Background

Focused on sustainable solutions, a renewable energy firm was developing advanced wind turbines for offshore installations. They required specialized components that could withstand harsh marine environments while maintaining optimal performance.

Challenge

- Long-Term Reliability: Parts had to perform reliably over extended periods to minimize maintenance.

- Environmental Resistance: Components needed to resist corrosion from saltwater and extreme weather.

- Precision Engineering: Tight tolerances were necessary for efficient turbine operation.

- Sustainability Goals: The manufacturing process had to align with the company's eco-friendly ethos.

Solution

ApexRapid's approach:

- Corrosion-Resistant Materials: Used materials like stainless steel alloys and applied protective coatings.

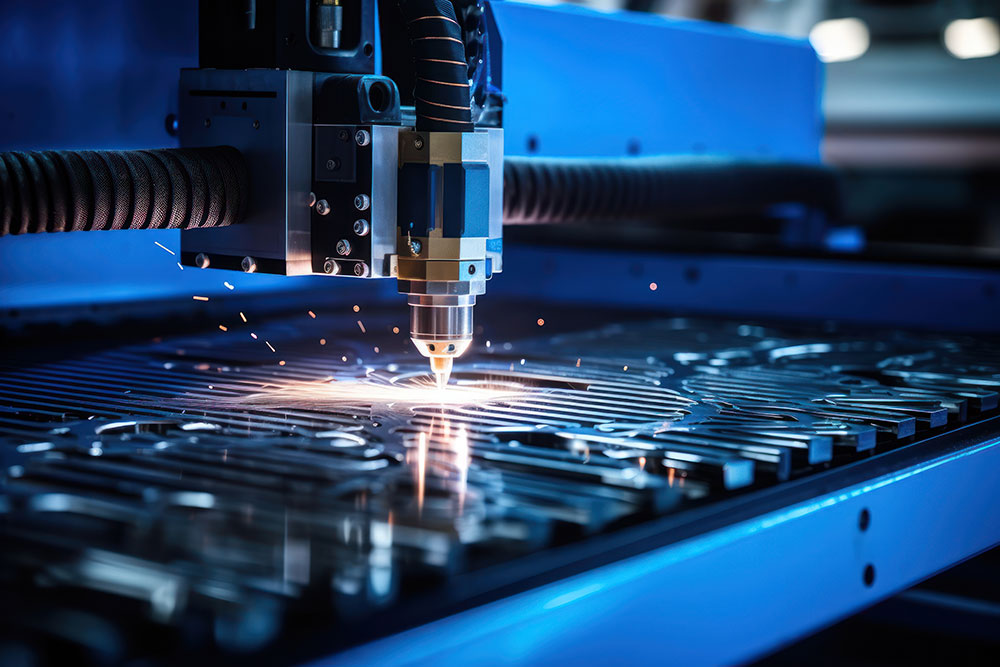

- Advanced Machining Techniques: Ensured precision in producing components critical to turbine efficiency.

- Eco-Friendly Manufacturing: Implemented sustainable practices, including waste reduction and energy-efficient processes.

- Rigorous Testing: Conducted environmental and stress testing to validate long-term performance.

- Lifecycle Support: Offered ongoing support for maintenance and future upgrades.

Results

- Extended Component Life: Parts exceeded expected lifespans by 25%.

- Improved Efficiency: Enhanced turbine performance due to precise engineering.

- Environmental Alignment: Manufacturing processes met the client's sustainability standards.

- Reduced Downtime: Reliable components minimized maintenance needs and operational interruptions.

- Positive Impact: Supported the client's mission to expand renewable energy adoption.

Client Testimonial

"ApexRapid's dedication to quality and sustainability made them the perfect partner for our project. Their components are a key part of our turbines' success." — Project Director, Renewable Energy Firm