When you need parts that do more than just fit, aluminium extrusion profiles give you real design flexibility. The process starts by heating a solid aluminium billet and forcing it through a custom die. What you get is a long, continuous shape made to your exact size and form.

This method works well when your project calls for more than just strength. You can include built-in channels, grooves, or mounting edges in a single piece. That means fewer joins, faster assembly, and better control over every part of your design.

Aluminium also brings key material benefits. It is light, strong, and naturally resists corrosion. Whether you are building frameworks, enclosures, or heat sinks, these profiles help you meet both technical and practical needs without added complexity.

Aluminum Extrusion Profiles

You use aluminium extrusion profiles when standard parts do not fit. Each profile is made by forcing hot aluminium through a steel die. The shape of the die controls the final profile cross-section.

You get long, straight parts with a fixed geometry. These profiles are used in frames, rails, and housing designs. They are strong, light, and made with high precision.

You can choose from solid, hollow, or semi-hollow shapes. The process supports both simple and complex profile designs. Every part is cut, cooled, and ready for final use.

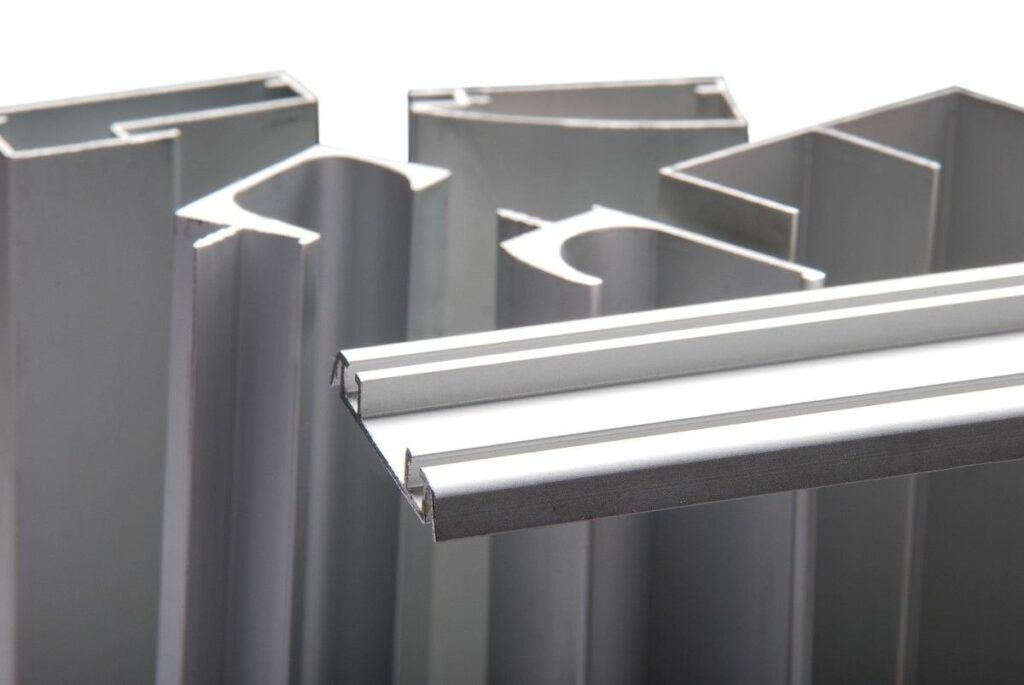

Close-up Aluminum Extrusion Profiles

The raw material is a round billet of pure aluminium. The billet has been cut and is heated to about 480 degrees Celsius. This heat is hot, but not hot enough for the aluminium. It is enabling the metal to flow easily through the die.

Contaminants on the surface of billets are removed by cleaning before heating. Defects are avoided during extrusion, and there is a better finish. When it is ready, it is transferred to the press to be shaped. All this has to be maintained in a narrow range of temperature.

The hot billet is put into the extrusion press chamber. The billet is forced into the steel die by a hydraulic ram. The profile shape is controlled by the die opening. The aluminium runs through and makes a long part with an unchanging cross-section.

The design should be according to your specifications. You may add fins, grooves, or interior cavities. The flow of aluminium should be even so that it does not warp or crack. The speed of the press and the temperature of the die influence part quality.

Once it comes out of the die, the aluminium profile is quickly cooled. The metal is brought to a stable temperature through the use of air or water systems. Rapid cooling assists in setting a cast and hinders warping. There is also a cooling influence on hardness and grain structure.

Then you will straighten the profile to straighten the minor twists. Stretching helps to make one straight and eliminates inner pressure. There is a slight tension maintained on the material. This action will take care of your end profiles in terms of dimensions.

After being cooled and stretched, you cut the profile. The process of cutting takes place when the metal remains warm, which is stable. To cut cleanly, a flying saw is used, which provides the profile speed. The output is of even length to be post-processed.

Depending on your application, you may order certain lengths of the cut. Long pieces can be applied in terms of framing and structure. Shorter episodes are able to be machined into boxes or panels. Precision here reduces the time in production.

It is now possible to subject your profiles to surface treatments in case you need them. These may be anodising, powder coating, or brushing. Corrosion resistance and a clean matte are provided by anodising. Depending on the brand colours or safety requirements, coatings can be of the same colour.

Other finishes enhance wear or thermal control as well. As an illustration, black anodised profiles dissipate heat better. Textured surfaces may also be needed to bond or assemble other profiles. The finish will be determined by your ultimate use.

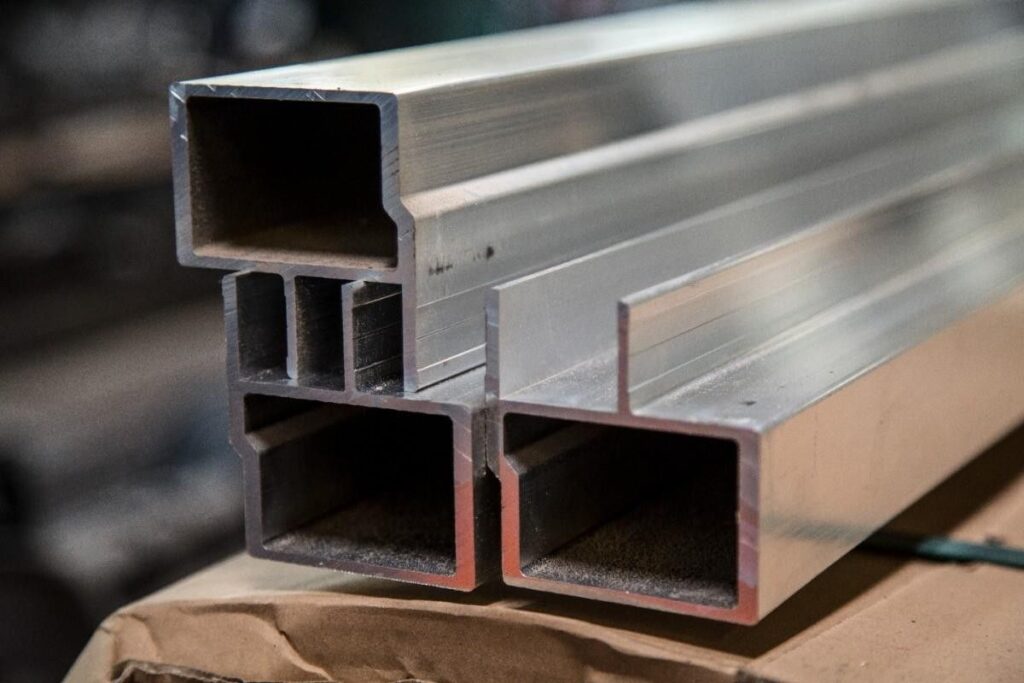

Aluminum Cross-Section Frames

You achieve great strength without using heavy weights. Aluminium possesses a good strength-to-weight ratio. This qualifies them to be used in transport or aerospace or lightweight structural frames. It is possible to minimize the amount of material and maximize the load.

Aluminium does not have excessive mass, unlike steel, and therefore resists impact. That assists in constructions requiring mobility or handling conveniences. Weight versus strength lends the design flexibility. You do not overdesign, but address every requirement of structure.

The profile can be modelled according to any design objective. The profile is exactly defined by the die. Channels, fins, slots, or internal supports can be incorporated. All these characteristics are inherent in the form and not afterward.

Complex shapes are not required to have additional welding or cutting. That minimizes weak points and saves time of production time. Your design will also be easier to build. All of the profiles can be adapted to your application.

Aluminium contains an oxide skin, which grows naturally. This coating prevents water corrosion, air corrosion, or chemical corrosion. General environments do not require special coatings. The profile is very low-maintenance and long-lasting.

It is also possible to select anodising to provide protection. This makes the oxide denser and more wear-resistant. Profiles are effective in outdoor applications, in the marine environment, or in high-humidity areas. They maintain form and finish over long periods.

Naturally, you obtain the benefits of the thermal conductivity of aluminium. It transports heat efficiently and in a non-uniform fashion. It means that profiles are perfect as a heat sink or enclosure. You are not in the hotspots, and you have constant temperatures.

Also, aluminium can conduct electricity with low resistance. Others are applied in the lighting systems, electronics, or the grounding systems. These are enhanced by conductive coating and design. Performance and safety are packaged together.

With simple devices, it is possible to cut, drill, or mill profiles. Aluminium machines do not chip or crack. This simplifies adapting to a variety of environments. Tolerances are hard even after changes.

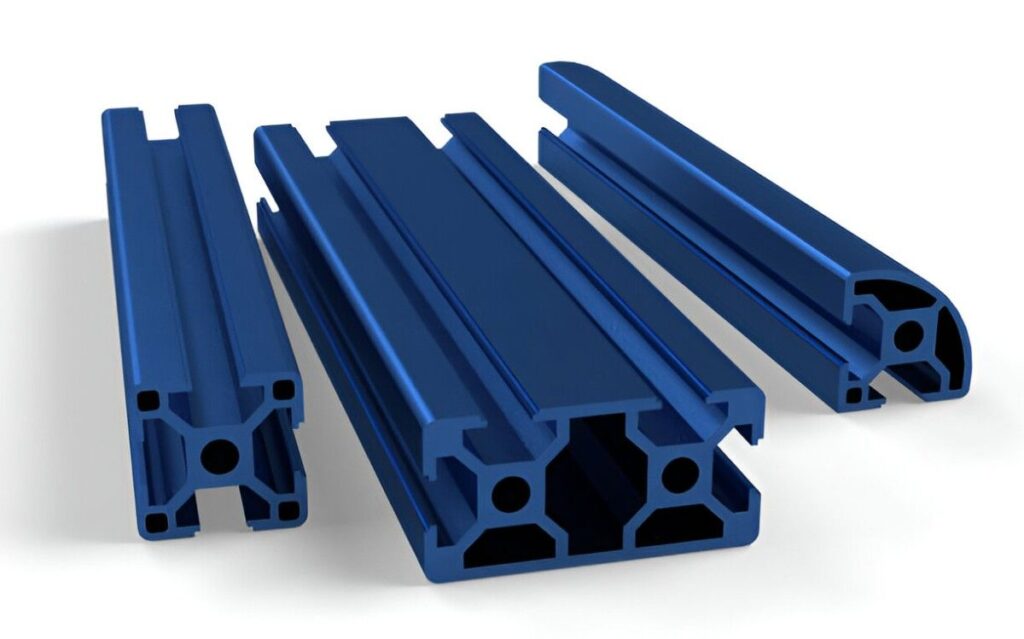

Modular Aluminum Framework

You have to balance the cross-section with the role of your part. Bigger profiles provide additional strength to load-bearing elements. Hollow geometries make them lighter and can be internally routed. The semi-hollow varieties are a compromise between the two and are good in complex applications.

The heat flow and distribution of strengths are dependent on profile shape, also. Square cross-sections are more resistant to twisting than flat cross-sections. The stress can be minimized using rounded edges, and finishing is enhanced. Depending on the shape, performance, as well as cost are impacted.

The profile should have regular wall thickness. The cool walls do not cool uniformly and can warp. It has an impact on tolerances, flatness, and appearance. Profiles that have stable walls are more structural.

Thinner walls decrease weight and should be strengthened correctly. Heavy walls can support more weight, but can prove to be expensive. You will have to strike a balance to fit the end use. This plays a central role in a transport or aerospace project.

It is preferable that you establish tolerances when you are still in the design phase. The majority of the extrusions are to the standard BS EN 755 or EN 12020. These establish flatness, twist, straightness, and dimension range. The extrusion may require post-machining to tighter tolerances.

Sliding assemblies or enclosures should have accurate profiles. Final builds have loose fits that result in rattling or misalignment. Repeatable profiles enhance the fit of assemblies and improve their repeatability. Do not compromise on the level of tolerance; it should be proportional to the project requirements.

Anodized Aluminum Extrusion Profiles

The finish that you select on the surface has an impact on durability and appearance. The extrusions are matte-silver on the die. Better corrosion resistance can be achieved through anodising. It provides an outer layer and a neat look.

Powder coating provides colour and additional protection of the surface. Visible parts have brushed or polished finishes that give them a better appearance. It is also possible to order your textures to be textured so they can grip or bond. Every finish has to be applied to the environment of use of the product.

You need to plan your profile to be compatible with the other parts. Fasteners should be the same as slots, screw ports, or end faces. There are connectors, hinges, or plates required by some systems that must have clearance. They should be planned during extrusion design and not afterward.

You want room to wire things as well, seal things, or make structural connections. Construction of these into the profile will save material and time. Profiles that are suitable for several functions reduce assembly work. This integration helps to streamline production and make it smoother.

You need to orient the profile shape to the applied load paths. Tube-like structures are closed and are resistant to torsion and buckling. The channels are open shapes that give way to cable access but lose stiffness. Always bear in mind how forces will flow through the part.

Where your profile will allow a cantilevered weight, add resistance to moments. You are able to make changes in wall thickness or provide internal webs. Design out sharp corners that cause stress concentration. Equality of cross-section also minimizes deformation with time.

You will need to evaluate axial, bending, and shear loads individually. The peak stresses are to be modelled by the beam theory or FEA. Light profiles are ineffective even when the stress zones are not considered. Set safety parameters of loading cycles to be realistic.

Fatigue is a significant issue in the case of moving assemblies. Not even repeated low loads can be considered not to fail. Choose the cross-sections and alloys that are less inclined to flexing. You maintain a long run stability and minimise part replacements.

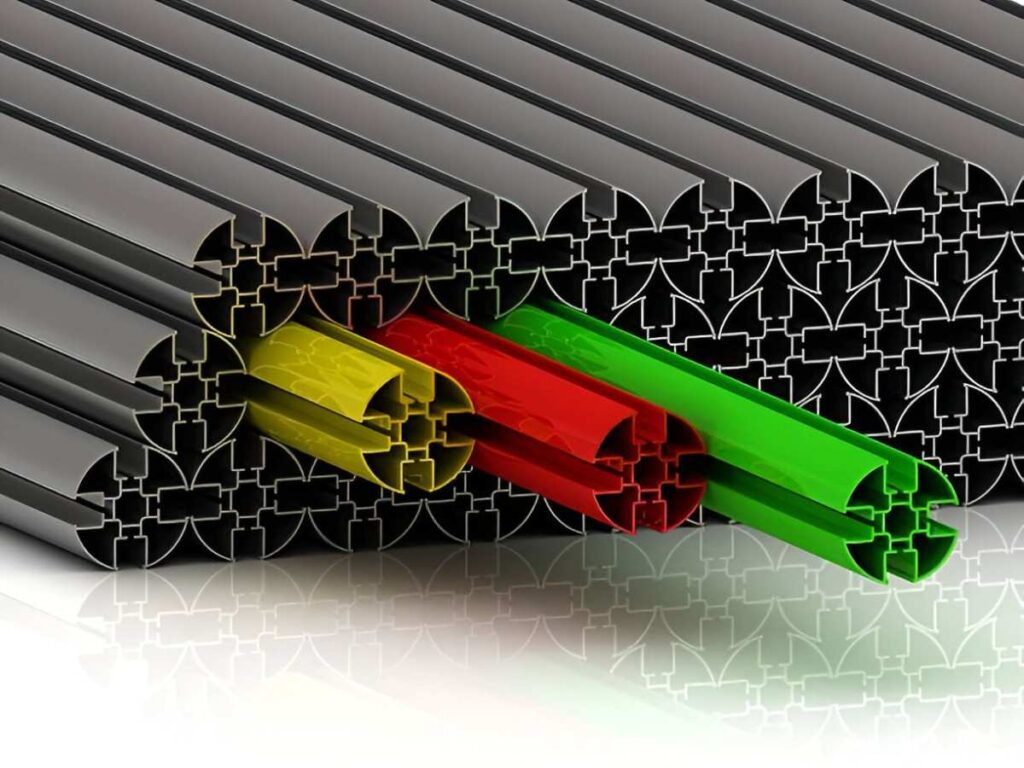

Metal Extrusion Profile of Red, Yellow, and Green

The strength, finish, and machinability can be influenced by your alloy choice; Al 6061-T6 is commonly used in structural profiles. It has good tensile strength, hardness, and weldability. Nevertheless, it is not as smooth as 6063-T5.

Choose 6063 to be high finish and corrosion resistant. It is appropriate to enclose rails and aesthetic products. Where it is required to be used in the marine industry, 6082-T6 aluminum has good strength and saltwater resistance. To ensure that you get the right alloy, you should verify the certification and temper condition of the alloy.

You need to select a finish that is suited to operating conditions. Clear anodising improves corrosion protection and the surface hardness. Black anodising is perfect when it comes to thermal performance in electronics. These two finishes get fixed on the molecular level and endure longer.

Powder coating is impact and UV-resistant. It is available in different RAL colours and textures. Mill finish can be fine with the structural parts of the building that are located indoors. Each finish influences the price, delivery time, and appearance.

The secondary machining profiles must comprise flat surfaces. It is recommended not to put fine details around stout cross-sections. It will distort milling and tapping due to uneven cooling.

In high-volume builds, verify the profile fits into automatic jigs. Add these features as alignment notches and locator tabs. Profiles that aid pre-assembly reduce the time used in production. Effective geometry will never extend the build hours.

Aluminium extrusion profiles are shaped by pushing hot aluminium through a die. This gives you parts with the same cross-section throughout. It also helps reduce material waste and adds built-in features like closed sections and support ribs.

These profiles are often used in frames, housings, and cooling parts. The shape and alloy you choose affect how strong the part is and how well it handles wear and corrosion. Many designs include slots, channels, and hollow sections to fit into larger systems.

Good design means thinking beyond just the shape. You need to make sure the profile works with cutting, drilling, and surface finishing. Features like even wall thickness, uniform shapes, and tight tolerances help the part fit and function well in real assemblies.

The minimum wall thickness depends on alloy type, profile complexity, and die design. For 6000-series alloys, a uniform wall as thin as 1.0 mm can be extruded. It provided the die land length and flow channels are optimised. Thin sections require precise temperature control to prevent tearing or uneven flow.

Die design influences metal flow, cooling rate, and dimensional accuracy. A symmetrical die promotes uniform flow and avoids twisting. For multi-void sections, mandrels and bridges must be designed to maintain void concentricity. Poor die alignment and inconsistent bearing lengths lead to warping and increased scrap rates.

Extrusion tolerances can vary by dimension and alloy. For example, a 40 mm width in an EN 755-9 profile may allow ±0.25 mm. However, tighter tolerances are achievable with precision dies and stretch straightening. These tolerances include flatness, twist, and wall thickness. All these affect part fit and load transfer in assemblies.

Yes, extrusions are widely used in heat sinks and cooling structures. These profiles include fin arrays, fluid channels, and surface textures to improve convective and conductive heat transfer. When designing for thermal use, make sure material continuity between the heat source and fins, and avoid sharp transitions that may interrupt heat flow.