Choosing the right online prototyping supplier can be overwhelming. Either it’s not about guesswork. You send your 3D files, cross your fingers, and hope the part turns out as expected. But when timelines are tight and design accuracy matters, that’s not a risk you want to take.

You need more than just a vendor who can print parts fast. You need someone who understands your project requirements, works with your materials, and delivers expected quality, every single time. With so many suppliers out there, how do you separate the reliable from the many?

In this guide, we’ll walk you through what matters when choosing an online rapid prototyping supplier. From checking turnaround times to evaluating their technical support, you’ll obtain clear, practical tips to help you eliminate costly mistakes and pick a partner you can trust.

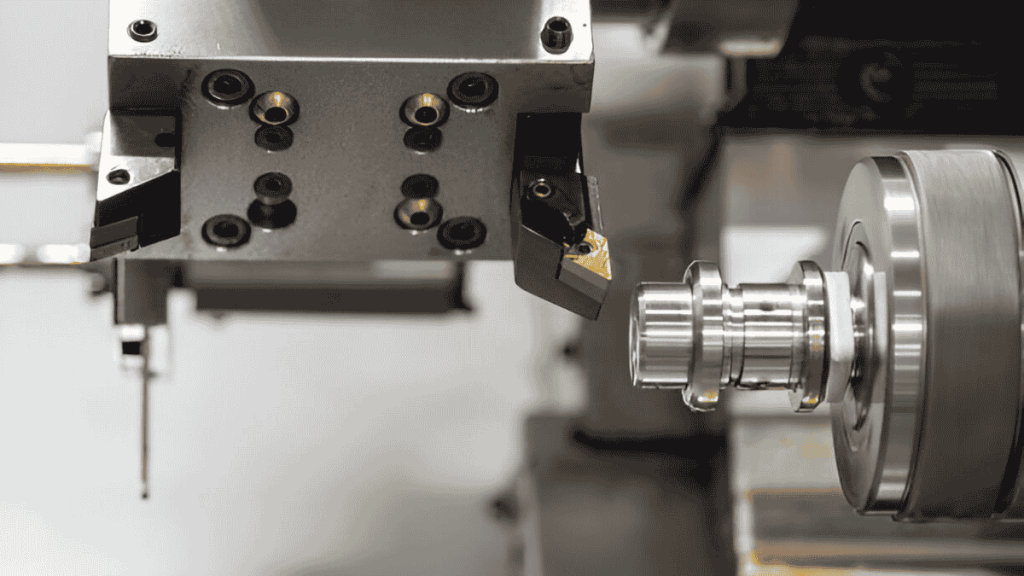

CNC Lathe Prototype Machining

Before reaching out to any supplier, first of all, define what you need from your prototype. Are you testing basic form and fit? Or, do you need a fully functional part to simulate final use? This clarity helps you select the right process and avoid overpaying for unnecessary features.

For instance, in case you are simply testing the design appearance, you might get away with 3D printing with cheaper materials. However, in case you wish to do a test with moving components or stress areas, then you will probably have to use CNC machining and high-strength plastics. Both goals will require varying tolerances, finishes, and material behavior.

Once you understand what the prototype is all about, you can match your expectations with the capabilities of the supplier. Such an easy move makes the whole process more efficient in terms of time and budget from day one.

Practical Tips to Find a Reliable Prototyping Supplier

Even though choosing an online prototyping supplier is not simply a matter of uploading a CAD file and placing an order. In fact, it needs to have a partner who is knowledgeable of your project goals, works on your schedule, and provides useful, dependable components that can be used in your design validation.

Here are the 10 handy hints that will guide you towards the right choice:

In-house Machining Set Up

Firstly, clarify and know the processes they run in-house. Some suppliers are merely brokers and outsource all. When it comes to critical parts, inquire whether they do CNC machining, 3D printing, or post-processing on their own. Production in-house offers you the benefit of better control over quality, timing, and responsibility.

Performance, testing, and certification are influenced by the material selection. Enquire about the source of their resin, aluminium, or stainless steel. Make sure that they present data sheets or certificates in high-grade materials. On top, verify whether they source the material from verified suppliers or not. It is crucial for stress or chemical testing of functional prototypes.

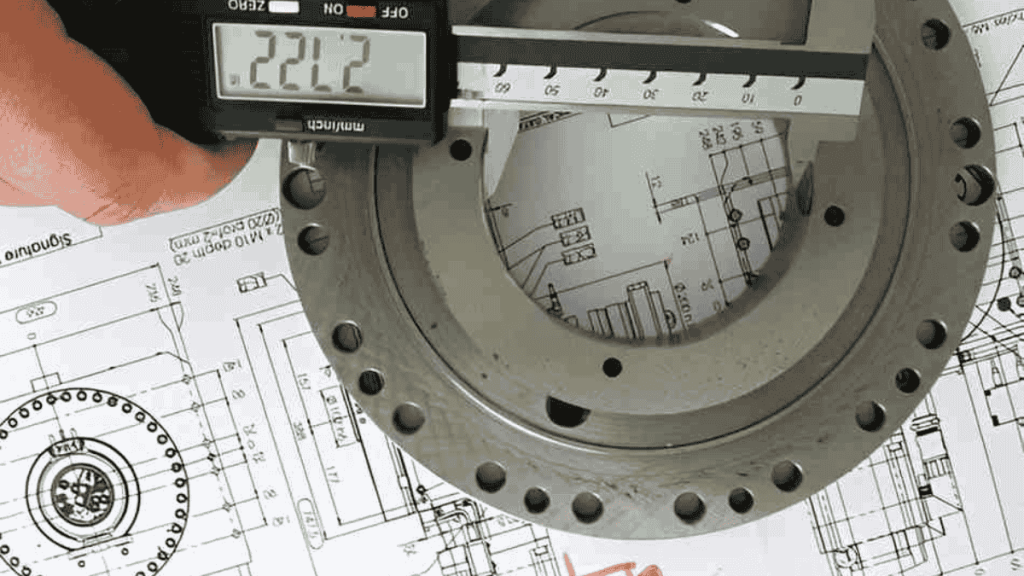

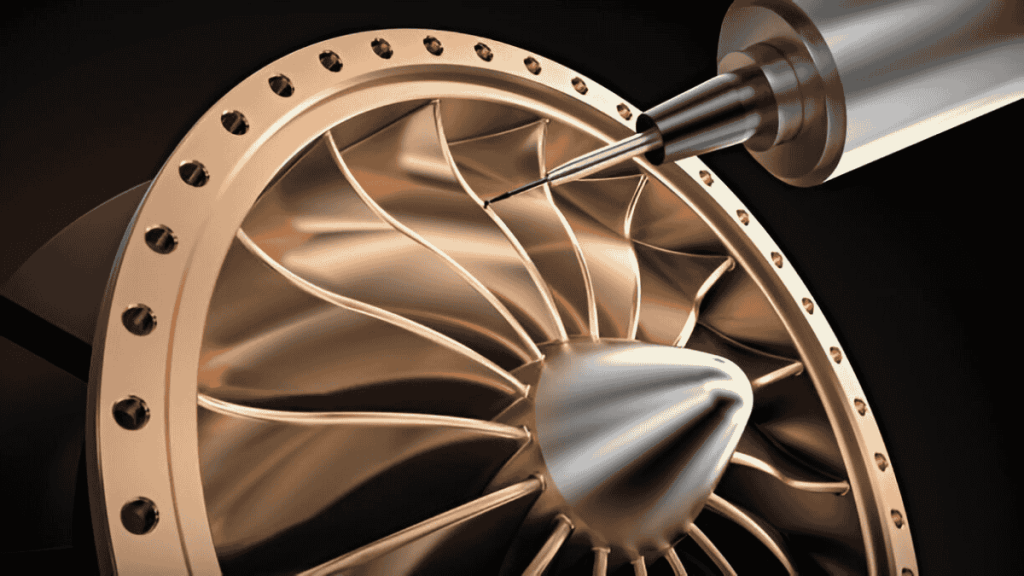

Tight Tolerance Machining

Dimensional tolerances determine the fit and the function of your prototype. Do not guess-inquire about what their normal tolerances are on every process. In the case of interference fits or critical mating features, make sure they are capable of maintaining the desired tolerances consistently.

A quick and timely response depicts the credibility of a reliable supplier. If the supplier answers your questions directly, it reduces confusion and speeds up design changes. Submit a pre-order inquiry and time the response. Availability of technical personnel or engineers is a plus point.

See their experience related to the products you want to outsource. You might belong to consumer electronics, or you may need medical parts to be prototyped, but experience in the field means they will be familiar with the usual difficulties and can maintain high accuracy. So, it's recommended to request case examples of their older work.

Modern facilities support and provide instant online quoting. However, not all of them are the same. An effective system allows you to upload CAD files, choice of surface finishes, and set tolerances. They get extra points when they tend to draw any possible DFM problems to attention. With these systems, time is saved, and the problems are highlighted at an early stage.

Finished Prototype Parts

The issue where prototypes tend to fail lies in surface treatment. Make sure they can do back sanding, anodizing, painting, or finishes of a certain texture you need. Assembled parts and the final product, ready to bring to the market, should be finished to your final design intent. Therefore, do not omit this step.

Request a reasonable standard and express lead time estimates for your type and material of part. A reputable supplier should not only guarantee quick delivery, and he will elaborate on the duration at every stage of the discussion. Confirm, the company supports ISO 9001:2015 service compliance.

It is a necessity to have a secure handling of your 3D files. Ensure that they possess strong confidentiality regulations. Automatic NDAs, encryption, or a certification such as ISO 27001 can be sought out. This helps you guard your thoughts and offers the rest of your mind in teamwork.

Test the supplier by asking him to deliver a simple part before plunging with him into large-scale projects. Select a part having important tolerances or surface finish requirements. Check their file deliverables, quality assurance, and packaging. Such experience can tell plenty about what reviews never can.

Choosing the right prototyping partner isn’t just about delivery. It’s about getting reliable results, expert input, and long-term value. Here's how the right manufacturer makes a real difference:

A good supplier meticulously designs to prototype in a short time. They minimize the waiting time and make you faster in general. This implies quicker testing, authorization, and market access.

Comprehensive Support In Prototyping Design

A qualified supplier will provide an upfront DFM (Design for Manufacturability) information. This helps you avoid expensive redesigns and wastes valuable development time.

Quality is important, whether it is tight tolerances or uniform finishing. A credible supplier makes an investment in facilities and qualified employees. Your parts will come up to spec, and they will be presented professionally.

Some partners sponsor prototyping runs and full-scale runs. That can aid you to expand quickly with no substitution of suppliers. It further maintains the standard product quality, and you produce as you expand.

Reliable suppliers adhere to measures of extreme data security. Your designs are secured in the form of NDAs, secure uploads, and internal controls. You remain in charge of your innovation throughout the process

Rapid prototyping isn’t limited to one field. It supports advancements across industries where speed, testing, and accuracy are demanded. Let’s explore the key settings where it is valued.

Decorative Car Interior Trim Elements

Automakers use prototyping to test components early. It helps validate fit, function, and design before tooling. This shortens development cycles and reduces production risks.

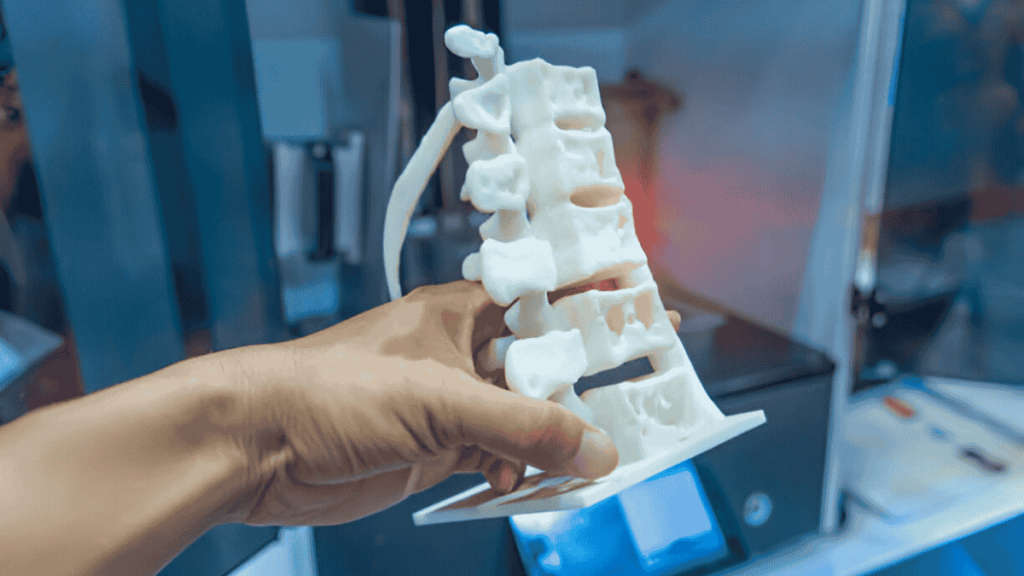

Human Spine 3D Printed

Healthcare facilities rely on fast iterations for compliance. From surgical tools to wearable devices, prototyping helps designers to test ergonomics and performance with real users quickly.

In tech, quality and speed-to-market are paramount. So, here, prototypes allow early usability testing, faster revisions. Even, they give aesthetics for launch-ready designs in gadgets and wearables.

Aircraft Wing CNC Milling

The aerospace sector is heavily dependent on strict tolerances and advanced materials. Rapid prototyping helps test form, airflow, and thermal properties without full production costs.

Prototyping reduces tooling errors, whether you need housing or enclosures. It also improves collaboration between designers, engineers, and end-users in complex machinery builds.

Choosing the right online prototyping supplier shapes how fast your product hits the market. This guide shared clear, practical tips that help you avoid delays, errors, and low-quality parts. We give all details on how you can assess materials, delivery speed, and engineering support.

Collaborating with a reliable supplier allows you to obtain the right prototypes with reduced revisions. It can also be used to minimize wastage, delays, and crucial deadlines. When you want your production to be completed quicker and with fewer risks, a qualified supplier can meet your precise needs in design.

At ApexRapid, we keep you updated and deliver high-precision parts quickly with short turnaround times. Our prototypes are designed to perform, not to pass.

If you need a reliable prototyping partner who gets it right the first time, ApexRapid can meet your expectations. We offer state-of-the-art CNC Machining that delivers fast, accurate parts without compromising quality standards and timelines.

We support product teams with:

Reach out to us to get a free quote now and move your project forward with confidence.