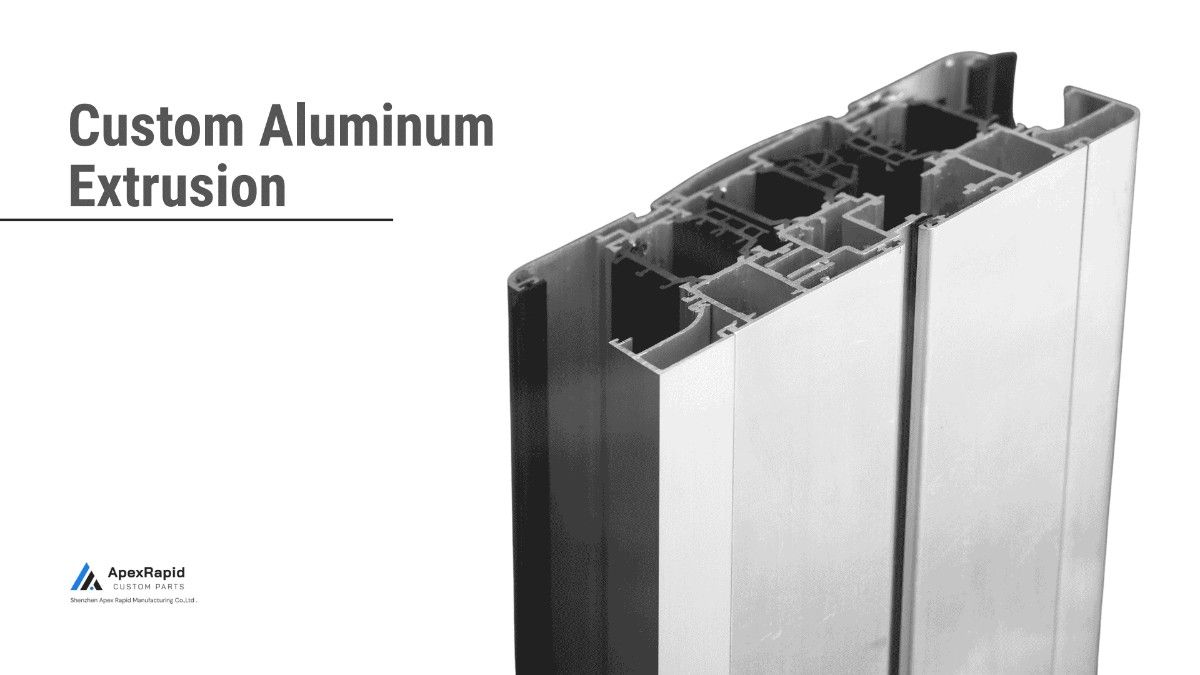

When your project requires exact shapes, standard parts fall short. Custom aluminum extrusions allow you to shape profiles to match your design intent. You can avoid extra machining and reduce time spent on adjustments.

This process pushes heated aluminum through a die with a specific shape. As a result, a continuous profile that matches your exact cross-section is produced. You can include slots, grooves, and mounting tracks in a single step.

Custom profiles allow stronger joints, better alignment, and easier assembly. For example, you can design channels to hold wiring and fasteners without adding extra parts. This saves material and improves the final product’s functionality.

Aluminum is also light, naturally corrosion-resistant, and easy to form into useful shapes. You can apply anodizing and powder coating to further improve appearance and durability. Custom extrusions give you the right shape from the start, with fewer challenges later.

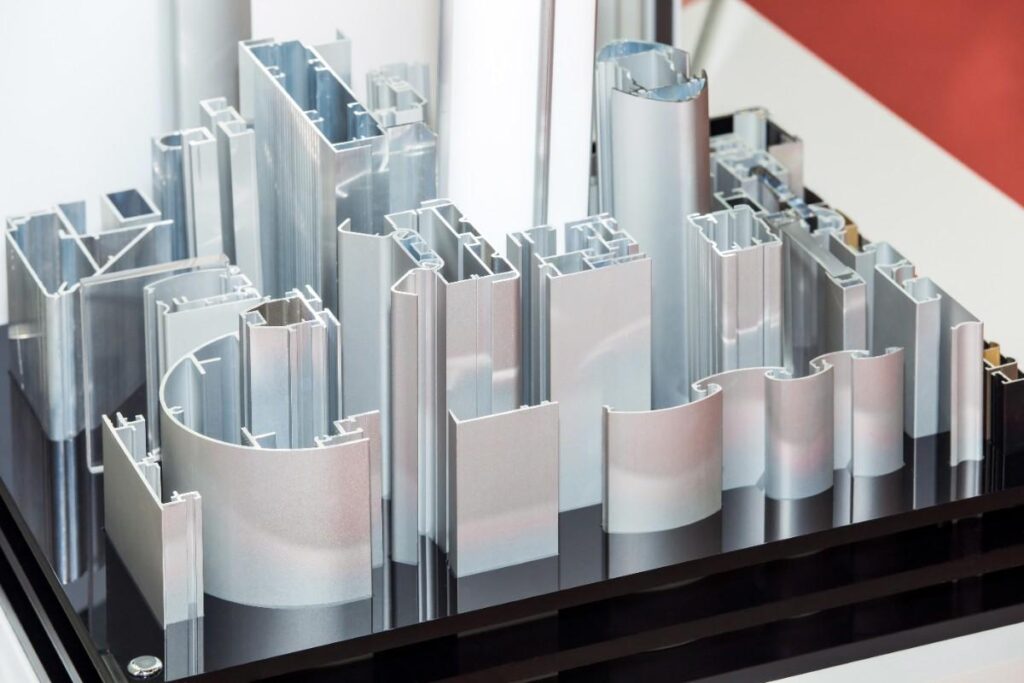

Custom Aluminum Profiles

The process starts when you define your profile’s cross-section. This shape is turned into a die. This die is usually made of hardened steel. The die acts like a mold. It forms the aluminum into your desired shape.

Aluminum billets are heated to a temperature of around 900°F to 925°F. The softened metal is then pushed through the die using hydraulic pressure. As it stays there, it takes on the full form of your custom design.

Once the extrusion cools, it is stretched to correct any twist and distortion. This improves strength and keeps dimensions tight. After that, the profile is cut to length and may go through further treatment.

Designing Aluminum Extrusion Profile

To get the best results, your design must guide manufacturing. Custom aluminum extrusions work best when your profile is optimized from the start.

Make wall parts near each other in thickness in profile. This allows the free flow of aluminum in the die. In the case of asymmetrical walls, you can observe distortion or vulnerability.

As an instance, uneven cooling may take place when a 2mm wall is adjacent to a 6mm rib. That causes accumulation of stress, and your parts may be warped during aging or cutting.

Stress is developed in the process of extrusion and finishing with sharp corners. And by rounding sharp edges that have small radii, you flow better and wear the dies less.

Improvement of materials movement can be achieved by just a 0.5mm radius. It also smoothens and makes a uniform anodizing and powder coating.

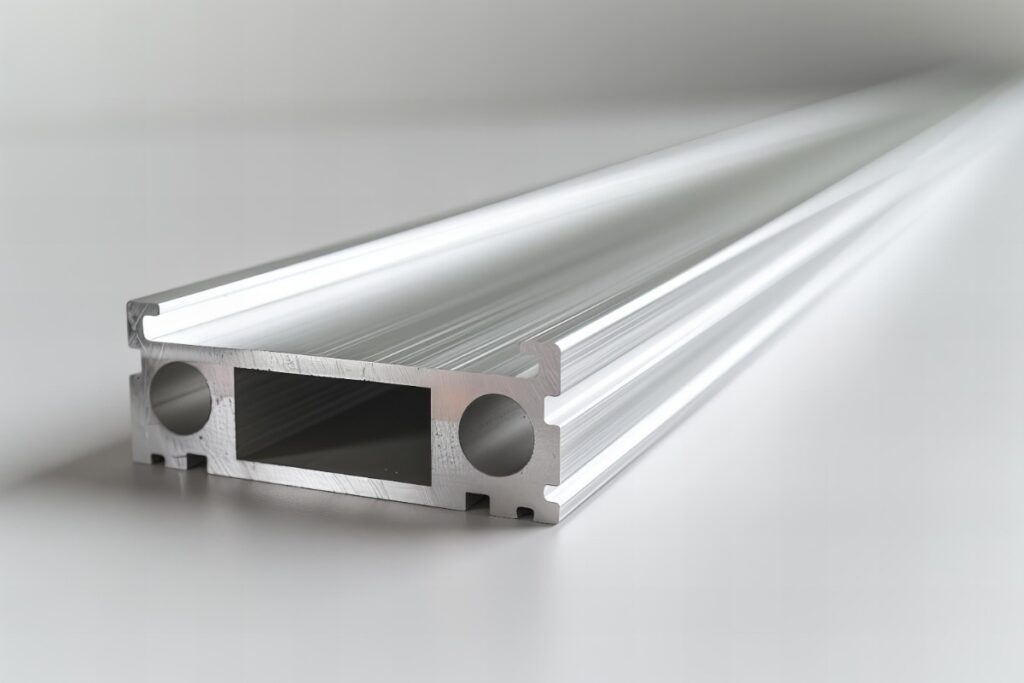

Hollow shapes reduce weight and improve strength without using extra material. Employ them in the routing of wiring. It will help to take up the bulk and to shield internal components.

For example, a square tube with internal guides in which a structure can be placed and cables concealed. That is the combination of usefulness and power in a single sleek form.

Consider your method of parts assembly, alignment, and mounting. The extrusion can be slotted to include slots, screw bosses, snap fits, and notches.

It is even possible to install internal guide rails for sliders and the brackets of sensors. In doing so, the secondary machining is eliminated and the part count decreased.

Custom aluminum extrusions are used where strength, shape, and fit matter. They’re especially valuable in industries where precision meets production volume.

You can add slots in PCBs, air flow vents, and mounting flanges. This is in place to use fewer additional brackets or fasteners.

As an example, one extrusion can be a complete case. It can also have end plate grooves, cable grooves, and switch mounting grooves.

The perfect usage of these profiles is for power supply, control boxes, and sensor housings. They preserve parts and are lightweight, space-saving.

Aluminum Roofing Frame

Machine custom aluminum extrusion frames and supports require meticulous attention and care. It is possible to insert channels to bolts or T-nuts, roof rails, right into the design.

This simplifies reconfiguration by way of not requiring drilling and welding. These features are in use every day with equipment frames, conveyors, and test rigs.

Profile shapes allow low weight and a long range for the vehicle. Custom aluminum can be used in battery trays and structural beams.

Profiles may be in the form of coolant channels, cable guides, and mounting tracks. This minimizes the need for single parts and fasteners.

Every inch and every gram counts in electric vehicles and mobility aids. With custom shapes, you have greater freedom when it comes to design, but at a reduced trade-off.

Aluminum Materials for Custom Profiles

Choosing the right aluminum alloy and surface finish is imperative. It directly influences strength, corrosion resistance, appearance, and machining needs.

You’ll most often work with 6000-series alloys like 6061 or 6063. They combine strength, corrosion resistance, and good extrusion flow.

Surface treatments protect your parts and improve aesthetics. Your choice depends on exposure, wear, and product appearance.

Anodized Aluminum Extrusion Profile

Anodizing creates a hard oxide layer for wear and corrosion resistance. You can choose clear and colored finishes for branding and visibility.

Polished Aluminum Profile

These coating offers thick, durable color options with excellent UV resistance. It’s common for outdoor or high-wear parts.

Brushed Aluminum Extruded Profile

Brushing improves surface texture before anodizing. These are ideal when parts will be visible to users or customers.

Each finish adds function and enhances product quality. You can combine finishes or use selective treatments for multi-purpose designs.

Precision matters when your parts must fit perfectly. Understanding tolerances and how quality is controlled helps avoid production issues.

Aluminum Extrusion Tolerance

Particularly, extruded parts are not machined; hence, they are subjected to extrusion tolerances. These are dependent on size, thickness of the walls, and complexity of the wall profile.

The dimensions tolerant to fit any given profile are between 0.25 and 5 mm, depending on the profile design. Thicker waists and closer tolerances will likely need post-processing such as CNC machining.

To sustain critical fits, you will be able to shape broader machining regions. As an example, a slot can be extruded having a slightly smaller size, and it can be milled with the required accuracy.

Parts can wriggle or bend a little after being extruded as they cool off. In order to straighten this, stretching and straightening of extrusions are done as required.

Long profiles need to be examined for bowing, and this is particularly so when they are attached to flat surfaces. Profile stability is enhanced when stretching and slow cooling are done.

Another way to minimize warping is to balance the thicknesses of the walls and avoid sharp changes. The shape with a proportional size is cooled evenly and is kept in shape.

The process of quality control performs its first checks by validating the die and performing material testing. The operator pays attention to the temperature, speed, and flow when extruding.

The inspection of profiles is made with calipers, gauges, and tailor-made fixtures after production. In the case of high-dimensional accuracy required, dimensions may be checked using 3D scanning or CMMs.

All of the steps will make your extrusions fit with design intent and reliability. Where assembly of parts is to be done subsequently, QC that is tight will prevent mismatch or rework.

Starting a custom extrusion project requires planning and technical input. The more clearly you define your needs, the better the final result.

To get started, determine the profile performance. Does it need to support a load, even a circuit board, or does it need to permit airflow? Outline the cross-section with all the functional features in it.

As an example, when you are designing a light housing, make it with channels to run wires, brackets to have it mounted, and slots to place diffusers. It is better not to begin with some general shape and then add details.

As far as possible, keep the thickness of the walls uniform. This prevents a cooling problem and enhances strength as well as the likelihood of distortion following extrusion.

Choose the right alloy depending on your application. In the case of lightweight frames, 6063 is an optimum choice. It is easy to form and has a smooth surface. In structural components, 6061 makes it stronger.

Consider corrosion, weight, thermal requirements, and finish requirements. In the case where your part would require welding or any post-machining, ensure that the alloy you have selected will facilitate such processes well.

It’s not true that everything comes right off the press. In case of anodizing, drill holes and no tight spaces where chemicals could be trapped. On machined surfaces, keep more material in highly precise regions.

Discuss with your supplier where the extrusion ends and machining will start. That means implementing just enough tolerances to save on time and expenditure.

A good extrusion partner will hone your design, choose the materials, and create the best dies. Select a provider who knows thermal behavior, the straightening process, and the control of finishing.

Good manufacturers provide input on the design, address minor defects at the early stages, and avoid tolerance stack-up. They are also conversant in extending the life of the dies and ensuring that your cost per part is not increased.

Performance, cost, and delivery rely upon the right selection of the supplier. Not all the shops are custom-profile or tight-tolerance shops.

Questions to ask are whether they have created similar profiles to yours before. The supplier that actually has experience will take note of flow problems, material behavior, and the complexity of shape.

Ask about the previous examples or references of the parts that have inbuilt features such as heat sinks, snap fits, or slots. It is a red flag in case they cannot demonstrate similar work.

A skilled crew will also be able to make your design better. The flow changes or die stress relief will be recommended by them, saving you money in manufacturing.

Not every supplier can have the capability to deal with the same profile sizes and complexity. The press tonnage should be asked for, and also support solid and hollow profiles.

A good vendor would have the manufacturing of dies in-house or would use a die shop. This means revisions will be faster, and it will control tolerances better.

In addition, enquire about their extrusion capabilities, whether they can extrude long lengths that are not distorted and tight radius shapes. Ensure that their equipment can go together with your design requirements.

In case anodizing, powder coating, and CNC machining are needed on your part, make sure that the supplier can provide all these services in one place. The fact that the in-house finishing is complete saves on accumulation and handling risks.

Find out how they perform surface prep and the thickness of their finish, and the quality. These details are of importance to visible parts or those used in critical assemblies.

Also, determine that they can offer cutting, drilling, and tapping. Fit is improved, and the freight time is also reduced by obtaining all the services in one location.

You should get a good supplier who has a clear definition of what the tolerance is capable of achieving. In the case of custom profiles, it is the extrusion tolerances and the accuracy after processing.

Enquire about their object of inspection of parts, such as inspection with gauges, CMMs, and visual inspection. Are they able to give a sample run or the first article inspection report?

You need a supplier capable of early identification of problems and not after hundreds of parts are produced.

Lastly, you should inquire about delivery schedules and the responsiveness of support. Its custom-made profiles usually involve design check-up, die making, and material preparation.

Quick responding suppliers who provide you with schedules that match reality and regularly inform you of what is happening during the production are more reliable.

Try to find a team that perceives you not as an order, but as a partner. The relationship will facilitate problem-solving, and when it is necessary, scaling up will be done.

While extrusion is efficient, some designs and volumes may demand alternatives. It usually depends on your shape, material use, and finish needs.

When your part includes deep pockets and varying wall thickness, CNC machining works well. It removes material from a solid aluminum block using computer-controlled tools.

This method gives you complete shape and design freedom. You can change dimensions easily without needing a new die.

For low-volume production and prototypes, machining avoids the tooling cost. But it’s slower and produces more material waste than extrusion.

Die Cast Aluminum Profiles

Die casting is ideal when your profile needs tight features and curved walls. Molten aluminum is injected into a steel mold under high pressure.

This gives you parts with integrated ribs, bosses, and smooth surfaces. It’s comparatively faster than machining once the molds are ready. However, the upfront tooling costs are high.

Die casting also suits small parts and multi-cavity production runs. You can obtain excellent detail, though with slightly lower material strength than extrusions.

Bending Aluminum Profiles

For simple profiles with flat walls or bends, sheet metal forming can be more efficient. You laser cut, bend, and stamp aluminum sheets into shape.

It’s a good choice for enclosures, brackets, or covers with uniform thickness. You avoid extrusion altogether and save time on setup.

However, sheet metal lacks the structural strength of extruded shapes. It’s better for lightweight components than load-bearing ones.

3D Printing Aluminum Extruded Profiles

Aluminum 3D printing (like DMLS) allows internal channels and complex features. You can shape organic designs and lattice structures impossible by extrusion.

However, it's slow and expensive for mass production. It is perfect for testing and small-batch production runs. You can skip dies, and parts are built directly from CAD files.

This article covered key points about custom aluminum profiles:

Use this guide to choose the right process for your project. Always match your design, budget, and volume to the best method.