Many manufacturers struggle with weak joints, distortion, and long welding cycles. Traditional welding often causes too much heat, which warps thin parts. It also leaves large weld beads, which need extra finishing. These issues slow production and raise costs.

Laser welding solves these problems by using a focused laser beam. The beam melts a small area, creating a narrow, clean weld. This reduces heat input, distortion, and post-weld work. It also allows faster welding and higher repeatability.

In this article, we will explain the laser welding process in simple terms. We will also cover key benefits, common challenges, and practical tips for better weld quality. You will learn how to choose the right laser type, set parameters, and avoid common mistakes.

Precision Laser Welding

Laser welding is a joining method that uses a focused laser beam to melt and fuse two metal parts. The laser creates a narrow and deep weld with very little heat spread. This keeps the surrounding material stable and reduces distortion. The process is ideal for parts that need high precision and clean welds.

A laser welding machine consists of a laser source, a beam delivery system, and a workholding system. The source of the laser may be fiber, CO 2, or diode basing on what it is and how it is used. Through the mirrors or fiber optics, the beam is guided to the welding head. The beam is concentrated by the welding head, resulting in the size of the spot. A protective gas nozzle is also required in the majority of systems in order to protect the weld area against contamination.

Surface preparation, such as cleaning and degreasing, is often necessary in laser welding. The components should be compact and have little space between them so as to guarantee proper welding. Following the welding, the post-weld treatment, such as stress relief or surface finishing, may be required based on the material and its intended use of the material.

The various techniques of laser welding are based on the thickness of the material, the nature of the joint, and the manufacturing requirements. The techniques differ in the application of heat, as well as the formation of the weld. The selection of an appropriate approach eliminates flaws and enhances productivity.

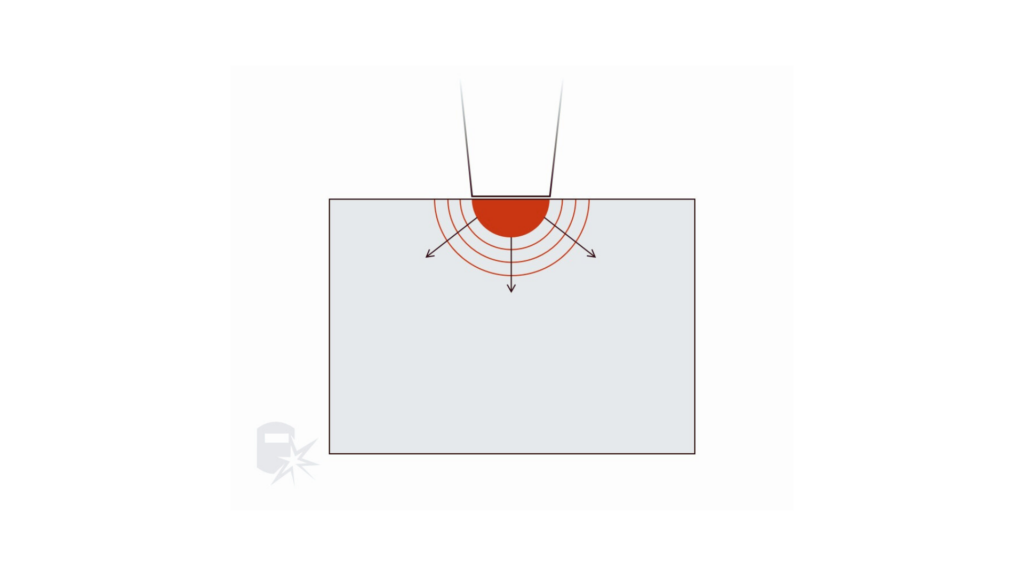

Conduction Welding Illustration

Conduction welding requires a broader laser spot and less power. The heat is kept on the surface, hence the depth of the weld is shallow. This is suitable for thin sheets and small parts. It also helps avoid burn-through, as well as distortion.

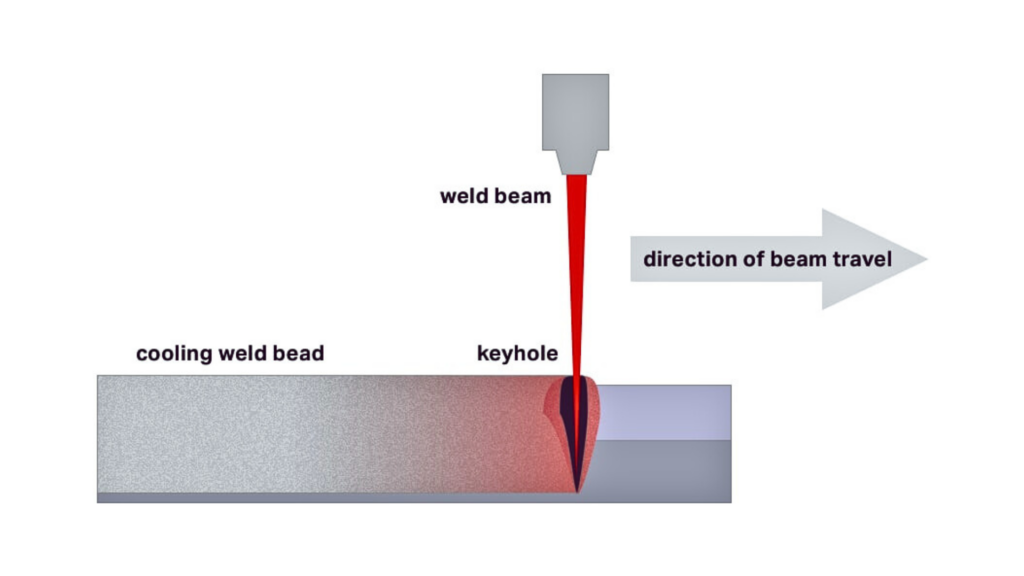

Keyhole Welding Process Illustration

Keyhole welding is very powerful and focused. A laser produces a hole in vapor, and it can penetrate deeply. This causes tight and powerful welts in heavier areas. Parts requiring high strength and tight joints should be used.

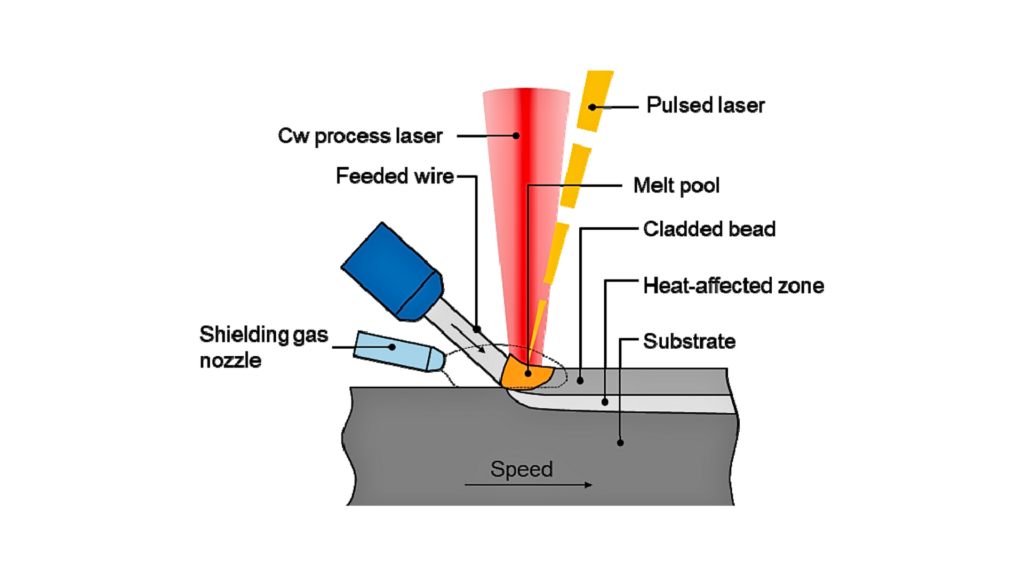

Pulsed Laser Welding Illustration

Short bursts of the laser are produced by pulsed welding. With every pulse, a bit of space is melted and solidifies very quickly. This restricts the amount of heat added and decreases warping. It is efficient with sensitive items, electronics, and thin materials.

Hybrid welding involves the combination of laser, MIG, or TIG. The arc fills the joint, and the laser provides a deep penetration. This enhances the welding rate and also enhances gap tolerance. It is applicable in thick sections and high-volume production.

Laser Spot Welding

In laser spot welding, the layers are welded at one point. It produces a small, intense weld focal point without melting the entire surface. This is usual in battery packs, electronics, and thin sheet assemblies. It also minimises distortion and enhances cycle time.

Laser welding is potent, yet it is not without actual challenges. These problems are frequent in cases when the joint is slender, the fit is weak, or the material is difficult to weld. Being informed of such obstacles will enable you to avoid flaws and wastage of time.

Laser welding requires tight parts. Any minor discontinuity may lead to partial fusion or burn-through. This is typical of thin sheets and complicated assemblies. It should have well-furnished and designed parts.

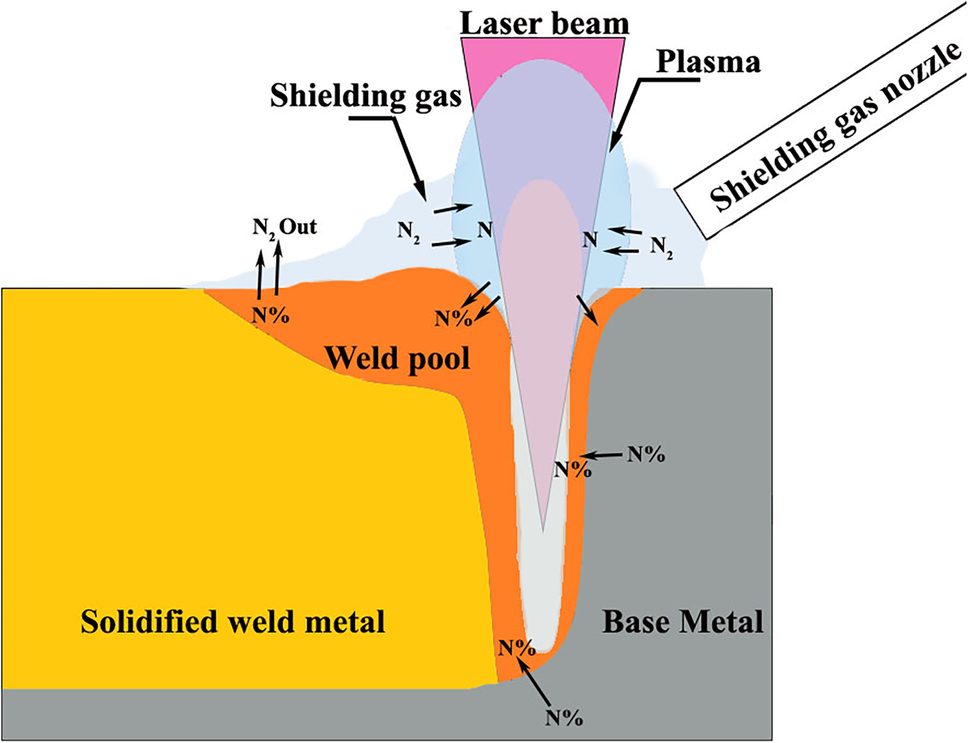

Porosity and Nitrogen Absorption

Gas may be trapped in the pool of weld, resulting in porosity. This compromises the joint and influences power. It regularly occurs with covered metals or greasy surfaces. This can be minimized by cleaning and the use of proper shielding gas.

Laser cut Crack in Acrylic Part

Cracking may occur under the influence of high heat input, and in particular, high-carbon steels and alloys. Stress is also caused by rapid cooling. Cracks can be prevented by using power, speed, and preheat that is controlled.

Warping in Laser Weld Material

Laser welding generates less heat than traditional welding, though distortion may still occur. Particularly thin parts are prone to warping. This risk can be mitigated through low heat input, good precautions in clamping, and through balanced welding tracks.

Laser energy is reflected by materials such as aluminum and copper. This reduces the efficiency of welding and may destroy laser optics. Increased power or specialized lasers are beneficial, but they are more expensive.

The important thing in consistent laser welding is to ensure that the setup is good. When the components are not motionless or when the laser is not focused, the quality of the weld is lost in a short time. These are steps to set up that can save you the trouble that can occur with them.

Laser welding requires stable parts that are stable. The parts should be clamped in the fixture that does not vibrate. Any motion alters the gap and leads to unfavorable fusion. Clamp or custom fittings to be able to position repeatably.

The joint has to be struck by the laser beam at the right angle. When the misalignment occurs, this results in weak or uneven penetration. A majority of installations have a fixed head and directed beam path. Good alignment is needed to achieve repeatable results.

Retain the space to a minimum. A close fit will guarantee that the laser energy is concentrated in the joint. When the gap is excessive, porosity can occur, fusion can be lacking, or burn-through can occur. Use exact machining or narrow tolerance.

Shielding gas prevents the contamination of the weld. Ordinary gases include helium and argon. The weld zone should also be covered by the gas nozzle. Porosity or oxidation may be coerced by wrong gas flow or nozzle distance.

Laser welding requires surfaces to be clean. Porosity and weak joints are brought about by oils, dirt, and coatings. Wipe down and clean surfaces before welding. This is a very easy, yet important step towards quality.

Laser welding is effective on a large number of metals. However, there are materials that require special arrangement, power, or shielding. The most used materials in laser welding are listed below.

Lasers weld very well with stainless steel. It gives a clean joint and great strength. It is also used with thin sheets without distortion. This causes its prevalence in medical and food equipment.

Carbon steel has easy laser welding. It utilizes average power and shielding. Laser welding produces powerful joints using little heat. Its wide usage is on automobile and industrial components.

Aluminum is laser weldable and requires more power. It reflects laser energy, hence it may be more difficult to melt. Good results are enhanced by proper beam focus and high welding speed. In automotive and aerospace, aluminum is used.

Copper contains much of the laser energy and heats up easily. This complicates welding. Copper is welded with high-power lasers and a proper arrangement. Brass is also to be taken care of, though it is weldable.

Titanium and nickel alloys are lasers that can be welded. They must have controlled shielding gas to avoid contamination. Such materials find use in the aerospace and medical industries.

In laser welding, precision and speed are important. It is appropriate in industries where clean welds, tight joints, and minimal distortion are required. Such are the most prevalent uses.

Fuel systems, transmission pieces, and engine parts are some of the uses of laser welding. It welds thin pieces and composite forms without deforming. It also enables mass production that is of quality.

Medical components require clean welds and close tolerances. Laser welding is suitable for surgical instruments, implants, and small tools. It develops accurate joints without harming delicate materials.

Battery tabs, connectors, and micro assemblies are laser-welded. It generates quality welds with low heat. This removes the destruction of sensitive parts and holds the components in place.

Laser welding is used to unite such essential components as fuel lines, brackets, and heat exchangers. It has high strength and low distortion. This assists in fulfilling high safety and performance requirements.

Small precision parts such as sensors and micro-mechanical components are welded by laser. It provides precise joints and does not distort the part shape or size.

Laser welding is more efficient when the components are closely stacked. When the gap is excessively large, the weld will not be able to fuse. This is what makes weak joints and porosity. Machining and clamps should be used correctly and firmly to hold the parts.

Weld defects are due to oil, dust, and coatings. They cause porosity and weak fusion. It is important to clean the area of the weld at all times. Welds can be enhanced significantly by a basic clean-up and wipe.

The thickness of the material should be equal to the power of the laser. Glorifying power means incinerating the component. The lack of sufficient power results in weak welds. Test some and get the balance with each material.

Shielding gas is used to cover the weld against contamination. When gas coverage is not good, then a weld may oxidize and may exhibit porosity. Apply the correct type of gas and flow rate, and ensure that the nozzle is over the weld area.

Heat results in warping and cracks. This is common in thin parts. Welding should be carried out at a speed that is faster than pulse welding. Reduced heat holds the shape of the parts constant.

The weld bead should always be checked at the time of production. Search for cracks, porosity, or burn-through. In case of defects, change settings or enhance fixturing. This maintains consistency in quality, and scrap is reduced.

At ApexRapid, we deliver laser welding that stays precise and clean. Our team uses modern fiber and diode laser systems. We match the right laser to your material and part thickness. We also use strong fixturing to keep parts stable. This reduces distortion and improves weld strength. If you need tight welds with minimal heat impact, we can help.

What joint gap is acceptable for laser welding?

For most laser welds, the gap should be under 0.1 mm. Wider gaps cause poor fusion and porosity. A tight fit is the key to a strong weld.

How does laser welding affect part distortion?

Laser welding has a small heat zone, so distortion is usually low. Still, thin parts can warp. Use proper fixturing and reduce heat input to control distortion.

Why does porosity appear in laser welds?

Porosity happens when gas, oil, or moisture is trapped in the weld. Poor shielding gas or dirty surfaces also cause it. Clean the parts and use the correct gas flow to avoid porosity.