Copper and zinc alloy brass is attractive, versatile, and exceptionally machinable; these qualities not only make brass a long-prized material in manufacturing but also, broadly, a means of expressing culture. It has a spectacular combination of properties (high electrical and thermal conductivity, corrosion resistance, easy cutting) that make it a top choice for CNC machining. In parts making, foreign machining is required in the electronics industry, for long-lasting fittings in the plumbing system. Moreover, brass always performs well and is cost-effective.

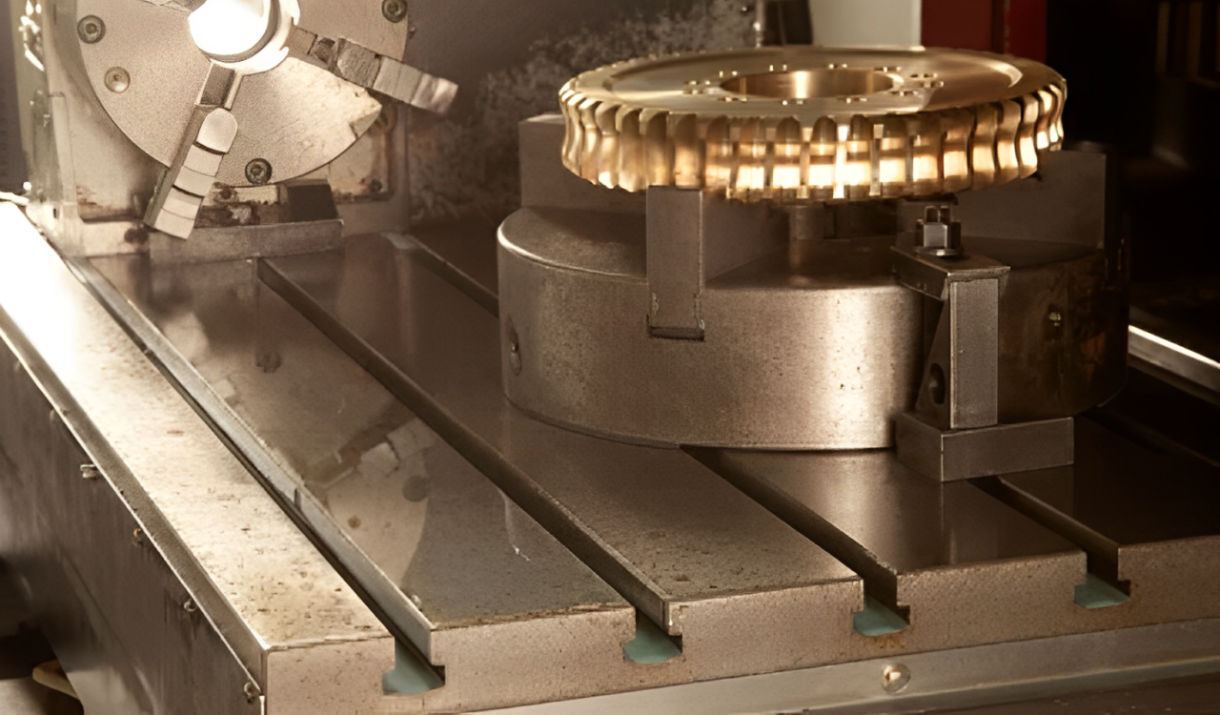

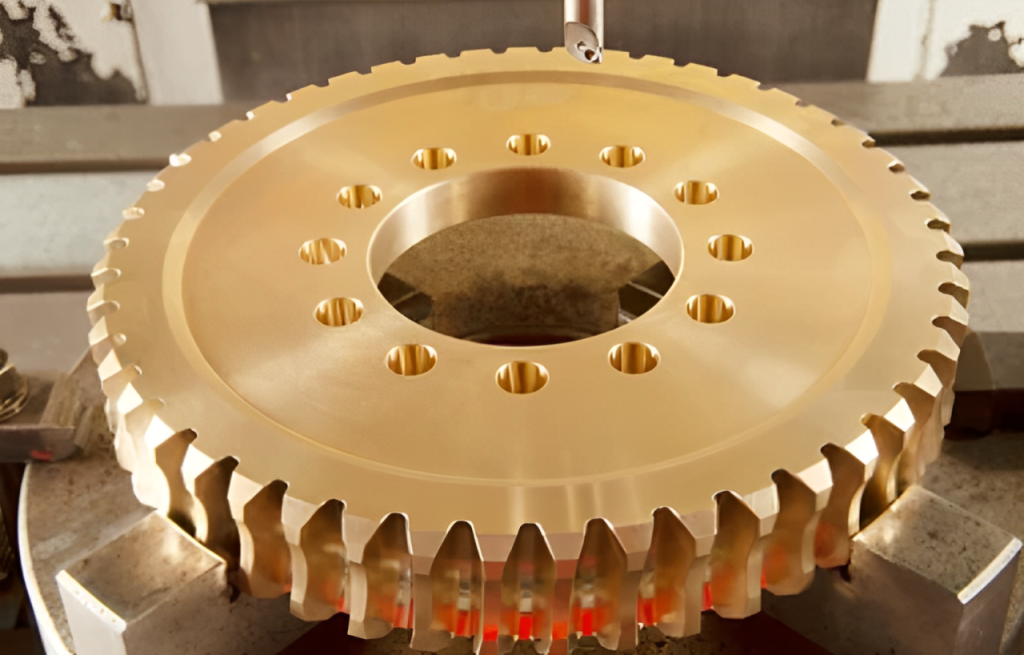

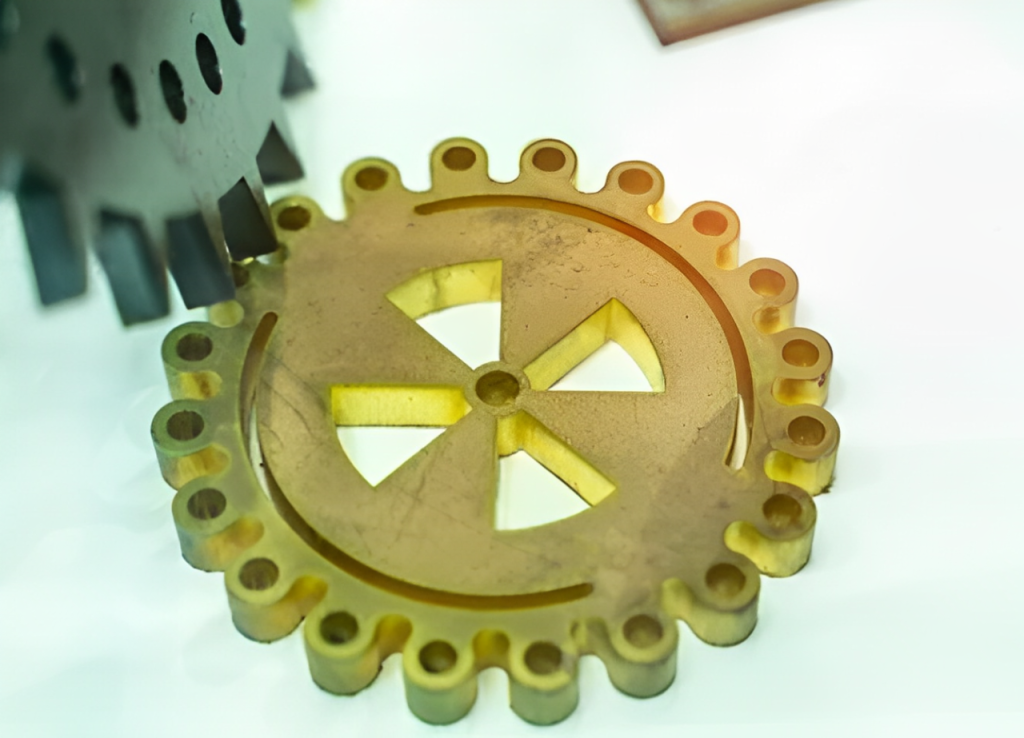

CNC fabrication excels in tight tolerances and repeatability, and excels at highlighting the best of brass, specifically free machining temperatures such as C360. In this article, we will examine the various brass alloys used in CNC machining, outline their characteristics, and explore common applications across different industries.

Brass is a broadly used metal alloy, chiefly copper and zinc, usually altered with other components such as lead, tin, or silicon to adjust a few unique properties, such as machinability, corrosion resistance, or strength. Its composition may differ widely, and this aspect makes it adaptable to many industrial uses. Brass is renowned for its bright, gold-like colour and is used only because of its good thermal and electrical conductivity, resistance to corrosion, and formability. Such properties, coupled with excellent machinability in some grades, make brass an ideal material in machining precision parts, fitting, and decorative hardware.

Here are its properties and main compositions;

| Property | Typical Range / Value | Explanation |

| Copper (Cu) | 55% – 90% | Provides ductility, conductivity, and corrosion resistance |

| Zinc (Zn) | 5% – 45% | Increases strength and hardness |

| Lead (Pb) | 0% – 3.7% | Improves machinability (in free-machining grades) |

| Tin (Sn) | ~1% (in Naval Brass) | Enhances corrosion resistance in marine use |

| Silicon (Si) | Present in lead-free brass (e.g., C693) | Improves strength and compliance |

| Machinability | 30% – 100% (C360 = 100%) | Varies significantly by grade |

| Electrical Conductivity | ~15% – 30% IACS | Depends on the copper content |

| Corrosion Resistance | Good to Excellent | Improves with higher copper or tin content |

| Color | Reddish to Golden Yellow | Depends on the copper/zinc ratio |

Brass grades commonly found in CNC machining include the following, which have different technical or commercial requirements. Although C360 is the benchmark for machinability, other alloys offer special benefits, making them environmentally friendly, corrosion-free, or easily formable.

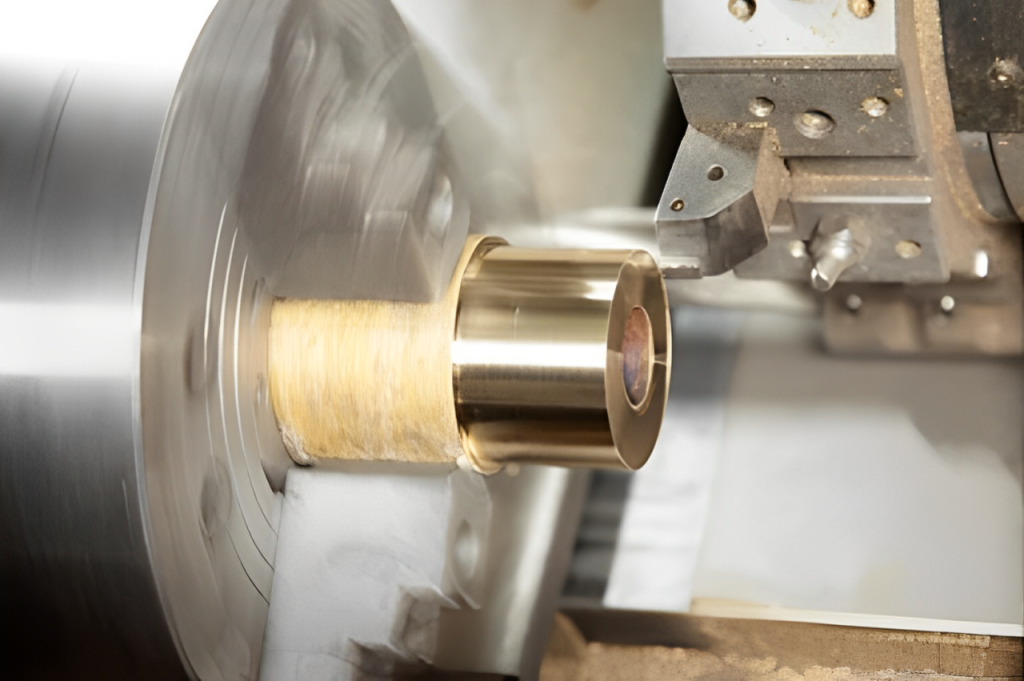

The alloy of brass with the highest usage volume in CNC machining is C360, since it cannot be topped in its machinability (100%). It consists of about 60% copper, 35% zinc, and 2.5 to 3.7% lead, which provides lubrication in the cutting process. It cuts in fine chips, increases tool life, and is an excellent choice in high-speed precision machines such as valve components, fittings, and electrical terminals.

| Property | Value |

| Machinability | 100% (Benchmark) |

| Copper Content (Cu) | ~60% |

| Zinc Content (Zn) | ~35% |

| Lead Content (Pb) | ~2.5%–3.7% |

| Electrical Conductivity | ~28% IACS |

| Tensile Strength | ~345 MPa |

| Yield Strength | ~103 MPa |

| Elongation | ~25% |

| Density | 8.44 g/cm³ |

| Corrosion Resistance | Excellent in dry/wet air |

This alloy compares to C360 in machinability, but is frequently selected on the basis of a slightly different composition and possibly different mechanical properties, whenever extrusion or decorative components are involved. C385 has compositions of approximately 57 61 percent copper and a maximum of 3.5 percent lead, great corrosion resistance, and average strength. It is applied in extrusions, lock hardware, and trim.

C260 is predominantly (c. 70%) copper, admixed with 30% zinc that provides it with the high ductility and acceptable strength, but reduced machinability in comparison to C360 (c. 30%). It may be suitable for deep draw/ forming processes, but not lumped into large amounts of CNC milling, but it can be machined when needed. It is commonly used in ammunition casing, musical instruments, and radiator cores.

Yellow Brass or C272 is made up of approximately 62.0 percent copper and 37.0 percent zinc, offering a trade-off between corrosion resistance and formability. Less machinable than C360 (machinability, why not msg & settlements~35%, it is sometimes chosen based on bright gold color and aesthetic effect in decorative or architectural parts.

It's a commercial bronze, consisting of about 85 percent copper and 15 percent zinc. It is not much machinable, but it is selected because of its dark reddish color, high corrosion resistance, and reasonable pressure tightness. It finds many applications in valves where machining requirements are secondary, in plumbing systems, and in decorative hardware.

C464 contains around 59 percent of copper, 40 percent of zinc, and 1 percent of tin. The tin makes the brass corrosion resistant, especially in marine and salt water, and thus the grade of brass is suited to be used in shipbuilding, propeller shafts, and other underwater parts. It is also moderately easy to machine ( ~35 -40 %), and I with corrosion-oriented designs is CNC milling and turning.

It is an environmental brass alternative, which has copper, zinc, silver, and silicon, and provides excellent machineability (~80 85%) and anti-corrosion qualities. C693 is RoHS compliant as a lead-free alloy and can be utilized in areas that have contact with potable water and food contact, and medical devices. It is becoming popular in those CNC machining applications where regulatory compliance becomes essential.

C353 contains high lead (up to 3.5 percent) for machinability and chip control. Not as popular as C360, it provides acceptable strength as well as machinability. It is applicable to small machined parts such as bushings, spacers, and screw-machine parts that entail small tolerances.

It has copper content, along with zinc and insignificant contraction of iron and aluminum; this brass bears elevated mechanical strength and hardness. It is comparable to C360, but is more wear-resistant and strong, and can be subjected to high-performance duties, meaning that it can perform in harsh environments. Mechanical components that are exposed to recurring stress or can be subjected to any form of moderate impact.

Brass is recyclable, and recycling can be repeated without the reduction of performance in line with the principles of green manufacturing. RoHS-compliant, lead-free brass substitutes (such as ECO BRASS) are already available off-the-shelf, with many suppliers now providing such brass substitutes to the regulated industries, i.e., medical-grade or food-grade production.

Here are some operations and suitability with brass;

| CNC Operation | Brass Suitability |

| Turning | Excellent |

| Milling | Excellent |

| Drilling | Excellent |

| Tapping | Very Good |

| Reaming | Very Good |

| Engraving | Excellent |

Although brass has its benefits, there are still certain limitations:

The machined brass parts are frequently surface-treated to improve the aesthetic and functional characteristics. Distinctive finishing alternatives are:

Here are some of its pros and cons;

High machinability: C360 especially, so CNC work can be done quickly and accurately.

Here are some of its cons;

Brass is very flexible due to the amalgamation of its machinability, conductivity, resistance to corrosion, and attractive appearance within the industries. CNC machined brass is used both functionally and aesthetically in harsh conditions, in critical mechanical components, as well as in consumer luxurious finishes.

Brass is commonly used as a valve, compression fitting, hose ends, and a manifold. It is impervious to corrosion and scaling by water, and the response is reliable at high temperatures and pressure.

Excellent conductivity means that it is used in terminal blocks, connector pins, and grounding lugs. Brass creates a steady electrical behavior, having very little oxidation.

Small rotating brass components, such as bushings and housings, are used because of their tight (precision-machined) tolerances.

It is easily safe in an aerospace environment as it will not spark in sensitive systems.

The fuel systems, sensors, and decorative trim have elements made of brass. These are durable, resistant to vibration, and have a polished and corrosion-resistant surface.

A common replacement is brass, used on handles, locks, zippers, and instrument panels.

It is easy to polish and has a luxurious look, together with good corrosion resistance.

We might have different CNC machining choices. We can compare them with brass and alternatives, i.e., aluminum, stainless steel, and carbon steel. So, let's explore the comparison of brass against key performance factors of other alternatives.

| Property | Brass (C360) | Aluminum (6061) | Stainless Steel (304) | Carbon Steel (1045) |

| Machinability | Excellent – industry benchmark | Very good – fast but gummy at times | Moderate – tough on tools | Fair – harder, more wear |

| Corrosion Resistance | Very good, especially in dry and freshwater environments | Good – resists most corrosion | Excellent – especially in harsh and marine environments | Poor – prone to rust without coating |

| Electrical Conductivity | High – ideal for connectors and terminals | Highly suitable for many electrical uses | Low – typically not used for conductivity | Low – limited electrical applications |

| Weight (Density) | Moderate – balanced for strength and form | Light – ideal for weight-sensitive parts | Heavy, dense, and strong | Heavy – similar to stainless |

| Cost (per kg) | High – but cost-effective due to easy machining | Moderate – affordable and widely available | High – more expensive and slower to machine | Less cost-effective but harder to process |

Brass—especially free-machining grades like C360—is a top choice for CNC machining thanks to its excellent efficiency, superior surface finish, and reliable performance in demanding industrial environments. Its ability to produce intricate parts quickly and precisely makes it a favorite among machinists and engineers alike.

From plumbing and electronics to aerospace and consumer products, brass offers the ideal combination of machinability, durability, and cost stability. At ApexRapid, we specialize in precision brass machining, delivering high-quality components tailored to meet your application needs—fast, accurate, and production-ready

Q1: Which brass grade is most suitable for CNC machining?

A: C360 (Free-Cutting Brass) is the most common and machinable grade of brass, having a machinability rating of 100 percent.

Q 2: Is brass machineable easier than aluminum or steel?

A: And yes, brass and particularly C360 is frequently easier to machine than aluminium or steel because of its chip-breaking tendency and self-lubricating characteristic.

Q3: Can brass be used on electrical parts?

A: Yes, it is very conductive as an electrical terminal, contact, and connector.

Q4: Do brass parts work in a marine environment?

A: Yes, such as grades, as C464 (Naval Brass), which has increased resistance to corrosion in sea water.

Q5: Do lead-free brass grades exist that are CNC machined?

A: Yes, environmentally controlled industries have lead-free and RoHS-compliant brasses such as ECO BRASS.