Precision machining is a specialised area in modern manufacturing, focused on parts with high tolerance and excellent surface finish. It goes beyond the simple task of material removal, as it is a careful blend of highly sophisticated machinery, custom tooling, complex programming, and intimate knowledge of materials science.

This guide will examine the principles, technologies, key considerations, and best practices that define precision machining and share a comprehensive overview for those seeking to master the production of high-quality components in industries such as aerospace, medical, automotive, and electronics.

Precision machining is the practice of redaction (removal of material) of a workpiece of a high order to achieve very tight tolerances on measurements (measured in terms of microns or fractions of thousandths of inches) and high surface qualities. It surpasses normal machining by having extremes of accuracy, repeatability, and complex geometries.

Several important factors determine the need for precision in contemporary industries:

The parts in such systems must be exceptionally accurate because any deviations, no matter how minimal, will lead to failure, inefficiency, or breakdowns (e.g, medical implants, aerospace parts, optical equipment).

The possibility of reproducible end-user results implies that there is no need to manufacture parts independently, requiring custom fitting, rather than being an essential aspect when it comes to massive production and global supply.

Higher precision minimizes friction and wear in complex assemblies, resulting in sustainability and stability of performance and a longer service life.

For smaller devices, there is a constant demand for greater precision in the internal components.

Several novel technologies, including micro-electromechanical systems ( MEMS ) or highly performing optics, are reliant on the utilization of high-level machining capabilities.

Precision begins with sound knowledge of the basics that define the accuracy and quality.

The allowable deviation of a dimension is called tolerance. In precision machining, such variations are small, which requires highly sophisticated measurement instruments and methods.

The dimensional tolerances should indicate the permissible size (e.g., ±0.0001" or ±2.5μm).

The type of symbolic language found on engineering drawings is used to describe and communicate specific geometric tolerances (e.g., flatness, perpendicularity, concentricity) that represent the shape, orientation, and location of a feature. This plays a vital role in functional mating parts.

It is used to measure the roughness of a surface. Very low Ra values are often required when processing precision components (e.g., 8μin or less).

A science of measuring. In precision machining, this entails the use of precise tools to confirm dimensions and surface properties.

Automatic machines measuring complex geometries with a high degree of accuracy, utilising touch probes.

3D profiles of parts were projected and could be compared to design overlays.

The material selected has a great influence on manufacturability, cost, and the precision that can be achieved.

Materials that have a low thermal expansion coefficient and that have low internal stresses are favored.

Hardness, chip shape, and thermal conductivity affect the wear of the tool, surface finishes, and machining power.

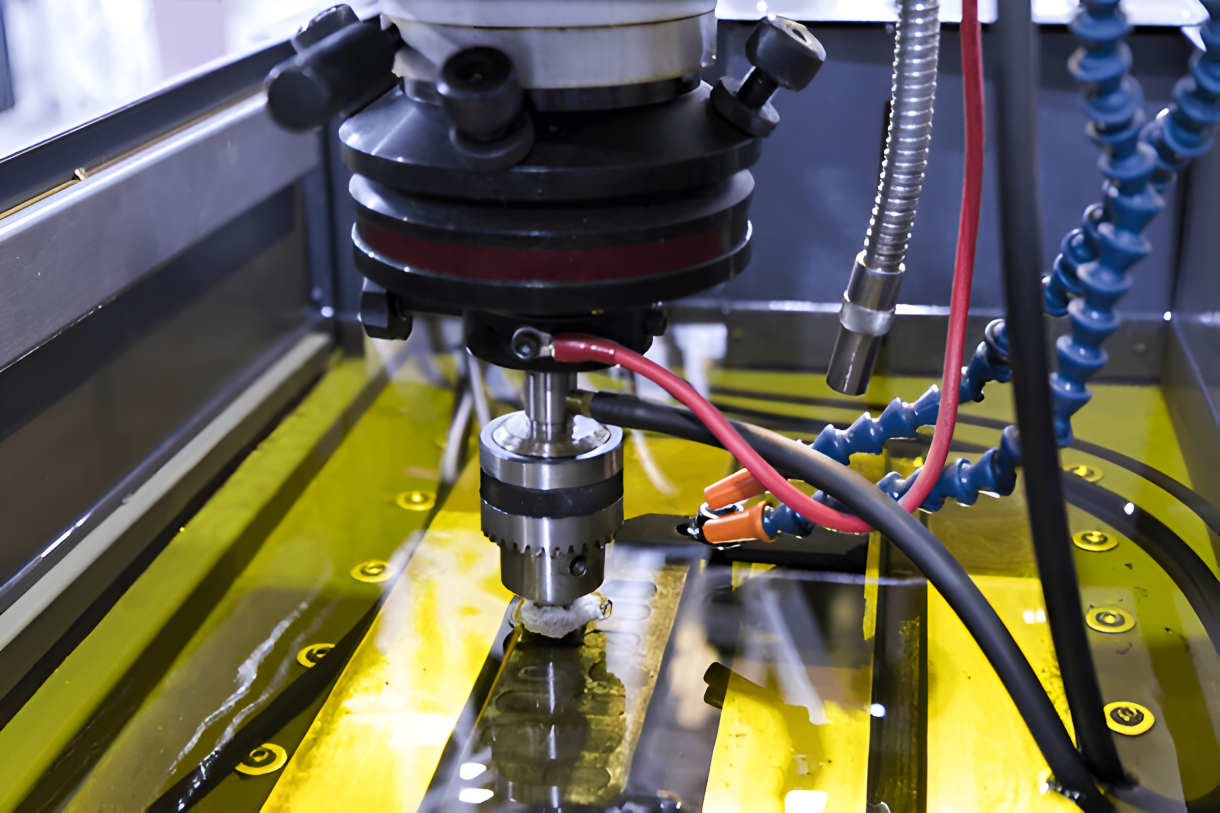

Precision machining depends on the latest equipment that is extremely rigid, accurate, and controlled.

The limitation of precision is mostly affected by the machine itself.

Precision machines are constructed using heavy, stable bases (usually of granite or polymer concretes) to reduce vibration and deformation.

A spindle chiller, linear motor cooling, and environmental controls limit thermal expansion/contraction considerations.

Provide an accurate indication of axis positions, enabling minute motions.

Superior speed, look-ahead, and interpolation to make tool moves smoother.

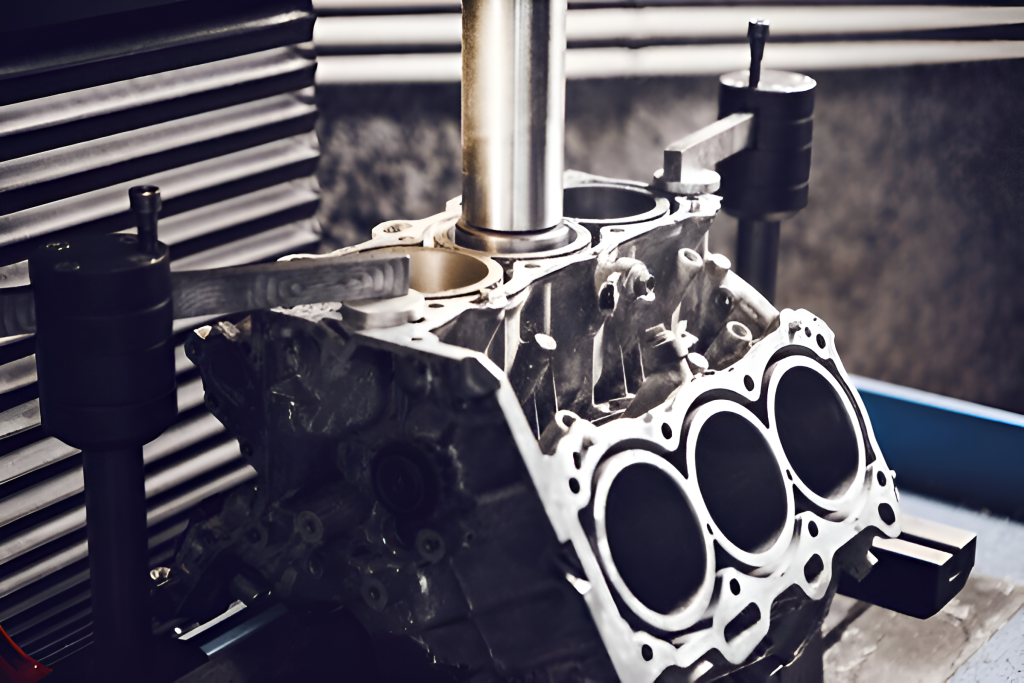

Complex geometries can be machined in a single setup, resulting in minimal repositioning error.

The point of contact is the tool; the quality of geometry and the condition of the tool are of crucial importance.

Ultra hard, wear-resistant, and high-temperature, Solid carbide, polycrystalline diamond (PCD), and cubic boron nitride (CBN).

Rake angles, helix angles, and chip-breaker geometry specific to the material to best eject the chip and leave a finish.

Multi-layered coatings (e.g., AlTiN, nano-composite) to lessen friction, heat extraction, prevent BUE, and increase the life of the tool.

Tools and holders should be dynamically balanced; this is particularly important with high RPM levels to avoid vibration and chatter.

High-precision holders (hydraulic, shrink-fit) provide superior clamping force and minimal runout compared to standard collets. These holders are used in precision machining with specialized tools.

Finishing passes equipment should be new, sharp, and clean to produce the best surface quality.

The process of precision is an incremental collection of optimizations for the entire sequence, starting with CAD/CAM to actual machining.

DFM principles have to be applied even more rigorously to precision components.

Put tight tolerances only in function-critical places. Over-tolerating is very costly.

Small tools tend to deflect or break during machining deep features, resulting in inaccuracy.

All essential functions need to be accessible to a machine with the largest possible rigid tool and inspection thereafter.

It is significant to take into account design characteristics or follow-on heat-treatment (annealing) of components, to de-stress by removing from the shape of parts internal forces liable to cause misshaping, to obtain high flatness.

Each re-fix is likely to create an error. Design that reduces setup and incorporates datum features that permit the maintenance of alignments.

Explicit callouts of GD&T on a drawing ensure that the machinist perceives critical features along with the precision authority required.

High-end strategies of CAM are necessary to fulfill the needed precision and finish.

Rough using high efficiency roughing (e.g., adaptive clearing) to remove bulk material rapidly and efficiently with consistent stock to use during finishing passes. This reduces tool wear and stresses the material equally.

Expect a consistent small portion of material (e.g., 0.005" to 0.010"/0.1mm to 0.25mm ) to pass finishing. Irregular stock may cause interchangeable cutting force and loss of accuracy.

In precision machining, relatively high spindle speeds, narrow band chip loads, and shallow depth of cut are predominantly used to reduce tool deflection and the cutting forces.

Include cooling phases or stoppages within lengthy programs, enabling the machine and work to cool thermally and preventing expansion and contraction inaccuracies.

CAM toolpaths should always be simulated to detect any collisions, verify stock removal, and predict potential issues.

Precision is easily affected by the machining atmosphere or environment, as well as preparation.

Rigid, high-quality workholding solutions (hydraulic vise, custom fixtures, vacuum chucks) should be used that eliminate any part movement or vibration during machining.

Evaluate the accuracy of tools' length and diameters with tool presetters or touch probes. Any inaccuracy in this case will simply translate to inaccuracy in dimensions.

Measure the position of the workpiece zero point accurately by using a probe or edge finder. It is vital that this step can be repeated.

Sustain the shop temperature and humidity. Thermal effects, such as significant temperature variation, may result in thermal expansion or contraction of the machine, tool, and the workpiece, which affects precision.

Routine calibration and maintenance of the CNC machining are required to ensure its accuracy, including backlash checking and aligning the axes.

Precision machining does not stop when the part is removed from the machine. Follow-up treatments are also needed in most instances.

Careful inspection is important to confirm the achieved precision.

Most high-end CNC machines are equipped with on-machine probes that can measure features and modify work offsets or tool offsets in-process, increasing accuracy and reducing set-up time.

Monitoring and controlling a manufacturing process with statistical tools can help achieve consistent quality and detect early signs of deviation.

An extended inspection of the first item to be made in a series is to ensure that all the specifications are met before mass production takes place.

Full check of all functional key dimensions and features with the help of appropriate metrology tools indicated in part I.

Part quality can also be enhanced through the post-machining processes.

Residual stresses, which may occur during machining, are alleviated by subjecting the part to heat treatments (e.g., annealing, tempering), preventing warping of a part, especially when high precision is required or when parts have thin walls.

After milling, it is frequently followed by a grinding operation that provides the most accuracy and surface finish. To accomplish very tight tolerances and mirror finishes, they use abrasive wheels to remove small quantities of material.

Abrasion procedures that can remove very little material to produce very smooth surfaces and smooth finishes.

The abrasive procedure is applicable in advancing the geometry and the finish of internal bores.

The removal of burrs by machining is significant to reduce impact on both fit function and appearance.

Thin, (very) hard, or corrosion-resistant coatings (e.g., hard anodizing, DLC, PVD/CVD coatings) that do not represent a significant dimensional change.

Precision machining is not only a procedure, but it is a dedication to quality in production. It involves detailed planning, thorough designing, sophisticated equipment, streamlined programming, and strict quality control. The skill to always make parts with tiny size gaps and great surface looks shows the skill, know-how, and hard work of precision machinists

The need for precision machining will grow as industries continue to push the edge of technology. Once ingrained with the values of mastering the principles presented in this guide, whether one be a novice in the field of metrology and material science, or seek to optimize the toolpaths and perfect the quality controls, one starts down a journey to creating the advanced components that will lead to the innovations of the future.

Keep in mind the following points:

Learn to embrace the challenges and lifelong learning. There is the joy of the feel of a part made in the perfect part of the part, of knowing the feat and precision behind this, and that is the joy of manufacturing.

The following are some frequently asked questions about precision machining.

Q1: What is the difference between general and precision machining?

A1: Functionality can be covered with general machining (e.g., tolerance is +/- 0.005"; precision machining can venture much closer, e.g., +/- 0.0001"; enable much finer surface finishes, using sophisticated machine tools with highly controlled process parameters, to serve the requirement of high-performance products.

Q2: What is thermal stability in precision machining, and why does it matter?

A2: Minor thermo-expansions or contractions can influence micron-tolerance due to the expansion or contraction of materials. Pieces in a precision setup have temperature control conditions to ensure dimensional accuracy.

Q3: What is GD&T, and what is it used for in precision parts?

A3: In high-precision, multi-source manufacturing, GD&T (Geometric Dimensioning and Tolerancing) specifies precise geometric tolerances (e.g., flatness, concentricity) to guarantee that parts with guaranteed fit and performance (e.g., fit and operate as designed).

Q4: What is tool runout, and how does it compromise accuracy, as well as how is it minimized?

A4: Tool runout leads to unbalanced cutting, shoddy finishes, and a lack of tolerances. It’s minimized with precision holders (e.g., hydraulic, shrink-fit), tool balancing, and following of proper seating.

Q5: Is it possible to have a mirror-like finish using CNC milling?

A5: CNC milling can only perform a fine finish (8 16 or so m in Ra), although mirror-like finishes (1 4 or so m in Ra) normally additionally necessitate post-treatment such as polishing or lapping.