When you design a part, you expect it to be cut exactly as the drawing shows. A missed tolerance or poor finish can hold up the entire build. That is where CNC machining steps in, giving you repeatable results that manual methods cannot match.

Still, not every company has the machines or people to handle this work in-house. Maintaining a full setup requires high capital costs, trained staff, and risks of downtime. Many engineers find it easier to rely on a shop that already has everything in place.

If you know how these shops operate, you will know what to ask, what to check, and how to avoid delays. That knowledge makes it easier to choose the right partner for your job.

CNC Machines in a Factory

A CNC machine shop is not a room with machines. It is a system in which programmers, machinists, and quality personnel collaborate to knit up your CAD file into finished parts. All the cuts are made with code rather than guesswork, and therefore, you can be assured of the accuracy.

Your design is the point of departure. The shop translates it to CNC code, feeds it through mills, lathes, or grinders, and checks the part against the spec. Not machine time, but process control consistency, that is what you are purchasing.

Industries that do not allow error, such as aerospace, automotive, and medical, rely on such shops daily. When you require sophisticated components in small or large quantities, the CNC shop connects your idea to the drawing board to a finished, workable hardware.

Every CNC shop bases its ability on the machines that it operates. The kind of machine is important because it determines the shapes, sizes, and tolerances you can get. When you send a design out, you need to know if the shop has the right setup to cut it.

Below are the core CNC machines that you will see in most professional shops. Each has its own strengths, and in many cases, jobs require a mix of them.

CNC Milling Rough Metal Cutting

The milling machine is the backbone of most shops. They take away material with rotary cutters and can work with complex 3D shapes. With the multi-axis capability,y you can cut pockets, contour, and fine details that the standard equipment cannot reach.

If you want parts with slots, holes, or precision surface finishes, milling is generally the method. Modern 5-axis mills can do jobs in a single setup, which reduces lead times and maintains accuracy tightly.

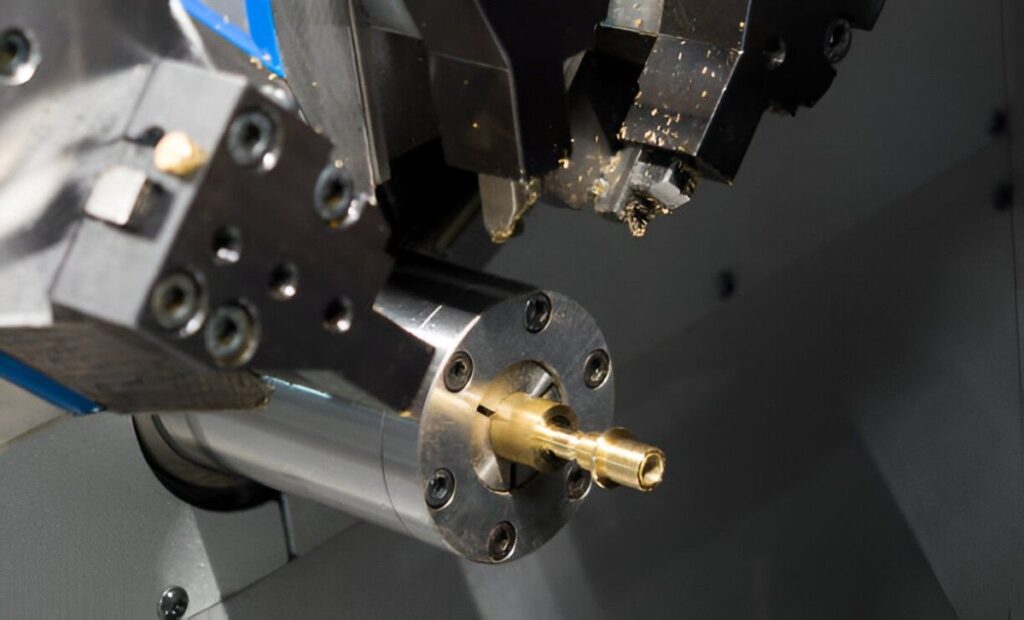

CNC Metal Lathe

When the part is round, it's a lathe. CNC lathes turn the material around as the cutting tool forms it. This makes them ideal for shafts, pins, bushings, and threaded parts.

Turning centres are sophisticated versions with live tooling. They enable you to make cuts on features such as flats or drilled holes without the need to move the part to another machine. This lessens handling and keeps parts accurate.

CNC Grinding

Grinding is where you go for the finest tolerances and surface finishes. It is done in those cases where even the best milling or turning cannot produce the desired precision. Aerospace and medical parts frequently undergo a grinding process as a finishing process.

These machines are slower, and they give accuracy in microns. If you have hardened steels or critical fits to grind, grinding is a necessity.

EDM Electroding Making a Precision Mold and Die

EDM is not like cutting using tools. It uses electrical sparks to form hard materials that normal cutters can't work on. Wire EDM is commonly an option for sharp corners, intricate cavities, or the creation of dies.

If your part design requires tight internal shapes or orhigh-hardnesss alloys, EDM is the go-to choice. Many shops have EDM in-house to handle jobs that are beyond standard milling and turning.

When you source machining locally, you don't just cut distance. You get faster, clearer, and easier control of your projects. Engineers often find that a nearby shop helps reduce risks associated with offshore or long-distance suppliers.

The following are some of the main benefits you receive when working with a CNC machine shop near me.

Parts transit faster from the machine to your site without long transit delays. This is critical when your project is on a tight schedule.

If a change in the design is brought up, a local shop can make the necessary adjustments and get these changes faster. You save days that are spent on international shipping and customs clearance.

For time-sensitive jobs, this speed can often be the difference between staying on schedule between missing deadlines.

When your supplier is close to you, the communication becomes direct and clear. You can come into the shop and look at samples, and have a chat about changes in person. This is building trust and avoiding costly misunderstandings.

Engineers often like this setup because technical details can be more easily explained in person. It also provides for fast feedback loops between your design team and the machinists.

With the support of a local manufacturer, you're solving problems before they become a larger issue.

Shipping costs greatly increase with distance, particularly for heavy or oversized parts. By selecting a local CNC shop, you will save or even eliminate freight costs.

Lower shipping also means fewer handling steps, which results in fewer possibilities where parts are damaged in transit. This is important if you are working with delicate components and high-value materials.

The amount you save in logistics can instead be spent to improve quality checks, invest in better materials, or speed up production.

CNC machine shops are used in many different industries. Each industry has its own set of requirements, ranging from tight tolerances to stringent material requirements. Local shops often play a critical role by providing parts in a timely fashion, reliably,y and with the flexibility that larger suppliers do not have.

Below are some of the major industries that depend on nearby CNC machining services.

Automotive as well as aerospace require the need for high accuracy, with zero margin for error. Local shops provide such parts as engine housings, brackets, and precision fittings. For Aerospace, especially, shops have strict quality systems in place to meet regulatory standards.

Working with a nearby supplier helps to speed up the prototype work and design validation. Engineers can visit the shop and look at samples, and know that the parts are meeting performance and safety requirements before scaling production.

Medical parts often demand precision in the micron range. Local CNC shops make surgical tools, implant parts, and housings for medical devices where you can't afford to compromise on reliability.

Electronics also relies on CNC machining for enclosures, heat sinks, and small precision fittings. Local suppliers can also make it easier to test prototypes and make revisions before making larger runs.

General industry includes all kinds of equipment, from pumps and valves to heavy-duty machinery. Local shops support this by making replacement parts, fixtures, and custom tooling.

Consumer product manufacturers also have CNC shops for prototypes and short production runs. With local support, they can alter designs more quickly and adapt to changes in the market without long delays.

The energy industry works with CNC machining for its turbines, drilling parts, and structural parts. These applications call for durable materials and tight tolerances, often in difficult operating conditions.

Local machine shops help by getting parts out more quickly, negating the need for large inventories. They also offer repair and replacement support in the event of down equipment.

Not all CNC shops provide the same level of service. Some are better suited to complex aerospace components, and others specialise in high-volume automotive components. To find the right partner, you need to look beyond price and check the factors that directly impact quality and delivery.

Here are 3 key points to consider for choosing a local CNC machining provider.

Quality Inspection of Machined Metal Part

Certifications are a sign of how serious a shop is about quality. Standards such as ISO 9001 or AS9100 indicate the shop is using structured processes in production and inspection. This lessens the risk and gives you the confidence that your parts will meet requirements.

If your project is in aerospace, defense, or medical, certifications are not an option. They are mandatory. Always verify a shop's credentials before you commit to a job.

A certified shop will also have documentation of traceability, which makes it easier to trace materials and processes used in your order.

Steel Tubes at the Metal Work Factory

Not every shop is working with the same materials. Some are designed for aluminium and plastics, and others accommodate hardened steels or titanium or exotic alloys. Make sure the shop has proven experience with what material your project calls for.

Capabilities also matter. Check to see if they can run multi-axis machining, grinding, or EDM if your part requires it. Ask about their inspection equipment, as well as precision is only as good as the measurement tools used to verify it.

This step helps to avoid costly delays in sending your design to a shop that cannot deal with it properly.

Customer feedback tells you how a shop is performing in the real situation. Look for reviews that include lead times, communication, and consistency. These are often the make-or-break factors for a project.

Talking to other engineers in your network can provide you with insight, as well. Often, a recommendation from a person who has already worked with the shop is better than online listings.

Shops that have established customer relationships are known to go that extra mile to support urgent jobs and design changes. That kind of service is worth a mention.

Before you commit to a machining partner, it pays to ask the right questions. A shop may appear to be capable on paper, but only by getting into the details will you know if they can fulfill your needs. Clear answers in the beginning save you from delays and expensive rework in the future.

Here are 3 important things to discuss when speaking to any CNC shop.

Low Volume Set of Machined Metal Parts

Some shops are more concentrated on high-volume production, whereas other shops are better at small runs. Ask about their minimum and maximum order sizes to avoid expectations that don't match.

If you're only looking to make a few prototypes, a high-volume shop might not prioritise your work. On the other hand, if you need thousands of parts, the machines or manpower that a small shop has might not be able to deliver within the specified time.

Delivery speed can often make or break a project. Ask the shop for their average lead times for prototypes as well as production runs. Be particular about your deadlines and see how they react.

A good shop will provide you with realistic timelines instead of over-promising. They should also explain how they tackle urgent orders or changes at the last minute.

Prototyping is where things get tested before they are made in mass. Ask if the shop does short runs or one-off prototypes. This is especially important if your project is to have multiple iterations.

Not all shops invest in flexible setups for small batch work. Some may consider low-quantity work as unprofitable. Choosing a shop that supports prototyping means that you can make sure that your design can get refined quickly without needing to switch suppliers late.r

Choosing a local supplier isn't just about speed/shipping. Local CNC shops often bring long-term value that offshore or far-away providers can't match. They provide trust, direct support, and greater understanding of your requirements.

Here are three good reasons why engineers like to work with local machining partners.

When you work with a local shop, you're not just placing orders - you're building a relationship. Over time, they learn your standards, tolerances, and preferred workflows. This keeps you from having to communicate the same details on every new project.

A long-term partner is also invested in your success. They are more likely to be supportive of urgent jobs, be able to suggest design improvements, and adjust quickly when priorities change. That sort of reliability is difficult to substitute.

Part Dimensional Verification

Local shops make it easier for a quality check. You are able to visit their facility, view inspection reports personally, and check to see if processes are up to your standards. If there is a problem, it can be fixed promptly before it ruins your project.

Engineers often find that being able to see the machining process first-hand is a confidence builder in the supplier's capabilities. It also helps to decrease the risk of miscommunication that occurs with remote providers.

Working with local CNC shops helps to strengthen the wider supply chain around you. It keeps good jobs in the community, and supports industries that may one day support yok.

From a practical view, local suppliers are also easier to coordinate with. Shared time zones, similar standards, and cultural alignment make it easier for collaboration.

Supporting local manufacturing is not just a good thing to do for the community - it is often the smarter business decision to boot.

At Apexrapid, we understand that precision and reliability drive your projects. Our CNC machine shop is equipped with advanced milling, turning, and EDM systems to deliver high-quality results across a wide range of industries.

Whether you need one-off prototypes or large production runs, we can adapt to your requirements. Our team works closely with engineers and manufacturers to ensure every part meets the drawing, tolerance, and finish you specify.

By choosing Apexrapid, you get more than just machinery; you gain a trusted partner who values accuracy, speed, and long-term collaboration.

Q1: What services do CNC machine shops usually provide?

Most shops offer CNC milling, turning, grinding, and EDM. Many also provide prototyping, assembly, and quality inspection to support full production workflows.

Q2: Which materials can CNC shops work with?

Shops typically handle metals like aluminium, steel, titanium, and copper alloys, as well as plastics and composites. Some specialise in hard-to-machine alloys for aerospace and medical use.

Q3: How precise are CNC machining processes in terms of tolerances?

CNC machining can achieve tolerances down to ±0.01 mm, depending on the machine, material, and part design. Critical aerospace and medical parts often require this level of precision.

Q4: Do CNC shops handle both prototypes and full production runs?

Yes, many shops support both. Prototypes allow design testing and refinement, while full production runs ensure consistent output at scale. Always check the shop’s minimum and maximum order capabilities.

Q5: What machining techniques are most commonly used in CNC shops?

The core methods include CNC milling for complex shapes, CNC turning for round parts, grinding for fine tolerances, and EDM for intricate features or hardened materials.