Automotive parts need to be very precise and work reliably. A single worn part can stop an entire assembly line. That's when precision machining comes into play.

CNC machining makes parts for engines, transmissions, brake systems, and custom brackets. These parts can take a lot of heat, pressure, and vibration all the time. They have to fit perfectly and last for thousands of miles.

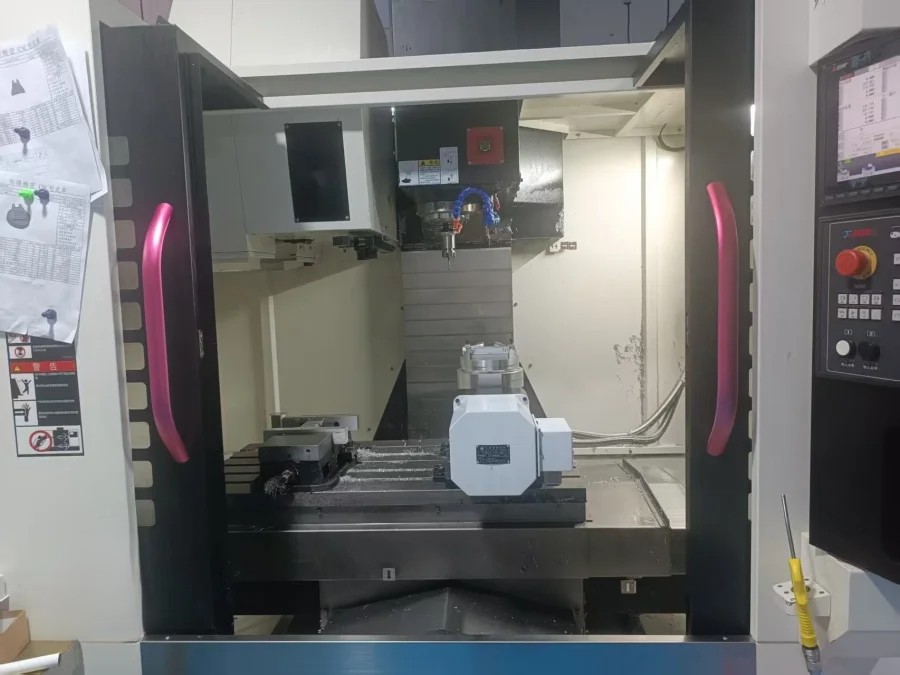

Multi-axis CNC machines are important for making cars today. These can cut complicated shapes out of aluminium, steel, and special alloys. To make sure everything fits and works right, tolerances are kept within microns.

Machined parts meet strict automotive standards, so you can use them to make prototypes or run production lines. This guide talks about the tools, methods, and quality standards for machining cars. You'll find out what makes these parts different and why it's important to be precise when driving.

Automotive Part Machining

Parts for cars have to deal with tough conditions. Heat cycles cause engine blocks to grow and shrink. Under load, the gears in the gearbox mesh thousands of times a minute. Brake rotors can stop at high temperatures over and over again.

There is a reason why tolerances need to be tight. A 0.1mm mistake in a bracket doesn't matter. That same mistake in a bearing seat makes things wobble and fail too soon. Automotive parts need to be accurate to within ±0.02mm because loose fits can cause noise, vibration, and early wear.

The job determines what materials to use. Aluminium 6061 is strong enough for engine housings but light enough to save fuel. Driveshafts can twist without breaking because they are made of steel 4140. Stainless 304 doesn't rust when it comes into contact with road salt and exhaust gases.

The way a part looks affects how it works. A piston bore that is rough increases friction, which lowers horsepower and burns more oil. Compression is done right, and leaks are stopped by smooth valve seats.

Quality standards keep people and equipment safe. A broken brake part could kill someone. If a gearbox part is weak, it can leave cars stuck. Suppliers have strict rules for inspections and keep records of every production batch so they can be traced.

High volume shows problems with consistency. Part one might be a perfect fit. Part 1,000 drifts out of spec as tools wear. During runs, machinists keep an eye on dimensions and change tool offsets before parts fail inspection.

Custom Automotive Parts

Automotive manufacturing needs hundreds of different machined components. Some parts are visible, others work hidden inside assemblies. Each requires specific machining approaches based on function and operating conditions.

We make parts for engines, transmissions, brakes, and chassis assemblies. These parts can be as simple as brackets or as complicated as housings with many features. Knowing what gets machined helps you understand why accuracy is important.

Parts of an engine work in very harsh conditions. Cylinder heads seal the combustion chambers and direct the coolant. To stop oil leaks and valve wear, valve guides need to stay round even when they are hot all the time.

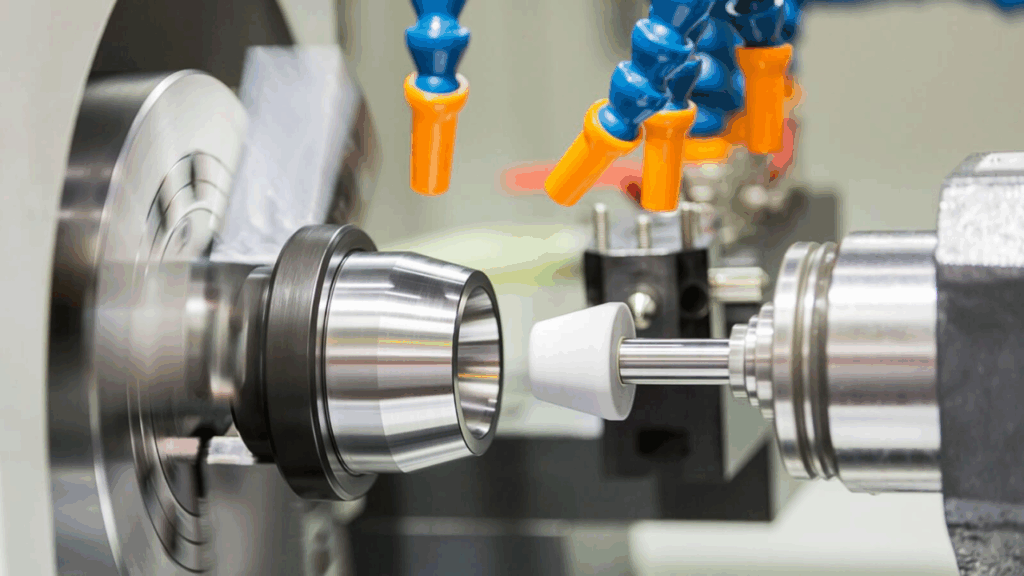

We use machines to make aluminum engine blocks with exact bore sizes. The walls of the cylinder need to be the same size and smooth. This makes sure that the piston rings seal well and the compression stays high.

CNC machining is used on timing chain guides, oil pump housings, and intake manifolds. Every part has important sealing surfaces and holes for mounting. Gaskets need to be evenly compressed, so bolt holes need to be spaced correctly.

Harmonic balancers and crankshaft pulleys need to be perfectly concentric. Any imbalance at high RPM causes vibration that hurts bearings. We keep the runout on these rotating parts below 0.03mm.

Transmission parts move power through gears that mesh and splines that slide. During the life of a vehicle, these parts go through millions of engagement cycles.

Before cutting the teeth, the gear blanks are machined. Face runout and bore concentricity need to be very close. Poor alignment makes the teeth touch unevenly, which leads to early failure.

We use machines to make shift forks, selector shafts, and synchronizer hubs. For smooth gear engagement, these parts need exact slots and grooves. A smooth finish on sliding surfaces stops wear and binding.

Bearings and seals are held in place by transmission housings. The alignment of the bore between the bearing pockets affects how the shaft turns. We machine these features in one setup to make sure they stay in the right place.

Thousands of times, brake parts turn kinetic energy into heat. It is important to machine calipers, mounting brackets, and backing plates very carefully.

Pistons inside caliper bodies push brake pads. The inside of the piston bores must be smooth and round. Seals break and fluids leak when surfaces are rough.

We make brake rotor hats that hold rotors to wheel hubs with bolts. Flat mounting surfaces stop the rotor from wobbling. The hub pilot diameters keep the rotor in the center so it spins straight.

The holes in the ABS sensor brackets and mounting tabs need to be spaced just right. Sensors need to be the right distance from tone rings. If the ABS is not positioned correctly, it may turn on by mistake, or the system may fail.

Automotive CNC Machined Parts

Sensors, wiring harnesses, and accessories need custom brackets in modern cars. These parts look simple, but they need holes that are close together and flat.

Engine mount brackets move torque from the engine to the frame. We make the mounting faces flat and drill the bolt holes so they are straight. Holes that are angled make clamping uneven and put stress on certain areas.

Sensor brackets keep parts at certain angles and distances. A misaligned oxygen sensor gives false readings and turns on the check engine light. Even on small brackets, the accuracy of the position is important.

We also make standoffs, bushings, and spacers. These keep moving parts from getting too close to each other. Thickness tolerances make sure that the gaps are the right size so that there is no rubbing or too much play.

The material you choose affects how well car parts work when they are under stress. The wrong material breaks down quickly. The right one lasts as long as the car does.

Auto manufacturers choose materials based on how much they weigh, how strong they are, how well they can handle heat, and how much they cost. The way something is machined also matters. Some materials cut cleanly, while others quickly wear out tools or need special techniques.

We work with stainless steel, aluminum alloys, and different grades of steel. Each material works best in certain automotive situations because of its unique properties.

Aluminum Auto Car Parts

Aluminum makes cars lighter without making them weaker. Every kilogram you save makes the car handle better and use less gas. That's why aluminum is used in so many modern cars.

The most common alloy for machining is aluminum 6061. It cuts cleanly even at high speeds and keeps tight tolerances. We use it for parts like engine brackets, transmission housings, and suspension.

This alloy can handle moderate stress well. After being heated, the tensile strength goes up to 310 MPa. It naturally resists corrosion by oxidizing its surface. Most uses don't need a coating.

For parts that need to be very strong, aluminum 7075 is better. It is 50% stronger than 6061, but it costs more and takes longer to machine. We use it for brackets that need to hold a lot of weight and parts for racing.

Both alloys lose heat quickly. Aluminum engine parts cool down faster than steel parts. This stops heat from building up, which would hurt performance.

Aluminum machines with carbide tools that are very sharp and turn very fast. When the speeds and feeds are right, chips come out cleanly. Flood coolant keeps cutting tools from getting a built-up edge.

Steel's toughness and resistance to wear and tear are important for gears, shafts, and structural parts.

For parts that need medium strength, we always use steel 1045. It works well with machines and responds well to heat treatment. We use it for brackets, gears, and shafts that have to deal with a lot of stress.

When this grade is in its normal state, it has a tensile strength of 570 MPa. Heat treating makes surfaces harder so they can resist wear. It's cheap and easy to find in bar stock.

Steel 4140 can handle even more stress. Chromium and molybdenum are examples of alloy elements that make things stronger. We use 4140 to make heavy-duty brackets, axle parts, and transmission shafts.

4140 gets a tensile strength of 1000 MPa after being heat-treated. It is better at resisting impact and fatigue cracking than regular carbon steels. Parts last longer when they are loaded in cycles.

Steel machines are slower than aluminum ones. At moderate speeds, we use HSS or coated carbide tools. Because cutting forces are higher, rigid setups stop deflection. Coolant controls heat and makes tools last longer.

Stainless Steel Automotive Parts

Stainless steel can handle tough conditions. Exterior hardware, fuel parts, and exhaust systems all need long-lasting corrosion protection.

The standard austenitic grade is stainless steel 304. It doesn't rust when it comes into contact with water, road salt, or most chemicals. We use 304 to make sensor housings, fuel rail parts, and exhaust flanges.

This grade has 18% chromium and 8% nickel in it. When scratched, the chromium makes a passive oxide layer that heals itself. Parts don't rust without painting or plating.

Stainless 316 has molybdenum in it to make it more resistant to chemicals. It works better with car fluids and exhaust gases than 304. We use it for parts of the fuel system and in marine automotive applications.

Cutting tools don't like either grade. If speeds are too slow or tools are dull, work hardening happens. We use sharp tools, feed rates that stay the same, and positive rake angles.

Stainless steel machines work more slowly than steel or aluminum. The biggest problem is the heat buildup. We use tools made for working with stainless steel and a lot of coolant.

Automotive Part Machining

To make accurate parts, you need smart processes and good machines. CNC machines follow programmed paths and do them exactly the same way every time.

You also need the right tools, the right speeds, and to check things often. If you miss these, the parts won't fit.

CNC Machining of Autocar Engine

Parts of cars have features on more than one side. Moving parts from one machine to another messes up alignment. This is fixed by multi-axis machines.

A 4-axis machine cuts while turning the part. You can drill holes at an angle without moving. In one setup, everything stays in line.

5-axis machines move the tool and the table at the same time. This can handle undercuts and hard angles. One setup always beats more than one setup.

Tools that are dull or wrong make bad dimensions. We choose tools based on the material and how much they can handle.

At high speeds, carbide works well with aluminum. Steel tools with a coating last longer. Short tools stop deep cuts from bending.

During production, tools wear out slowly. Check parts often and switch out tools before the dimensions go out of spec.

Before you run the batch, check the first part. This finds setup problems early on.

During production, measure every 25 to 50 pieces. Wear on tools shows up as changes in size. Make changes before parts break. The final inspection makes sure that all the dimensions are correct. Keep records for the requirements of automotive traceability.

When you make a lot of things at once, you run into problems that don't happen when you make a few. It's easy to make five parts. It's hard to make five thousand parts that are all the same.

Tool wear speeds up over long runs. Repeated clamping causes fixtures to wear out. When you're not paying attention, small mistakes can turn into big problems.

Automotive Spare Parts

The first part could be just right. Part 1,000 might not fit the spec at all. Tools get dull over time, and the sizes change.

We keep an eye on important features during production. Count every 50 parts and keep track of the numbers. We change the tool offsets when the dimensions get close to their limits.

Wear on fixtures also affects consistency. Clamps get loose. The locating pins get worn down. A part that is 0.05mm off position causes alignment problems.

We check our fixtures often and replace parts that are worn out. Tight setups make sure that parts stay in the same place for every cut.

Tools don't stop working all of a sudden. They wear out slowly until the dimensions are wrong. The key is to change them before that happens.

We keep track of how many parts each tool cuts. A carbide drill can make 800 holes before the hole gets too big. At 700, change it, and all the parts will still be in spec.

In high-volume work, the cost of tools adds up. But parts that are thrown away cost more. We weigh the tool's life against the quality needs.

Tools for backup are always ready at the machine. If one wears out, switch it out quickly and keep going. In car manufacturing, downtime hurts productivity.

Breakdowns stop the flow of goods. Schedules for cars are tight. If you miss your delivery window, your assembly plants will close.

Preventive maintenance finds problems before they become failures. Regularly, we check the spindle bearings, lubrication systems, and coolant pumps.

The cutting parameters are also important. If you push machines too hard, parts will break down early. For long production runs, use slow speeds and feeds.

We also have spare parts on hand that are used a lot. Bearings, seals, and belts are quickly replaced when they need to be. Quick repairs cut down on downtime.

Customers in the automotive industry want their orders to arrive on time. You pay fines when parts arrive late. If you arrive early, you'll take up space in their warehouse.

We plan production with extra time for inspections and possible rework. When you rush, you make mistakes that take longer to fix.

Talking to customers ahead of time keeps things from being a surprise. Let them know right away if something goes wrong. If you give them a heads-up, they can change their plans.

Need precision automotive components that meet strict tolerances? Apexrapid machines parts that fit perfectly and perform reliably.

Send us your drawings or CAD files today. Our engineering team reviews your specs and provides a fast quote. We handle prototypes and production runs with the same attention to quality.

Our CNC equipment produces engine components, transmission parts, brake system pieces, and custom brackets. We work with aluminum, steel, and stainless steel to match your application requirements.

Contact Apexrapid now to discuss your project. Email your specifications or call our team directly. We'll get your parts into production quickly and delivered on schedule.

Get your instant quote today.