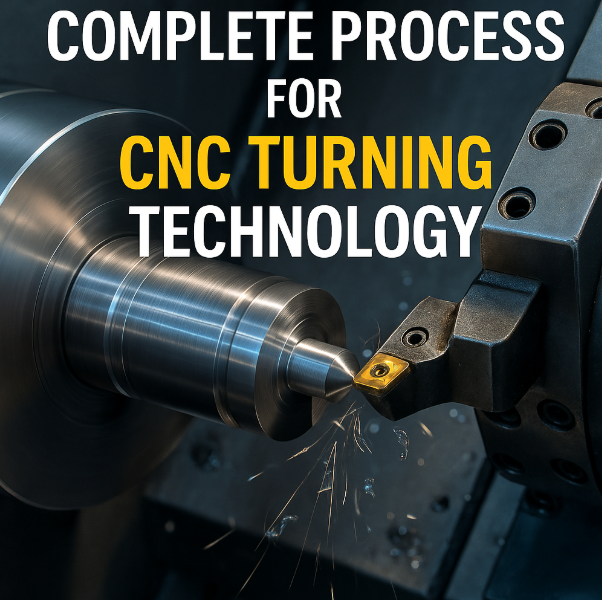

CNC Turning Technology has become important for modern manufacturing because it can make very accurate cylindrical parts. CNC turning is a vital process of high importance for utilization in all industries—from automotive components to aerospace hardware to medical devices. Production has been revolutionized due to the annual lathes to computer-controlled turning machines. It happens with the increase in accuracy, repeatability, and speed. Besides this, we will describe CNC turning technology in detail in this article, what it is, how it functions, processes, materials involved, types of operations, advantages, and limitations.

CNC (Computer Numerical Control) subtractive machining process works when a cutting tool helps remove material from a rotating workpiece. It can make cylindrical or conical shapes. Computer programs are used to automate CNC turning operations. In the actual process, a cutting tool is fed into the rotating workpiece, which is stuck in a chuck and rotated at a very high speed. It moves in one or more axes to shape the workpiece into desired dimensions and geometry.

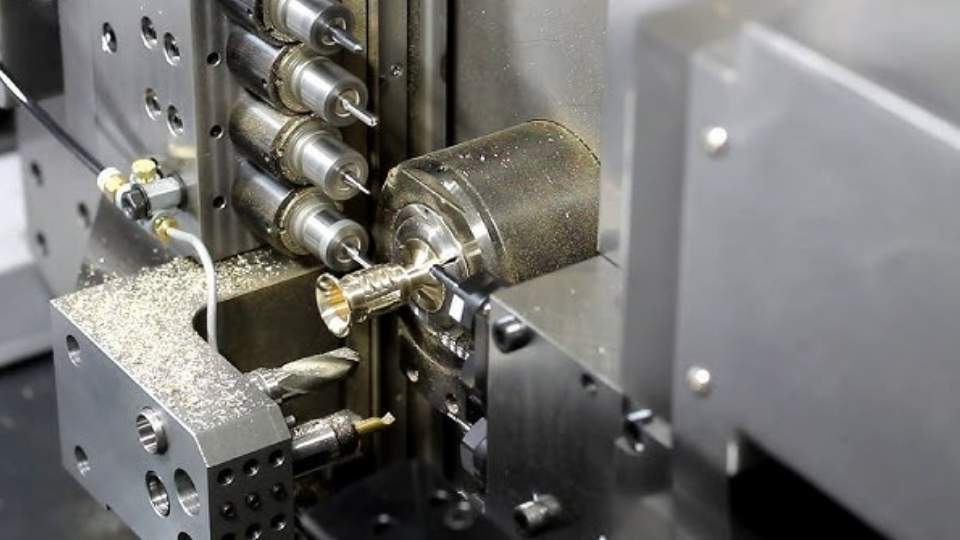

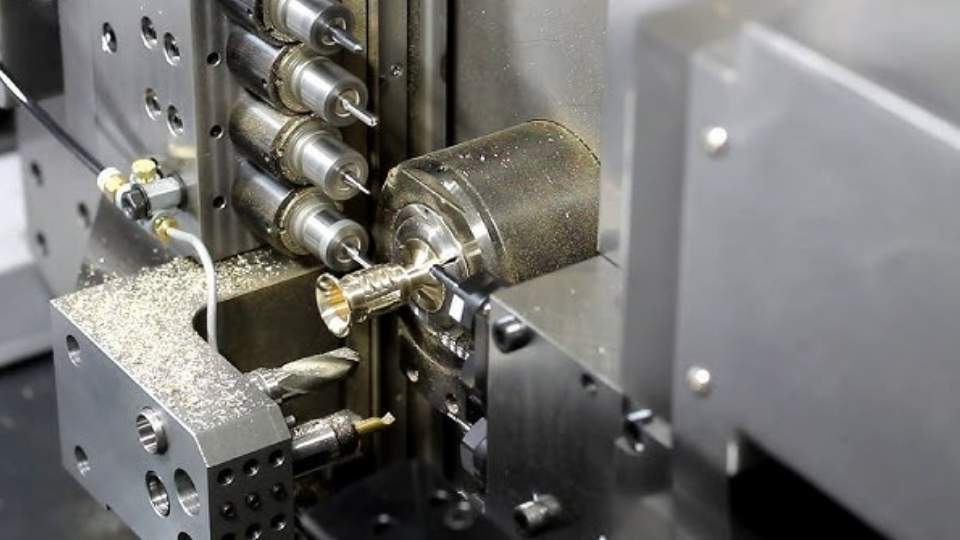

We can attain high precision for creating symmetrical parts like shafts, bolts, bushings, fittings, etc. Lathe or turning center-based CNC turning is the most common type of action executed and can include additional features (live tool and automatic tool changer, etc.).

Turning is a vastly systematic and highly controlled technique for cutting and finishing parts by rotating a workpiece against a cutting tool. The theoretical development of this process involves several critical stages that contribute to achieving better accuracy and efficiency.

Design of a component for the CNC turning is the first step. How CAD (Computer Aided Design) software works is that engineers and designers use it to create precise digital blueprints for the part. Different CAD models can help us get every dimensional detail required for production. After that, its design is converted to CAM (Computer Aided Manufacturing) software that will generate a G code file. THE CNC machine must be programmed using a standard programming language known as the G-code. This GCode tells the machine where it should move, which cuts it should make, what speed, and how deep it should cut. It makes sure the machine can read how the design should be done with absolute precision.

Beginning here is a CNC lathe or turning center, set up the CNC lathe or turning center, and then prepare the G-code. The workpiece — often a cylindrical bar of raw material such as metal or plastic — is mounted on the machine’s (spindle) using fixtures such as chucks, collets, face plate, etc. After that, the tool turret or tool post is loaded with the proper cutting tool. Operators input and check machining parameters, i.e., spindle speed, feed rate, tool path, and face off the cut. Here, we can check that machine calibration and tool alignment are also checked to guarantee the highest precision during the turning operation.

Whenever everything is set, the machine starts cutting. High-speed shields the workpiece with the cutting tool that moves along certain axes to remove the material to obtain the desired geometry. There are simple facing or complex multi-axis movements for intricate shapes in CNC turning. Therefore, CNC turning is an automated process; the results are consistent and repeatable from unit to unit, even in high-volume production runs. However, such a series of tools may be sequentially used to execute appropriate operations like roughing, finishing, grooving, or threading, depending upon the complexity of the component.

After inspecting the machine parts, ensure proper quality. Here, CMM (coordinated measuring machines) will provide dimensional accuracy. Then, we can test surface finishing to check that it satisfies the specs. Additionally, secondary finishing processes help improve the parts' appearance, performance, or durability. These processes may include deburring, polishing, heat treatment, coating, or threading.

After parts inspection, we wash, label, and package according to customer or project specifications. It is possible to be protected from being damaged in transportation by protective packaging around it. They are sent for assembly either in-house or to the customer. It facilitates moving ready-to-use high-quality components uniquely to the end users.

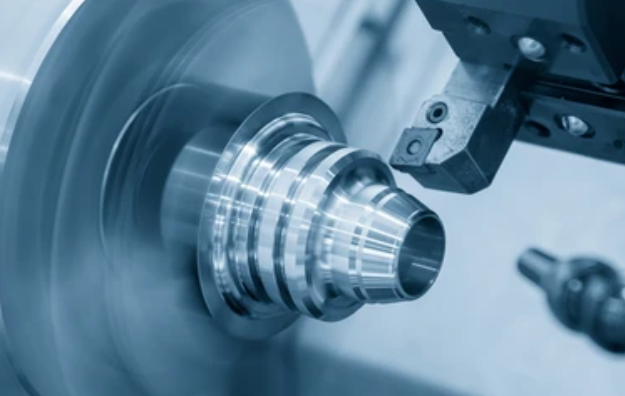

CNC turning procedures are diverse; they are created for the intended shape or dimension, or any required surface texture. Beyond that, the following are the most common types of CNC turning operations.

The first operation normally applied to a new workpiece is facing. To produce a flat surface at the end, another cutting tool moves. It makes an angle with the axis of the workpiece and is perpendicular to the axis of rotation. It leaves a smooth, square face, allowing the next machining stage a nice, precise reference point. Besides this, it creates parts with uniform length in preparation for further cuts.

In straight turning, the workpiece’s diameter is decreased along its length using the cutting tool moving parallel to the axis of rotation to create a smooth cylindrical shape. We can perform it at the rough and finishing stages. It all depends on the material and dimensional tolerances to be satisfied.

This process, taper turning, helps make conical shapes with a gradual increase or decrease in diameter with the growth of the length of the part. The tool’s path is at an angle to the axis of rotation, and it is adjusted to do this. Shafts or pins, or tool holders, have tapered parts.

Grooving is a cutting operation for a narrow line or recess in the outer diameter or internal surface. It is used to form seating areas for rings, for seals, or snap-fits. Very high-speed operations require extremely precise grooving tools.

It’s different from the remaining stock material. Here, we slice the workpiece cleanly as the cutting tool moves radially into it. It helps avoid base tool breakage or part deformation during this final step requires precision and care.

Here, we can observe helical grooves on the outer or inner surface of the workpiece to permit its screwing into or receiving other threaded components. We can perform it with single-point threading tools on the lathe or by using premade dies (or taps). The thread pitch and depth of the CNC machine are accurate and consistent.

Boring enlarges or finishes the inside diameter of the hole. It improves the internal feature dimensional precision and surface finish through a single-point cutting tool. When drilling to ensure tight tolerances on internal diameters, boring is often used afterwards.

CNC turning centers are configured for rotational work, many are equipped with live tooling to accommodate drilling operations. In this case, the drill bit is rotated and moved into the stationary workpiece along the central axis. It permits placing the holes precisely and repetitively.

Knurling is a process where a textured area surface is formed on the workpiece. For aesthetic and functional use it is often present on tool handles, knobs, etc. for mechanical fasteners. It is achieved by rotating the part with the tool pushed against a knurling.

Material choice varies with tool wear, finish, and functionality. Proper material selection brings about efficient machining and part performance at an economical rate. Knowing material behavior also precludes defects and lengthens the life of the tool.

| Category | Materials | Key Traits | Applications |

| Ferrous Metals | Carbon Steel, Stainless Steel, Alloy Steel | Strong, durable, corrosion-resistant (stainless) | Shafts, gears, tools, and auto parts |

| Non-Ferrous Metals | Aluminum, Brass, Copper, Bronze | Lightweight, conductive, easy to machine | Aerospace, fittings, electronics |

| Plastics | Nylon, ABS, PTFE, PEEK | Lightweight, corrosion-resistant, low-friction | Medical, bushings, insulators |

| Hard Metals & Alloys | Titanium, Inconel, Magnesium Alloys | High strength-to-weight, heat/chemical resistance | Aerospace, defense, and high-performance use |

| Composites | Carbon Fiber Reinforced Polymers (CFRP) | Ultra-lightweight and strong | Aerospace, sports equipment |

CNC turning is applicable across numerous industries due to its versatility and precision.

Let’s discuss all the possible benefits and drawbacks of CNC turning in detail;

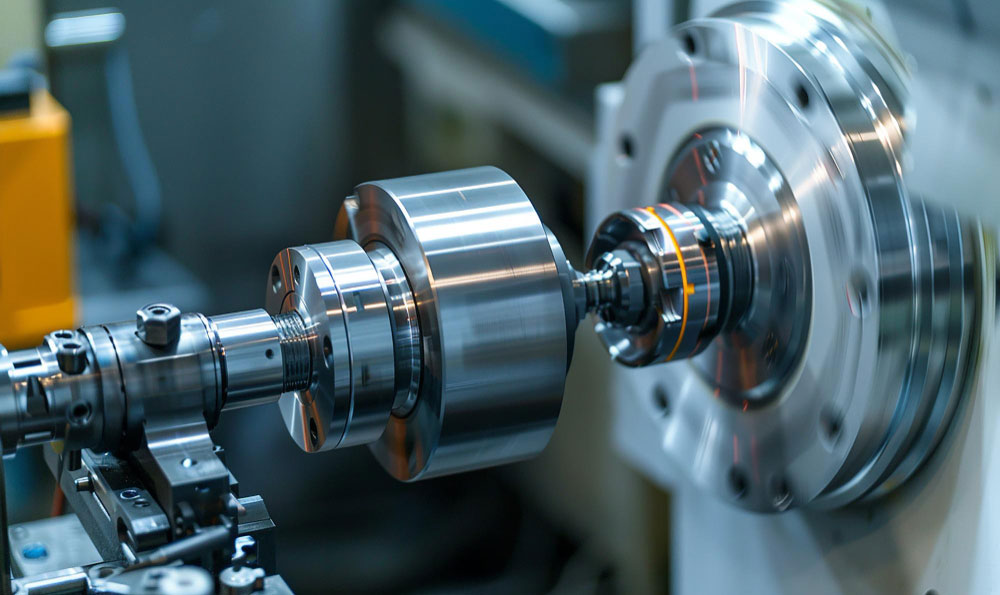

Although both machines perform turning tasks, CNC lathes perform the simpler jobs while CNC turning centers feature multi-axis movement and live tooling for the more complex parts and greater efficiency.

Production needs, part complexity, and budget will all determine the. This means that manufacturers know their differences and can maximize output and streamline their operations. Here is a brief table for highlighting the difference between CNC turning and CNC lathes;

| Feature | CNC Lathes | CNC Turning Centers |

| Basic Definition | Simplified CNC machines are primarily for turning operations | Advanced machines capable of turning plus milling, and drilling |

| Axis Configuration | Typically 2-axis (X and Z) | Multi-axis (often 3, 4, or 5-axis) |

| Tool Capacity | Fewer tool positions, often manual tool change | Automated tool changers with multiple tools |

| Live Tooling Support | Rare or not supported | Common – allows milling, tapping, and cross-drilling |

| Automation Level | Lower – more operator involvement | Higher – supports automatic loading/unloading, tool change |

| Complex Part Machining | Limited to simple geometries | Capable of complex, multi-operation machining in one setup |

| Cost | Lower initial and operational cost | Higher investment but increased productivity |

| Ideal Use | Basic turning tasks, prototyping, and small production runs | High-volume production, complex, and multi-operation parts |

CNC turning is a vital part of the whole manufacturing ecosystem to achieve cylindrical components production efficiently and precisely throughout various industries. With CNC turning continuing to grow from its foundational principles to advanced multi-axis turning centers, capability increases and integration continue.

A competent understanding of the processes, materials, and applications of CNC turning enables manufacturers to decide what they need for CNC turning machines. They can decide how they should use those to optimize the production workflow. With technological progress, CNC turning will still be an integral part of automated precision machinery.

1. Differentiate between CNC turning vs. CNC milling?

CNC turning turns the workpiece, leaving the cutting tool stationary, and is best for turned cylindrical parts. On the contrary, CNC milling moves the cutting tool to remove material. Here, the workpiece is stationary, which is good for workpieces with more complicated, noncylindrical shapes.

2. Can CNC turning be used for plastic material?

Indeed, CNC turning is appropriate for many plastics such as nylon, PTFE, and ABS. Industries that need lightweight and corrosion-resistant materials in their parts often use these materials.

3. Which common industries can take advantage of the CNC turning?

Automotive, aerospace, medical, oil and gas, and electronic industries widely use CNC turning for components such as shafts, fittings, and implants.

4. How accurate is CNC turning?

In the case of CNC turning machines, tolerances can be as small as plus or minus 0.001 inches plus or minus 0.0254 mm, depending on the material and the tool used.

5. What is the life tooling for CNC turning centers?

CNC turning centers equipped with live tooling can add additional operations like drilling or milling without unloading the piece, and increase efficiency and accuracy.

6. Is CNC turning a good choice for high-volume production?

CNC turning is highly scalable, can be used to produce large quantities of precision parts efficiently, and this is certainly due to the advent of the advanced turning centers, which possess automation features.