Heat treatment plays a vital role in enhancing the strength, hardness, toughness, and corrosion resistance of metals through controlled heating and cooling. It’s essential for meeting performance standards in demanding industries like automotive, aerospace, energy, and construction.From high-stress components to chemical storage systems, heat treatment ensures reliability and extended part life. Understanding its processes, technologies, and applications is key for engineers and manufacturers aiming to produce durable, high-performance parts.

An assortment of industrial & metalworking techniques known as "heat treatment" entail deliberately heating and cooling metals in order to alter their physical and mechanical features without altering their form. Improving the metal's performance properties such as its durability, hardness, ductility, machinability, & resistance to fatigue and stress is the main goal,Although heat treatment is usually attributed to steel & iron-based alloys, it is additionally applicable to materials that include copper, magnesium, titanium, & aluminum. The kind of material, the element's intended purpose, and its performance standards all impact the heat treatment process selection.

Three key phases make up a heat treatment process's basic sequence:

Simply put, heat treatment is a technique that changes a metal's microstructure, particularly the atoms' arrangement inside the crystal lattice. The substantial change in material properties following treatment is caused by these microstructural alterations.

The method usually entails transitions in phase between ferrite, pearlite, austenite, martensite, & bainite structures in steel, which is most frequently treated with heat metal. Steel experiences a structural change to the elevated temperatures phase austenite when heated over its critical transformation temperature, meaning around 727°C for typical carbon steel. Which structure develops depends on the speed at which the temperature is cooled:

The manner in which a metal behaves to heat treatment is additionally affected by alloying elements including carbon, chromium, manganese, & molybdenum. For instance, a larger carbon content decreases ductility whilst improving hardenability.

The features that follow may be impacted by heat treatment:

Determining the correct method for every industrial application needs a comprehension of fundamental metallurgical ideas, particularly when components are exposed to high-pressure operating conditions, temperature cycling, or stress from mechanical contact.

A variety of techniques are involved in industrial heat treatment, all of them have the goal of changing the microstructure of a substance & functionality in a specific manner. Some of the most popular methods are listed below:

Annealing is a method of heating metal to an appropriate temperature, keeping it there (soaking), and then slowly cooling it—typically in a furnace. Relieving internal tensions, increasing ductility, while softening the metal are the goals. This method is frequently employed for alloys composed of brass, copper, aluminum, & steel. Annealing is crucial for manufacturing for improving flexibility before machining or reshaping processes.

As a heat treatment technique, hardening entails heating the metal over the transitional temperature before quickly cooling it down, which is referred to as quenching. Brine, water, oil, & air are some of the common quenching media. A more difficult yet more delicate substance is the final result. Usually, tempering occurs after hardening to achieve a balance among toughness & hardness.

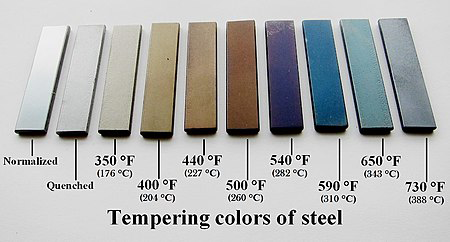

Post hardening, tempering is done to minimize brittleness yet preserve hardness. After being heated to a lower temperature (which is frequently between 150°C & 650°C), the metal continues to heat for a specific period of time before being cooled. In tools, springs, & automotive components that need to be adaptable but durable, this treatment is necessary.

For the purpose of to relieve inner residual stresses without altering the material's overall structure, a material gets heated to a sub-critical temperature (typically between 550°C to 650°C). It is frequently employed after cold forming, machining, or welding, particularly for big components or assemblies.

Merely a component's surface undergoes change during case hardening, leaving its innermost layer resilient and soft. While nitriding adds nitrogen to the surface, carburizing adds carbon by burning it in a carbon-rich atmosphere. This is ideal for parts which need ductile cores and durable surfaces, including gears, camshafts, & bearings.

PWHT is employed on welded parts to improve structural integrity, reduce hardness, & relieve residual stresses. Stress vessels, pipelines, & structural steel must all receive this procedure if they are to meet ASME Section VIII as well as API 650 standards.

Many industrial sectors, each of which has particular characteristics & regulatory requirements, rely heavily on heat treatment. The ones that follow are the primary industries that use treated with heat components extensively:

heat treatment increases the fatigue strength, durability, & wear resistance of components that include axles, gears, crankshafts, & engine blocks. Gearboxes often receive case hardening, while spring components receive tempering in order to achieve an acceptable balance between hardness and elasticity.

Materials used in aerospace have to withstand high pressures, temperatures, & fatigue cycles. Heat treatment ensures good strength-to-weight ratios as well as dimensional integrity for titanium as well as aluminum alloys used in landing gears, turbines, as well as aircraft frames.

Post-Weld Heat Treatment (PWHT) is often needed for drill parts, pressure vessels, pipelines, including valves. Heat treatment increases the resistance to sulphide stress cracking, hydrogen embrittlement, & thermal fatigue whilst ensuring compliance to API & ASME requirements.

Heat-treated parts such as cutting blades, tracks, reinforcement bars, & hydraulic cylinders ensure exceptional durability in harsh environments. Construction tools frequently employ induction hardening & tempering.

For the purpose of guaranteeing consistent mechanical performance in storage tanks or pressure vessels and also to lessen residual stress after welding, heat treatment becomes important. PWHT & stress-relieving processes, for instance, ensure compliance to standards set by the industry & extend service life.

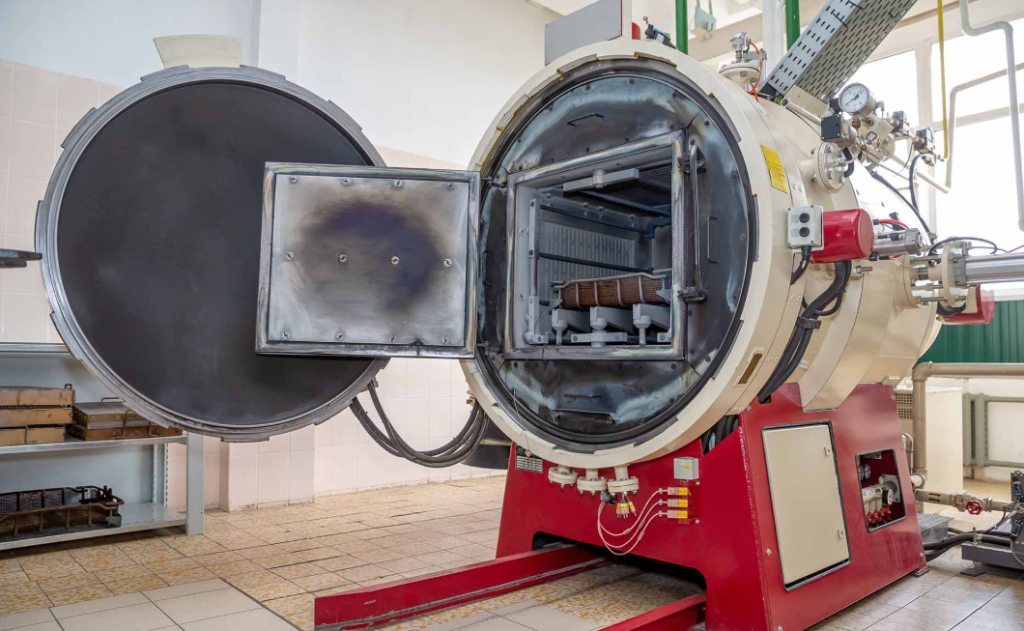

For manufacturing processes to be exact, repeatable, as well as effective, sophisticated heat treatment technologies & equipment are required. The material, treatment method, & manufacturing scale all impact the equipment selection.

Electric furnaces are ideal for hygiene-conscious environments because they offer accurate temperature control.

Different cooling media, such as oil, water, brine, air, even polymer-based solutions, serve their purpose in quenching systems. The substance's hardness, distortion, & crack resistance are all affected by the selection.

PLC as well as SCADA systems are employed nowadays in heat treatment plants for cycle capturing, temperature monitoring, and procedure automation. Predictive upkeep and immediate form optimization are increasingly using AI and IoT interfaces to function.

Methane-based or ammonia-based regulated atmospheres along with sealed chambers are required for operations like nitriding & carburizing. Constant diffusion depth & surface hardness are ensured by these arrangements.

Adherence to heat treatment standards is crucial in industrial manufacture & storage to ensure satisfactory performance, safety, & regulatory approval. The equipment, processes, & inspection methods employed for heat treatment are governed by an array of international standards.

Materials undergo to dimensional inspections, microstructural analysis, including testing for hardness (Rockwell, Brinell, Vickers) following treatment. Non-destructive testing (NDT) technologies such as magnetic particle examination (MPI) & ultrasonic testing (UT) are additionally employed in critical situations to identify surface or subsurface flaws.

Manufacturers may ensure the safety, dependability, and efficiency compliance of treated with heat components through adhering to these guidelines.

Heat treatment has downsides notwithstanding its benefits, especially when used frequently in complex manufacturing environments. Important issues include:

Warping or dimensional changes can occur from improper heating or excess cooling. This is especially difficult for thin or complicated parts like plates or shafts.

Surface features may deteriorate as a result of oxidation or carbon loss at the surface carried on by air exposure during heating. Vacuum furnaces & protecting atmospheres (inert gases) are examples of such solutions.

Heat treatment takes a lot of energy, especially for traditional electric or gas furnaces. Carbon emissions as well as expenses can be reduced by using environmentally friendly control systems, improving insulation, or switching to induction heating.

Heat treatment is essential in modern manufacturing, enabling metal components to meet demanding standards of strength, durability, and reliability. By precisely controlling heating and cooling cycles, manufacturers can enhance critical properties such as hardness, tensile strength, toughness, wear resistance, and stress tolerance. Industries like aerospace, automotive, energy, and heavy machinery rely heavily on these processes to ensure long-term performance and safety.

At ApexRapid, we offer professional heat treatment services to help your CNC machined parts achieve optimal mechanical performance and long-term reliability. Feel free to contact us for tailored heat treatment solutions.