The selection of aluminum alloy for CNC machining processes presents a difficult decision. Industries mostly utilize two major grades, AI 6061 and 7075, as the most common choices. The special characteristics of materials determine direct influences on machining speed alongside tool wear and structural performance results. The selection of aluminum alloy for CNC machining tasks requires more attention than one might imagine.

Although aluminum 7075 provides superior strength. It is outperformed in machinability by aluminum 6061. Manufacturing decisions throughout the aerospace industry, and automotive sector, and the robotics field base their operations on this single trade-off relationship. The two alloys behave differently when subjected to CNC loads. Each aluminum grade demonstrates unique capabilities when it comes to forming chips and heat tolerance. The analysis of material distinctions will allow you to make better material choices for your production needs.

The comparison between these materials produces practical consequences for manufacturing expenses, operation speed, and product quality criteria. Your decision-making process requires examination of standards, which include ASTM and EN and DIN, and AA, that set performance boundaries. The lack of preparedness for unexpected part breakdowns, as well as the waste of time in tooling cycles, is unaffordable.

The guide will present actual machining information about industries and analyze how each alloy works in practical applications. Let’s get into the numbers, performance, and the practical side of 6061 vs 7075.

The manufacturing sector employs 6061 aluminum as one of its primary choices of alloys. It exists throughout applications in aerospace, marine, and automotive industry segments. The material group of the 6xxx series features magnesium and silicon elements, which deliver increased strength to the alloy. The combination of elements in 6061 material structure achieves good resistance to corrosion and workability properties.

The T6 condition is where you generally encounter this material for use. The stability of this material comes from its solution heat-treatment followed by an artificial aging process. T6 condition provides 42,000 psi tensile strength suitable for medium-load application parts. The material achieves a yield strength measurement of close to 35,000 psi. It delivers outstanding surface quality retention when processed through CNC machinery.

The identification of 6061 meets international standards requirements. The material carries four different international labels: AA 6061, ASTM B221, EN AW-6061, as well as DIN AlMg1SiCu. Each code system supports worldwide production standards. You can perform fast machining operations on this material and weld it easily and achieve anodization results effortlessly. Therefore, many businesses employ it for machining frames, enclosures, and fittings.

7075 aluminum exists as a high-strength material structure intended for optimal performance applications. You will primarily find it in military aircraft components and defensive equipment, as well as motor racing components. The 7xxx series group includes this material. It consists of aluminum and zinc. The zinc content increases its hardness and tensile strength characteristics. Under heavy loading conditions, choose 7075 aluminum as the ideal material of choice.

The T6 or T651 temper is the standard condition when working with 7075. It attains a maximum tensile strength of 83,000 psi when in its T6 or T651 temper state. The yield strength level reaches 73,000 psi, which is nearly two times stronger than 6061. Welding this metal type proves challenging, and it also contains limited corrosion resistance properties. The process requires high accuracy to defend your tools from damage.

The material classification for 7075 includes AA 7075, ASTM B209, EN AW-7075, as well as DIN AlZnMgCu1.5. The standards establish both its chemical substance formulation and its operational mechanical boundaries. It finds its main uses in aircraft wing production, bike framework construction, and structural link building. The processing difficulties are greater, but performance excellence manifests particularly strongly when using this material.

The tensile strength of 6061 aluminum measures at 42,000 psi with moderate levels. The material achieves approximately 35,000 psi as its yield threshold. It is well-suited for manufacturing various components and producing structural parts with average resistance. Moreover, it demonstrates effective performance under normal stress situations and delivers dependable long-term stability. You can find this alloy used in automotive frames and marine equipment, used in harsh conditions.

The strength level of 7075 aluminum exceeds 6061 aluminum since it exhibits tensile strength at 83,000 psi. You can find its yield strength at approximately 73,000 psi. The alloy functions optimally as a solution for high-performance applications. Aerospace military operations use this material extensively. The highest demands for product strength require the implementation of 7075 as the primary selection.

The corrosion resistance properties of 6061 aluminum make it well-known to the metal industry. It demonstrates superior resistance against saltwater damage, and oxidation. Marine environments benefit from it because of their suitable nature. The anodized treatment helps the material become more resistant to corrosion. Outdoor applications find it to be an excellent material solution.

The resistance to corrosion in 7075 aluminum is lower than that of 6061 aluminum. The zinc content in this material improves its susceptibility to galvanic corrosion. To protect aluminum used in marine applications, additional measures like anodizing or coating are necessary. The material's resistance to damage proves vital when applying it to military and aerospace systems.

The machining process of 6061 aluminum proves very effortless. Quick and efficient cutting operations occur through this material while tool wear remains minimal. Besides, it functions well for manufacturing environments requiring substantial production runs. Standard machine tools will operate optimally during the manufacturing process. The industries value aluminum's clean machining ability due to its high preference.

In contrast, the machining process is relatively difficult for 7075 aluminum. The elevated strength level results in raised tool deterioration and heating effects. Thus, manufacturing 7075 aluminum requires unique equipment. The proper implementation of carbide tooling and effective coolant management stands as an essential requirement. The proper execution of 7075 aluminum provides superb results in terms of performance.

There are potentially two welding processes for 6061 aluminum that yield easy weldability: TIG and MIG. The material has a low distortion level and a good heat-affected zone, which makes it suitable for welded assemblies. Additionally, it stands out as the preferred choice for automotive as well as marine sector uses. Reliable welds that maintain their strength emerge without crack formation.

On the other hand, the welding process of 7075 aluminum presents a great challenge. The presence of high zinc content leads to brittleness throughout the welded area. Additional heat procedures become necessary for 7075 aluminum following welding applications. The weld process needs preheating and post-weld cooling for several applications. So, the welding of 7075 should be limited to vital applications.

You can easily obtain 6061 aluminum because it is inexpensive and widespread. The aluminum material exists in three forms: bars, sheets, and extrusions. The competitive price of 6061 aluminum makes it suitable for manufacturing applications on a large scale. You can easily find this product among global suppliers. The production timeline remains brief because of this characteristic.

Comparingly, the acquisition of 7075 aluminum requires payment of elevated costs. The production method for this alloy requires additional complexity, and the raw materials are less readily available in the market. The costly price of 7075 gets balanced by its remarkable resistance properties that make it suitable for unique component applications. The higher price of this material does not stop industries such as aerospace and military from relying on it for their needs.

Custom CNC 6061 Aluminum Machined Part

6061 aluminum is perfect for anodizing. It forms a tough oxidation coating that protects aluminum from corrosion. Not limited here, the anodizing process also strengthens the surface and improves appearance. This metal can be colored into multiple variations through anodizing processes successfully. The material works well for architectural uses as well as consumer goods.

On the other hand, the anodization process is challenging for 7075 aluminum because of its strong zinc content. It results in irregular finishes in addition to subpar anodized coating quality. So, it becomes harder to maintain uniformity when finishing processes. The need for visual quality makes 6061 a more suitable material selection.

Aluminum 6061 Machined Parts

6061 aluminum is widely used in general manufacturing. It is commonly used in automotive frames, bicycle parts, and marine components. The material stands out due to its welding properties and superior resistance to corrosion, which brings benefits to structural applications. In addition, it finds its applications in consumer products and industrial machinery equipment.

Placing 7075 aluminum in high-performance applications results in its best possible use. Lt usually finds its uses throughout aircraft wings while also serving military equipment and motorsports parts. In general, aerospace structures need 7075 because it provides the best strength-to-weight properties.

Choosing between 6061 vs 7075 aluminum can be challenging. Well, it doesn’t have to be. In real-world scenarios, your decision should depend on factors such as project scale, affordability and availability, performance demands, and production requirements. Both materials have their unique benefits. But knowing when and where to use each will ensure your project's success.

Most industries rely on 6061 aluminum as their primary material for general-purpose tasks. It shows properties such as lightweight characteristics and durability, with excellent workability. The standard manufacturing requirements of machinery frames, fixtures, and support structures favor 6061 aluminum as the most suitable material. Furthermore, the welding properties, in line with its moderate strength capabilities, make it a perfect selection for producing high-volume items and applications involving moderate stress levels.

In contrast, select 7075 as your material for machining when your project requires both high resistance to intense stress forces. The aerospace, military, and high-performance automotive sectors extensively employ this metal alloy. Customers prefer 7075 for extreme force applications. Because it offers exceptional strength with low weight. Aircraft wings and military vehicle parts, and racing components demand materials that will not fail since failure is not acceptable.

A limited budget requires you to choose 6061 aluminum. The material provides excellent sourcing options at low cost points. This makes it suitable for large-scale production and cheap projects. Moreover, it demonstrates reliability and plentiful availability that assists in maintaining cost-effectiveness. Projects needing only moderate strength levels can obtain the most cost-effective solution by using 6061 aluminum.

In comparison, the cost of 7075 aluminum surpasses the price of other aluminum varieties. The elevated manufacturing expenses of the alloy stem from its purpose-specific applications. You should reconsider buying 7075 when your application does not require its superior strength qualities. Additionally, 7075 aluminum proves to be appropriate for critical long-term applications when durabilty matters most because its higher cost offers exceptional performance reliability.

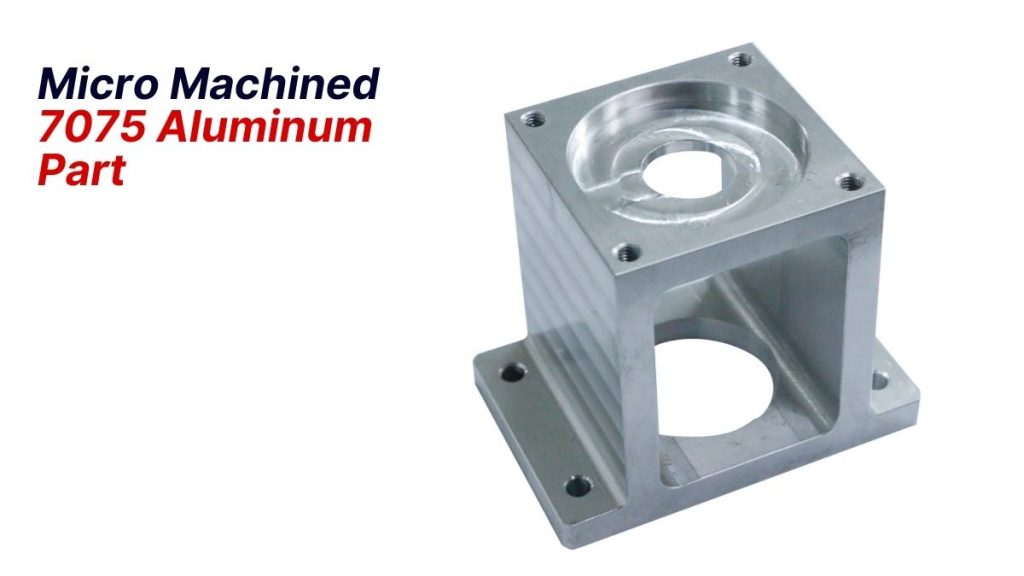

Micro machined 7075 Aluminum Part

The production of high-volume machining projects benefits greatly from a selection of 6061 aluminum material. The material is simple to machine through various operations, including CNC milling, welding and cutting, as well as anodizing procedures. Its preferred use occurs in production environments that need rapid completion alongside uniform quality output from extensive quantities.

On the other side, the high hardness of 7075 aluminum reduces its suitability for high-volume production since machining it becomes increasingly difficult. Specialized equipment and increased manufacturing precision define its production process. Your project requires 7075 when you need high-strength parts for applications such as aircraft components and military-grade machinery. Even though it demands more complex machining with slower processing times.

6661 aluminum stands out because suppliers commonly stock it, which results in brief delivery periods. The material is commonly available through most suppliers, so projects can begin quickly. The short deadline of your project will be addressed by 6061 aluminum if you value prompt delivery times. Therefore, when fast prototyping or small-scale manufacturing projects need an alloy, it stands as an ideal choice.

Contrastingly, as it serves specific uses, 7075 aluminum experiences delays in delivery times. The availability of 7075 aluminum tends to be lower than 606. So it may need a special order to acquire it from suppliers. The necessity of fast project completion makes 6061 an unfavorable choice. The number of suppliers offering 7075 aluminum is limited, thus, your procurement process will likely become more difficult and time-consuming.

Anodized 7075 Aluminum Part

The wide-ranging attributes of 6061 aluminum allow manufacturers to make adjustments according to their project requirements. Companies can easily modify 6061 aluminum to meet their needs by choosing custom shapes and machining parts, and anodizing finishes. Its versatile characteristics make 6061 aluminum particularly useful for projects that demand many shapes, different sizes, and quick design alterations throughout the process.

Although 7075 aluminum shows capability for customization, its availability across different product forms remains limited compared to 6061 aluminum. The metal’s toughness requires dedicated processing time. Moreover, it demands specialized methods to reshape or transform it. The solid choice for aerospace or defense precision applications requiring customized parts is 7075 aluminum. The need for primary reshaping of projects with regular modifications and extensive custom requirements makes 6061 a more convenient selection than 7075.

The broad industrial acceptance of 6061 aluminum exists in multiple industries. It follows general standards of ASTM, ISO, and DIN, which makes it appropriate for many construction and manufacturing applications. When no particular regulatory standards apply to a project, 6061 can provide reliable performance. The automotive sector and the general manufacturing field use this material as a standard because of its dependable performance record.

On the other hand, the aerospace, military sectors use 7075 aluminum because they need a material with higher performance standards and must abide by strict compliance requirements. The material meets all requirements of MIL-STD military standards alongside aerospace certifications. Besides, you can choose it for your selection when your project needs to follow strict high-level standards. Specialized use of this material limits its suitability in industrial settings, with ease in regulatory compliance.

Choosing between 6061 and 7075 aluminum depends on your unique project requirements. For cost-effective, high-volume applications, 6061 is ideal. It offers great strength, flexibility, and ease of machining. It’s the perfect choice for general manufacturing, with quick sourcing and shorter lead times.

However, if your project demands maximum strength, high precision, and performance under harsh conditions, 7075 is a go-to option. It is used in industries like aerospace and military as it offers superior durability. But, it normally presents higher costs and longer machining times.

The selection process can be quite challenging for you. But don't fret. For expert selection assistance as per your specific needs, Apex Rapid can help guide you in choosing the right alloy for machining. Our knowledge and industry experience make sure your project is optimized for both cost and performance.