Background

The aerospace industry demands unparalleled precision and reliability due to the critical nature of its applications. A leading aerospace manufacturer approached ApexRapid to produce high-precision components for a new aircraft model. These components were integral to the aircraft's performance and safety systems, requiring meticulous attention to detail and adherence to stringent industry standards.

Challenge

- Time Constraints: The project had a tight deadline to align with the client's production schedule.

- Complex Geometries: The components featured intricate designs, including internal cavities and tight radii, making them challenging to machine.

- Stringent Tolerances: Required tolerances were within ±0.002mm to ensure optimal functionality and safety.

- Exotic Materials: The use of titanium alloys and high-strength composites, which are difficult to machine due to their hardness and thermal properties.

- Regulatory Compliance: Compliance with aerospace standards such as AS9100 and ISO 9001 was mandatory.

Solution

ApexRapid leveraged its advanced capabilities to address these challenges:

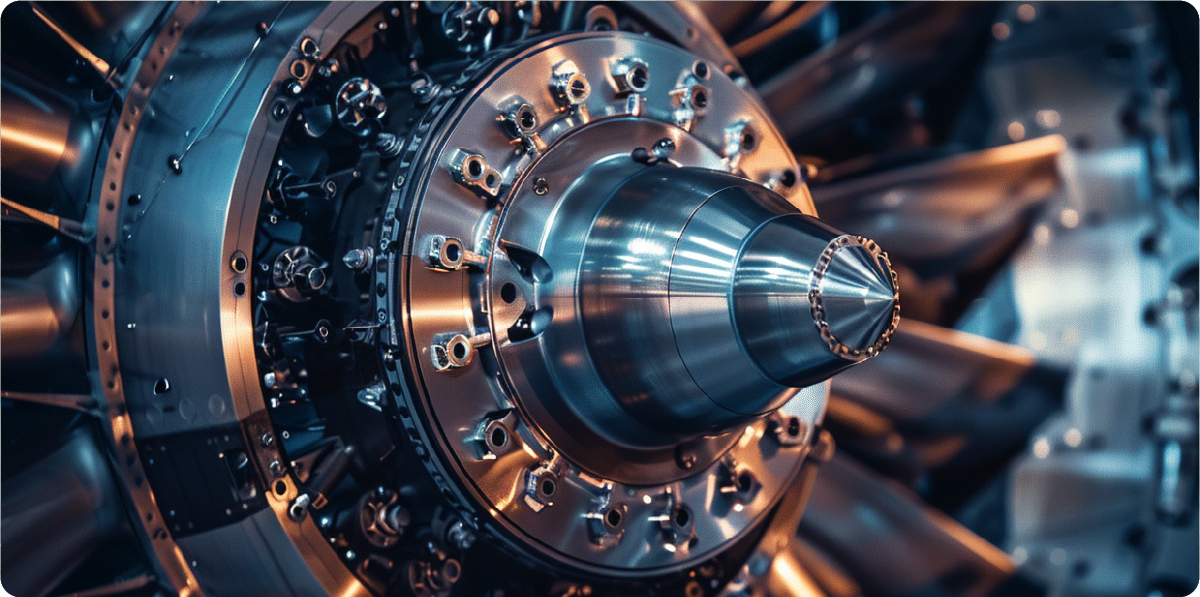

- 5-Axis CNC Machining: Utilized state-of-the-art 5-axis CNC machines to handle complex geometries with high precision.

- Expert Engineering Team: Collaborated closely with the client's engineers to optimize designs for manufacturability without compromising integrity.

- Specialized Tooling: Developed custom tooling solutions to effectively machine hard-to-cut materials like titanium.

- Quality Assurance: Implemented a rigorous quality management system, including in-process inspections and final quality checks using CMM technology.

- Efficient Workflow: Streamlined production processes to meet the tight deadline without sacrificing quality.

Results

- High Precision Achieved: Met all tolerance requirements, ensuring the components fit perfectly within the aircraft systems.

- Timely Delivery: Completed the project 20% faster than the industry average, allowing the client to stay on schedule.

- Cost Savings: Optimized machining processes reduced material waste and production time, resulting in cost savings for the client.

- Regulatory Compliance: Successfully passed all regulatory inspections and audits, fully complying with aerospace standards.

- Enhanced Performance: The components contributed to improved fuel efficiency and reduced maintenance needs for the aircraft.

Client Testimonial

"ApexRapid's expertise in precision machining was evident from day one. Their ability to deliver complex components on time and within spec was crucial for our project's success." — Chief Procurement Officer, Leading Aerospace Manufacturer