Medical machining makes precise parts for medical devices, surgical instruments, and dental tools. These parts must meet strict tolerances and have smooth surfaces because patient safety depends on them. Materials like stainless steel, titanium, and medical-grade plastics are used. Every cut, drill, or mill is done carefully to ensure accuracy and consistency.

At ApexRapid, we provide on-demand manufacturing for custom medical parts. We use CNC machining, injection molding, sheet metal fabrication, 3D printing, and vacuum casting. We make small intricate parts for surgical tools, complex components for dental equipment, and strong assemblies for medical devices.

We focus on quality and reliability. Every part meets tight tolerances and high safety standards. Lead times are fast, usually one to three working days. This allows designers and engineers to test and improve their products quickly.

Whether it is a prototype or full production, ApexRapid delivers precise and reliable medical components. Send your CAD files, get a clear quote, and receive high-quality parts ready for use. We support your project every step of the way.

Medical Part Machining

Medical machining refers to the manufacture of components of medical apparatus, surgical instruments, and toothbrushes. The components should be accurate, powerful, and secure. Stainless steel, titanium, and medical-grade plastics are used.

The process ensures all the parts are of high quality and meet safety standards. Machining produces precision in shapes and smooth finishes. This makes the components reliable in actual medical applications.

ApexRapid is a company that produces custom medical parts on order. Our machining technologies are CNC machining, sheet metal machining, 3D printing, injection machining, and vacuum casting. Components are manufactured in a fast and precise way, to be tested or produced.

Surgical Metal Tools

It starts with the design of an elaborate CAD model of the part. Designers provide specific dimensions, form, and functionality. The tolerances, surface finishes, and assembly requirements are also part of the model. This is done to ensure that the end component is used as intended in the medical applications.

It is important to select the appropriate material. They are usually made of stainless steel, titanium, and medical-grade plastics. The choice of material will be based on strength, resistance to corrosion, biocompatibility, and the nature of the medical device. The application of the right material would make it safe and reliable in the field of usage.

The selected material is fixed securely in the CNC machine. Milling heads, cutting tools, and drills are fitted and aligned. The CAD data is used to program the machine to follow specific tracks. Proper installation makes the machining accurate and minimizes errors.

Machining starts with cutting, drilling, or milling of the material based on the design. Multifaceted figures and delicacies are torturously executed. The process is very high-precision oriented so as to keep a tight tolerance necessary in medical parts.

Durability and safety are enhanced by polishing, smoothing, or applying a coating. Surgical tools and implants that come in contact with human tissue require a smooth surface.

All the parts are carefully inspected. Checking of measurements is done by the use of precise instruments. The quality of the surfaces, dimensions, and functionality is checked. Only that which is of all quality and safety standards is sanctioned to be used or put together.

Cleaning, packaging, and delivery of approved parts are done. Packaging secures the components in the course of transportation and storage. Quick and safe delivery is ensured to prevent damage to the manufacturers, hospitals, or labs.

Medical manufacturing involves a large amount of CNC machining since it creates very precise and reliable parts. Various methods are used with different materials, complexities, and applications of the part.

Conventional Milling Machine

Milling is the cutting of a workpiece by rotary tools. It is applied in making intricate forms, flat areas, and finely detailed images. In medical components, milling is used to manufacture surgical instruments, implant plates, and housings of medical devices. Multi-axis milling machines enable cutting at many angles, and this is required in complex geometries.

Turning involves a rotary piece of work and fixed cutting tools to form cylindrical components. It is typically applied to screws, pins, rods, and implant components. CNC lathes are able to cut tightly and small and large diameter parts to smooth finishes.

5-Axis CNC Machining Center

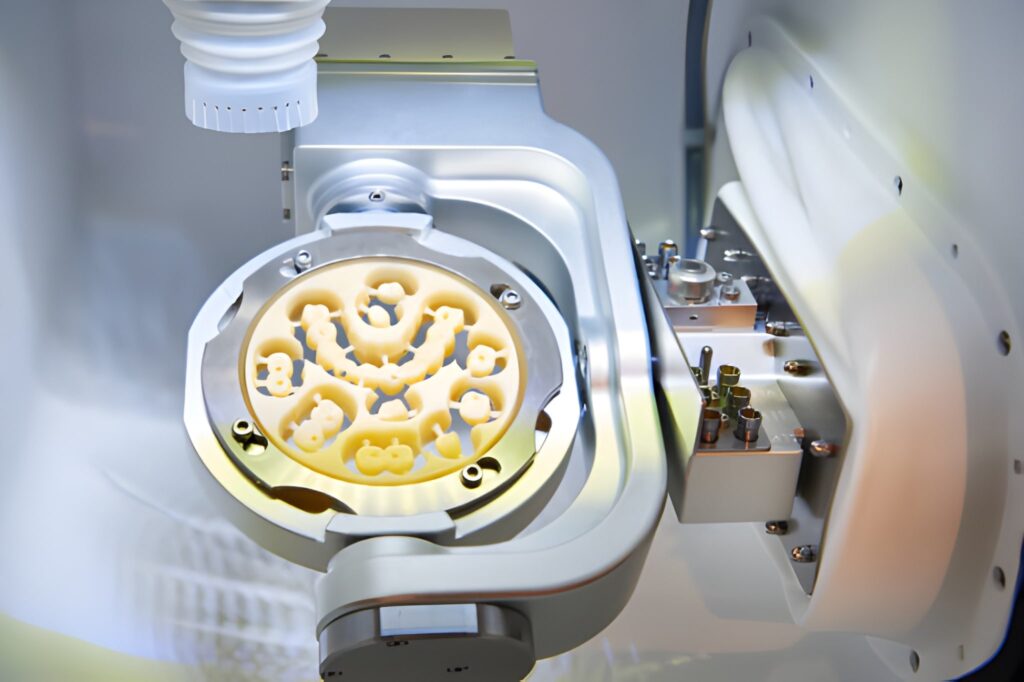

In 5-axis machining, it is possible to cut in a variety of axes simultaneously. It is suited to components with complicated curves, or angled surfaces, or deep hollows. CNC machines are commonly used in making hip implants, dental abutments, and surgical guides that are made using 5-axis machines. This method saves on set-up time and has greater precision.

The drilling provides accurate holes in medical parts. It is applied to screws, plates, and device housings where precise hole location is a necessity. The depth, diameter, and alignment are also maintained with CNC drilling, which is essential to assembly and performance.

Finishing and grinding are used to eliminate material to create small tolerances and smooth surfaces. Implants and surgical tools are polished, deburred, and fine-ground to enhance surface finish. Such methods are necessary when dealing with components touching the human body.

EDM Machine

Wire EDM involves cutting hard metals such as titanium using a thin piece of wire. It is applicable in complex geometry, tiny parts, and hard-to-machinable materials. This is a process that creates very accurate edges with no stress or deformation.

The elements of the medicine should be very specific. Even minor bends can influence the functioning or the fitting of the device to another part. Tolerances of 0.001 inches or less are only sustainable with sophisticated CNC machinery and trained personnel. Constant inspection and accuracy of adjustments are important during the machining process.

Commonly used materials include titanium, stainless steel, medical-grade plastics, etc. The cutting tools may be worn out in no time by metals, thus necessitating special methods to avoid deformation or stress. Plastics and polymers are heat-sensitive and may melt or warp when being cut. Speed and precision are the main issues because it can be damaged.

Medical components can be of complex form, with small holes, threads, or a curved surface. The accuracy in machining these features is also very difficult and demands proper planning, tooling, and sophisticated programming. In order to achieve challenging angles and contours, a multi-axis machine may be necessary.

Medical Dialysis Machine

Most parts used in medicine are subject to ultra-smooth surfaces that are required to be safe and functioning properly. Uneven or rough surfaces may lead to wear, friction, or contamination. The final finish that has to be obtained requires further stages such as polishing or grinding, or coating, thereby increasing the time and complexity.

Surgical tools, dental tools, and dental implants can be small and delicate. It takes constant operations and special attention to quality control at all steps to work with such small parts and to machine them without damage.

The medical part needs to be in line with the required industry standards and regulations. These are material traceability, process documentation, and comprehensive quality checks. Checking compliance introduces additional procedures to the production process and raises the requirement for close supervision.

Tight tolerances, sophisticated components, complicated designs, and compliance costs add costs to the production. The use of skilled labor, the tools and equipment of high quality, as well as accurate inspection machinery, makes it costly, and hence, efficiency and proper planning are very significant.

Medical device development usually needs to be fast prototyped and short lead time. The manufacture of high-quality parts in a short time without affecting precision is one of the key challenges. Quick iterations and on-demand manufacturing demand effective workflow management.

When cutting hard metals such as titanium, cutting tools wear out. The maintenance and replacement of the tools are very important to ensure no downtime and the maintenance of quality parts. Tools that are poorly taken care of may lead to malpractices or break delicate components.

Medical Work Station

Select the appropriate material for your part. Common ones include stainless steel, titanium, or medical-grade plastics. This will require it to be robust, secure, and appropriate to the apparatus. It has costs and machining difficulty, also.

Medical components must be extremely precise. Test to see whether the supplier is capable of fulfilling the tolerances your design entails. Uniformity is a requirement of various components.

Components tend to require smooth surfaces so as to be safe and functioning properly. Ensure that the manufacturer will be able to offer the needed finish.

Medical components should be of the highest quality in terms of safety and industry. Make sure that the supplier adheres to quality, documentation, and traceability requirements.

Sophisticated forms or minor details require sophisticated equipment and professionals. Assure that the supplier is equipped and experienced.

Determine whether you require a prototype, a small batch, or full production. Test the lead time and deadlines capability of the supplier.

Precision and quality may be very costly. Compare prices, but do not emphasize cost alone; emphasize reliability and experience.

Inquire about inspection processes. Each of the parts is to be examined as per its accuracy, surface finish, and strength.

Good suppliers will take you through the design, choice of material, and manufacturing. Ensure that they are fast and have a clue about what you want.

Medical machining produces precise parts used in surgical, dental, orthopedic, and diagnostic applications. These components should be very precise, powerful, and safe to use by patients.

Components such as scalpels, forceps, clamps, and retractors are made of stainless steel or titanium. These instruments are to have cutting edges, flat surfaces, and precise sizes. Accuracy is used to guarantee that the tools are safe and reliable in the operating room.

Dental Prostheses

Dental exercises, dental abutments, dental braces, and dental crowns are often machined. Biocompatibility is achieved by the use of titanium and medical-grade plastics. Every section should be fitted perfectly and work properly to make sure that the patient feels and is treated successfully.

Implants in the hips, knees, bone screws, and spinal rods are also made out of titanium, stainless steel, or cobalt-chrome alloy. Components have to support massive weight and comply with patient-specific measurements. Close tolerances are done to guarantee a correct fit and durability.

Machined Hip Stem Implant

Devices such as infusion pumps, ventilators, and surgical robots have housings, brackets, connectors, and gears that are machined. These components are usually complicated in geometry and must maintain very fine tolerances to fit together and work well.

Accurate parts of imaging equipment, centrifuges, and laboratory analyzers contain pins, shafts, casings, and sensor mounts. Machining provides correct dimensions, clean cut surfaces, and consistency in testing and analysis.

Prosthetic Medical Equipment

Prosthetic gates are machine-sculpted to fit the anatomy of the patient. Such materials as titanium and hard polymers are applied. Comfort, functionality, and long performance are guaranteed by accuracy.

Surgical tools, implants, or medical equipment involve tiny screws, pins, connectors, and guide rods that must be machined precisely. Any small mistake may impact assembly or patient safety. Quality requires special tools and close examinations.

ApexRapid deals with all these medical machine parts. We integrate CNC machining, sheet metal fabrication, 3D printing, injection molding, and vacuum casting. All the components are precision-made using high-quality materials and highly inspected to meet medical standards.

Medical machining makes parts used in surgeries, dental work, implants, and medical devices. These parts must be very precise, strong, and safe. Materials like stainless steel, titanium, and medical plastics are common. Each part must meet high-quality and safety standards.

Before starting a medical machining project, think about the material, how precise the part needs to be, the surface finish, complexity, production size, and deadlines. Make sure the manufacturer follows safety rules and checks every part carefully.

CNC machining is used a lot for medical parts. Milling, turning, drilling, 5-axis machining, grinding, and wire EDM are common techniques. These help make complex shapes, small parts, and smooth surfaces. Examples include surgical tools, dental implants, orthopedic implants, device housings, prosthetics, and tiny screws and pins.

At ApexRapid, we make custom medical parts on demand. We use CNC machining, 3D printing, sheet metal fabrication, injection molding, and vacuum casting. We ensure all parts are precise, high-quality, and ready fast. Our team helps you move from design to finished parts efficiently.