Finding a CNC milling service in China that offers quality, efficiency, and good prices is essential for businesses aiming for success. China is a leading destination for CNC machining, providing many options for different industries. This guide highlights key factors to consider when selecting a CNC milling service in China to help your business thrive.

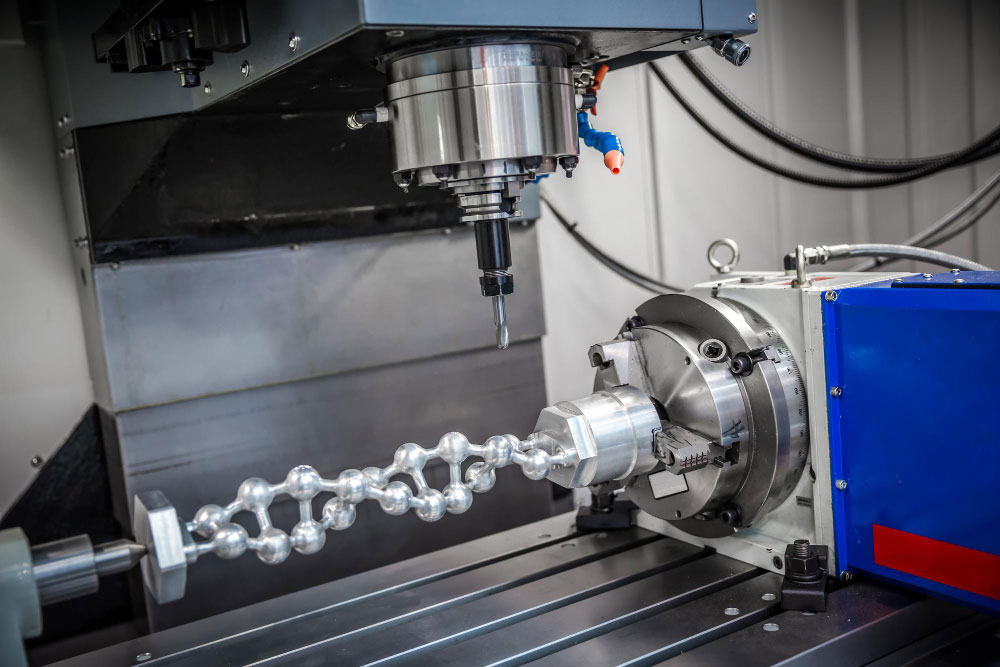

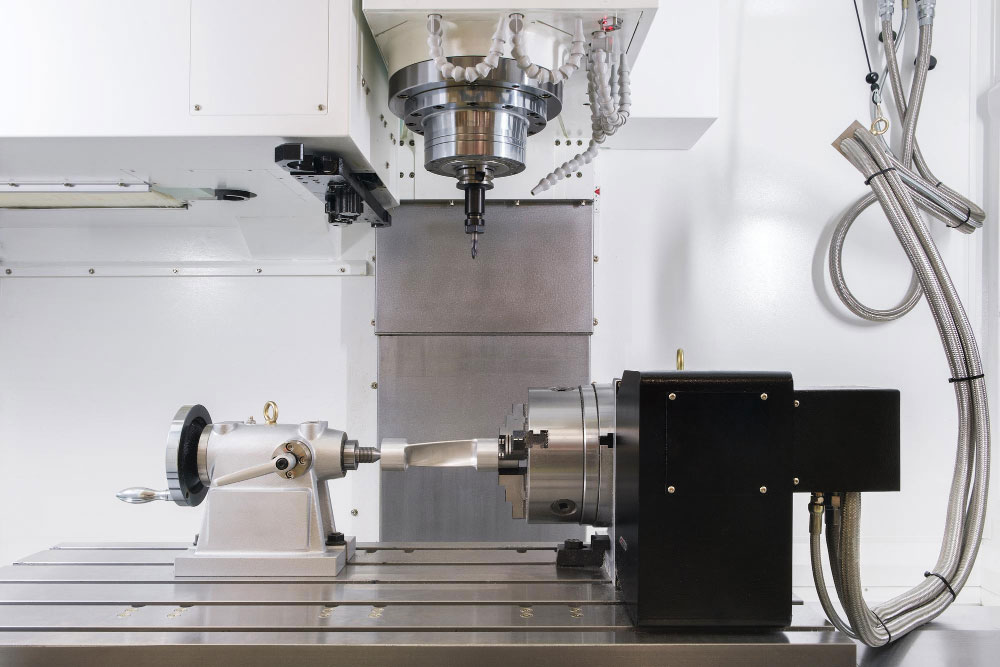

CNC (Computer Numerical Control) milling uses computer programs to control machine tools. This method creates precise and complex parts consistently, making it vital for industries like aerospace, automotive, and electronics. Whether you need prototypes or large production runs, CNC milling ensures accuracy and reliability. To learn more about the general process of milling, refer to the detailed entry on Milling (Machining) on Wikipedia.

Quality is crucial in CNC milling. A reliable service follows strict quality standards to ensure your projects succeed.

Meeting deadlines is essential in manufacturing. Choose a service that delivers quickly without sacrificing quality.

Balancing cost with quality is key to staying profitable and competitive.

Experienced CNC milling services understand your specific needs better.

Good communication is essential for a successful partnership.

A reputable service reduces the risk of delays and quality issues.

Start by researching online, using industry forums and professional networks. Look for customer reviews and testimonials to understand satisfaction levels and any common problems.

Ask for sample parts to check the quality and precision of their work before placing a large order.

Ensure the service has relevant certifications like ISO 9001:2015, indicating they follow international quality standards.

Contact potential providers with your project details and see how promptly and clearly they respond.

Provide detailed specifications, including tolerances, materials, and finishes, to avoid errors and rework.

Work with your CNC milling service to optimize your designs for easier and more efficient production.

Establishing a long-term partnership can lead to better pricing, priority service, and a deeper understanding of your needs.

Choose providers with good English skills or use translation services to ensure clear communication.

Select services with strong quality control and conduct regular inspections to maintain consistency.

Partner with experienced providers or use third-party logistics services to manage international shipments smoothly.

Choosing the right CNC milling service in China involves evaluating quality, turnaround times, costs, and other important factors. By researching thoroughly, assessing potential partners carefully, and maintaining clear communication, you can find a CNC milling partner that supports your business goals. The right partner will enhance your manufacturing capabilities and contribute to your project's ongoing success.

By focusing on these key points, businesses can effectively select a CNC milling service in China that meets their quality and efficiency needs.