Aluminum extrusion is one of the central procedures in contemporary manufacturing. It enables you to design complex, lightweight and high high-strength, and accurate profiles. Extrusion provides flexibility in design that is difficult to surpass, whether you work in aerospace, automotive, or general fabrication.

Here, the molten aluminum is forced through a profiled die to give continuous profiles. It is fast, efficient, and applicable to the standard shapes as well as to the special pieces. The result? Interchangeable and simple to machine, finish, and assemble clean, clean, clean parts.

This guide will provide a concise, practical insight into the process of aluminum extrusion. We will discuss material, tooling, tolerance, design hints, and practical application.

Aluminum Extrusion

Aluminum extrusion is a process of manufacturing in which material is forced into a die. It converts raw aluminum into long and uniform profiles having predetermined cross-sections. The technique is popular because it is fast, material-friendly, and adaptable.

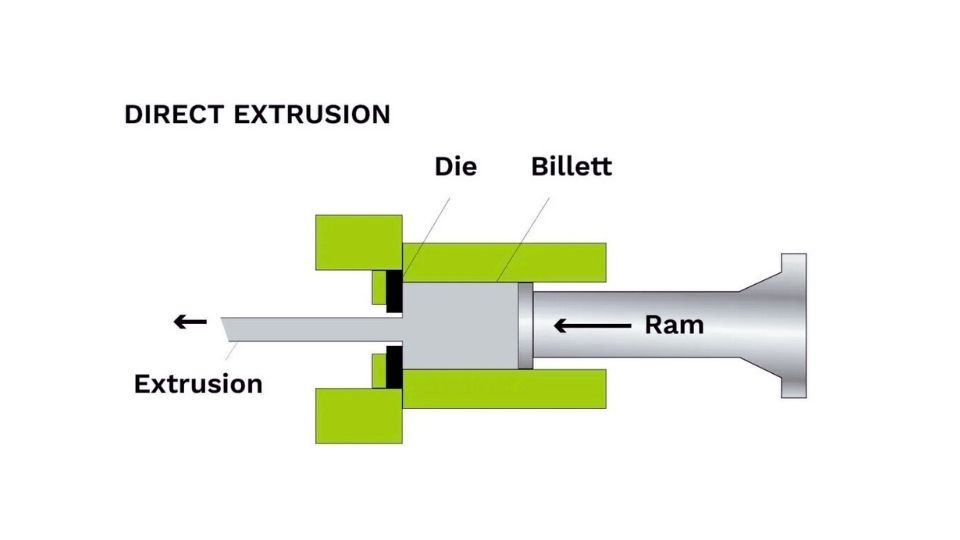

In the extrusion process, a hot aluminum billet is forced through a fine die with the help of a hydraulic press. The profile is determined by the shape of the die; it may be a simple angle or a complicated hollow section. After the extrusion profile is cooled, stretched, cut, and aged to stabilize its final shape.

Aluminum Extrusion Process Illustration

Aluminum extrusion is quick- you just have to plan correctly. You must know the impact of each of the steps on strength, form, and finish.

Take a good piece of aluminum billet. Select the proper alloy in terms of strength, corrosion resistance, and finish requirements. Most general-purpose extrusions are 6000-series.

Extrude a billet that has been heated evenly. The majority of presses operate at 800 to 925°F. This is done by proper temperature to have an even flow of metal and less internal stress in the profile.

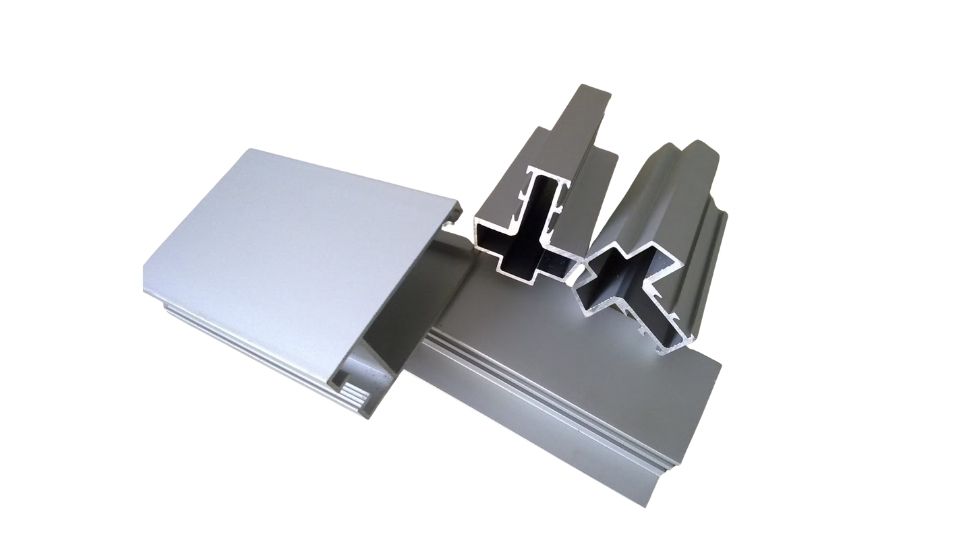

Aluminum Extrusion Dies

Your last profile shape is defined by the die. Multi-part dies and good venting are required in complex shapes. Make walls consistent in order to prevent uneven flow and deformation.

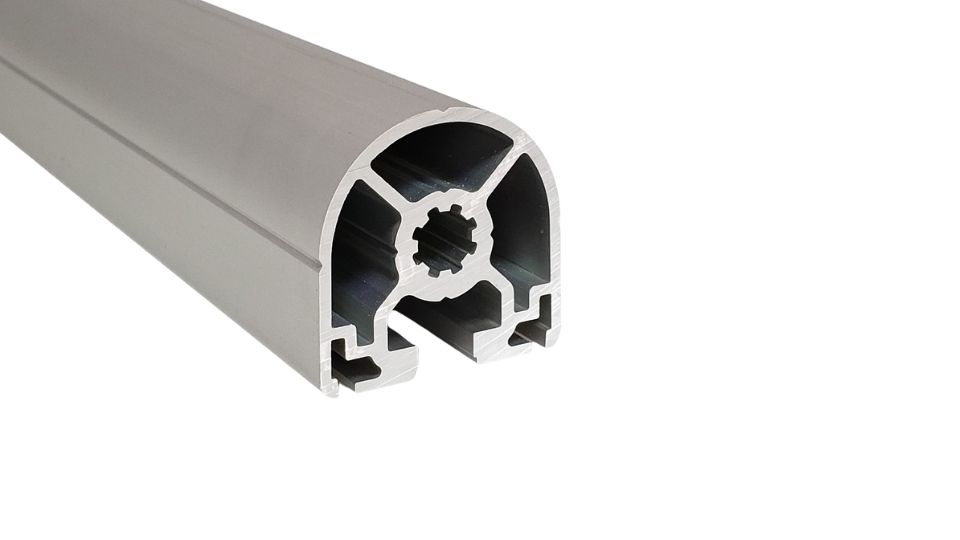

45mm x 45mm Half Round 10mm Aluminum Extrusion

A ram pushes the billet through a die. The shape is created immediately when the aluminum comes out. Apply a constant pressure that will not distort or crack it.

The cooling of the profiles is done by spraying air or water. Even cooling at a fast rate traps strength and reduces warping. Dimensional shift may be caused by uneven cooling.

When cooled, the profile is stretched straight. Then it is cut to the lengths that are necessary. Stretching is also a stress reliever to enhance the stability of tolerance.

Extrusion is not always alike. The technique adopted influences the price, the strength of the parts, and the speed of production. The difference will enable you to select the appropriate process for your job.

It is the most widespread one. The billet and ram follow one direction. Longer runs and fancy forms are possible, but the pressure tends to build up rapidly-so heat control is important.

In this case, the die will be travelling towards the billet. It applies less and provides a good finish on the surface. It is best when there is a need for tight tolerances or low-friction surfaces.

Hot Aluminum Extrusion

Hot extrusion is done at high temperatures (approximately 900°F). The metal is easily formed, hence suitable for complex or large profiles. To hold tolerances, you will require careful cooling.

This is carried out at close to room temperature. It provides a fine surface finish and close tolerances and is best suited to smaller more simpler parts. Needs greater pressure as compared to hot extrusion.

These forms are made on a multi-part die with mandrels. It fits well into tubing, frames, or wire channels. Maintain the thickness of walls so as not to have a problem with flows.

The custom dies are used to produce special shapes to fit a certain application. Consider enclosures, heat sinks, or building trims. An optimum die design reduces machining and reduces the cost of parts..

Extrusion tolerances are not standard. They rely on profile design, wall thickness, and alloy. The knowledge of the functioning of tolerances assists you in designing smartly and prevents post-processing.

The majority of the profiles are ISO or ANSI tolerance classes. ±0.005" to 0.015" expected, depending upon shape and size. Width, height, and wall thickness are subject to standard rules.

The thickness of the wall, shape, and alloy selection are important. The walls are usually thinner or asymmetrical, which may need looser tolerances. The rate of cooling determines the flatness and the straightness.

Tighter specs are required of some applications, such as enclosures or mechanical tracks. When this is done, precision dies, post-stretching, and careful cooling should be used. The tighter the results are, the greater the cost is expected.

Not all surfaces require close tolerance. Concentrate on the fit regions and the sliding point. To accelerate the production, relax the tolerances on non-functional or cosmetic surfaces.

When ultra-precise work is required, CNC machining or grinding is added to extrusion. This will allow you to strike +/- 0.001" or better in those places where you want it. This is to be used sparingly as it is expensive.

Always specify tolerances in the drawing and not the spec sheet. Add notes on functionality and flatness/straightness. Effective communication minimizes work rework and leads to time savings.

Design is a major contributor to extrusion quality. Intelligent decisions minimize production problems, enhance strength, and simplify downstream operations.

The thickness of the wall is uneven, leading to inconsistent flow and cooling of metal. That causes warpage, twisting, or surface flaws. The goal should be uniform walls across the profile, preferably 1.5mm to 5mm. In case of variation, transition should be gradual so as to prevent the accumulation of stress.

The sharp corners generate stress points to both the die and the final part. The inside corners are particularly susceptible to the flow. Fillets or radius addition: It will give a smooth flow of metal, less tool wear, and better structural strength. It is a good rule to employ internal radii of not less than 0.020".

The flow is restricted by narrow channels, and this adds to resistance. When they are too deep, metal solidifies before they are filled, causing some empty parts or unfinished parts. Make the channel as wide as it is deep, and preferably wider. Secondary machine those features to attain high-precision details.

Strict tolerances increase the cost and the time of production. Use them only on functional or mating features, e.g., snap fits or sliding joints. In cosmetic or non-critical parts, give normal extrusion tolerances. Never forget to weigh in manufacturability against functionality.

Unsupported thin or wide sections may bow, bend, or collapse. Ribs make it stiffer and not too heavy. To minimize distortion during cooling, put them on long spans or behind flat faces. Balance the rib thickness at 50-75 per cent of the wall.

Extrusion is not the only part. Plan where you will machine, drill, or cut. Put in locator tabs, additional stock, or pilot holes as necessary. The pre-planning of the said features enhances fit and reduces the assembly time in the future.

Not every aluminum is the same. Strength, machinability, corrosion resistance, and finish depend on the alloy you use. Picking the alloy to suit the job increases the effectiveness of your extrusion.

Aluminium Extrusion Profile 6061-T6 alloy

6061 is robust, multifunctional, and simple to work with. It is excellent in structural use, brackets, and frames. It can be welded easily and can be cleaned and finished, yet it is not suitable for tight bends and deep draws.

6053 Aluminum for Extrusion

6063 is an excellent surface finish and is corrosion-resistant. It is commonly applied in windows, doors, and ornamental trims. It is not as good as 6061, however, it forms and anodizes well.

6082 is stronger than 6061, particularly in bigger parts. It is a clean machine, and the welds are good. It is commonly applied in transport, cranes, and heavy-duty frames.

7075 Aluminum Extruded Profiles

One of the most powerful aluminum alloys is 7075. It finds application in aerospace and defense. It is more difficult to cast, costly, and not as resistant to corrosion as 6xxx-series products.

3003 can be easily formed, and it is soft. It is very resistant to corrosion even in chemical or marine conditions. It cannot be heat-treated; thus, it is applied in places where strength is not a key factor.

Function is always the basis of choosing an alloy. Need strength? Take 6061 or 6082. Choose appearance or rust proofing? Use 6063 or 3003. Determine first the purpose of your part-then select the alloy.

It is not only about the look, but also in order to finish. It enhances corrosion, wear, and performance. Select the appropriate finish on the basis of purpose, price, and final application setting.

This is the unfinished straight out of the press. It is bland and a little bit rough, yet it is adequate in the case of non-cosmetic or concealed areas. It is free, and no corrosion protection is provided.

Anodized Aluminum Heat Sink

Anodizing increases the thickness of the oxide layer in aluminum. It enhances corrosion resistance, and it can be colored. It is suitable for architectural or consumer products that have visible surfaces.

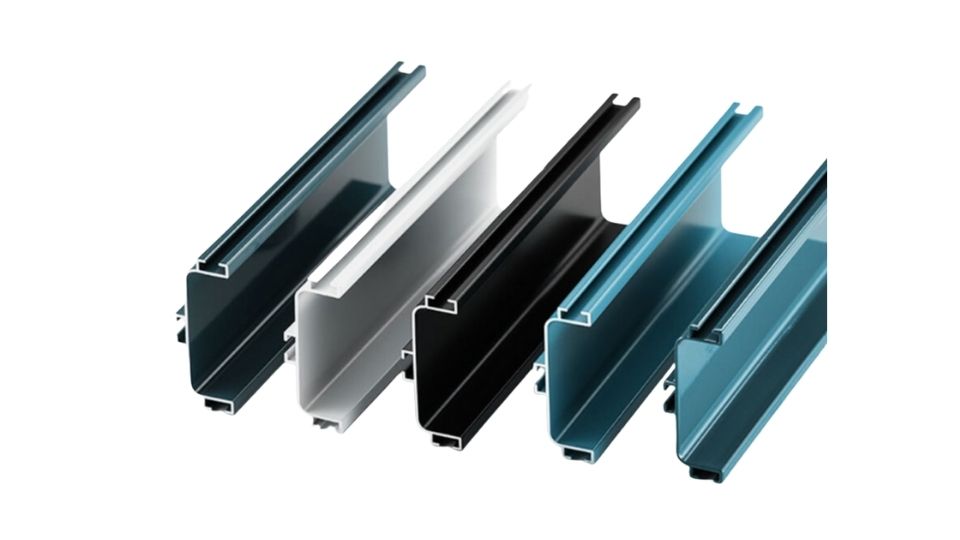

Powder Coated Aluminum Extruded Profiles

Powder coating provides a tough, smooth finish in a variety of colors. It is anti-chipping, UV, and moisture resistant. It is commonly applied to the enclosures of machines, railings, or outdoors.

The wet painting has a simple application and a wide color spectrum. It is less costly as compared to powder coating but not as lasting. Suitable for areas that are not subjected to intense wear.

A matte linear grain is made by brushing; a mirror-like finish is made by polishing. The two are cosmetic options. Apply them on the surface where looks are important, e.g,. Consumer electronics, furniture.

Chemical conversion coatings (like chromate) protect without adding thickness. They are applied when you require conductivity or MIL-SPEC. It is usually used before painting or assembly.

Defects may happen even when the process is the best. Being aware of their causes, you can identify problems early enough and maintain the quality.

The cracks normally occur as a result of irregular cooling or high extrusion rate. Avoid this by controlling billet temperature and reducing the speed of extrusion. Check out profiles regularly to get the first signs.

The profiles cool unevenly, or they are not stretched correctly, and warping takes place. Keep a shape and dimensional accuracy with the help of controlled cooling and straightening methods.

Lines on the profile surface are due to die wear or poor lubrication. Dies should be maintained frequently, and lubricants should be used to prevent rough surfaces.

Porosity is caused by entrapped gases or a bad billet condition. Apply high-quality billets and degassing of the metal before extrusion to minimize the number of voids within the metal.

Pitting usually occurs as a result of corrosion or contamination during cooling. Make sure that the water and fluid systems are clean, and check them regularly to see whether they are contaminated.

Surface burns result from too high extrusion temperature or speed, and the profile becomes weak. Be careful of the temperature and set the speed accordingly to prevent overheating.

The regular quality is achieved upon careful inspection and management at all stages. You should have clear checks in order to detect early and meet specs.

Profile dimensions can be checked with calipers, micrometers, and CMM machines. Measure width, height, wall thickness, and straightness against drawings frequently.

Physically and using surface profilometers, check the presence of scratches, dents, and defects in the surface. Early catch helps to avoid rework or rejects.

The tensile strength, hardness, and elongation should be checked to determine whether the alloy is within the necessary specifications. Batch testing regularly also enables consistency in the processes.

Determine alloy content by use of spectrometers. Standard chemistry makes extrusion do what it is supposed to do and up to the standards.

Such non-destructive inspection methods include ultrasonic testing, where internal voids and cracking may be identified. Critical or aerospace-grade profiles should be made by use of NDT.

Make comprehensive notes of inspection, materials, and machine settings. Traceability assists in defining the root causes in case of defect occurrence and quality audits.

Extrusion by itself does not finish your part. Final dimensions, fit, and finish are frequently assured by machining and other processes.

Profiles require accurate cutting after the extrusion. Saws or shear machines provide ends that are clean with precise lengths. Proper cutting saves wastage and helps the assembly of parts to fit. Repeatability and speed may be improved through the utilization of automated cutting systems.

Lots of profiles need holes, slots, or other additions after the extrusion. These operations have high precision with CNC machining. Machining allowance design is useful to keep final tolerances, and critical surfaces are not damaged.

Others have to be bent to accommodate complicated shapes or combinations. Presses or rollers that exert a low rate of force are used to prevent cracking or deformation. Integrity of profile and surface finish is all a matter of proper tooling and process control.

Extruded aluminum is put through heat treatment to make it more strong and dimensionally stable. Processes like artificial aging (T5, T6) adjust mechanical properties to meet specific needs. Appropriate heat cycles eliminate internal stresses and keep parts in tolerances with time.

Ensure that the surface to be anodized or painted is cleaned in order to get rid of oils, oxides, and dirt. The prepping of surfaces enhances the adhesion of the coating and quality of the finish. The ways are chemical cleaning, abrasive cleaning, or alkaline wash, depending on the finish.

Extrusions may require welding, fastening, and adhesives to join. The built-in tabs, slots, or holes during designing make it easier to carry out assembly and also make the joint stronger. Design to accommodate the thermal expansion and compatibility of surface treatment, to eliminate these problems in the future.

Aluminum extrusion is a flexible and strong way to make parts. Knowing the process, materials, and design rules helps you avoid problems and save time.

Good design, the right alloy, and proper finishing make a big difference. Quality checks and machining ensure the final part meets your needs.

This guide covers all the basics to help you get started and make better decisions for your projects.