Black chrome plating is a type of surface finish treatment. It combines both functional and cosmetic electroplating of a thin dark coating of chromium on a metal base.

Automotive, aerospace, military, and medical sectors widely use black chrome plating. In contrast to conventional chrome, which provides a silver-reflective finish, black chrome gives a darker, satin or matte, anti-glare finish. This coating is not only aesthetically different but also resistant to corrosion, sturdy, and unlikely to be scratched.

A typical black chrome finish consists of a base nickel adhesion layer, on top of which technicians apply a chromium layer with additives such as sulfur and selenium to achieve the black color. Manufacturers use black chrome plating to improve infrared absorbance. Usually, it is used on optical parts, control knobs, and precision parts where both the appearance and the performance are of concern.

Moreover, black chrome is a high-temperature-resistant material. So, it reduces glare and prevents tarnishing. It makes black chrome a predictable option in disciplined engineering environments. Black chrome plating is a favorite of engineers and machinists who have to deal with parts that require precise tolerances, as black chrome plating not only preserves dimensional integrity but also does not compromise on mechanical properties.

Matte Black Steel Boards hang on the Wall

To achieve a high-quality finish with black chrome plating, engineers follow a step-by-step process. Here is a breakdown of five basic steps for black chrome plating:

There should be no oils, residues, or debris on all substrates. Alkaline cleaners and ultrasonic agitation remove microscopic contaminants that may cause adhesion loss. In specific sophisticated systems, electrolytic cleaning is used to guarantee total surface cleanliness.

The metal is activated by putting it in an acid dip to be ready to be plated. It eliminates oxides and establishes a chemically receptive layer. The activation solution tends to be selected depending on the composition and the surface condition of the base metal.

It is done on a base of bright or semi-bright nickel. It offers corrosion protection as well as good bonding of the final chromium coating. Nickel deposits a smooth layer, which adds aesthetic and uniformity to the top coat.

A controlled current is applied to the nickel layer with a black chrome plating solution, which is generally a mixture of trivalent chromium, catalysts, and buffering agents to deposit the chromium alloy. The technicians observe real-time temperature and chemistry of the bath to maintain a uniform layer thickness and prevent color variation.

Technicians wash the part in deionized water and dry it in a clean atmosphere. Any leftovers are cleared to prevent staining or chemical damage. In large-scale production, this is mechanized through multi-stage rinsing tanks and air knives.

Hard Chrome Electroplated Shaft Metal

Both electroplating and PVD are applicable in applying black chrome finishes, and yet both are very different in methodology and outcomes. Let’s see the clear differences between these two techniques:

In electroplating, material is deposited by an electrolytic bath and an electric current. It can penetrate more into the complicated geometries and gives a thicker and stronger coating. It's also more cost-effective for high-volume runs. In this approach, it is also possible to change the current density and dwell time, which is more flexible.

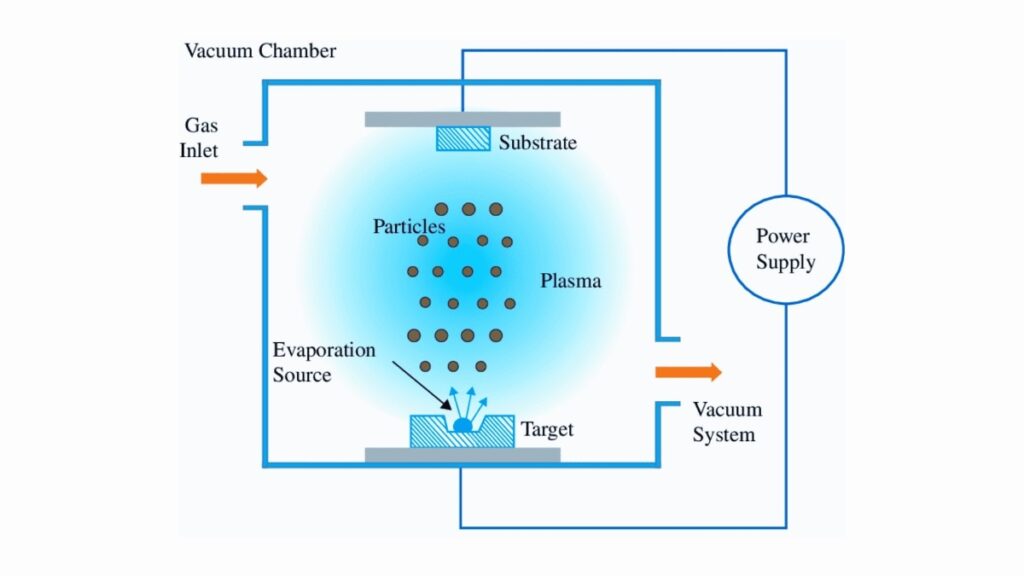

Physical Vapor Deposition (PVD)

PVD process is characterized by vaporizing the coating material in a vacuum chamber and then depositing the same on the surface of the part. It provides low-thickness, smooth, and consistent layers of high hardness and high wear resistance. But PVD might not be able to compare with electroplated black chrome in terms of corrosion resistance and adhesion to complex CNC parts.

Electroplating is still the most popular technique when the application of high durability is required in industries.

For black chrome plating to look perfect, the surface needs to be prepared optimally. Here are some key considerations that should be taken into account to prepare good-quality surfaces:

Contamination, such as oils, dirt, or oxidation, can cause plating defects. Cleaning operations usually entail solvent cleaning, alkaline cleaning, and acid cleaning. Under magnification, parts are frequently visually inspected before further processing.

Polishing or blasting of machined parts is frequently necessary to obtain the proper surface profile. Too smooth or rough surfaces may be problematic in terms of adhesion or aesthetic quality. It is usually desirable to have a Ra value of 4-8 microinches.

Specific components require selective plating. Masking is also provided by the use of waxes or elastomeric compounds, which will determine only the areas in which the black chrome coating is to be applied. Masking also protects internal threads, bores, and contact surfaces.

The chemical composition of the plating solution determines the coating’s quality, hardness, and appearance. Environmental regulations have increased the use of trivalent chromium baths. Such additives as sulfur compounds and complexing agents modify the color and the structure of deposits.

Temperature, pH, and current density must be tightly controlled. Poor chemistry can cause uneven deposition, dull finishes, or poor adhesion. In-line monitoring systems are helpful in high-precision industries to maintain the consistency of the process. Stores usually keep a history of bath logs so that they can track and analyze root causes in case a defect is present.

Chrome CNC Aluminum Black Brake Clutch Skull

A common substrate on which black chrome is plated is stainless steel, especially in aerospace and medical equipment. It, however, needs a nickel strike or a copper under-layer to encourage adhesion.

Aluminum, brass, and copper are also compatible but require varied pre-treatment cycles. Chromium can peel or blister with thermal or mechanical stress without proper under-plating.

In the plating of high-carbon steels, special precautions have to be exercised to avoid hydrogen embrittlement. After plating, baking processes are used to relieve entrapped hydrogen and maintain part integrity.

Poor adhesion is due to contamination of the surface, incorrect current density, or poor surface activation. To mitigate these risks:

Adhesion may also be tested by mechanical pull tests or by thermal cycling before parts are released to the field. Process control charts allow documenting test results to maintain long-term quality.

Black chrome plating offers a clean and shiny finish. But some other solutions are also present in the market. Here is a comparison of some well-known alternatives to black chrome plating:

Black Chrome Round Metal Rings Banks for Bearings

Black chrome paint is cheaper and does not have the durability and appearance consistency. It tends to flake under mechanical pressure and fails to provide absolute corrosion protection. Plating is more expensive, but it creates a bonded layer that improves performance.

Paint is appropriate on decorative pieces, but fails to perform in industrial or high-wear situations where chemical resistance and surface integrity are essential.

Powder coating provides a denser and more resistant to impacts layer, but does not offer such fine control and uniformity of finish as black chrome plating. It is also less tolerant of higher temperatures, and so is not used in aerospace and automotive interiors.

Also, powder coats usually need a thicker buildup, and this can impact dimensional tolerances. Plating is more precise in maintaining engineered fits.

Black Nickel Electroplating

Conventional chrome is bright and reflective, and it fits the aesthetic components. Black chrome has a darker, non-reflective appearance and has improved infrared properties. Its anti-glare characteristics make it suitable for optical equipment and tactical use.

Depending on the requirements, such as thermal management, wear, and reflectivity, engineers tend to choose between them depending on the application requirements.

Shiny promises of black chrome plating are tempting, but one needs to decide based on practical requirements. Here are some key practical considerations for black chrome plating:

The black chrome plating price will be based on several factors:

Industrial application cost averages are 100 to 600 dollars per part. Very complicated or aerospace-qualified work may cost over a thousand dollars.

Most specialty plating shops provide black chrome services, but not all deal with industrial-grade parts. When you search for black chrome plating near me, look out for:

Plating facilities should conduct testing in-house, and the service providers should well document the process. Request lead times, particularly in case your component needs numerous finishing procedures.

Black Chrome Electroplated Car Wheel Rim

Hobbyists and prototyping engineers may be interested in a black chrome plating kit. These kits have small-volume plating solutions, power supplies, and cleaning materials.

DIY kits are not enough to be used in most CNC applications. Professionals should rely on certified plating vendors.

Black chrome plating might give you a nice surface finish and a good-looking product, but it needs inspection and maintenance afterward. Here are some post-plating considerations for black chrome plating:

Parts must meet dimensional and visual standards. Common inspections include:

The salt spray, humidity chambers, tests, and abrasion cycles are used to test black chrome coating. Up to 1,000 hours of salt spray resistance may be needed in aerospace applications.

Other tests, such as Taber abrasion, thermal cycling, and contact resistance, are optional on mission-critical components.

Avoid abrasive cleaners. Use microfiber cloths and pH-neutral detergents. In the case of aerospace and optical components, routine inspections and records are required.

The wear patterns can be tracked using a maintenance log, and re-coating can be scheduled before a failure occurs.

Many service providers promise high-quality plating. It’s an important decision for professionals. Here we discuss some key things to consider while selecting a service provider for black chrome plating:

Black chrome plating has an exclusive blend of strength, corrosion resistance, and aesthetic beauty. It might be more expensive to invest upfront as compared to other options such as powder coating or paints, but the overall advantages in the long run, particularly in high-performance sectors, make it worth the expenditure. The ability to make informed decisions allows CNC professionals to know what is going on, the materials used, the inspection criteria, and the qualification of the providers.

Q1: What is the black chrome plating process?

It involves cleaning, activating, nickel plating, black chrome deposition, and rinsing the substrate in sequence.

Q2: Can I use black chrome plating on stainless steel?

Yes, but a nickel or copper underlayer is essential for adhesion.

Q3: What is the cost of black chrome plating?

The cost ranges from $100 to $600+ per part. It depends on size, complexity, and plating thickness.

Q4: Where can I find black chrome plating near me?

Look for certified metal finishing shops with experience in your specific industry or substrate type.