Aluminum makes cars lighter and more fuel-efficient. That’s why it’s so popular in automotive parts. In our workshop, we focus on making engine blocks, wheels, brackets, and heat exchangers. We pick the right aluminum alloy for each part so it can handle real driving conditions without bending or breaking.

We use hands-on methods like CNC machining and die casting, followed by careful finishing. Every part is measured and tested to make sure it meets automotive standards. We also apply coatings and treatments to prevent rust and extend the life of the parts.

By working with us, you get parts that fit right the first time, last longer, and perform reliably. We take care of everything from choosing the material to final inspection, so your vehicles are safer and you save time fixing problems.

Aluminum alloy wheel

In cars, aluminum is popular since it helps in making the cars light and easy to manage. It is also resistant to heat, and rust does not come easily. These are the typical advantages of using aluminum in the production of car parts.

Compared to steel, aluminum is a lot lighter, hence it decreases the weight of the car. The light cars consume little fuel and maneuver well on the road. This explains why, in many cases, manufacturers prefer to use aluminum in engine components, wheels, and body metal.

Aluminum is strong, even though it is light. It does not bend or fracture with the appropriate alloy and heat treatment. This is suitable for engine blocks, suspension brackets, and structural components.

Aluminum conducts heat well. Components such as radiators, heat exchangers, and brake components remain cool and enhance performance, with and low chance of overheating.

Aluminum has a natural resistance to rust. It also has a longer life in wet or salty conditions with additional coating or anodizing. This is an enormous boost to car parts that are left out in the sun.

Aluminum may be cast, machined, or extruded into complicated shapes. This creates flexibility since manufacturers are able to manufacture parts having exact sizes and a smooth surface that is essential to engine or body parts.

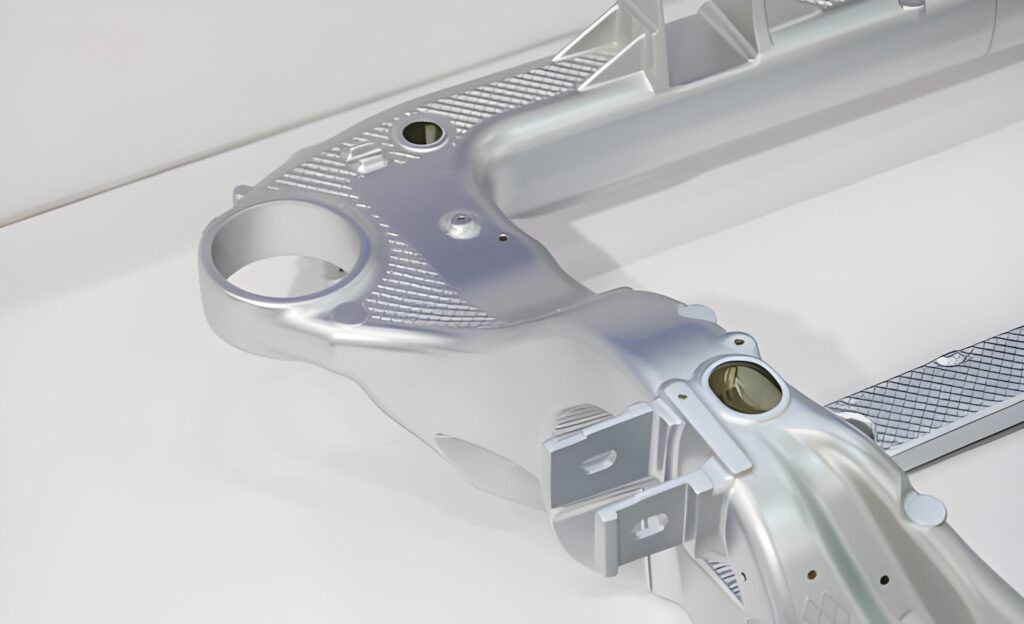

In the case of aluminum car parts, it is critical to obtain the appropriate technique. The component must be durable, should fit perfectly, and should stand the test of actual driving. We select the method in our workshop depending on the shape, size, and utilization of the part. Let us go through the major techniques we employ.

Parts that require fineness and intricate designs, such as engine blocks, brackets, or transmission parts, are sent to CNC machining.

Milling is simply a process of subtractive manufacturing of a solid piece of aluminum to achieve the desired shape. We apply it to components that require each millimeter. It maintains a close fit to prevent the need to make additional adjustments to get the part to fit.

CNC turned car parts

Round parts, such as shafts or hubs of the wheel, are turned. The part is rotated, and the tool that cuts forms it. This provides a smooth finish and accurate diameters, which are crucial to those parts that are rotating or loaded.

A single car can use every bolt hole. We ensure that every hole is in the correct position with CNC drilling and tapping. This reduces the number of mistakes made in assembly and saves time.

Automotive engine cover

Die casting is ideal for high-volume parts with complex designs, such as wheels or housings.

Hot chamber casting is quick and applicable for smaller parts. It allows us to duplicate a specific part numerous times without loss of quality.

Cold chamber casting is more effective with larger pieces. It provides accuracy in the handling of molten aluminum, thus even thick or complex components emerge clean with fewer defects.

Long parts, such as frames or structural rails, are extruded.

It is done by pressing aluminum in a die to obtain a uniform profile. This is perfect for structural components that require the use of the same strength throughout the entire component.

Indirect extrusion causes the die to move rather than the aluminum. This minimizes friction and surface imperfections, and this is excellent where the finish on parts is required to be smooth.

Aluminum bending

Panel, bracket, and cover manufacturing, Sheet metal forming are ideal when there is a need to have lightweight but strong cases.

Stamping is quick and effective to produce several parts of the same type, such as body panels or small brackets.

We cut, not bend or fold sheets into exact angles that hold the aluminum strongly. It is ideal for components that require precision and loads.

Hydroforming involves fluid pressure in shaping intricate curves. It also provides smooth, powerful pieces and fewer seams, which are best suited to frames and chassis parts.

After shaping a part, we pay attention to finishing. This helps it to last longer, appear nice, and be resistant to corrosion.

Aluminum anodized parts

A protective oxide layer is provided by the process of anodizing. It is particularly applied to components that are open to the elements or friction.

The powder coating provides a resistant layer that prevents chipping and scratches. It works excellently with exterior components or anything that can be seen in the car.

Finishing and rubbing smooth surfaces and making them less frictional. We even do it to things such as wheels or trim in order to make them shine as they do a better job.

Cars use aluminum as it is a strong metal, but it is much lighter than steel. Its use facilitates a smoother running of cars, improved fuel economy, and improved handling of the cars. At our workshop, we emphasize producing parts that endure well and fit well, such that the mechanics do not have to modify anything.

Machined engine components

Our engines are made of aluminum and include the cylinder heads, engine block, and pistons. These components have to endure hot weather and intensive work. We machine them and check the fit, and test them to ensure that they do not warp and break along the road.

The aluminum wheels weigh less, and this enhances braking and strength in tuel. We manufacture wheels of high quality, with perfect CNC machining and casting, to make them powerful and balanced, and easily fitted immediately.

Aluminum car radiator

The radiators made of aluminum are effective in cooling engines. The fins and tubes are machine-workshopped in order to enable the heat to pass very fast, and all parts are checked to ensure they are automotive.

Metal frame corners

Components such as suspension brackets or cross-members are required to be hard yet light. We shape and cut them to act in actual road conditions, and that too without extra weight.

Even small aluminum parts matter. Brackets, mounts, and connectors are also designed in perfect fits. This implies that in the case of assembling a car by mechanics, all things fall into place and nothing goes wrong.

It is not only the price but trust and experience that bring one to the right company. You desire someone who is knowledgeable of the working conditions of car parts and is capable of performing at a constant level.

Determine whether they are really performing CNC machining, die casting, or forging. Inquire about the way they manage aluminum alloys in terms of strength and heat resistance. A good company will justify why they want one practice to be applied to other different sections, such as wheels, engine blocks, or brackets.

Ensure that they check all the parts. Request them to answer whether they use ISO 9001 or auto-specific standards. The material, the final size, and even the coats to avoid corrosion are checked by a trustworthy company.

Get examples or illustrations of items or products they have made. Assuming this is possible, communicate with their clients to understand whether the parts fit well and they endure on the road.

An operationally based company takes you through the design process to delivery. They are supposed to assist in drawings, prototyping, and finishing options. Also, verify that they are able to work with urgent orders without making a sacrifice in quality.

Inquire about the speed at which they can deliver and whether they can safely handle large orders. You save your headaches and time in a firm that manages to pack, ship properly.

Apexrapid works directly with manufacturers and repair shops to supply aluminum car parts that are ready to install. Each part goes through hands-on checks for size, strength, and surface quality, so you don’t have to deal with rework or adjustments. We focus on parts like engine blocks, brackets, wheels, and heat exchangers that actually get used every day.

Our team also helps you choose the right alloy and finish for the part’s purpose. You get parts that last longer, resist corrosion, and fit perfectly in your vehicles. With our process, you save time, reduce waste, and know the parts coming from us will perform reliably on the road.