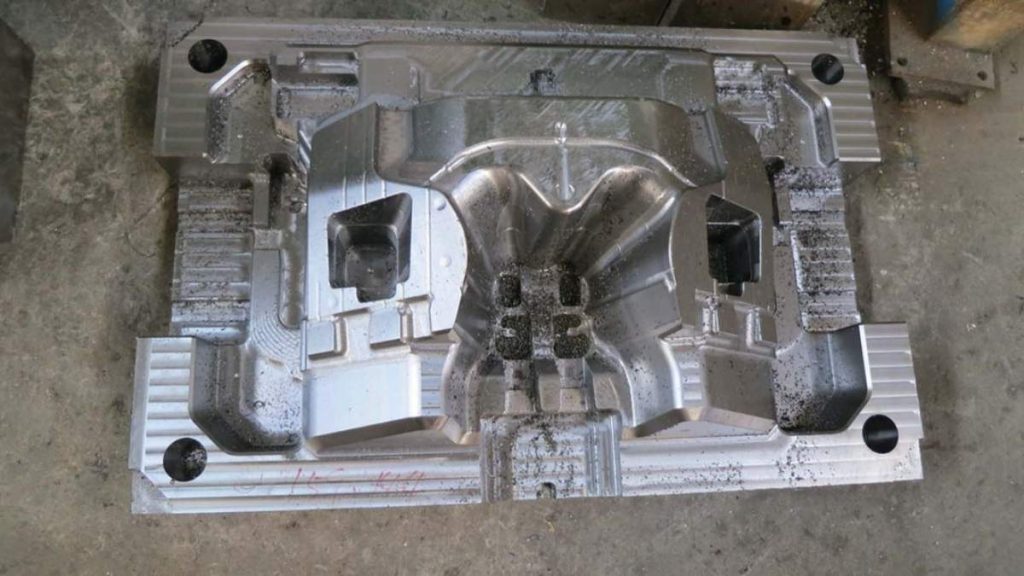

Hard tooling describes the set of durable tools that maintain high precision during factory-scale mold production. Mass production demands steel as its primary material to resist mechanical pressure during manufacturing operations. Hard tooling tools function for extended production periods after their initial manufacture.

The production requires hard tooling because it delivers extended service life with precise results. The production technique allows manufacturers to generate numerous parts that meet strict dimensional requirements. The production methods are perfect for sectors needing exact match-ups between high-quality results that can be consistently achieved including automotive along with aerospace and medical device manufacturing.

The initial price of hard tooling systems remains high, but the tool will pay for itself through repeated use. The tools will yield thousands or millions of parts post-production without compromising their quality. Manufacturers should select hard tooling systems to produce reliable products in bulk.

Here are the unique benefits of hard tooling;

The lifetime duration of hard tooling exceeds that of soft tooling. The steel material composition allows hard tooling to maintain production volumes at high rates through extended usage periods. Long production runs thrive when durability becomes essential to maintaining continuous output, so hard tooling stands out as the top choice.

Hard tooling offers better precision. The tool maintains part consistency and achieves strict dimensional requirements. Tools built from hard materials enable precise matches of specification across extensive quantities of products throughout manufacturing.

Hard tooling costs more at purchase but generates financial benefits down the line. Your production expenses drop level by level as your volume of parts rises. The initial investment for hard tooling decreases its production cost when producing large quantities of parts.

Due to its design capabilities, hard tooling successfully processes various raw materials. The machine supports various materials, including metals and plastics, which allows it to process large numbers of products effectively. The tool's flexibility enables its use in businesses that produce intricate or specialized products.

Let’s figure out the limitations of hard tooling.

A significant amount of financial capital is required to establish hard tooling machining systems. The high expense of materials combined with production runs defines hard tooling as more expensive than soft tooling at the beginning. Organizations with constrained budgets, along with minimal production demands, find it extremely difficult to use hard tooling processes.

Creating hard tooling takes time. The entire manufacturing period spans numerous weeks to several months while starting from design inception to ending at production completion. Production cycle start-up delays will grow longer during your first production phase, particularly when post-tooling change requirements occur.

Once hard tooling reaches its installation spot the implementation of modifications turns out to be costly and labor-intensive. The changes made to design or part specifications after tooling production requires essential retooling that creates extensive project delays while increasing project expenses. Soft tooling offers better change flexibility than hard tooling systems do.

Manufacturers who implement hard tooling perform their production at elevated levels. The investment of money into making large batch production tools, together with implementation costs exceeds the advantages manufacturers gain from producing small quantities of components. The production method works optimally with business sectors which require sustained manufacturing operations particularly automotive and electronics.

The selection between using soft or hard tooling tools represents a critical business choice for manufacturers. Soft and hard tooling tools exist for different manufacturing scenarios according to your specific requirements and financial resources and manufacturing timeline. Starting with soft tooling enables you to receive parts quickly while testing design affordability without substantial financial commitments. Manufacturers should use hard tooling as their preferred solution for precise high-volume manufacturing after reaching the production stage.

Various determining factors influence your selection between soft and hard tooling.

Soft tooling delivers rapid market entry because it meets short-term production requirements.

Soft tooling provides better initial cost efficiency than hard tooling, which becomes more economical during major production quantities.

The production of large products at high precision requires hard tooling as a necessary solution. The two production methods deliver varying advantages to end-users.

Long-term manufacturing efficiency requires equilibrium with flexible production methods to generate maximum results. Your decision strategy selection depends on both your project specifications and your specified production volume.

How to choose between soft vs hard tooling. Here are the frequent factors to consider;

Complex geometrical shapes typically lead manufacturers to choose soft tooling options. The manufacturing process of cast urethanes combines 3D-printed master patterns and CNC molding techniques instead of using time-intensive methods from traditional plastic injection molding. The method enables the quick manufacture of intricate and elaborate equipment through processes that take little more than several days.

The length of time a tool survives counts as an essential manufacturing consideration. Soft tools function in limited production cycles, amounting to 25 to 50 shots until manufacturers require replacements of the tools. Such tooling works adequately for projects that run for brief periods and prototyping requirements. Your choice should be hard tools since they offer superior durability over a long period. These tools possess the ability to sustain through many production cycles, which results in them becoming essential for manufacturing operations requiring extended long-term durability.

The budget plays a decisive role in all purchasing decisions. For manufacturers with a smaller budget or low-volume production, soft tooling offers a more affordable solution. The reduced upfront expenses allow you to test or create prototypes without being exposed to major financial loss. Starting costs for hard tooling are higher, yet the tool becomes progressively cheaper to operate as product quantities expand. Manufacturers requiring substantial quantity production at the cost of higher initial expense should choose this tooling method.

Finishing requirements of your parts become important criteria when selecting tooling methods. Your project requires a smooth, polished surface with minimum post-processing, which would make cast urethane tooling the optimal selection. The parts that come directly from the mold display high-quality finishes through these tools. The production speed of hard tooling slows down during large run production since it needs additional steps to reach equivalent surface quality.

Time represents one of the fundamental elements that determines manufacturing operations. Soft tooling provides manufacturers with essential time benefits that accelerate their operations. The process enables quick transitions between design and production, which commonly span from a week to less than that period. The speedy production capability of this technology is dedicated to quick prototyping operations and low-volume manufacturing requirements. The creation process for hard tooling extends into several weeks, which makes it undesirable for situations requiring quick manufacturing acceleration.

Your choice between soft tooling or hard tooling relies on project specifications together with production duration together with financial resources. The major benefit of soft tooling becomes evident during prototype development or low-volume manufacturing alongside complicated part designs because it enables quick manufacturing alongside cost-effective startup expenses. The tool features limited operational durability and imprecise performance that reduces its capacity to support major plant production needs.

The production process of consistent and precise items requires hard tooling for manufacturing runs. The initial cost of purchasing hard tools remains high but leads to financial savings in the long term since it can manufacture large quantities through its extended operational life while enabling high production capacity.

The choice between soft and hard tooling depends on your production volume, part complexity, timeline, and budget. Soft tooling is ideal for fast, flexible manufacturing, while hard tooling suits high-volume, precision production. At ApexRapid, we offer both options—including advanced Vacuum Casting and Injection Mold Tooling —to help you accelerate development with the right tooling solution.

How long does soft tooling last?

Soft tooling generally lasts for 25-50 shots. Normally, it depends on the material used. This makes it suitable for low-volume runs or prototyping.

Can hard tooling be modified after production starts?

Modifying hard tooling can be a costly and time-consuming process. Once the tool is created, changes typically require significant rework.

Is soft tooling suitable for mass production?

Soft tooling is not ideal for mass-scale production due to its limited lifespan. It works best for smaller batches or testing initial designs. For large-scale runs, you need to use hard tooling.

Can soft tooling be used for high-temperature products?

Soft tooling is generally not suitable for high-temperature applications. It may not withstand the stress and wear caused by extreme heat. Hard tooling, on the other hand, is specifically designed to handle high-temperature products.