Stainless steel filter cartridge assemblies are built for tough circumstances. They are used in systems that run under constant flow. These include chemical lines, water filtration, oil circuits, and more. So, these parts must retain their shape under pressure and heat.

Each assembly includes a perforated core, mesh wrap, and end rings. These components are usually thin-walled and require a tight fit. If even one section is off, the flow can leak. Poor surface finish and warping can also cause weld failure.

CNC machining is ideal for producing these parts accurately. It controls tight tolerance, surface alignment, and weld-ready geometry. At Apex Rapid, we machine 304 and 316 stainless parts with care. Our process avoids stress points and helps your assembly stay reliable. Every part is shaped for real-time performance, not just functional fit.

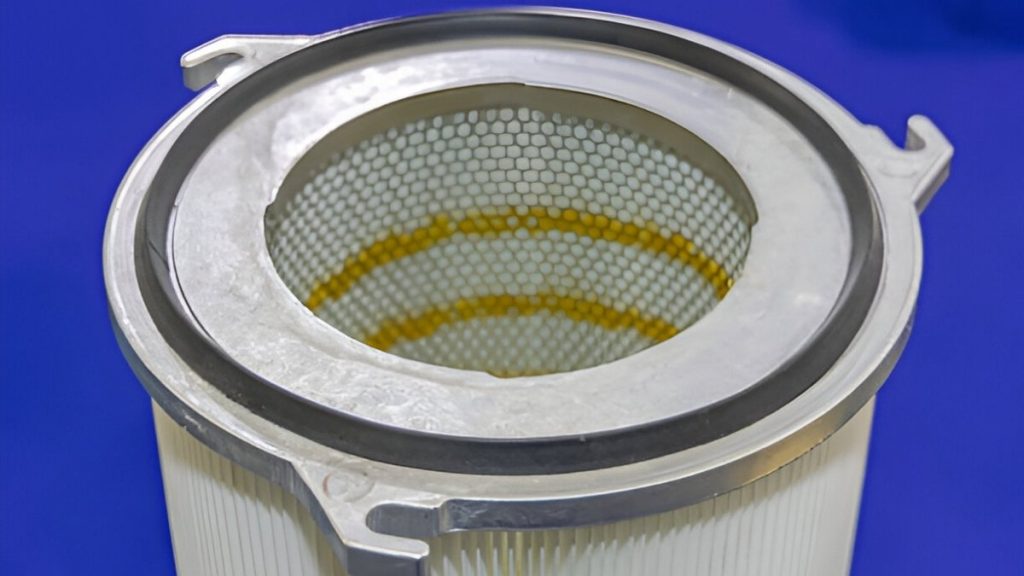

Stainless Steel Air Filter

Manufacturing of stainless filter cartridges requires more than tight tolerances. You must take into account the wall's strength, edge finish, and quality of surfaces. All the components must fit, seal, and weld appropriately. This is the reason why CNC should accommodate thin-wall distortion, bore alignment, and thermal conductivity in cutting.

Filter cores can be long and thin-walled and completely perforated. These should remain circular throughout the entire length. When there is distortion, then the mesh settles or becomes uneven or even breaks when being subjected to pressure cycles. During core machining, we turn at low rpm and support bushings. That prevents ovality and keeps runout of the bore within tight limits.

The sealing face should have end caps flush against it. When the flatness is out, the cartridge leaks under high pressure. The stainless steels are susceptible to tool heating. We do finish passes in coolant-controlled low step downs. This maintains the flange surface cool and in microns of desired flatness.

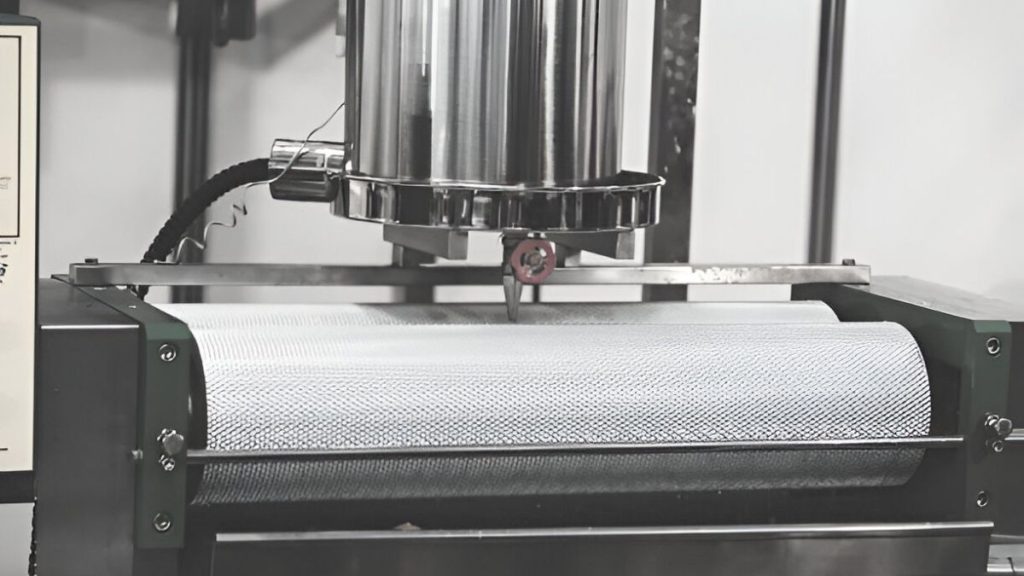

Filter Thin-Walled Mesh

When not controlled, outer mesh supports tend to deform during milling. Thin walls may be moved out of shape by CNC tool pressure. To avoid deflection of walls, we apply specially made soft jaws and timed cuts. The end product is a straight clean sleeve ready to have mesh bonded or laser welded.

Insufficient preparations on the edges form weak welds and burn zones. To bond well with each other, weld seams have to be clean and even. We machine-controlled chamfers and use tight-profile transitions in roughing. This saves post-machining work and increases the success of welding stainless joints.

Stainless steel work hardens if it is overheated or cut dry. This causes areas of stress, resulting in cracks when used. We use completely flooded coolant and remove tool interactions in the vicinity of the weld. That makes the material stable and prevents additional tension prior to final assembly.

The components of a filter cartridge are usually weak-walled and pierced. So, the lack of appropriate fixturing and setup can cause even basic operations to distort and get scrapped.

Stainless steel brings more challenges due to its high hardness and has the effects of expansion and thermal transfer resistance. This is the reason why our setup strategy is the amalgamation of custom workholding, heat management, and tool access planning. The different parts are ready to be in structural accuracy in the cycle.

Inner Soft Jaw Design of Machined Filter Cartridge

Ordinary vise jaws exert an unbalanced pressure on filter parts. Thin-walled walls are subject to flexural strains, which give rise to out-of-round bores. This impacts the fit and the downstream weld seam.

We set up soft jaws to the profile of the tubes and machine. The contact points are distributed uniformly to minimize regional pressure. We are also providing vent reliefs to avoid jaw slip while cutting. This makes the part stiff and assists it in keeping the bore tolerance.

The filter cores of long filters sag or deflect when unsupported. The part may be moved by tool pressure even with perfect clamping. This leads to a spiral out of round or oval turning.

At several locations, we apply steady rests and roller blocks. The supports are manually adjusted to every part diameter. Tool passes are divided into strips to reduce overloading of sections. Consequently, every core remains faithful throughout the entire process.

End caps need to have clean bore alignments and flat faces. In case of shifting of the cap during facing, flange flatness will not work. This brings in sealing issues when fitted in the housing.

We have face clamps having center stops to locate caps. There are backing plates that absorb pressure when boring. Each batch is checked with gauge blocks before all fixturing is done. This maintains bore centers and contact faces in position each time.

When heat accumulates around the areas of contact, stainless steel grows rapidly. Thin parts distort, even during rough cuts, due to heat. When early part shifting happens, the last passes will be inaccurate.

We tolerate brief sojourn times in the face-to-face and profiling. The tool speeds are reduced in steps to minimize friction buildup. Coolant is used during the first pass, not the final. This helps protect the edge quality during setup and finish machining.

Post-Machined Filter Cartridge In Stack Displayed

After the machining is completed, every part takes a different step. Post-treatment processes are critical in achieving long-term performance. Stainless assemblies used as filters cannot be easily corroded, must have tight welds, and should be of visual quality. The finishing not only has a cosmetic impact, but it also influences the weld reliability, the fit, and the strength of the pressure seals. We also do these steps with the same precision as cutting.

Burrs and rough edges do not allow assembly. Mesh wraps may tear and get out of position at sharp corners. Unless the burr is removed, end caps may not lie flat.

We utilize the use of toolpath-based edge breaks as we go through the cycle. In the critical areas, we operate manual edge smoothing with no grinding. This helps avoid over-removal to maintain the spec parts. We would like to have clean contact lines that do not need any rework.

Oil and debris get mixed on stainless steel parts during the cutting. These residues have their impact on the weld quality and strength of the seals. They also trap warm and may result in hard points.

We use an ultrasonic cleaning or solvent wipes, followed by fit-up. It allows us to clean every contact surface, so that there is no oxide or coolant on the surface. This guarantees batch-to-batch weld strength and cleanliness of joints.

After welding using heat, some filter components are distorted. This happens once there is residual stress left in the important places after machining. The parts made of thin walls are particularly susceptible to movement after welding.

Components that are at high risk of damage are relieved at low temperatures. Sometimes we manipulate the weld sequence so as to avoid thermal buildup. This enables improved dimensional holding in the assembly work.

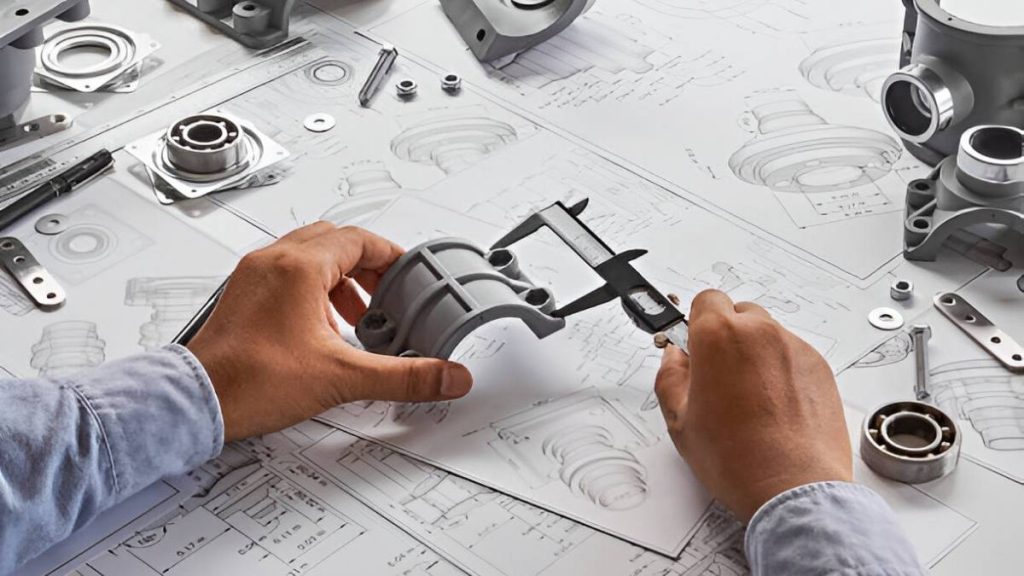

Dimensional Checks Using Caliper

Parts have to be inspected before transferring to welding or press-fitting. Full rework can be caused by dimensional drift, scratches, or bore offset.

The checks on bores, faces, and alignment features are inspected through gauges. The surface finish is checked both visually and, where necessary, using magnification. This phase eliminates wastes, unfavorable welds, and defects in the field in the future.

Consistency is important when making stainless filter assemblies in a batch. A single part that is out of tolerance may destroy complete assemblies. The thin-walled components, a large degree of perforation, and welded-fit areas increase the possibility of variation.

The Apexrapid team always hits the specs. But not only that, we keep results consistent across all the batches and every cycle. We adjust the process and the inspection loop to behavior that is predictable.

Tool-related drift tends to be missed during manual checks following machining. In mass production, even a minute offset may replicate itself in dozens of pieces. That causes scrap or weld misalignment, which appears costly.

To verify important features, we utilize in-cycle probing procedures. These are the bore size, face height, as well as flatness. Any change of toolpath and material response is raised instantly. Tool compensation is not carried out with a halt in production.

Stainless steel is abrasive and cuts the tools off quicker than anticipated. Bearings were subject to wear in sizes, edge finish, and flatness. Without checking wear, there may be quality problems may appear in the middle of a run.

We measure the spindle time as well as the number of parts per cutter. Tools are replaced to prevent mistakes from emerging when there are limits. This method decreases variation and maintains a consistent finish on the surface.

Batch Sampling for Critical Dimensional Checks

Other features are to be inspected further beyond the machine. Sampling of weld surfaces and core alignment zones is to be done by hand. That assists in detecting the problems before.

At Apexrapid, sampling schedules are made on the basis of former performance. After a set period, we gauge runout, flatness, and bore consistency. In the event of a failure of either part, the setup upstream is instantly corrected.

The repeat orders have to be as per the previous specifications without guesswork. Compromised set-up information leads to job/shift drift.

We record all the confirmed settings, RPM, stepdown, and coolant flow. Fixturing positions and the clamping pressure are noted on a part type. This will make sure that new runs will be started with known conditions and without any variation.

Clean welds and tight tolerances cannot be used alone. Stainless filter cartridges have to undergo visual and dimensional inspection before assembly. When any of the units is warped on the surface or the bore is not at the center, the entire system can run the risk of a leak or breakage. So, our team applies automated inspection systems that have been combined with the CNC process.

In-Process Probing During CNC Operation

Manual measurement is only able to pick up errors when they are already there. Touch probes are used in CNC machines that check parts during the cycle. This will prevent doing several bad pieces consecutively.

We check the bore size, the face depth, and the edge runout on our measuring machines. There are corrections made automatically in case of a drift. This makes it possible to receive real-time feedback when the production is in high volumes.

The rough surface causes more friction, influences sealing, and holds the debris. The stainless steel needs to fulfil Ra standards of pressure-fit or welded joints.

In finish control, we have tool wear sensors and spark-out detection. In case of an increase in roughness due to RPM or pressure, the system warns the operators. This maintains the surface finish the same - there are no surprises during fit-up.

Tracking is important when several parts are to be incorporated in a single assembly. The errors occur in case of a mix-up of batches or lost records of the value measurements.

Marking of each component is done by using a digital trace ID that is applied after machining. Inspection logs, tool history, and material certs are related to that ID. This allows post-build audit or warranty claims to be made easily.

A manual verification is carried out before granting permission for any filter part to be welded or fitted into the housing.

Press fits are performed by the use of go/no-go gauges and custom jigs. Thread pitch, alignment of bores, as well as flatness of seats, are also checked. We are sure not only that the bit fits right--but that it works when so assembled.

Stainless steel has the strength and resistance to corrosive effects, though it is difficult to machine. It hardens quickly, wears tools fast, and builds heat that distorts small features. When there is no tailored control, then there is reduced edge quality, lost tolerance in bores, and warping of parts when under pressure. This is the reason why all machining strategies are customized to fit stainless steel behavior. Automation assists in performing such adjustments on a real-time basis in order to achieve better consistency and tool life.

When stainless steel is cut with standard chopping and rubbing tools, it chips or rubs. They are poor at dissipating heat quickly and sustaining a sharp, clean edge line. That reduces the part accuracy and tool life.

We select sharp-edged cutters with positive rakes. These instruments cut with no extra pressure and accumulation. They, together with settings of high feed, decrease the tool wear and enhance the quality of the surface.

Stainless steel usually becomes hard when heated and resulting in the cutter bouncing or vibration. Dimensional drift mid-cut is caused by wrong settings.

We have material libraries that our CNC machines auto-adjust feeds to. During an increase in tool load, the RPM and plunge rates are adjusted respectively. This makes finishes much smoother and less strain on minor details.

Coolant Flooding In CNC Milling

Thermal drift is caused by poor flow of coolants or dry machining. That distorts flat surfaces and hauls holes around. Without conscious efforts, stainless steel does not cool evenly.

On every pass, we run coolant straight in the cut area. The spray nozzles are pointed depending on the part shape and the cutter path. This maintains the temperature level and stable parts after finishing cycles.

Stainless steel hardens when tool pressure repeats over the same path. That causes further breakage of the tools and rough finishes. In case of the thin sections or the use of the filter bores, this is even more risky.

Our CAM techniques switch at layers so as to prevent congestion. The angle of entry is different, and the balance of tool loads is maintained during the pass. This reduces surface stress and keeps the grain intact.

Working with stainless steel filter cartridges isn’t simple. You’re dealing with thin materials, tight tolerances, and parts that must weld or seal without failure. That leaves no room for guesswork. CNC automation gives you the control and consistency needed to meet those demands, every time, every part.

At Apex Rapid, we don’t just run your parts through a machine. We tune every cut, every toolpath, and every setup to match your stainless specs. From press-fit caps to precision-weld zones, we handle the machining side so you can move straight into assembly without delays or rework.

When quality matters and repeatability can’t be compromised, our CNC approach keeps your production moving forward, clean, accurate, and ready for the next stage.