There are very few manufacturing processes as widely used as CNC milling. Based on CAD and CAM fused with action-cutting tools. It can generate high-accuracy and complex parts. Whether you are a newcomer to the process or an expert inspecting machining options, you must familiarize yourself with CNC milling technology.

So, let’s get a detailed CNC Milling Technology overview. Then we will decide if it suits our project or not.

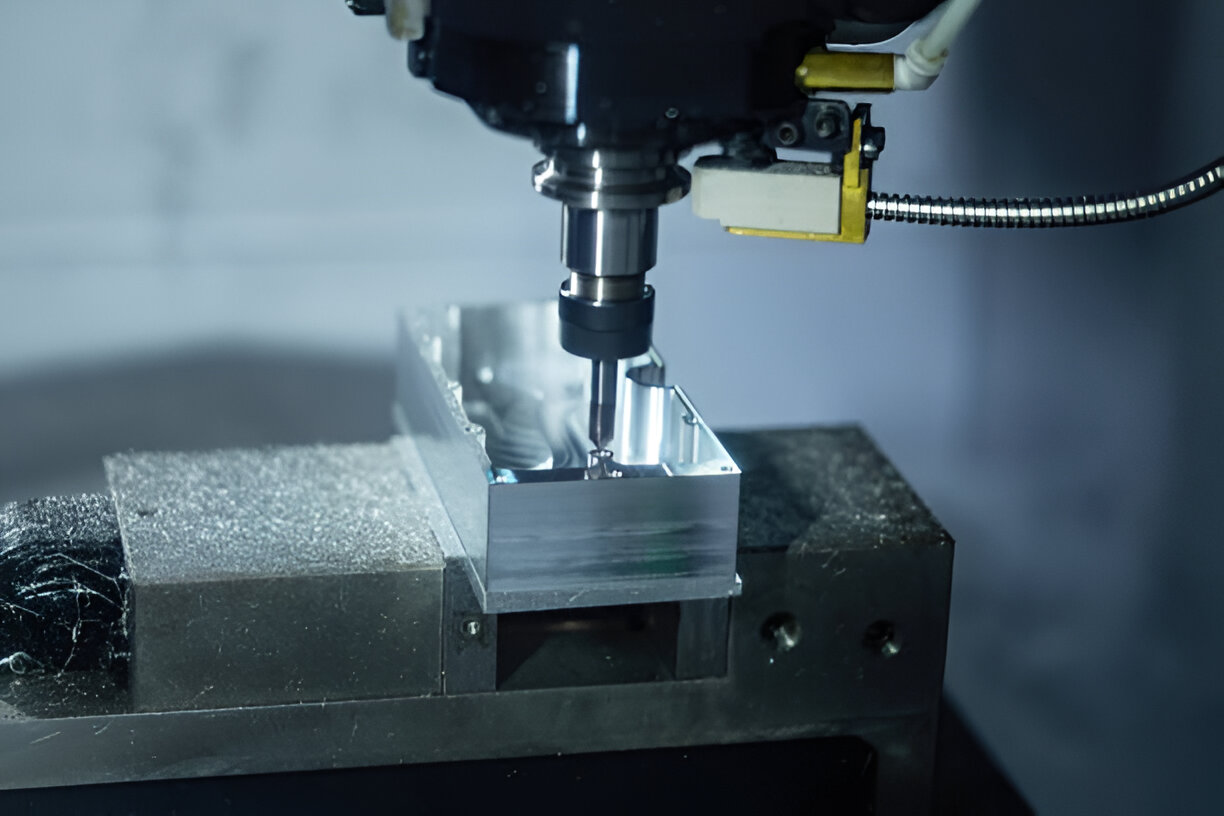

The subtractive manufacturing process is known as CNC (Computer Numerical Control) milling, where a computer-controlled rotating cutting tool removes the material from a workpiece. That process works on preprogrammed sequences of commands meant to cut, drill, and shape metals, plastics, and other materials to the most exacting precision.

CNC milling differs from manual milling in that the whole operation is automated. It helps reduce human error, is less prone to inconsistencies, and has a greater ranking. This is necessary for parts production with complex geometry and tight tolerances in areas, i.e., aerospace, automotive, electronics, medical devices, etc.

The type of CNC milling machine is discussed in terms of its configuration, movement capability, and spindle orientation. The increase in the number of axes they can move along increases the complexity of the parts they can produce. Let’s break these down into the main types:

A very fundamental type of machine is the 3-axis machine, which is mostly used in shops and manufacturing units. An example of such an investigation is done along three linear axes: X (left-right), Y (front-back), and Z (up-down). For machining simple parts such as flat surfaces, slots, and holes, these are perfect machines.

They are cheap, easy to program, and good for beginner or general-purpose operations. But, they are not applicable to more complex shapes for which you need to access from multiple angles.

The rotational movement is added, making the table or tool available with a fourth axis known as the A axis. It provides rotation of the workpiece around the X-axis, which allows access to multiple sides and does not need to reposition it manually. This is especially helpful for small parts or components with features across two or more planes.

And 4-axis machines are also fairly complex yet fast and are used in the manufacturing of gears, camshafts, jewelry, etc.

The most advanced type is a 5 5-axis machine whose tool or workpiece can move along five different axes, X, Y, Z, A, and B (rotation around X and Y). This directing allows the tool to virtually approach the workpiece from all directions, allowing it to machine extremely complicated and intricate parts in a single setup.

These machines are more expensive, but their ability to eliminate or minimize part setup and increase part accuracy makes them worth the investment for applications that benefit from shorter setup times and higher part accuracy.

It has a vertically oriented spindle that allows the workpiece to remain fixed on the bed and requires the cutting tool (tool movement is dictated in other axes) to move up and down (Z-axis). VMCs, which are essentially small to mid-sized parts using small to mid-sized parts manufacturing machines, are generally described as simple, versatile, and useful.

Hence, they are a standard in many job shops and are well-suited for face milling, slotting, and contouring. Since at least gravity co-opts to help prize off the chip, they provide good visibility and access while machining.

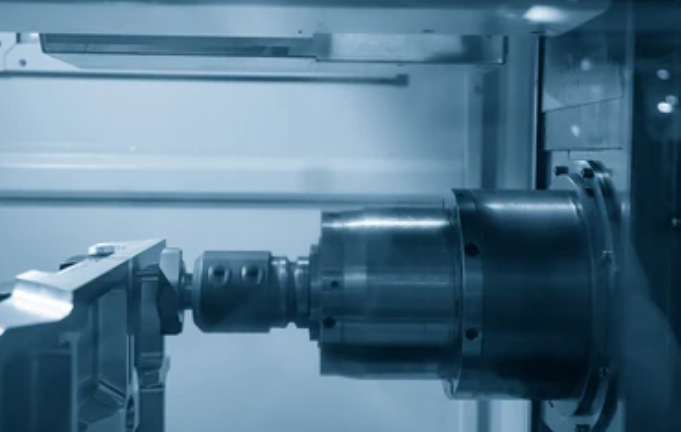

Horizontal milling machines are completely different from the first one in the sense that the spindle is parallel to the horizontal plane. Such machines are more robust and built for heavy-duty tasks and bigger components. HMCs enable multiaxis machining of a workpiece from many sides with a pallet changer. It helps allow for fewer downtimes and better productivity.

These are widely used in automotive and industrial equipment manufacturing environments that demand mass processes. They are essential in high-volume settings because they can remove material quickly and handle larger workpieces.

CNC milling is a systematic and step-by-step approach to ensure precision, efficiency, and repeatability. It takes a digital design and turns it into a physical product with the help of a suite of software and machine operations. Here’s a detailed look at the stages.

The adventure starts in Computer Aided Design (CAD), where the part is digitally modeled. CAD software is used by engineers to develop accurate 2D drawings or 3D models of shapes, dimensions, tolerances, and features. Through these models, the entire manufacturing process is built. CAD tools also support the assembly and function simulation of the part, catching design flaws early and optimizing part performance or manufacturability.

Commonly used CAD programs include:

Good CAD models are key to the success of CNC milling as they act as a seamless transfer to the next stage.

Once the CAD system is finished, it is exported to a CAM (Computer-aided manufacturing) system. The design is read by CAM software and translated to machining instructions in G code that the CNC machine acts on to know where and how to cut.

In this stage, the machinist or programmer defines:

1. Spindle speed and feed rate:

2. The planning of the sequence of operations (i.e., roughing, finishing) is a strategy related to machining.

3 Determination of the exact path that the tool will be following:

4. Previewing the milling process; used to simulate collisions or inefficiency.

Popular CAM programs include:

Very good CAM programming is good because it decreases cycle time and tool life, besides being precise.

The machine setup bridges the digital preparation and the physical machining. The configuration of the machine is part of it to match the job requirements. Key steps are:

The entire stream is aligned precisely, which makes it more unlikely for errors or defects to take place during production.

CNC Milling and CNC Routing have much in common but are used for different applications depending on which material type, which machine has the strongest, and which precision is the most appropriate. This will help you select the one to use during each circumstance.

| Feature | CNC Milling | CNC Routing |

| Materials | Metals, plastics, composites | Primarily wood, plastics, soft metals |

| Machine Rigidity | More rigid, heavy-duty | Lighter, less rigid |

| Spindle Speed | Lower, more torque | Higher speed, less torque |

| Application Type | Industrial-grade parts | Sign making, woodworking |

| Precision | Higher precision and repeatability | Good for soft material shaping |

Where Precision is Critical: e.g., Medical implants, Aerospace parts, or Fine mechanical components.

Here is a useful process for a variety of industries that require accuracy and efficiency. It is due to its ability to craft complex, durable, and reliable components, which are indispensable across a variety of different businesses.

CNC Milling has all of its flexibility due to its very wide compatibility with various material types. CNC machines handle everything from lightweight plastics to high-strength metals and all manner of ceramics.

Strength, thermal resistance, and corrosion resistance are all factors that make materials suitable for CNC Milling.

While CNC Milling has some disadvantages, there are plenty of advantages to offer that make it an ideal process of modern production. This helps one better understand both sides and see whether it’s the right choice for a specific application.

One of the cornerstones of modern manufacturing is CNC Milling, which, because of its ability to produce highly detailed, very accurate parts, is used on a daily basis. Across industries, they trust PL, making it fast and accurate enough to be used for both rapid prototyping and large-volume manufacturing.

In conclusion, typical CNC milling is at the center of modern manufacturing for its ability to rapidly, precisely, and scalably produce parts. Its impact extends to and has an impact on interior and exterior day-to-day consumer goods, i.e., aerospace components that are made from it. However, advances in software, hardware, and automation make CNC milling more realizable than ever, which facilitates the designers, engineers, and manufacturers to try out new thinking in practice.

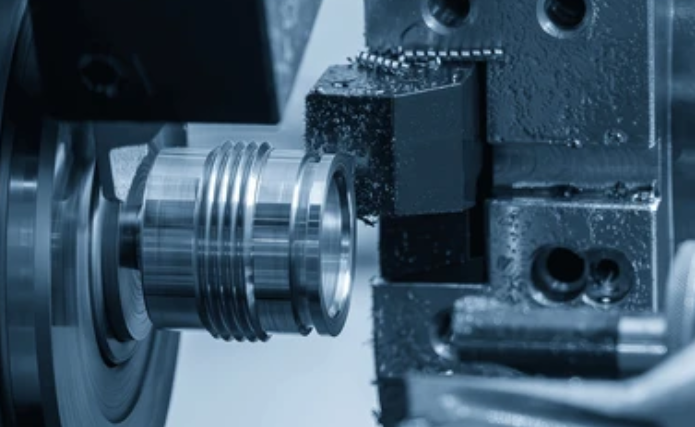

1. Generally, what is CNC milling, and what is CNC turning?

The tools used in CNC milling rotate, whereas in CNC turning, the workpiece is rotated. Turning is the best for cylindrical shapes, while milling is for complex surfaces.

2. Which is better: CNC milling or 3D printing?

Depends on the application. 3D printing is more suitable for complex geometries to are lightweight and for which speed and accuracy would not be the most important criteria for a structural part, whereas milling can produce these structural components with superior precision.

3. How much time does CNC milling take?

Part complexity, material, and machine setup all vary the duration. Simple parts may take minutes, and complex parts may require a few hours.

4. Can CNC milling be mass-produced?

Other than with automated tool changers and multi-axis setups, it is, yes, especially for high volumes, in which case injection might be more efficient.

5. What is the G code in CNC milling?

CNC machines are generally controlled through G code, the language that tells them to move the tools, the speeds, and everything in between.

6. Do I have to know CAD/CAM in order to use a CNC machine?

While basic operation can be learned, there is much to be gained in efficiency and control of final output by understanding CAD/CAM machining.