Injection mold tooling is essential for producing high-quality plastic parts. At ApexRapid, we create custom molds tailored to your project's unique needs. We collaborate closely to understand your design's complexities, ensuring precision and attention to detail in every mold. Our capabilities cover both prototype molds and production molds, with rapid lead times and competitive pricing. Whether for low or high-volume production, we ensure efficient, high-quality output. Leveraging advanced technologies and skilled technicians, ApexRapid supports your goals, delivering reliable and fast solutions for your plastic part production needs.

ApexRapid specializes in advanced injection mold tooling solutions designed to meet a wide spectrum of manufacturing needs. With our strong focus on precision and efficiency, we provide outstanding services to bring your projects to life.

Ideal for low-volume production, our single cavity molds ensure exceptional quality and cost-effectiveness. These molds allow for maximum control over the injection molding process, making them perfect for prototyping and specialized parts.

Designed for high-volume production, our multi-cavity molds dramatically improve cycle times while reducing the cost per unit. These molds facilitate the simultaneous production of multiple parts, enhancing operational efficiency and output.

Our stack molds provide a cutting-edge solution for injection molding processes, allowing for increased production efficiency. With the ability to create multi-component assemblies in one cycle, these molds optimize output and minimize overall costs.

Our 2K injection molds combine two different materials in a single production cycle, enabling the creation of innovative products that require distinct material properties. This method reduces manufacturing costs and streamlines assembly processes.

At ApexRapid, we leverage advanced manufacturing techniques and high-quality materials to deliver superior injection mold tooling solutions. Regardless of complexity, we are equipped to meet your specific production demands with precision.

Our tool steel molds are designed for durability and high precision, ideal for high-volume production. With excellent wear resistance and the ability to withstand high temperatures, these molds provide exceptional longevity and precision for complex parts.

Utilized in applications that require high strength and corrosion resistance, stainless steel molds ensure consistent and high-quality output. They are optimal for products that face harsh environments and offer exceptional integrity in long-term production.

Our aluminum molds offer a cost-effective alternative for low to medium-volume production runs. Known for their lightweight and excellent thermal conductivity, aluminum molds enable quicker cycle times and faster market entry while maintaining good precision.

| Purpose | Class 105 : Prototype Testing Class 104 : Low-volume Production Class 103 : Low-volume Production Class 102 : Medium-volume Production Class 101 : High-volume Production |

| Shot Life | Class 105 : Under 500 cycles Class 104 : Under 100.000 cycles Class 103 : Under 500.000 cycles Class 102 : Medium-volume Production Class 101 : Over 1,000,000 cycles |

| Tolerance | Class 105 : ± 0.02mm Class 104 : ± 0.02mm Class 103 : ± 0.02mm Class 102 : ± 0.02mm Class 101 : ± 0.02mm |

| Lead Time | Class 105 : 7-10 days Class 104 : 10-15 days Class 103 : 10-15 days Class 102 : 10-15 days Class 101 : 10-18 days |

Prototype tooling is crucial for accelerating product development in injection molding, enabling a streamlined transition from design to functional prototypes. Here are the standout benefits:

ApexRapid accelerates prototyping, cutting development time and getting products to market faster.

We use advanced manufacturing to create high-quality prototype molds at lower costs, reducing upfront investment.

Our prototype tooling identifies and resolves potential production issues, ensuring compliance with industry standards.

Our agile prototyping enables rapid iterations with feedback, ensuring your design meets top performance standards.

We enable thorough prototype testing to validate design and functionality, ensuring informed decisions before mass production.

At ApexRapid, we stand out in the injection molding industry by delivering high precision and quality that you can trust. Our commitment to excellence is reflected in our ISO certification and adherence to strict quality standards, ensuring that your parts are manufactured to your exact specifications with utmost accuracy.

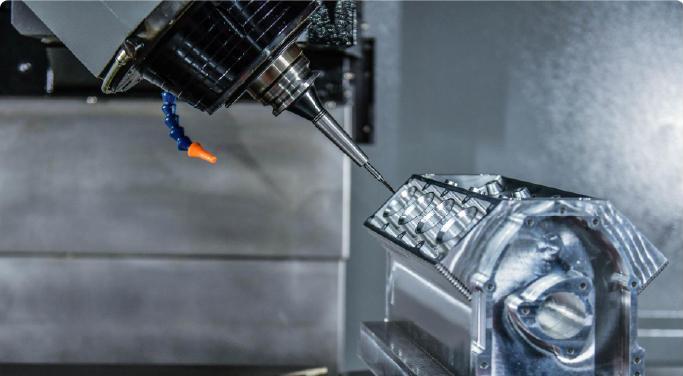

Our workshops are equipped with the latest injection molding technology, allowing us to produce complex parts with exceptional efficiency and accuracy. This ensures faster turnaround times and reduced costs for our clients.

We utilize state-of-the-art machinery and software to deliver superior injection molding services. Our advanced equipment is capable of handling a variety of materials and complex geometries, ensuring high-quality outputs every time.

We prioritize quality at every step of the manufacturing process. Our rigorous quality control measures guarantee that each component meets international standards, giving you peace of mind in every order.

Our dedicated customer service team is available 24/7 to assist you with any inquiries or support you may need. We are committed to ensuring that your project runs smoothly from start to finish.

At ApexRapid, we aim to provide clarity and understanding of our injection mold tooling services. Here you will find answers to some common questions our clients ask.

ApexRapid has extensive manufacturing capabilities, capable of producing any geometrically complex part and offering on-demand manufacturing services.