Competitive pressure in the race toward tinier, smarter, more powerful electronic overloads the mechanical subsystems that host, protect, connect, and cool them. Whether in the fine-tuned devices on smartphones, the sturdy server and sensor enclosures, components are of utmost quality and precision. There are two manufacturing processes for these highly valuable mechanical parts: CNC (Computer Numerical Control) Machining and Injection Molding. The factors that make one manufacturing process better than another include benefits and drawbacks; thus, the decision will be critical in making products successful, through factors such as performance, cost, volume, and time-to-market.

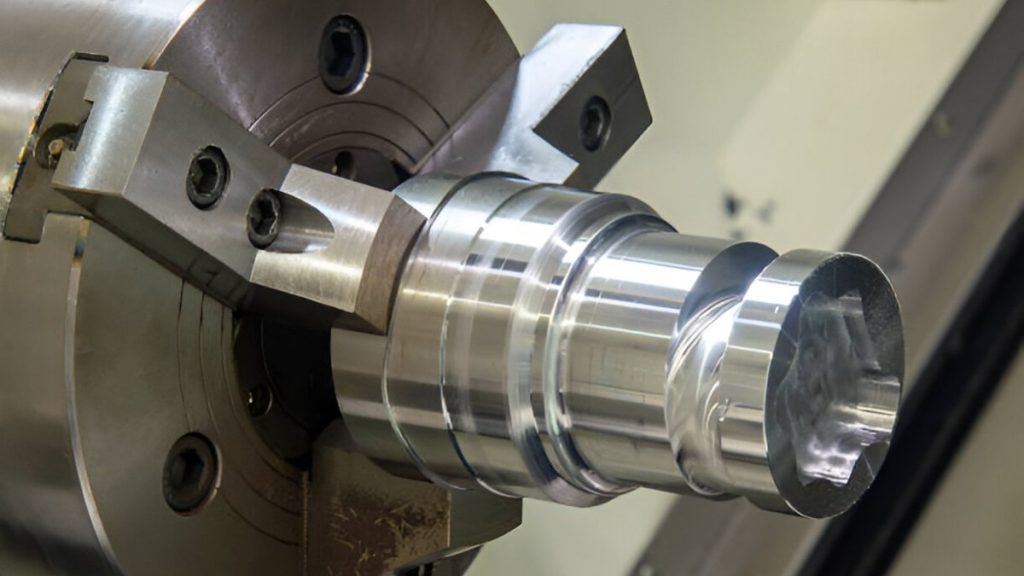

CNC Machining is a subtractive manufacturing process. It is a precision subtraction process that consists of using computer-controlled machine tools (mills, lathes, routers, and grinders) to precisely cut away a solid block (called a blank or workpiece; typically metal, plastic, or composite) to produce a predetermined part geometry.

Central Doctrine: A computer programmed in advance determines the trajectory of cutting blades in multiple planes (3, 4, 5 or more) to eliminate the material in layers until the desired form is obtained. It is a manufacturing process performed by removing material to shape a raw stock into a finished part.

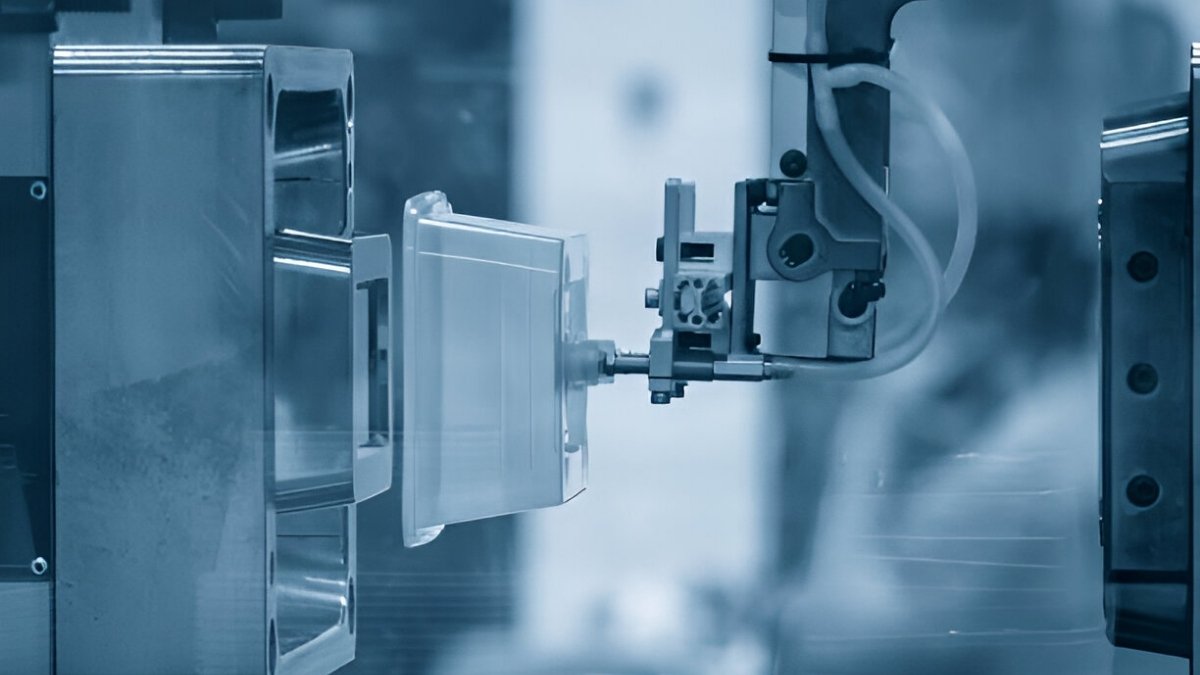

An additive manufacturing process is Injection Molding (when considered in the context of shaping a work-piece, but in this case, the material is melted and injected into a mold). It entails the manufacturing process of thermoplastics or thermosetting polymer pellets in a melted form through high-pressure injection into a precision-machined metal mold cavity.

Fundamental Concept: The melted material, plastic, fills the mould, fitting it exactly. It is then solidified and cooled down. The mold opens, and the complete part gets ejected. The cycle rotates with a high frequency to generate the same parts.

1.CAD Model: Part design generated using 3D CAD.

2.CAM Programming: The CAD drawing is opened in CAM (Computer-Aided Manufacturing) software. Toolpaths are created by designating cutting tools, speeds, feeds, depth of cut, and tool movements. This is subsequently post-processed to G-code specific to the machine.

3.Machine Setup: The raw material (metal billet, plastic sheet, or rod) is firmly clamped to the table of the CNC machine. They put the necessary cutting tools in the tool changer/spindle of the machine.

4.Machining Operations: The CNC machine runs the G-code program. In common use, it involves milling (three-dimensional profiling, pocketing, drilling, threading), turning (of rotational parts), drilling, and boring. Complex parts may require several setups or machines.

5.Post-Processing (Optional): Parts can be deburred, cleaned, and surface finishing (i.e., sanding, bead blasting, anodizing, painting, plating), or inspected.

6.Quality Control: Finished parts are inspected using CMMs (Coordinate Measuring Machines), calipers, micrometers, gauges, or optical comparators to verify dimensional accuracy and tolerances.

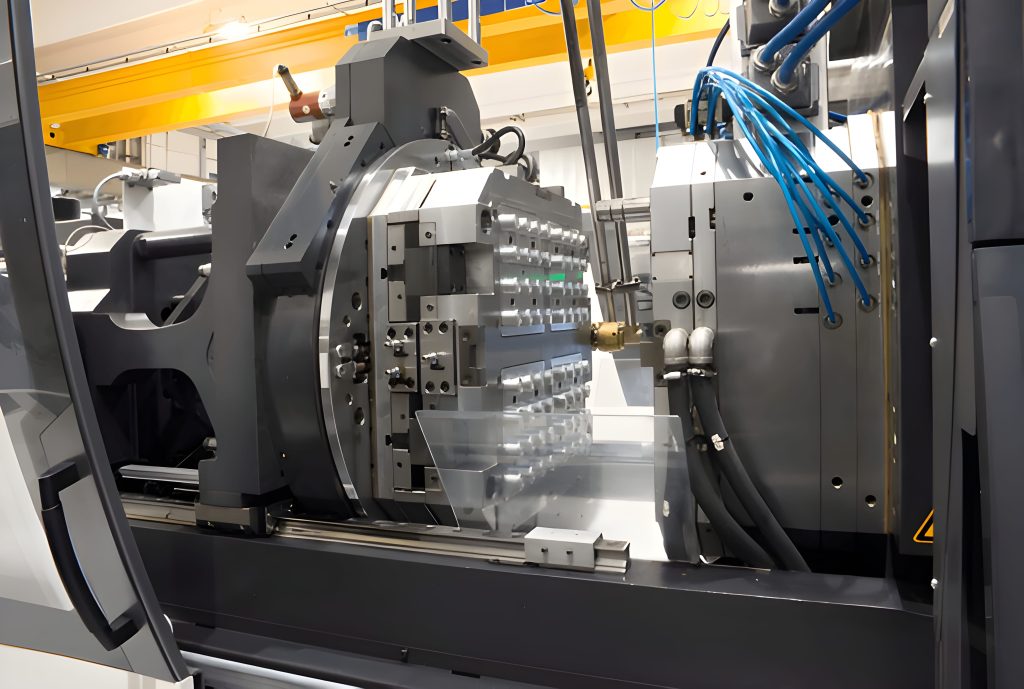

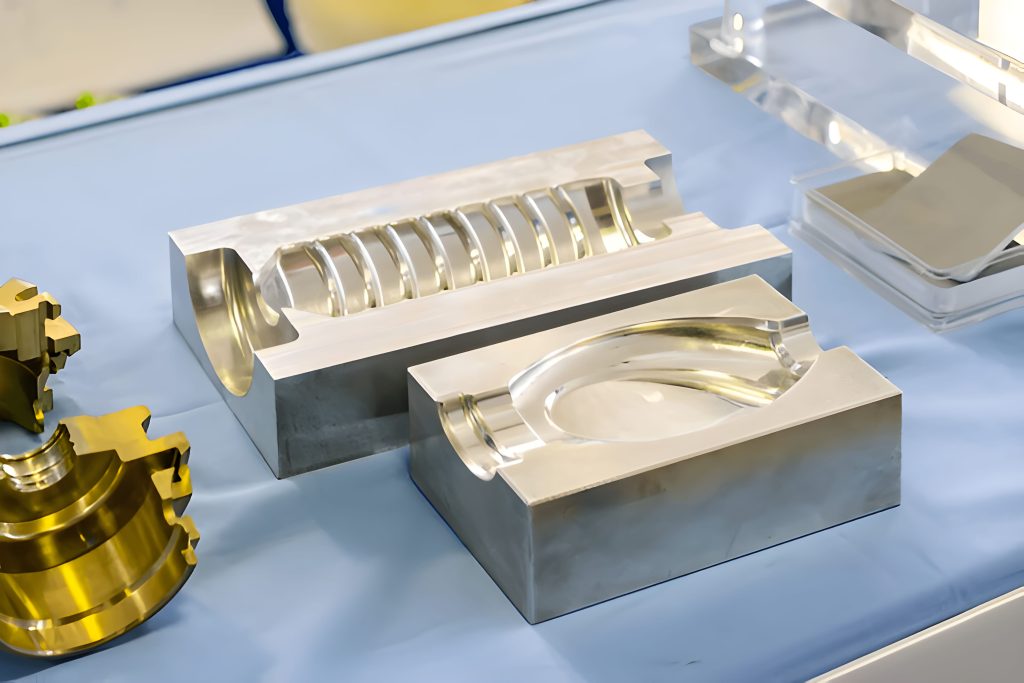

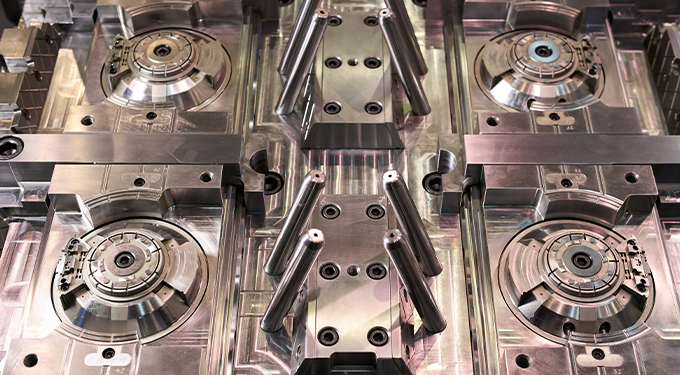

1.Part and Mold Design: Once the conditioned part is designed, it is produced in a manner that considers manufacturability (DFM - Design for Manufacturability). Key issues that should be addressed include draft angles, even thickness of wall, ribs, bosses, and gate location. The complex, multiple-piece mold (core, cavity, inserts, ejector system, cooling channels) is molded and fabricated (typically, by CNC).

2.Mold Fabrication: Hardened tool steel or aluminum is typically machined (using CNC milling component, EDM) with extremely close tolerances. It is the most time-consuming and costly procedure.

3.Preparation of Material: Dried (where necessary, owing to their hygroscopic nature) thermoplastic pellets are fed into the hopper of the injection molding machine.

4.Cycle of Injection Mold:

Clamping: The two halves of the mold are firmly sealed with the clamping unit.

Injection: Pare attracted to the screw and are extruded out by their rotation. They are melted in the barrel. The screw has now become a plunger, pushing the high- pressure molten plastic into the mold cavity.

Cooling: The plastic in the form of a melt solidifies in the mold cavity. A significant part of the cycle consists of cooling time.

Plasticizing: As the part cools, the screw travels back, turning to melt and prepare for the next shot of product.

Mold Opening: The clamping unit unplugs the mold halves.Pins known as Ejector pins force the solidified part out of the mold cavity.

5.Cycle Repeat: This is an automatic process where the mold is closed, and the process repeats.

Post-Processing (Optional): Parts may require removal of sprues, runners, and gates (degating), flash trimming, and additional processes such as painting, pad printing, ultrasonic welding, or assembling.

Quality Control: The parts are examined for dimensional accuracy (using gauges or CMMs), surface flaws (such as sink marks, warpage, flash), and for specific material properties.

Extraordinary Precision /Very Close Tolerances: Can produce very close tolerances (usually ±0.001" / ±0.025mm or better), important in precision fit, optics mount, and electronic high-frequency connectors.

Superior Surface Finish: Can produce fine surface finishes directly off the machine; extensive finishing options available.

Material Flexibility: The machines are versatile and cover a vast range of materials, metals (Aluminum, Steel, Stainless, Brass, Copper, Titanium), Plastics (ABS, PC, Nylon, PEEK, PTFE), and Composites. Ideal for metal cases, heat sinks, EMI shields, and high-performance plastics.

Design flexibility/complexity: Ideal for complex 3D geometries, deep cavities, intricate features, and internal designs that are free of parting lines. The updates to make the changes are fairly simple through CAD/CAM.

Rapid Prototyping & Low-Volume: Ideal considering prototypes, functional trial, bridge tooling, and low and medium-range manufacturers. No costly mold was required in advance.

Isotropic Properties: Parts maintain steady mechanical applications in any direction as they are formed out of solid stock.

Strength and Durability: Solid metal components are robust, offering resilience and durability to challenging tasks.

Higher Cost per Part: Especially an issue at higher volumes due to labor, machine time, and material wastage (chips).

Material Waste: A large amount of scrap material (chips/swarf) is produced through a subtractive process.

Reduced Production Rate: Each component is machined specially, hence ineffective to produce high volumes relative to molding.

Geometric Restrictions: Geometric restrictions occur in thin walls or intricate inner cavities, achieved through molding. Setting up changes with the complex parts consumes time.

Set Up intensive (Configuration/Operation): These processes require qualified programmers and machine operators, particularly for complex components.

Very Low Cost per Part (High Volumes): In injection molding, once the mold is paid off, the cost per part decreases significantly in high-volume applications (thousands to millions of parts).

High Speed of Production: Production speed is fast (seconds to minutes), so the production output is very high.

Complex Geometries Productively: Perfect for making complex shapes, fine details, thin-walled, and undercuts (side actions possible), and internal detail, all in one go.

Minimal Post-Processing: Post-moulded components typically have minimal or no finishing (it depends on the application).

Superior Reproducibility: Able to make thousands of very similar parts with a minimum amount of differences in parts.

Extensive Selection of Plastic Materials: an enormous choice of engineering thermoplastics having precise features (flame retardancy, EMI shielding, high temp, chemical resistance, optically clear).

Low Labor Cost per Part: One-time set up, highly automated process.

Expensive Tooling: Molds are difficult and costly to design and manufacture. There is a high risk of investment, particularly for new products

Tooling: The long lead time, mold design, and manufacturing may take weeks or months.

Design Changes are Costly and Time-Consuming: It is generally expensive to make a change in the design of a part requiring a costly mold to be changed or replaced.

Part Geometry Limitation: DFM (draft angles, uniform walls, etc.) has to be taken into account. Undercuts make things more complex and costly. There are limitations on sizes because of mold and machine capacities.

Anisotropic properties: During filling, material flow can create weld lines and may cause mechanical properties to vary depending on direction.

Primarily on Plastics: Only polymers, and a few composites (overmold)

The two are common in electronics and tend to be complementary in their uses:

Metal Enclosures and Chassis: Premium servers and networking, test & measurement, aerospace/defense electronics (as EMI shielding, strength, heat transfer).

Heat Sinks and Cold Plates: Critical in thermal management in CPUs, GPUs, and power electronics (high conductivity of machined Aluminum/Copper).

Precision Brackets and Mounts: Sensors, lenses, displays, and circuit boards that specify precision and a rigid mount location.

Connectors & Sockets: Metal housings that hold subassembly electrical contacts requiring tight tolerance electrical contacts and mating.

Waveguide Parts and RF Shields: Fine RF/microwave components are machined of Aluminum or Brass.

Prototypes & Low-Volume Production Runs: Enclosures, functional R&D purpose components, pilot production, and specialized/low-volume devices.

Mold Fabrication and Tooling Inserts: Making the injection molding molds, themselves.

Plastic Enclosures & Housings: Consumer electronics (phones, laptops, tablets, wearables), networking and communication appliances (Wi-Fi router casings), power tools, and medical devices (cost-effective, complex shapes and aesthetic options).

Plastic connectors and sockets: Require complex pin configurations and snap fits in a plastic body.

Knobs, Buttons, & Control Interfaces: user interface elements.

Automotive Parts: Dashboard panels, Center consoles, etc.

Cable Management Components: Strain reliefs, cable gland clips.

Internal Structural Parts: The brackets, device supports, and guides.

Lens Housings & Light Pipes: Lens housings and light pipes that need clarity or to transmit light.

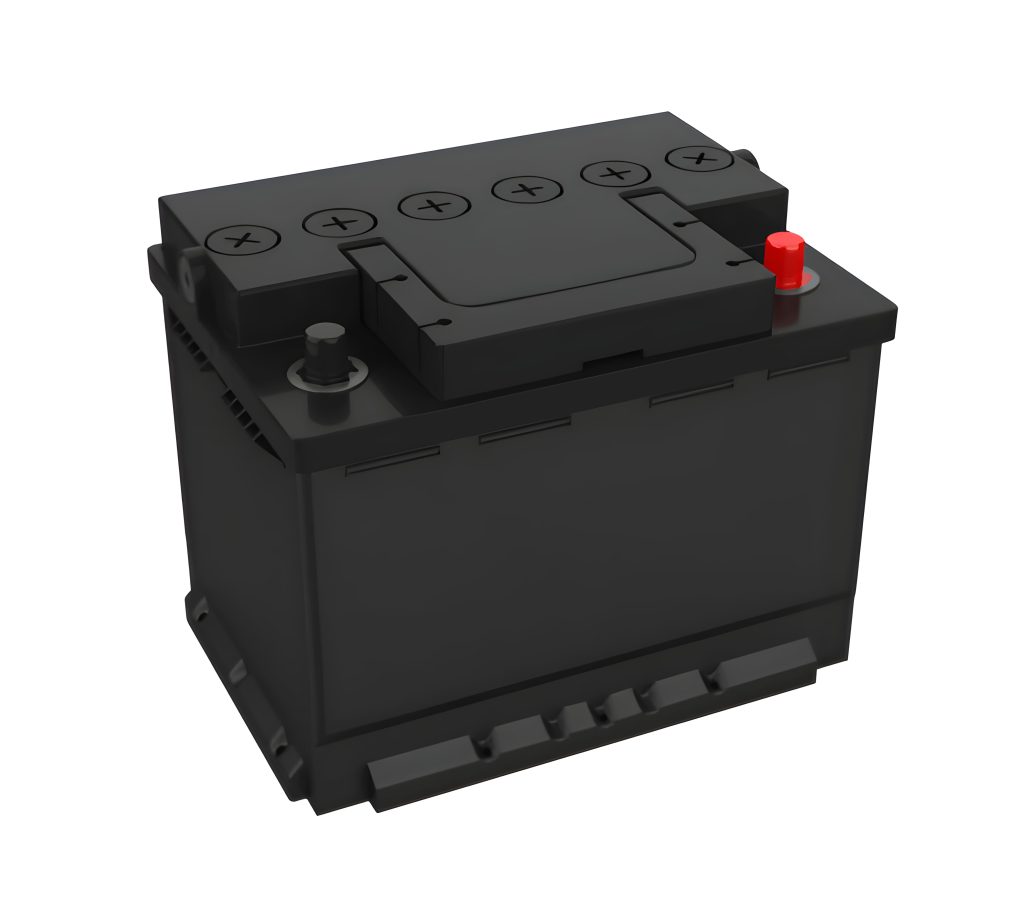

Battery Housings: Special shapes of different sizes of batteries.

High volume consumables: Cases of cartridges, filters, etc.

Accessibility of tool: Ensure the cutting tool is accessible to all features (avoid deep, narrow cavities; take into consideration the diameter of the tool when making internal corners - radius bigger than tool radius).

Internal Corners: The radius will always be larger than the cutting tool’s radius. Do not specify sharp corners inside.

Wall Thickness: Avoid thin walls that may vibrate or be broken during machining. Make everything consistent.

Setups: Reduce the number of overall part reorientations (setups) to lower cost and potential mistakes. Design features have fewer sides to access.

Standard Tooling: Where possible, use conventional drill sizes and shapes of tooling to prevent special tooling costs.

Selection of Material: Select readily available stock sizes and minimize the waste and cost. Consider machinability.

Tolerances: Tolerances should be given only where necessary. Strict tolerances add excessive cost and time in machining.

Surface Finish: Requirements of finishes. The smoother the finishes, the slower the machining or secondary processes.

Draft Angles: Critical! include draft ( normally 1-3° per side) on all surfaces that are normal to the mold opening direction, such that the part can be ejected.

Consistency in wall thickness: Essential in the avoidance of sink marks, warpage, and voids. A thick section is to be avoided; the strength is to be secured by ribs.

Radii and Fillets: Apply large radii to all corners (both inside and outside) to enhance material flow, decrease stress concentration, and increase part strength.

Ribs and Bosses: Design ribs less than nominal wall thickness (e.g., 50-60%), and make bosses with sufficient support ribs to avoid sinking and cracking.

Undercuts: Try to skip them. They demand complicated (and expensive) side motions (cams, lifters) or shrinkable cores in the mold, when they become obligatory.

Gate Location: Pay attention to the manner and position of pouring melted plastic into the cavity. There are marks left by gates that can affect cosmetics or stress.

Shrinkage: Material selection is critical in mold design because different plastics shrink at varying rates during cooling. To compensate for this shrinkage, the mold cavity is slightly oversized compared to the final part.

Sink marks: Minimize by ensuring the wall is relatively uniform in thickness and does not have thick junctions.

Ejection: It is paramount that you have proper ejection surface area; the ejector pins should push the piece out without removing materials to leave a mark and cause damage to the material.

CNC Milling: Most common 3-axis, 4-axis (indexing or full rotary), 5-axis (simultaneous movement of complex contours). Applied to prismatic parts. The boss of electronics.

CNC Turning: To manufacture rotational parts (lathes). Milling (Mill-Turn centers) is often, but not always, used with complex parts such as connectors.

CNC Drilling/Tapping: Holes are drilled precisely, and threads are performed in their holes.

CNC Grinding: Hardened metals to produce very high precision and finish of the surface.

CNC EDM (Electrical Discharge Machining): This process uses controlled electrical sparks to erode material, making it ideal for machining hard metals and intricate features—such as mold cavities—that are difficult to achieve with traditional cutting tools. In wire EDM, a thin electrically charged wire precisely cuts through the material along a programmed path.

CNC Routing: Same as with milling, except that it is commonly used in softer materials (wood, plastics, composites) or bigger panels.

Standard Thermoplastic Molding: The most prevalent method.

Insert Molding: A metal or other pre-formed insert is inserted in the mold, and the insert is surrounded by plastic using injection (e.g., a threaded metal insert into a housing made of plastic, or connector pins).

Overmolding: Injection of a second component over a pre-molded component (e.g., soft-touch finger grips on a hard substrate, two-shot molding).

Gas-Assist Injection Molding (GAIM): Molten plastic is injected into a thick part, and inert gases are released into the molten liquid, resulting in hollow channels, decreased weight or sink marks, and increased stiffness.

Structural Foam Molding: Plastic is injected and combined with a blowing agent to produce a characteristic rigid, low-density body of cellular core and solid skin. Good on the large sections.

LSR has applications in the electronics industry where it is used to manufacture flexible parts with high-temperature resistance (seals, gaskets, and keypads).

As-Machined: As prepared on the machine tool. Tool marks. Different by tool and operation.

Bead/Sand Blasting: produces an even matte or satin texture, conceals small tool marks, and improves paint adhesion. Metal enclosures are common.

Polishing/Buffing: makes metals smooth and shiny. Often for cosmetic pieces.

Anodizing (Aluminum): A material is oxidized using electricity in a hard, abrasion-resistant, and corrosion-resistant oxide layer. It is capable of being dyed in many colors (Type II). Hard Anodizing (Type III) of extreme wear resistance. Very common in electronics.

Plating: Corrosion resistance, conductivity (e.g., electromagnetic interference shielding), solderability, or appearance using electroplating (Nickel, Chrome, Zinc, Tin, Gold, Silver).

Painting/Powder Coating: This offers a hue, finish, and environmental security to both metals and occasionally plastics.

Laser Engraving/Marking: To add logos, serial numbers, Barcodes, or labels permanently.

As-Molded: This is the standard surface finish that results from the mold without additional post-processing. The final appearance depends on the mold's surface texture, which can be polished, textured, or created using EDM techniques.

Mold Texturing: Careful choice and application of any desired texture of the surface of the mold (grain, leather, matte) duplicated on all pieces. Does away with second finishing.

Paint: For color, brand, or to use certain textures where none are obtainable in-mold. Paints require surface preparation.

Pad Printing: For applying detailed logos, text, or graphics onto curved or irregular surfaces.

Hot Stamping: The process of applying metallic foil or colored film with the help of heat and pressure.

Laser Engraving/Marking: As with CNC parts.

Ultrasonic Welding: The method of welding plastic parts, which involves sending vibrations at high frequencies to the parts.

Vapor Smoothing (Chemical Smoothing): (mainly ABS) with solvent vapours used to melt the surface layer to achieve a glossy finish, concealing layer lines (more pertinent to 3D printing, and sometimes applied to moulded work).

CNC machining is ideal for rapid prototyping, high precision, and low-volume production, especially with metals and strong plastics. Injection molding, on the other hand, is best for mass production of complex plastic parts at low per-unit cost. Each has its strengths—CNC offers speed and accuracy, while molding excels in high-volume efficiency. At ApexRapid, we provide both CNC machining and injection molding services to meet your project needs from prototype to production.

A: When you need: Metal parts (enclosures, heatsinks, shields), very tight tolerances (< ±0.005"), complex geometries difficult to mold, prototypes or very low volumes (< 100-500 parts), parts requiring isotropic strength, or the ability to make frequent design changes quickly.

Q&A CNC machining vs. Injection mold electronics

A: When wanted: Metal pieces (cases, cooling devices, protecting, etc.), extremely tight tolerances (< ±0.005"), complicated shapes that do not lend themselves to molding, very low volume ( less than 100-500 parts), parts that are necessitate isotropic strength (like metal parts), or must be made to alter design easily and quickly.

A: When you require: High quantities of plastic components (> 1000-5000 + pieces), complex plastic geometries at high-efficiencies (thin wall structures, finely detailed), lowest cost per unit at scale, high repeatability on part-to-part identical parts, or special plastic material properties (FR, EMI shielding grades).

A: Estimate: Breakeven Quantity = Injection Mold Cost / (CNC Cost per Part Injection Molding Cost per Part). Include material costs and costs (machine time, labor, secondary ops, mold-amortization). This provides the volume, and the total cost becomes less than CNC. Be practical regarding estimations of expenses.

A: It is most commonly done by CNC machining of plastic prototypes. It also employs the same type of plastic as molding (engineering grade and can produce functional parts with comparable properties (but may have different stresses and internal anisotropy). An alternative is high-resolution 3D printing (SLA, MJF, SLS) when functionality and high precision are not required, but rather form-fit checking

A: CNC: Denying access to tools (deep pockets/tight corners), neglecting the internal radii of the corner, and stipulating unattainable tolerances throughout/designing thin walls that are likely to chatter/break.

Injection molding: Mistaking draft angle, not thinking about wall thickness (e.g. sink/warp, internal sharp corners (stress concentrators), neglecting the effect of the gate, designing undercuts without considering side action mechanisms.