Tired of dealing with shaft failures in your machinery? You know what, shafts are everywhere around us. From the car you drive to the factory machines that make your favorite products. So the basic point is this - without proper CNC shaft machining, nothing moves the way it should. CNC machining companies have changed the way we produce these vital parts. You see, today’s manufacturing calls for nothing less than the most precise operations that only CNC shaft machining will allow.

Simply put, custom shaft manufacturing has evolved far past simple lathe turning. Engineers know that there is more to meeting the expectations of today than rotating metal. This is key – precision is no longer a luxury. It's absolutely essential.

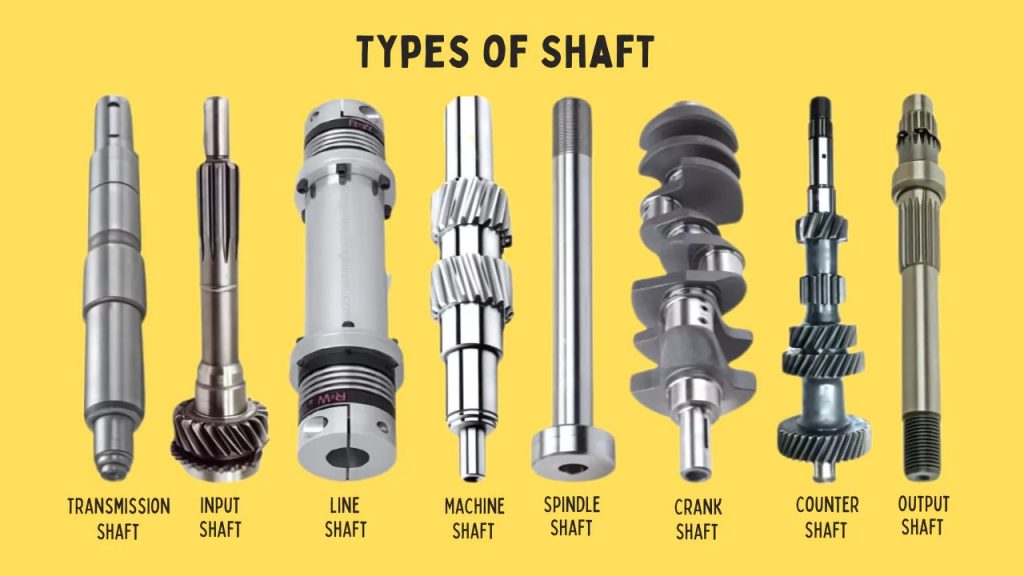

So what exactly is a shaft? Just so you know, a shaft is a rotating machine part. It serves to transfer power from one component to another. These parts will be found in nearly every mechanical system. The next step is figuring out why they’re so important.

Shafts only really have one job: they transfer rotary motion and torque. You might say that this is the number one error: the degree to which people undervalue themselves. But just because a shaft looks simple doesn’t mean it is simple to make. Manufacturers of CNC metal parts understand that any small mistake can result in an epic failure.

These are the simplest to deal with. Well, solid shafts are definitely the strongest and are actually pretty awesome for high-torque applications. They are favorites among CNC machinists because they are very easy to machine.

This is an offset - hollow shafts have a good strength-to-weight ratio. Engineers understand that they are weighty, and that the good ones are worth their weight in gold. At the same time, they are more difficult to machine, but they have huge benefits as far as aerospace applications.”

So the point is just that stepped shafts may have varying diameters along their length. It’s like this design has space for the bearing race and mounting. CNC shops make these all the time for automotive use.

Certainly, it is clear that crankshafts are one of the most intricate types of shafts. Manufacturing must be kept very close to design specs. These will be found in all IC engines.

These are the device throttling times in the engine. Point no. This is important — the level of precision demanded is unreal. Even small differences have big effects on an engine's capabilities.

You see, the splined shafts have grooves for other parts to ride along while still being rotationally secured. CNC metal parts suppliers make these features by using processes that are specially designed for them.

They're like threaded on the sides if that makes any sense. Applications run from the Union between ordinary fasteners and complex positioning systems.

Now things start to get interesting. Because, you know , every industry has special things to consider. Engineers have the tools to create precisely what they want, with custom shaft production.

Drive shafts transfer power in vehicles. Transmission shafts manage gear changes. Pump shafts move fluids in industrial systems. So the basic point is this: each application demands specific characteristics. Why does it matter? Customers give importance to the final results, and choosing the wrong shaft type leads to system failures.

You see, creating precision machined shafts isn't something you just wing. The process starts somewhere specific and follows proven steps. You know it takes careful planning from start to finish.

CAD Design

Everything starts here. You will see that modern CAD software allows incredible precision in design. This point is important - mistakes caught in design save massive costs later. So designers must consider every aspect from material properties to manufacturing constraints.

CAM Software, CNC Programming

The next step is to convert the design into machine instructions. CNC machinists use sophisticated software to generate toolpaths. You know, this step requires a deep understanding of both the part and the machining process.

Material Selection

In simple words, picking the right material makes or breaks the project. CNC machining shops maintain extensive material libraries. Simultaneously, they consider factors like strength, machinability, and cost.

Machining

This is where the magic happens. You see, CNC machines follow programmed instructions with incredible precision. This point is noticeable - modern machines can hold tolerances that were impossible just decades ago.

Finishing

So the basic point is that raw machined surfaces rarely meet final requirements. Surface finishing processes create the final product characteristics. Everything counts in this step.

Quality Control

It is the most common fault to skip a thorough inspection. You know it's better to catch problems before parts leave the shop.

CNC Turning for Shafts

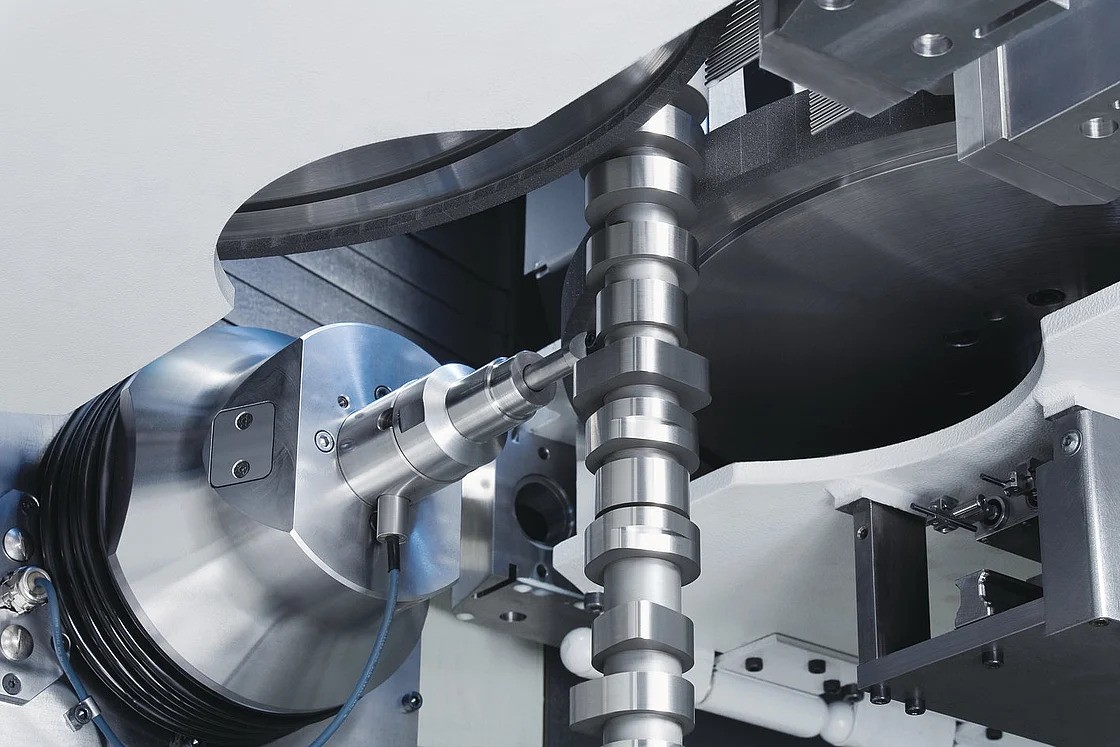

This is the foundation of shaft manufacturing. You see, CNC turning for shafts involves rotating the workpiece while cutting tools remove material. The process description sounds simple, but achieving precision requires expertise. You will see CNC turning used for almost every cylindrical shaft feature. CNC machining shops rely heavily on this process because it's efficient and accurate.

Applications in shaft manufacturing are extensive. So the basic point is that turning creates the basic shaft geometry. You know, everything from simple pins to complex stepped shafts starts with turning operations.

CNC Milling

The next thing is adding complex features that cannot be created. In simple words, CNC milling uses rotating cutting tools to remove material from stationary workpieces. This point is important - milling allows the creation of keyways, flats, and other non-cylindrical features.

Applications for complex shaft features include splines, keyways, and mounting surfaces. Some shaft features require milling. CNC metal parts manufacturers combine turning and milling for complete shaft production.

CNC Grinding

You see, grinding achieves the highest precision levels. The process description involves abrasive wheels removing tiny amounts of material. Simultaneously, grinding creates exceptional surface finishes.

Achieving high precision and surface roughness is grinding's specialty. So the fact is when tolerances get really tight, grinding becomes necessary. This point is noticeable - ground shafts perform better and last longer.

EDM

So the basic point is that EDM handles difficult situations. The process uses electrical sparks to remove material. You know, this technique works on any conductive material regardless of hardness.

Applications for intricate or hard materials make EDM valuable. CNC machining shops use EDM when conventional methods won't work. Why does it matter? Some shaft geometries are impossible to create any other way.

This point is important - material selection affects everything else. You see, the wrong material choice can make even perfect machining worthless. One should understand the application requirements.

In simple words, materials determine what's possible. You will see that shaft materials must handle specific loads, environments, and operating conditions. So the basic point is matching material properties to application needs. Customers give importance to the final results, so material selection can't be an afterthought.

Well, steel and steel alloys are the workhorses of shaft making. Carbon steel gives good strength for a fair price. Corrosion resistance is further enhanced with stainless steel. CNC machining shops will carry all kinds of steel alloys because they’re extremely versatile.

This is clearly the case - aluminum is unmatched in terms of strength-to-weight ratios. The problem was that for aerospace uses, you often need aluminum shafts. At the same time, aluminum machines well and has a decent surface finish.

Of course, titanium is a high quality material. The tensile strength is fantastic, and so is the corrosion resistance. Well, the next is to think about price - titanium is costly, but occasionally, needs must!

CNC metal parts suppliers sometimes use exotic materials. You can call it the greatest sin to assume that, through all the standard material, you can work. Some uses require special metal alloys with exceptional properties.

Application-specific requirements determine the selection of materials. Every little bit matters in choosing materials. You see, environmental factors, loading conditions, and cost make a difference.

So, what exactly is precision engineering in shaft production? In simple words, it means making parts exactly as designed. You see, precision machined shafts isn't just about tight tolerances. It's about consistency and reliability.

This point is important - tolerancing defines acceptable variation. Engineers know that proper tolerancing balances function with manufacturability. You will see tolerance specifications on every quality shaft drawing.

Why does it matter? Customers give importance to the final results, and parts that don't fit cause major problems. CNC machining shops must understand tolerance to quote jobs accurately.

Machine rigidity makes a huge difference. You know, flexible machines can't hold tight tolerances. Tooling quality affects every cut. So the basic point is that precision requires attention to every detail.

Environmental control matters more than people realize. You see, temperature changes affect both machines and workpieces. This point is noticeable - the best CNC machining shops control their environments carefully.

Start somewhere with good planning. Have patience with the setup process. Stay focused during machining operations. Look within the process for improvement opportunities. Everything counts when pursuing precision.

CNC machinists develop techniques through experience. Simultaneously, they learn from each job. Precision takes practice to master.

You see, surface finishing is where shafts get their final characteristics. In simple words, raw machined surfaces rarely meet application requirements. This point is important - surface finish affects function, not just appearance.

So the basic point is that surface finish influences performance. You know, rough surfaces wear faster and create more friction. For example, proper surface finishing extends component life dramatically.

Polishing

This creates smooth, reflective surfaces. You will see polished shafts in high-performance applications. CNC machining shops often polish critical bearing surfaces.

Honing

The next thing is understanding honing's unique capabilities. The process creates controlled surface textures. It is the most common fault to overlook honing for specific applications.

Lapping

It is obvious that lapping achieves incredible precision. The process removes microscopic amounts of material. Simultaneously, it creates exceptionally flat surfaces.

Coatings

Chrome plating adds hardness and corrosion resistance. Anodizing protects aluminum surfaces. CNC metal parts manufacturers coordinate with finishing specialists for coatings.

Heat Treatments

Hardening increases surface durability. Tempering balances hardness with toughness. You see, heat treatment often follows machining to achieve final properties.

This point is important - quality control makes the difference between success and failure. You know, producing precision machined shafts without proper inspection will lead you nowhere. If you catch the problems early, it saves time and money.

In simple words, quality control ensures parts meet specifications. You see, shaft failures can be catastrophic. So the basic point is preventing problems before they occur. Customers give importance to the final results, so quality can't be optional.

In-Process Inspection

Start somewhere by checking the first piece. Notice things during machining that might indicate problems. CNC machining shops incorporate different gauges and tools to produce parts.

Post-Machining Inspection

The next thing is a thorough final inspection. You will see coordinate measuring machines (CMM) used for complex geometries. Micrometers check diameter specifications. Similarly, you should know that profilometers measure surface roughness.

Statistical Process Control

This point is noticeable - SPC identifies trends before they become problems. Another important thing is that tracking data will help you improve processes continuously. CNC machinists use SPC to maintain consistency.

Industry Standards are Important

It is definitely obvious that standards exist for good reasons. Everything counts when following specifications. Engineers know that standards prevent confusion and ensure compatibility.

You see, good shaft design makes manufacturing easier and more reliable. In simple words, design decisions affect every aspect of production. This point is important - design and manufacturing must work together.

So the basic point is understanding load paths and stress concentrations. You know, shafts must transmit loads without failure. You should keep in mind that proper design considers all operating conditions.

Start somewhere with understanding what the material can do. Have patience when selecting materials - the choice affects everything else.

You will see that loads determine shaft size and material. Static loads differ from dynamic loads. Simultaneously, consider both normal and emergency loading conditions.

This point is noticeable - the environment affects material selection. Corrosive environments require special materials or coatings. Temperature extremes change material properties.

The next thing to consider is how shafts fit into assemblies. Everything counts in assembly design. You can say it is the most common fault to design shafts without considering assembly.

Stay focused on balancing performance with cost. Look within the design for optimization opportunities. CNC metal parts manufacturers can suggest cost-saving alternatives.

You see, automotive applications demand incredible reliability. In simple words, automotive shafts must perform flawlessly for years. This point is important - automotive failures can be dangerous.

Transmission systems use numerous shaft types. You know, gear shafts, shift shafts, and output shafts all require precision manufacturing. CNC machining shops specialize in automotive work because volumes are high and tolerances are tight.

So the basic point is that aerospace demands the highest standards. Turbine shafts operate under extreme conditions. It is obvious that failure isn't an option in aerospace applications.

Actuator shafts control flight surfaces. You will see incredible precision requirements in these components.

You know what, CNC machining has transformed shaft manufacturing completely. From simple turned parts to complex multi-feature components, the capabilities are pretty awesome. Precision, materials, and processes must work together perfectly.

Do you need precision CNC shaft machining services? Apex Rapid delivers custom shaft manufacturing with rapid turnaround time. You can contact our team to get a free online quote for custom parts.