It is not always easy to make acrylic parts. Slow delivery, poor fits, or rough edges are common issues encountered by engineers. Acrylic is tricky to machine as it can crack or melt, or become cloudy when not treated with care.

The problems are solved by CNC machining. It portrays acrylic with computerized tools according to your specific design. The output is an accurate, smooth, and clean part that can be used. It is practical for both one-off prototyping and full production. It is normally applied to covers, screens, display parts, and bespoke enclosures.

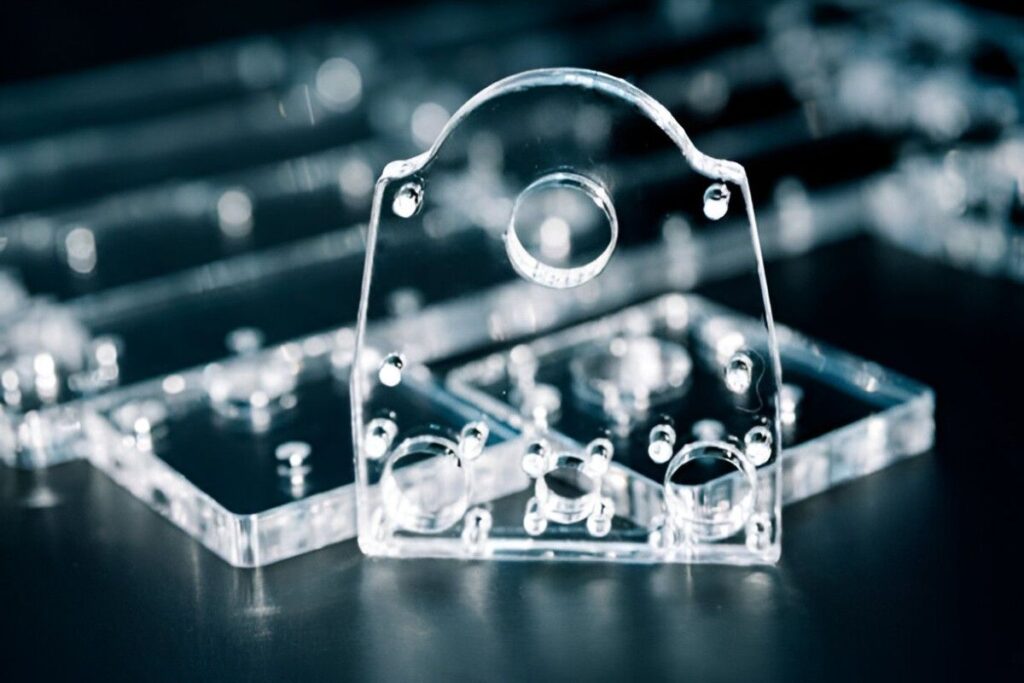

Acrylic CNC Machining

Here are the common steps involved in acrylic CNC Machining

Acrylic parts need careful CNC machining to stay precise and strong. Different machines and methods suit different shapes and production needs. Using the right approach keeps parts clear, accurate, and free from defects.

3-axis routers move in the X, Y, and Z directions. They are perfect with a flat panel, display board, and simple cutout. Such machines cut smooth edges and are most suitable for moderate volume production and in simple geometries.

4-axis routers give an additional rotational axis to the 3-axis for machining at multiple angles without repositioning. They can be applied to cylindrical components, curved surfaces, and enclosures that are round. This process saves time in setup and increases dimensional uniformity.

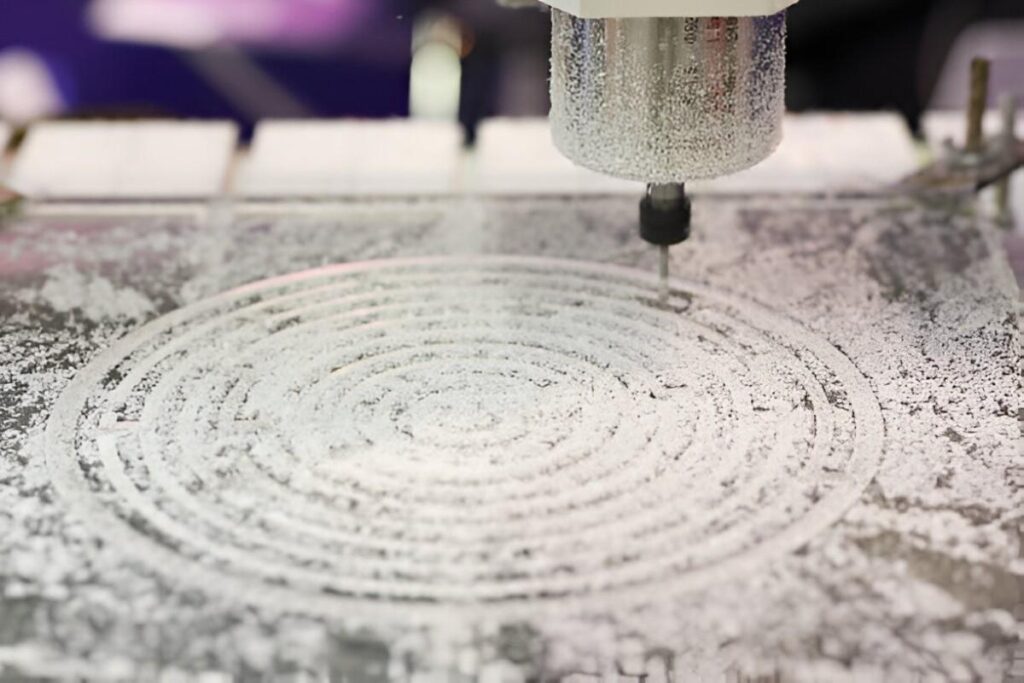

CNC Milling Acrylic Machining

5-axis mills may be able to move in three linear axes with two rotational axes. They work with complexities, deep pockets, and complicated shapes. Precision is possible to 10-100. Minimal finishing is also attained using this approach.

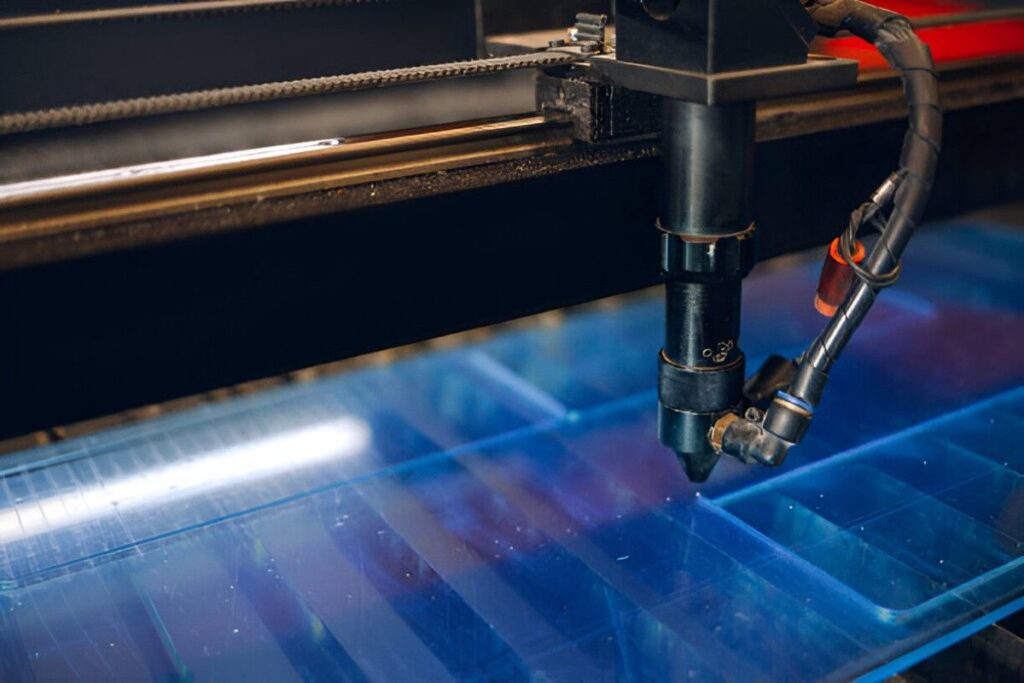

Acrylic Laser Cutting

Laser CNC machines can cut or engrave acrylic with an intense light. They can generate delicate patterns and have smooth, sharp edges. Correct power and speed settings eliminate melting, color, or micro-cracking on the acrylic.

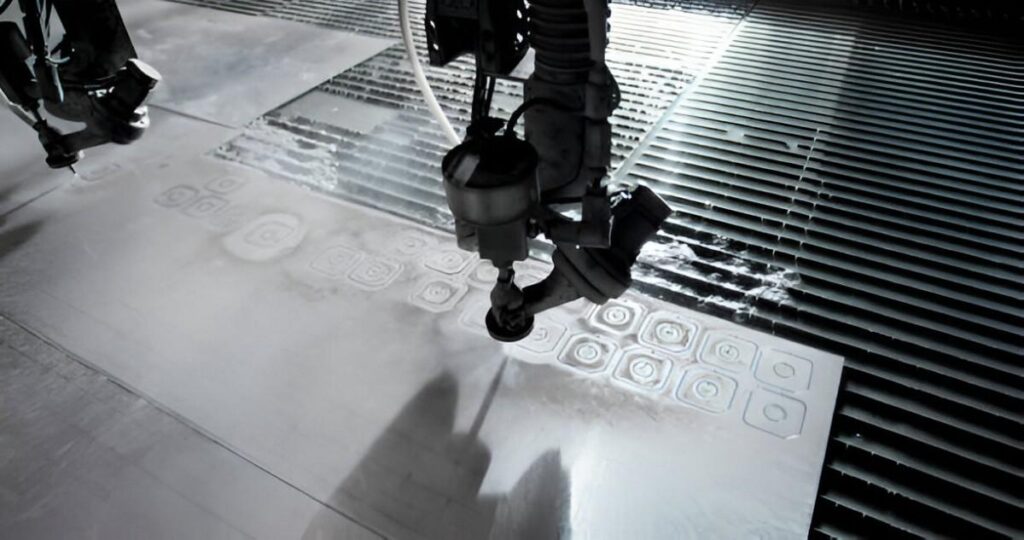

Acrylic Waterjet Cutting

Cutting of acrylic is carried out through water jet machines that are equipped with an abrasive material that is mixed with high-pressure water. This cold cutting process does not cause any heating or warping. It can be applicable to thick sheets or components that need sharp edges and intricate profiles.

Acrylic pieces are rotated in rotary CNC systems in the event of cylindrical or tube-shaped parts. It is an accurate way to calculate columns and rods, and custom connectors. It provides a consistent removal of materials and consistent diameters in length.

Multi-station centers can combine cutting, drilling, and engraving in one setup. They are more efficient when it comes to medium to large-scale production. Inspection with the use of integrated CCD inspection systems allows the parts to pass stringent dimensional and visual requirements.

Acrylic CNC machining is applied in industries that require clear, robust, and accurate parts. It can be shaped accurately, have smooth edges, and dimensions.

Transparent Acrylic Parts

Acrylic is carved to form showcases, banners, and promotion stands. CNC machining makes each part have neat edges and accurate dimensions. This assists the brands in displaying the products professionally, and it ensures that the products have uniform quality.

Insulating components, housings, and device covers of products are made of acrylic. CNC machines make precise connectors and wire cutouts. This eliminates errors during assembly crowning and makes it fit well.

Acrylic Transparent Glass Sign Plate

Acrylic can be CNC-machined into decorative panels, light diffusers, and partitions. The process enables the designers to produce complicated figures with smooth surfaces. It is in the best interest of both the prototypes and large production runs to be accurately machined.

Transparent barriers, protective covers, and containers in labs and medical settings are made up of acrylic. CNC machining provides smooth edges and accuracy. The components are strong and secure to be used repeatedly.

Designing parts for acrylic CNC machining requires careful planning to maintain precision, strength, and clarity. Understanding material behaviour and machining limits ensures high-quality results for industrial and commercial applications.

A crack or a chip can develop on acrylic in case the walls are too thin. The wall thickness of designers should be 2-3 mm to achieve stability. Heavier gages enhance rigidity at the cost of material. During the CNC machining, stress points have to be considered to prevent breakages when cutting or drilling takes place.

CNC machining is able to hold tight tolerances on most parts; most standard parts can be held to +/- 0.1 mm, and very high-precision parts can be held to +/-0.05mm. Consider thermal expansion and machining allowance, because this prevents the mistake; the part does not fit in the assembly. The right spacing would avoid subsequent stress and warping during machining.

To avoid cracking and for optical clarity, acrylic edges must be smooth. CNC machines must employ sharp single or double flutes and the feed rates at fixed feed rates. Polishing may be done manually or by the use of a flame, which depends on the design requirement.

Intricate designs, deep pockets, or fine cutouts require careful planning. CNC programming must minimise rapid tool changes and excessive passes. Using multi-axis CNC machines allows machining of curves and angled surfaces without repositioning, reducing errors and improving surface finish.

For parts that integrate into assemblies, designers must reinforce screw bosses, slots, or pegs. Accurate hole placement and countersinking ensure stable assembly and prevent cracking during installation. CNC drilling and milling should follow the specified tolerances strictly.

Acrylic CNC machining delivers precise, strong, and visually clear parts suitable for various industries. It combines accuracy, repeatability, and surface quality, making it ideal for functional and decorative applications.

CNC machines cut acrylic to a close tolerance. Normal tolerances are around +/- 0.1 mm and +/- 0.05 mm tolerance on high precision parts. This will make parts fit properly in assemblies and minimize the errors in fitting.

The acrylic machined is smooth-edged and clear. Adequate feed rates and sharp tools can avoid chipping and cracking. Optical clarity can be improved by polishing, which is necessary when the item will be used in a display or protective cover.

CNC can do complex designs and inclined cuts. Multi-axis CNC can make curves, slots, and pocketing in a single setup. This minimizes the need to reposition and enhance dimensional accuracy.

After programming, CNC machines are capable of making many repetitive parts very fast. This is perfect for prototyping or high production. It minimizes wastage of materials and waste, and it guarantees that all parts fit the design.

Designs can be easily modified for different applications. CNC machining supports rapid changes in dimensions or features. This flexibility suits industries like medical, electronics, and architectural products.

Although acrylic is multifunctional and aesthetically attractive, it possesses some drawbacks that the designers and engineers need to take into consideration during CNC machining. Knowledge of these limitations can be used to avoid component failures and deliver quality results.

Acrylic should be cut at low stress, or it may crack or chip. Thin walls or acute angles expose the patient to a greater vulnerability to fractures. The CNC programming should take note of the feed rates, spindle speed, and the cutting angles to ensure that stress is minimal on the material.

Acrylic becomes hot easily in the process of machining. Unnecessary heat may result in melting, warping, or having an imperfect surface. Correct cooling, slower cutting rates, and sharp tooling are necessary in order to ensure surface finish and dimensional stability.

Acrylic is not impact-resistant as compared to some other plastics. It is stiff and is not able to bend or flex without breaking, which restricts its application to any mechanical resilience requirements. Designers should design thicker parts or even a reinforcement design in order to make functional sections.

Acrylic is prone to scratches when handling and machining. Optical clarity can be damaged as small as abrasions. Protective films, careful fixturing, and controlled tool paths can all be used to avoid damaging surface finish.

Acrylic is reactive with some solvents and adhesives, resulting in crazing or clouding. During post-machining operations, the selection of compatible cleaning fluids, glues, and finishes should be done to ensure part integrity is maintained.

These restrictions make it essential to plan properly and tool and program carefully with CNC when using acrylic. Through knowledge of its properties, manufacturers can make clear and durable pieces of high quality.

Although CNC machining is widely applied to acrylic, there are a number of other methods that effectively create, cut, and polish acrylic parts. All the methods fit into various production requirements, the size of parts, and part complexity of part designs.

Laser cutting is an approach where they cut acrylic sheets through the use of an intense beam. It renders clean edges and low stresses of the mechanism. This technique is most suitable for thin pieces, complex patterns or designs, and quick prototyping. Yet, thicker materials can take several passes and have to be treated with heat.

In thermal forming, acrylic sheets are heated until flexible, so that they can be bent or shaped around molds. This is appropriate for curved components, housing, and embellishments. Heating and slow cooling occur in a controlled manner, er and there is no cracking or distortion of the surface.

The injection molding process involves melting acrylic pellets and injecting the molten material into a mold. It is very effective to mass-produce intricate forms. Shrinkage, stress points, and surface finish have to be considered in mold design so that part quality is achieved.

In solvent welding, the parts are made of acrylic, and the surfaces are softened with solvents and pressed together. It makes joints without sticking together and fasteners. To prevent clouding or weak bonds, it is important to use the appropriate solvent and curing time.

It can be either mechanically or chemically polished to enhance optical clarity and to smooth the edges. Flame finishing involves a controlled flame running along edges to smooth and melt surfaces. The two methods improve aesthetics, particularly dissimilar kinds of display parts and protective shields.

Acrylic cutting is done by waterjet cutting, which is an abrasive particle with high-pressure water. It prevents warping due to heat and also enables one to cut thick sheets accurately. Its speed is lower than laser cutting, but it is less thermally stressful to delicate components.

In routing, spinning cutters are employed to cut away material in acrylic sheets or blocks. It can be used in thicker materials and produce pockets, grooves, or 3D surfaces. Correct tool and feed rates: to avoid chipping.

At Apex Rapid, we provide high-quality CNC machining for acrylic parts. Our experienced team works with five- and six-axis machines to ensure accurate cuts, smooth edges, and consistent results. We also handle material selection, polishing, and post-processing to meet your project needs.

Whether you require prototypes or high-volume production, Apex Rapid delivers reliable solutions on time. Reach out to our experts and discuss your next acrylic CNC machining project.

Q1. What types of acrylic can the You machine?

We machine both cast and extruded acrylic. Cast acrylic gives clear, polished surfaces, while extruded acrylic is ideal for functional components.

Q2. What tolerances are possible in acrylic CNC machining?

We achieve tight tolerances between ±0.1 mm and ±0.05 mm. This allows us to maintain consistent dimensions even for complex shapes.

Q3. Can Apex Rapid handle thick or large acrylic sheets?

Yes, our CNC machines can process thick sheets or blocks. Careful tool selection and speed control prevent cracking or chipping.

Q4. How is surface quality maintained during machining?

We use sharp tools, correct feed rates, and controlled spindle speeds. Our polishing and flame finishing improve part clarity and smoothness.