Choosing between aluminium vs zinc for die casting is a challenging decision. Each metal performs better in certain situations. You must consider what the part will do and how it will be made.

Aluminium is strong and light. It deals well with heat and does not rust easily. This makes it suitable for parts that face harsh conditions. It can wear out tools faster and requires more pressure to cast.

Zinc flows into moulds easily. It gives smooth and detailed parts. It lasts longer on tools and speeds up production. While zinc is not as strong as aluminium, it is suitable for small parts made in large numbers. This guide will explain which material is best for your project, what features it brings, and practical applications across different manufacturing facilities. So, keep on reading.

Aluminum Die Casting

Aluminium die casting is popular for parts that must be strong and light. It works well where heat and corrosion resistance matter. This makes it common in cars, planes, and electronics.

The process uses high pressure to push molten aluminium into steel moulds. This allows you to make parts with thin walls and complex shapes. Aluminium’s light weight helps reduce overall product weight while keeping strength.

Casting aluminium demands more pressure and can wear tools faster than zinc. Parts often need extra finishing to get a uniform surface, even though aluminium is the best choice when strength and weight are top priorities.

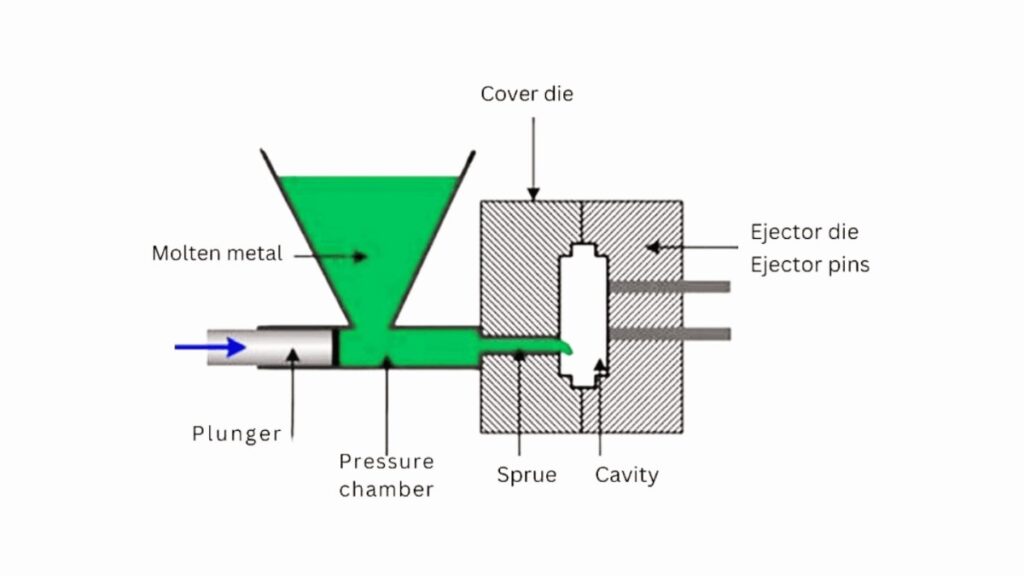

Aluminum Die Casting Process

Aluminium die cast parts are formed by forcing molten aluminium into a mould under high pressure. This method produces strong, lightweight parts quickly and precisely. Here are the common steps involved.

Aluminium is melted at temperatures of about 660 °C. The optimal temperature should be maintained. In case it is too hot, which causes defects, and it is too low, meaning the metal will not flow easily.

At high pressure, the molten aluminium is directed into a steel mould. This pressure aids in filling any mould with all its details, even thin and complex walls.

Aluminium cools quickly, usually down to around 200°C. Fast cooling helps the part harden. However, it also makes it harder to control the final shape.

The mould then opens after the casting has solidified, and the casting is gently pulled out. The mould is immediately prepared for the next cycle.

The casting may have extra metal called flash. This needs to be removed. Parts can additionally be surface finished and machined depending on the intended application.

Individual castings are measured, checked, and analyzed based on their dimensions, surface finish, defects, etc. This will make sure that only quality parts are progressing.

Aluminium die casting produces strong and lightweight parts. You can find these parts across many industries.

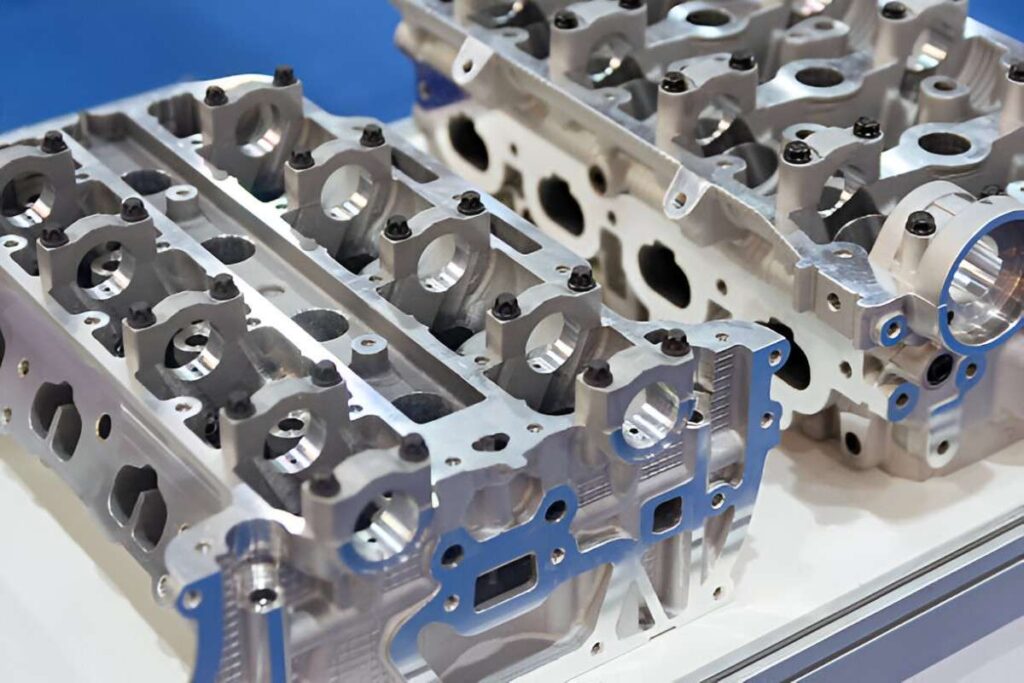

Aluminum Cylinder Head of the Engine

Manufacturers employ aluminium in cylinder heads and engine blocks. These components lighten the weight of the vehicle. Aluminium takes less time to cool, thus safeguarding engine parts. This enhances efficiency and less fuel consumption.

Aluminium transmission covers are resistant to pressure. It makes lighter and durable components. These cases are good companions to delicate gears and interiors.

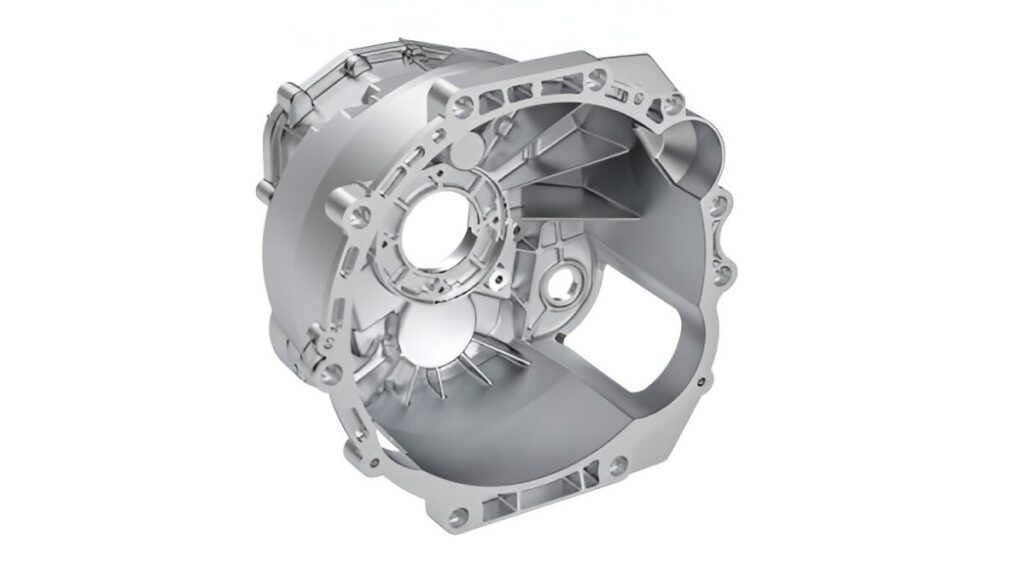

Die Casting Gearbox Housing

Aluminium gearbox covers can withstand stress and are corrosion-resistant. They can be accommodated in small areas. This eases assembly and lessens maintenance.

Heat sinks made of aluminium are efficient in transferring heat from electronics. You will depend on them to cool and protect devices. Aluminium is also used to cover fragile components without any increase in weight.

Aluminium is extensively used in pump housings and valve bodies. It copes with pressure and wear. Such endurance extends the smooth machine operation.

Aluminium is light and hence is used as the casing of power tools. It protects against knocks and falls to the interior parts.

Aluminium die casting is strong but not always the optimal choice. You should know its limits before choosing it.

The melting point of aluminium is approximately 660°CC. Such a hot temperature demands an increased amount of energy. It also causes more wear of moulds and tools.

The heat and pressure required result in quicker tool wear. You will require increased maintenance of the mould. This increases the cost of production in the long run.

Additional finishing is usually required in aluminium parts. The cast is either rough or porous. Finishing costs time and money in production.

For medium and small sizes, the cost and complexity increase in exceedingly large parts. You may need to think of other manufacturing techniques in this scenario.

The porosity may arise in casting, where small holes appear in parts. This undermines structural strength and may impact aesthetics. It is crucial to have control of the process parameters.

Although aluminium can achieve thin walls, fragile pieces can cause defects. These are wonderful details, but they may not cast well. You require a measured design and management of the process.

The decision to use aluminium die casting demands a technical baseline. Choosing the right one maximizes the part quality and manufacturing success.

Aluminium die casting favors complex shapes. However, too much complexity will wear out the tools and lead to more defects. Thin ribs and sharp corners should be designed carefully so that no stress concentration or porosity due to shrinkage appears.

The wall thickness has to be maintained uniformly throughout. Differences in the manufacturing process bring about the issues of uneven cooling, which causes warping and internal porosity. The wall thickness between 1.5 and 4 millimeters should be substantial and manufacturable.

The surface of die-cast aluminium parts is grainy. The smooth finishes require secondary processes such as machining or polishing. Early specs of finish standards to be used to direct tooling and processing.

Mould wear is caused by high-pressure injection and the molten temperature of aluminium. Choose wear-resistant tool steels and design with efficient cooling to increase the tool's life. The cost of tooling makes large manufacturing volumes worthwhile.

Aluminium alloys present a high tensile strength and provide excellent corrosion resistance with lesser thermal durability. Consider operation limits (usually below 200 °C) when parts are specified.

The fast production speed (cycles) of around 20 to 45 seconds per shot in aluminium die casting results in a high rate of production applied in the process. Other processes can be cost-effective when dealing with low volumes.

Zinc Die-Cast Part

Zinc die casting is popular for making small and medium-sized parts. It melts at a lower temperature than many other metals. This helps reduce wear on the moulds and tools. As a result, zinc casting tools last longer and need less frequent replacement.

The metal flows well into complex mould shapes. This means you can create parts with fine details and thin walls. Zinc also cools quickly, which speeds up the production cycle. Because of this, zinc is ideal for high-volume manufacturing.

Zinc parts have good strength and toughness for many uses. They resist corrosion and provide a smooth finish straight from the mould. This reduces the need for extra machining or surface treatments. Overall, zinc is a cost-effective choice when detail and volume matter.

Zinc Die Casting Process

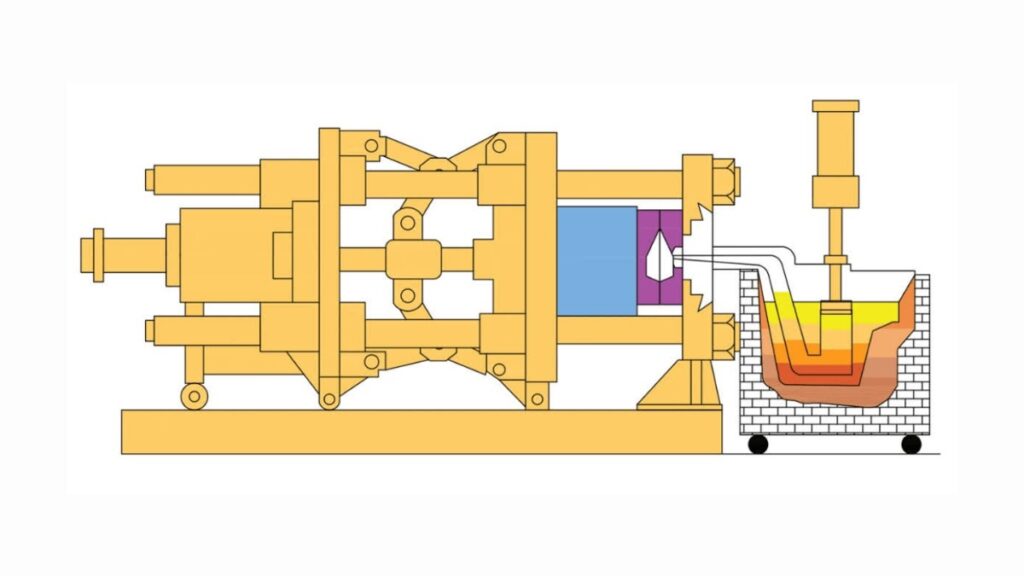

Zinc die casting is a high-precision, rapid method of injection casting metal parts of fine detail. It is based on the injection of molten zinc into a high-pressure steel mold. The process renders homogeneous, powerful casting in bulk. The steps involve several elements.

The manufacture involves heating zinc in a furnace till it becomes molten. It is essential to maintain the temperature. When it becomes too hot, the metal will deteriorate. Should it be too cool, it will not fill the mould correctly. The normal boiling point of zinc is about 420 °C.

The molten zinc is then injected into a mould of steel. The moulding is done in the form of the actual part. The pressure makes the zinc move quickly into all the mold cavities. This pressure ensures that the metal touches each detail before cooling down.

When poured into the mould, the zinc solidifies at a high rate. This rapid cooling aids the metal in having good strength and tight tolerances. Rapid solidification saves time, which can be followed by quick production.

The moulding after solidification is pushed out, and the mould is opened. This process should be controlled well so that the part is not destroyed. Then the mould closes to get ready for another cycle.

The casting can include some small over-metal along the edges, known as flash. This is shaved off to clean the portion. Surfaces of parts can also be polished, plated, or painted, depending on their final use.

Lastly, every casting is checked. This involves dimension and surface finish checks as well as structural checks. Before parts get shipped or go to assembly, ensuring their quality is consistent is crucial.

Many various parts are manufactured using zinc die casting in multiple industries. Its characteristics apply to items needing precision, toughness, and a smooth surface. The following are just some of the standard components that are manufactured through zinc die casting.

Zinc Cast Automotive Part

Part of zinc can be obtained from automobiles. They comprise such parts as door handles, locks, and brackets. Such details should be fine and strong, and zinc can be used. In other instances, zinc makes vehicles lighter.

Electronic housings are commonly made of zinc die casting. It guards against damage and the heat of sensitive items. The metal has been known to have a good finish, which can be closed safely and neatly without any additional work.

Zinc is used in many hardware items found in the house and industries. The examples are hinges, knobs, and fasteners. These components take advantage of zinc's long life and can contain intricate shapes.

Zinc is widely applied to tools, toys, and kitchen appliances. It is suitable for mass-produced consumer goods since it can cheaply make detailed parts.

Zinc castings are used in valves and connectors in plumbing. These components must be corrosion-resistant and have strict dimensions; zinc offers that.

Zinc enables the manufacturer to produce decorated items of great detail. These furniture fittings, ornaments, and trim pieces require a fine finish and strong constitution.

Zinc die casting has its strengths, but it also has certain limitations. Understanding these helps you decide when zinc is the right choice.

A lower temperature is needed to melt zinc than aluminium or steel. This implies that zinc components cannot be applied in hot temperature areas. The metal can be weakened by exposure to high temperatures above 200 °C, which will shorten its life.

Zinc is not as strong as other metals, such as aluminium. It fails to perform in heavy loads and high mechanical stress. Zinc can be inappropriate when high-strength parts are involved.

The density of zinc is greater than that of aluminium. This implies that zinc parts tend to be heavier. Zinc might not be the material of choice in industries where weight saving is an issue.

Zinc is prone to corrosion in either an acidic or an alkaline medium. In unprotected conditions, zinc components can wear out more quickly. This introduces more procedures and increases the manufacturing expenses.

Zinc die casting needs to be accurately moulded. Improperly designed tooling may lead to such defects as porosity or shrinkage. The complex parts require further finishing, slowing down production, and adding to the cost of production.

Zinc works to perfection on small to medium-sized parts. Massive castings are not so standard because of the mechanical and cost factors. Other materials can be more convenient in the case of large parts.

Zinc die casting works well for many parts, but you must remember some technical points. These will help you get the best results.

Zinc melts at a low temperature; thus, it can flow into moulds easily. This assists you in getting thin and detailed parts. However, when your design is overdone, it may lead to some defects, such as imperfections in the form of small cracks or voids. Curved forms and curves prevent such problems.

You prefer to maintain an even wall thickness, which is best between 0.8 and 3 millimeters. The metal does not cool evenly when there are either too-thick or too-thin walls. Depending on that, it can shrink or distort.

Zinc components tend to emerge from the mould and maintain a smooth surface. This implies fewer casting involvements; however, mould design and the casting process must be accurate when you require tight tolerances.

Zinc melts at a lower temperature and hence is lighter on the moulds. It implies a longer life for the tools. Nevertheless, you require good cooling to prevent overheating of the metal in certain mold sections that may lead to its damage.

Zinc alloys are sturdy and wear-resistant at room temperature. However, they diminish rapidly when the part becomes hotter than 200 °C. Zinc, therefore, is not suitable for high-heat applications.

Zinc casts very fast, sometimes in less than 20 seconds per part. This puts it at an advantage in a large production run. Its low melting point also implies that it consumes less energy. Zinc may be economical on shorter runs due to both the longer life of the moulds and quicker cycles.

| Aspect | Aluminium Die Casting | Zinc Die Casting |

| Melting Point | Around 660°C | Around 420°C |

| Weight | Lightweight parts | Slightly heavier parts |

| Strength | Good strength and heat resistance | High strength but lower heat tolerance |

| Surface Finish | Rougher often needs finishing | Smooth finish, less finishing needed |

| Wall Thickness | Usually 1.5 to 4 mm | Usually 0.8 to 3 mm |

| Tool Wear | Higher due to hotter metal | Lower because of the lower casting temperature |

| Production Speed | Moderate cycle time (20–45 seconds) | Faster cycle time (under 20 seconds) |

| Cost | Higher tooling and energy costs | Lower tooling and energy costs |

Aluminium and zinc die casting each have their strengths. Aluminium is strong and handles heat well, so it suits parts like engines. Zinc is great for quickly making detailed, thin parts with a smooth finish. Choosing the right one depends on what your part needs and how many you make.

ApexRapid offers quality aluminium and zinc die casting. We make parts that fit your exact design and deliver on time. With skilled engineers and sound equipment, ApexRapid helps you get the necessary parts without hassle. Whether for cars, electronics, or other industries, we have you covered. Contact us now to discuss your project requirements and get an instant free quote online.