Aluminium die-cast products are made through precision moulding. Manufacturers inject molten aluminium into a hardened steel tool. This forms complex shapes with tight tolerances and good strength.

The die casting process gives uniform parts with clean surface finishes. Aluminium die casting supports rapid production with minimal waste. The method suits components that need accuracy and high repeatability.

This process works well for both small and large parts. It is used in enclosures, brackets, handles, and housings. You can obtain strong, lightweight parts ready for further machining and finishing.

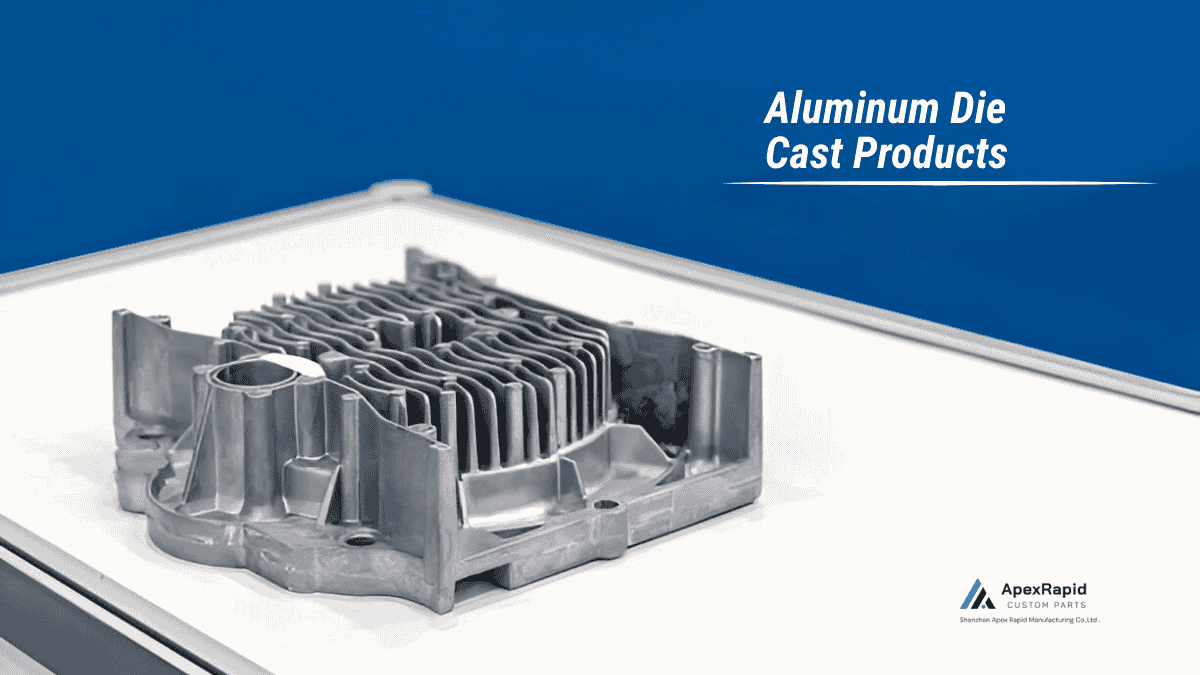

Aluminum Die Cast Products In Display

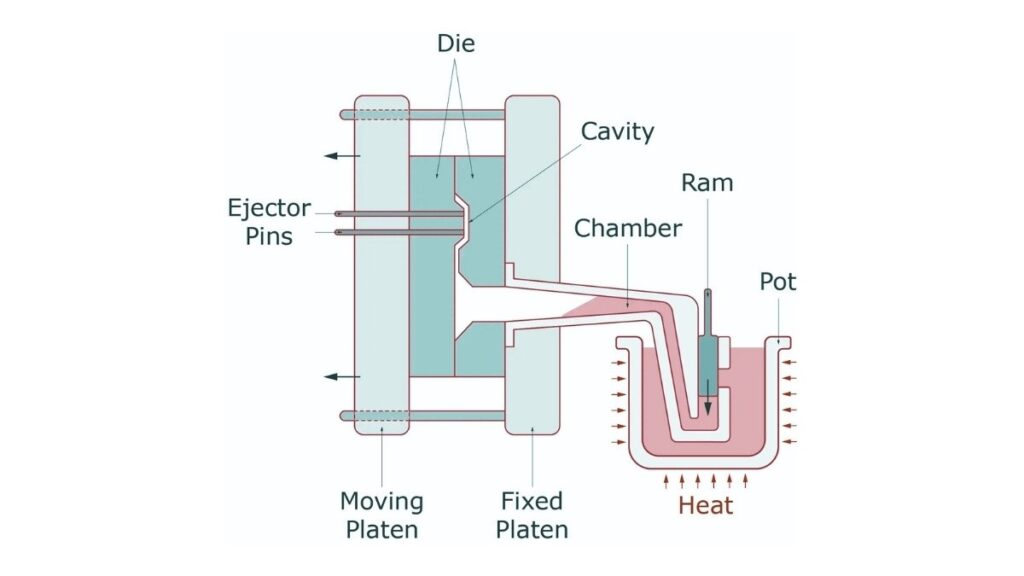

Aluminum Die Casting Process

Aluminium die casting follows a sequence of precise steps. You must control each phase to ensure consistent results. Proper execution minimises defects and material waste.

The steps below show how you turn molten aluminium into finished parts ready for post-processing or assembly.

The first thing is to preheat the steel mould. The process of preheating helps to avoid thermal shock and has a better flow of metal. Thereafter, use a release agent on the die surfaces.

This is done to enable easy ejection of this part upon solidification. It also enhances die life and wear.

Raw Aluminum Alloy for Casting

Then, you smelt out the alloy of aluminium in a furnace. The common temperatures are between 660degrees C and 700degrees C. The melt should be clean; it should have no oxides or slag.

With the right use of temperature, the gas porosity will be minimized. Degassing tools can be utilized in case of necessity before transfer.

Pouring Liquid Metal Into A Cast

Now, pour the molten aluminium into the closed die. The cavity is filled with a high-pressure injection in a relatively short amount of time and to the millimeter. Usually, pressures of 100 to 150 MPa are used during injections.

High fill speeds minimize the cold shuts, misruns. Take advantage of properly designed runners and gates in order to control the flow.

Apply pressure momentarily so that the metal can be compacted. This makes up the contraction when it cools. Depending on the thickness of the wall and the complexity of the part, holding time is different.

Dimensional stability must be achieved through proper solidification. Make sure of even cooling of the whole die.

After the section has set you open the die. The casting comes out of the mould with the help of ejector pins. It is necessary to make sure that parts are ejected without damage.

The casting can be deformed by misaligned pins or early ejection. Wait long enough to cool them off and then take them out.

Aluminum Die Cast Parts

Lastly, you get rid of any unnecessary products, such as flash or runners. Trimming tools cut the unwanted edges off. Finally, the portion goes to the stage of machining or finishing the surface.

Drilling, tapping, blasting, or coating are performed in the post-processing. This is done to finish up your casting into a form to be used in the end.

Before die casting begins, your design must be ready. Small choices affect flow, cooling, strength, and machining. You must plan each feature to avoid costly adjustments later.

These design factors directly impact quality, repeatability, and tool life.

You must strive to have a uniform thickness of walls in all parts. Poor thickness distribution will cause differential cooling, contraction, or internal porosity. Thicker zones may take a lot of time to solidify and can trap gases. The thin areas cool down too fast, resulting in underfill or cold joints.

The optimum wall thickness should be in the range of 2.5 mm to 4 mm. In case of variation, the transition has to be made smooth, never abrupt. Flow is also made easier, and hence internal stress during solidification is reduced by uniform walls.

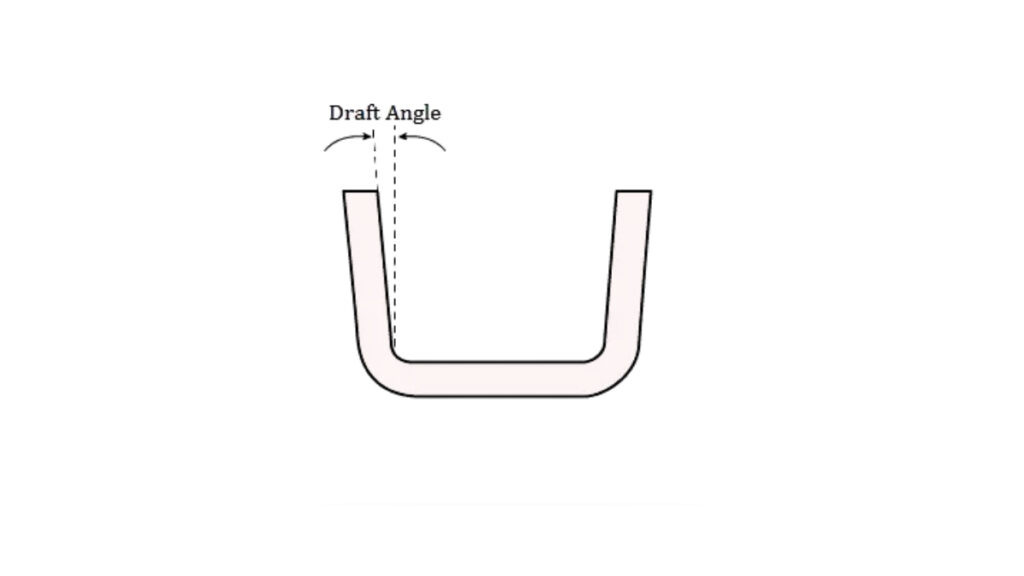

Draft Angle in Aluminum Die Casting

Draft angles need to be applied to the vertical surfaces of die-cast parts so that they can be ejected readily. A proper draft is essential, or some parts will stick to the die and get deformed in the process of removal. The wall number should be not least 10 to 20 on the outside walls and 30 on the deep internal cavities.

Draft is very important in the case of tight surfaces against the die steel. It minimizes wear on ejector pins and die surfaces, keeping things smooth as production goes on. When you design, put the draft in early, not later.

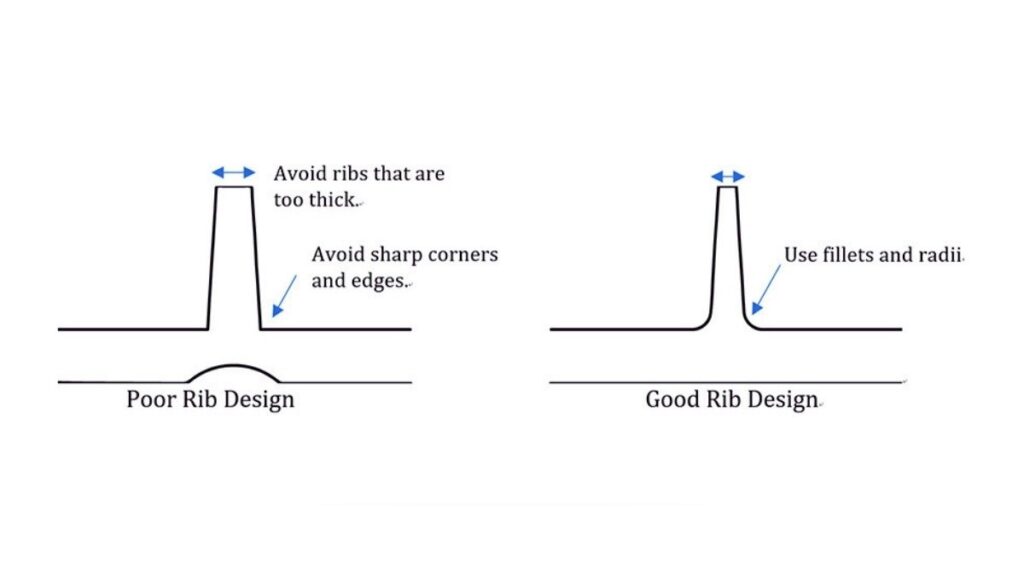

When dealing with molten aluminium, sharp edges interfere with the flow of the metal and cause turbulence. Any edge that you need to round off, you must do so with the use of fillets or radii with a minimum of 0.5 mm. This permits the free flow of metal into any open space, and there are no traps or air pockets.

There is also a prevention of hot spots that cause cracks on cooling by the fillets. They reduce the local stress and aid in keeping dimensions. Do not have harsh internal transitions, particularly at junctions between ribs or bosses.

Right & Incorrect Ribs Angle In Die Casting

When you need to reinforce the thin-walled parts, ribs are necessary to increase the strength without adding weight increments. They direct the water, they cause no distortion, and they bear the load. Ribs ought to be in the range of 50- 60 percent of the wall thickness and must be spaced such that they allow full fill.

To minimize the sink marks, place the ribs beneath large flat areas. Make them short and well-grounded. Taper the ribs to have an easier ejection and wear down the dies.

Bosses can be required to be assembled, fastened, or utilized with shafts. You must make them vented and supported so they do not sink or be porous. Use ribs to help in distributing stress and passing flows between bosses and walls.

The boss should not have walls as thick as the main walls because this would be too much; it should not have too thick boss walls. It should have a radius at the base to enable the smooth flow of materials. Wherever possible, where later drilling or tapping of the boss may take place, the clearance should be included in the boss

Close to final form is achieved by aluminium die casting, but tolerances are not precise. You are to leave excess material where you require higher precision, like on bearing seats or thread holes, etc. Roundness, concentricity, and flatness may have to be post-machined.

Learn the tolerance grade of your die casting standard (e.g., the standards of ISO 8062 or NADCA specs). Determine what is critical-to-function and make sure to have plenty of machining material. This is to maintain a good fit and reproducibility of operation between batches.

Selecting the correct aluminium alloy is critical for performance. Each alloy offers different mechanical strength, fluidity, corrosion resistance, and thermal behavior.

In die casting, ADC12, A380, and A360 are the most common in applications. These alloys are combinations of strength and casting, and heat resistance. The most common structural and electronic housings are done using A380.

ADC12 is similar, but it is more fluid and resistant to corrosion. A360 has outstanding pressure-tightness and is more process-sensitive. The decision should be made on the basis of mechanical loads and casting complexity.

Each of the alloys comes with distinct mechanical properties for the part. An example is that the A380 has good tensile strength and hardness of structural components. A360 or 413 might be superior in the event that pressure or sealing is required.

Examine the yield strength, elongation, and Brinell hardness. In case there is impact or fatigue on your part, look at heat-treatable or reinforced types of alloys. The properties of the materials should be similar to the operating stress in the real world.

The choice of the alloy should be steered by the environment to which your product is exposed. In case of outdoor application or application in a moisture-laden environment, choose an alloy such as ADC12 that has strong corrosion behavior. Areas that are marine or wet can require additional coatings.

Although aluminium is a protective film-forming metal, not all alloys are the same. Extra protection can be given through anodizing, powder coating, or treatment with chromate. The type of material can influence the durability of the surface on a long-term basis.

Thin-walled dies cannot fill all of the aluminium alloys equally. To prevent cold shuts, gaps, or short shots, you must keep high fluidity. ADC12 and A380 are fantastic in terms of giving good flow, even in complicated tool designs.

High pressure may be required to cast low fluidity alloys, or bigger gates may be needed. The oxidation rate of some alloys is quicker, and so it influences the surface finish. One should always take note of the behavior of the alloy in the die when it is under pressure.

The thermal properties of aluminium are advantageous to electronics and thermal dissipating components. A360 or 413 will give better performance if you have a part that conducts heat, such as housings, heat sinks, or enclosures.

The alloys do not distort or have hotspots, and the heat is dissipated rapidly. Alloys having too much silicon should be avoided when we are concerned with high conductivity. The type of match alloy depends upon thermal load.

After casting, some of the alloys are easier to machine, weld, or finish. You also need to verify that the alloy you chose can be drilled or tapped, or subjected to surface finishing. A380 is excellent for machining, but 383 can produce a better surface finish.

Do not use overly brittle alloys in parts that require anodizing or where the machining tolerances are very tight. It is worth considering the behavior of the alloy when trimming, cleaning, and plating so that the final decision can be made.

After die casting, surface enhancement is crucial. It improves appearance, corrosion resistance, and functionality. The chosen method depends on part usage, alloy type, and post-process steps.

In shot blasting, flash is removed and textures are levelled. It cleanses the surface to be painted or coated. It also covers up casting marks.

It applies beads that are made of steel or ceramic. This is followed by most of the parts before coating any of them. It is quick and suits batches in mass.

Tightening of tolerances or the addition of features is done by machining. Familiar processes are drilling, tapping, or facing the contact surfaces.

The designers will have to provide excess in the casting. Precise fixturing is essential so that there is no warping when a cut is made.

Powder Coated Die Cast Aluminum Parts

Powder coating produces a protective layer that is hard. It is scratch-resistant, anti-UV UV and chemical-resistant. It finds application in outdoor or consumer parts.

It is an electrostatic spraying of powder on the part. It is then baked to melt the finish. It can be either a smooth or textured finish.

Anodizing is used on die-cast parts, but more usually on extrusions. It forms an oxide layer to resist and look.

The aluminium used to make the alloy should be appropriate (typically high-purity aluminium). Since poor cast surfaces restrict replicable anodizing success, many properties do not apply to cast material.

It is a conductive coating that is thin and electrical. It is applied in advance of any painting or where conductivity is needed.

It is perfect to be use in electronics enclosures. It is easy to perform, but needs to be regulated so that there is no uneven film or graining.

The paint will provide the flexibility of color and a branding opportunity. Metallic sheen is Copper and Nickel plate, chrome, and so on.

The plating demands proper surface preparations, and in some instances, it needs a copper underplate. It is widely applied to cars, appliances, and hardware.

Aluminum die casting is a quick way to make strong and detailed parts. Molten aluminum is pushed into a metal mold under high pressure. This creates parts that are smooth, accurate, and ready to use with little extra work. It works best for large batches and parts that need to be the same every time. A good design helps with strength, clean surfaces, and easy machining or coating later.

Q1. What’s the typical wall thickness for aluminum die-cast parts?

Most designs keep a wall thickness between 2.0 mm and 4.0 mm. Uniform walls reduce shrinkage, improve filling, and prevent distortion during cooling.

Q2. Can aluminum die-cast parts be used in structural applications?

Yes, but it depends on the alloy and geometry. Alloys like A380 offer a good strength-to-weight ratio, and ribbing or gussets can boost stiffness.

Q3. What surface finishes are possible after die casting?

You can apply machining, powder coating, anodizing, or plating. The choice depends on corrosion resistance, aesthetics, and conductivity requirements.

Q4. How accurate are aluminum die-cast components?

Standard tolerance ranges are ±0.1 mm for small dimensions. Tight tolerances are possible with secondary machining and well-maintained dies.