Carbide disc knives demand ultra-precise shaping under extreme conditions. These knives are often used for cutting abrasive films, fibres, and sheet metal. Even slight dimensional errors can cause premature failure or uneven cutting performance.

CNC automation solves these problems through closed-loop machining control. You can regulate wheel pressure, infeed rates, and coolant flow precisely. This helps prevent thermal shock, grain pullout, and edge chipping during grinding.

Most shops now rely on multi-axis CNC grinders for bevel forming. These machines track edge position within ±2 microns across cycles. That level of repeatability is significant when processing brittle materials like tungsten carbide.

Carbide Discs In Bulk

The conventional machining is not able to sustain the tolerance bands needed by carbide. Hands grinding can usually result in heat spots, cracks on the surface, or even bizarre edge geometry. In the long run, that compromises cut quality and raises downtimes in slitting systems.

Carbide responds to pressure and heat differently from steel. In the absence of controlled feed and regular coolant flow, the operators can face microfractures on the cutting edge. Such flaws cannot be eliminated easily, yet they affect performance within a short time.

Besides, manual setups do not have in-process feedback or wheel wear adjustments. By hand, you cannot maintain flatness, runout, or uniform radial relief. That is where CNC automation makes use of no human error and waste of materials.

CNC Disc Machining

Introducing CNC does not imply changing everything at a go. You may automate the most crucial procedures without interfering with the entire process. This enhances management by taking advantage of what you already have in the floor layout.

The majority of the teams start with the profiling or end the grinding phases. Manual work fails in most places where precision is required. CNC automation guarantees repeatability that does not require continuous attention from an operator.

Another benefit of automation is that it minimizes the number of moving parts during setups. You merge edge profiling, balancing, and inspection into a single cell. That simplifies the production of knives and prevents loss of quality within steps.

CNC Grinder Retrofit

Traditional grinding systems have a tendency to use manual edge control. The CNC module can be retrofitted to the existing grinding stations. This offers axis control, spindle feedback, and repeatability of motions.

The majority of CNC packages are interconnected through a normal machine interface or input output ports. It implies that there is no necessity for a complete redesign and custom frameworks. Your operators are fast to adjust and need minimal retraining.

Knife blanks are brought in by robotic loaders directly to the CNC table. You eliminate the manual handling, prevent wear of part surfaces, and accelerate the cycles. This further enhances safety in workplaces.

The integrated systems synchronize machines and robots. You have tight tolerances as you put on more throughput per hour. This is appropriate for high-mix, low-volume carbide knives.

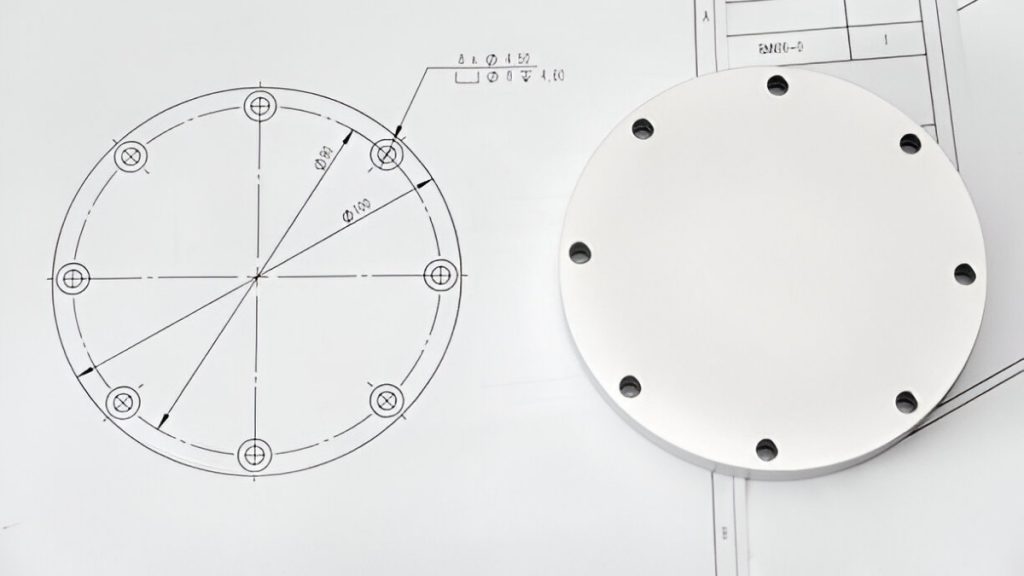

CNC Disc Drawing

Exporting DXF or STEP files is are direct export option of your design team. CNC machines transform them into dispatchable toolpaths. You pass the yearly setting or recutting between CAM and grinding.

Bevel mismatch and set up time are minimized using toolpath syncing. What you design is what you grind-blade time after time. This backs lean processes as far as design to dispatch.

The CNC automation permits the inspection in the cycle with non-destructive probes. Before unloading, these are track thickness, runout, and edge form. The parts that are out of spec are automatically reprocessed.

This removes last-minute manual inspection and less wastage. You do not ship incorrect knives down the line and endanger downstream operations. So, it is quick, trustworthy, and it minimizes the stress among operators.

When it comes to reducing dependence on skilled labour, the addition of CNC automation helps. There is the capability of using several grinders or cells under one operator. This facilitates the production scale-up when there is high demand.

It does not compromise quality for quantity. Longer shifts allow the machine to be precise. That will save you extra training expenses and floor space to produce more.

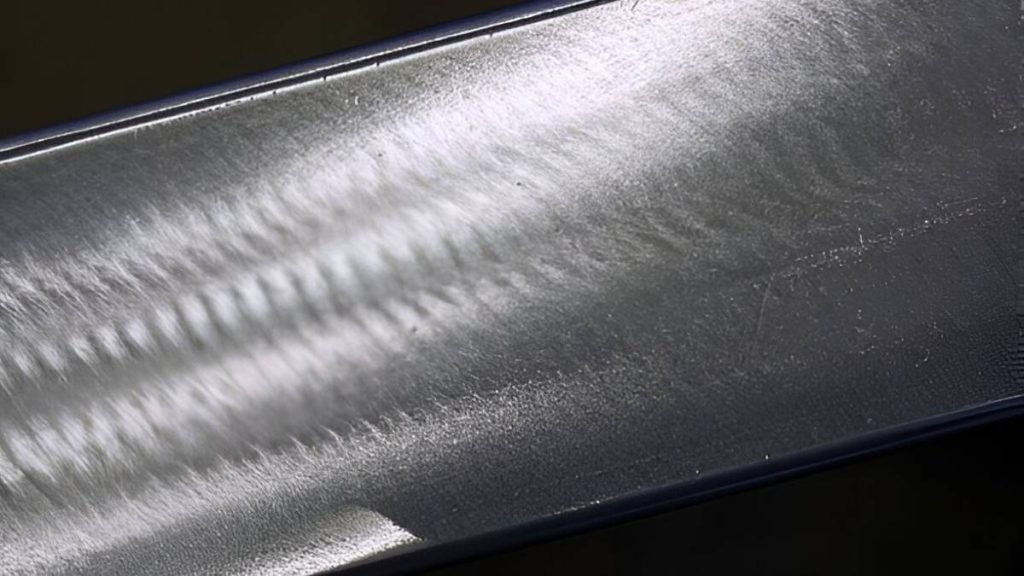

During the manufacturing of the carbide disc knives, the edge polish is the determinant of blade life. Even tiny burn-marks, stress-cracks, or grain pullout may be an early inducer of edge failure. CNC automation directly manages these variables on a real-time basis.

It is not possible to rely on manual feel in terms of edge quality. CNC concentrates the wheel-to-part pressure, axis acceleration, and spark-out timing. That makes every edge come out clean, cool, and defect-free even when a tool has a heavy load.

CNC provides better consistency of surfaces on bevels and flats, too. It does not produce heat loading and buildup by controlling spark engagement and delivery of coolants. You have clean edges that need fewer finishing or lapping after grinding.

Carbide is a very hard, brittle substance that is held together with the help of cobalt. Grains are dislodged at the edge when final passes are hasty and inconsistent. This makes the blade weaker and prone to unpredictable wear and tear.

CNC systems do not do this by regulating dwell time and spark-out rates. They finish the grind slowly. That keeps a microstructure intact but provides clean and sharp bevels.

Synchronized Feed and RPM in CNC

Burn marks not only provide an ugly appearance, but they also weaken edges thermally. They are the consequences of excessive pressure or lack of cooling, or incorrect RPMs. The parameters are synced on CNC platforms according to the material and the size of the tools.

In case of narrow bevels, CNC lessens feed and incorporates bursts of coolant. That keeps the edge temperatures low to avoid oxide discoloration or weakening of the structure. You achieve fine and performance edge quality.

Roughing Pass CNC Knife Blade

Other disc knives demand smooth areas that are mirror finishes. Rough edges or uneven swirl patterns are quite common to manual machines. CNC grinders adopt programmed step-down passes and crosshatch offsets to make surfaces smooth in uniform.

Wheel load and variance are also recorded using advanced machines. Their auto-adjustment of pressure or dressing occurs in case of an increase in roughness. This keeps the Ra value consistent between knife runs.

Burrs lower the cutting capacity and may be harmful to the substances. By hand grinding, it usually results in small burrs requiring a second deburring. CNC machineries control the direction of pass, wheel angle, and exit paths of edges.

This burr finish takes off the need for extra steps of polishing down the line. It comes in handy, especially in case knives are coated or mounted immediately after grinding. You eliminate time in the process and the chances of rework.

There are carbide blanks whose composition is dense or stratified. During prolonged grinds, these accumulate heat in an unbalanced fashion. CNC machines bring coolant into the cutting area only and monitor the increase in temperature by passing.

You prevent the edge or the core from being heat soaked, resulting in microcracking. Cooling is effective and synchronized with the movement of the tools. This helps in extending the life of the edges, particularly in high-RPM slitters.

Repeatability in every step of the knife can be achieved in CNC automation. You control every pass: from center-hole boring on to edge shaping. This makes it round, symmetrical, and tightly aligned on its edges.

CNC sequencing makes discs homogeneous before the process of grinding. That decreases imbalance, unevenness, thickness, and eccentricity failures.

Center Hole Boring in Disc

For carbide discs, there is a need to align the bore well so as to prevent vibration. CNC machines also had center holes, but in a symmetrical position. Holes are checked at the outer edge, not only raw stock.

In the event that a thermal expansion is noted, the toolpaths are automatically adjusted. That makes sure a concentric mount is even for high-speed rotating knives.

Disc knives come in different sizes, chamfer or edge shapes. In CNC routers or lathes, the outer profile is traced with a real-time axis sync system. Without shutting down the setup, you will be able to cut grooves, bevels, or radius shapes.

This simplifies making small design alterations to customize orders. It also makes sure that the discs are well balanced before downstream finishing.

Some drive slots or key notches are built into disc knives. These features are cut in the same fixture with which the perimeter is shaped by a CNC unit. That prevents the positional errors through re-clamping.

Slot depth, slot width, and spacing are all digitally programmed. This provides the exact repeatability, including complex drive systems.

In thin-profile knives, bending makes the edges unstable. CNC mills include relief cuts to lessen stress on the non-cutting surface. These are trimmed to the right lengths to maintain weight balance and avoid bowing.

This brings about a stabilized disc under rotation, particularly in slitters. It is useful in converting long-form, in which there is a variation in knife pressure.

CNC systems apply rigid control in adding pre-grind chamfers. Such chamfers are to safeguard the edge against chipping by finishing. They also play an essential role in the case of coating or the final honing of knives.

When using CNC, the size and angle of chamfers remain consistent in each unit. That enhances the adhesion of the coating and minimizes the variation of sharpness in the field.

In carbide knife production, tool selection impacts cost and quality. CNC automation allows you to plan tooling around real wear, not assumptions. That improves edge consistency, surface finish, and cutter longevity.

Rather than trial and error, you set defined cutter paths, spindle speeds, and chip loads for carbide. CNC routines apply this data accurately across complex part geometries.

Standard tools are inadequate for carbide blanks because they are too hard. Polycrystalline diamond (PCD) cutters deal with slotting and facing heads without edge breakdown. CNC software uses low chip loads and is conservative to save a tool.

Knife discs are flexible, particularly in the process of machining edges. The CNC configurations incorporate shrink fit or hydraulic housings in order to minimize tool vibration. The holders have improved balance when cutting radius or chamfer.

Snug runout assists in retention of plus-minus 0.01 mm on the OD and slots. You have accuracy without straining the disc or overspinning the spindle.

Carbide has thermal cracks as the major point of failure. CNC programs do not make full-width cuts but make radial entries in multiple steps. This reduces friction as well as keeps the coolant effective.

This is used by shops in OD profiling, edge relief, and drive notches. The strategy extends life lifetime of tools and parts.

Cutter engagement impacts on finish and tool wear in an equal manner. The radial and axial depth is precisely controlled in CNC platforms so as to prevent overloading. This is most important when one needs to complete near-sharp bevels or thin walls.

You do not overwrite the tool in unsupported areas. That makes edge lines free and prevents repair after the post-process.

Small wear, which influences the carbide finish, is not detected during manual checks. CNC machines monitor how many spindles are being used by the tool and indicate wear limits. You establish tool life limits by material and not only by the number of parts.

This will make all the passes done with a uniform edge. It is also able to cushion discs against chatter or finish problems.

At Apex Rapid, we understand that running carbide disc knives through CNC systems demands more than just speed. It takes tight control over how your parts are held, how your cutters engage, and how your edge tolerances hold up over long production cycles. That’s where our engineers step in, not just to tune a program, but to build a complete production solution around your actual material and machine limits.

Our focus is always on practical stability. We don’t just deliver drawings or tool specs; we get on the floor, troubleshoot problems, and guide each process stage until results are repeatable. That’s how we help knife manufacturers move confidently into CNC production without sacrificing quality.

Standard fixtures often fail when used for thin, hard discs. Our team designs holding systems that support each knife based on its geometry, not just diameter. We account for disc reliefs, slot positions, and rotational forces when designing each contact point.

By distributing clamping force across critical zones, we help you prevent bore distortion and edge lift during cutting. This keeps your output concentric and balanced, especially at high RPMs or during multi-pass operations.

Our engineers don’t use canned toolpath orders. We study how your carbide behaves when machined, where stress collects, how it deflects, and which transitions affect finish quality. Then, we build sequences that reduce that risk.

In many cases, we shift cutting from outside-in or reverse the usual slot-before-edge order. These adjustments lower thermal buildup and keep fracture zones away from key cutting surfaces.

Even when we do a sample run, we always start with your actual carbide blanks. We check the material structure, binder ratio, and the response of the surface finish, and then we are ready to set RPM, feed rates, or depth.

This enables us not to load tools or to generate extra heat. We do not base our cutting on some generic feed charts but rather calibrate your CNC to your material on a cut-by-cut/part-by-part basis.

Flooding coolant is not enough, especially with sharp bevels or stepped disc profiles. We design directed coolant paths that follow tool movement, matching flow rate and angle to spindle load.

Our setups help reduce thermal cracking and edge oxidation. That means fewer failures in the field and better prep if you're planning to coat or treat the knife post-machining.

There is no assumption when we start full programs. Rather, we cycle test small lot batches, with your carbide and stack. In these runs, we monitor dimensional stability, tool wear, and edge finish using probes and sensor tools.

We make toolpaths or cycle time adjustments on the spot when there is drift. When you are ready to scale up then your setup is already functional. That is how we can make manufacturers save time, eliminate rework, and preserve carbide before it can be damaged due to causes that can be avoided.

Carbide disc knife production can be made precise by incorporating CNC automation. It eliminates manual errors such as the appearance of heat spots and tool breakage. Clean bevels are held to close tolerances in multi-axis grinders. Manual machining leads to edge cracks and low-quality surfaces. CNC implements fewer procedures in shaping, boring, and slotting.

CNC retrofitting does not involve an exchange of entire grinding systems. Robotic loaders lessen the time of handling and enhance safety. They cut CAD file toolpaths in sync to reduce cut setup time. In-cycle inspection identifies defects prior to the unloading of parts. CNC scales production without the need for extra-skilled labour.

It handles burrs, burn marks, and surface finish problems. The coolant lines are directed at protecting the carbide in the grinding process. The fixtures eliminate deflection and create even disc rotation. The toolpaths of Apex Rapid engineers are constructed on the basis of real stress. We do parameter adjustments by testing your actual material, carbide. Cooling and cutting plans are checked before complete runs. This minimizes reworking, use of time, and safeguards edge quality.