Electrical Discharge Machining (EDM) is an exception in the global manufacturing world, where processes such as milling and turning are founded on the application of mechanical forces to cut the material.

Controlled discharges are employed in the removal of electrically conductive material, regardless of the material hardness, a process known colloquially as spark machining, a term commonly applied to spark EDM. It is a unique, contact-free process that has completely revolutionized the machining of complex shapes, generating features of miniature dimensions and processing materials that could only be machined in a cumbersome manner with traditional processes. In this guide, we shall delve deeper into the different sub-sets of EDM, go through its many uses (in high-tech sectors), and the many advantages that EDM provides, transforming it into a precision manufacturing process.

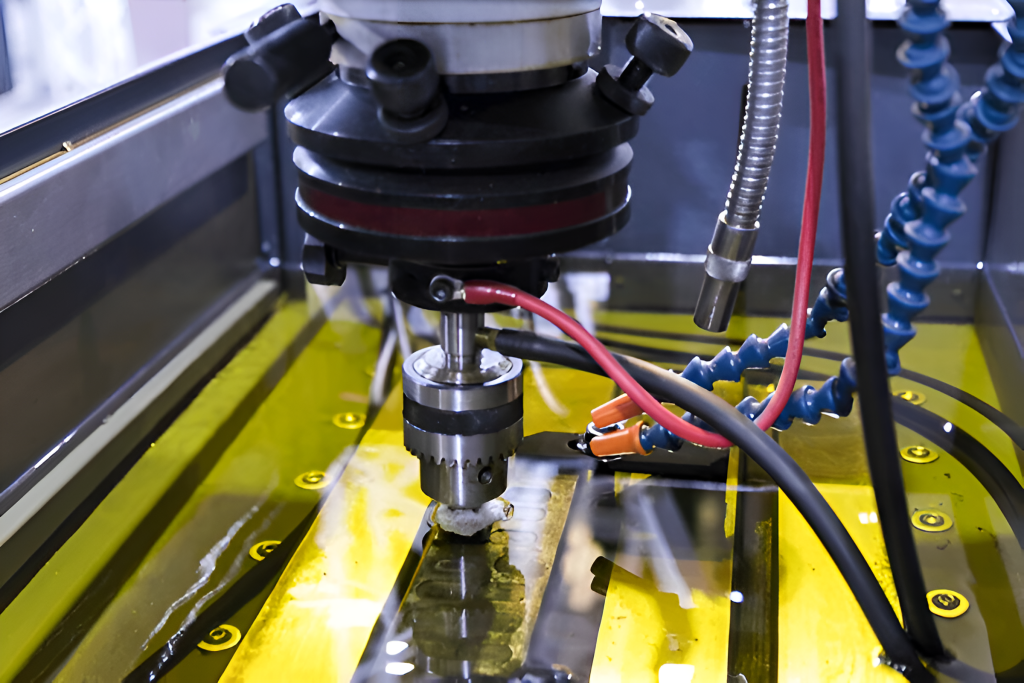

EDM Process Principle EDM stands for an unusual machining process that takes place to remove material from the workpiece with the help of a variety of short and quick electrical discharges (sparks). The workpiece (anode) and the electrode (cutting tool) are dipped in a dielectric fluid, which is normally in the form of a combination of deionized water or oil. When the two are brought close together and a voltage is applied, the dielectric fluid breaks down, allowing a spark to jump the gap.

The spark produces local high temperatures, up to 12,000 °C. This heat melts and partially vaporizes a small amount of the electrode material as well as the workpiece, but the latter is more affected than the former. The dielectric fluid flushes away the molten material, and the same process is repeated thousands to millions of times each second.

In the following, we will be discussing some of the key principles of EDM.

A non-contact process, Electrical Discharge Machining (EDM), implies no physical touching of the tool and the workpiece. It removes mechanical stress, sheet deflection and formation of burr experienced during conventional machining.

Among the main benefits of EDM is the fact that it does not depend on the hardness of the materials to be machined; all that is important is that the workpiece should be electrically conductive.

It is of extreme importance that the dielectric fluid isolates the gap, regulates spark discharges, cools the working area, and cleans off the work by flushing the eroded particles to ensure precision in machining.

This cutting tool is an electrode, made of graphite, copper, or brass. The electrode experiences minimal wear during the process, which ensures high precision in fine and complex machining operations

Some of the various types of EDM Machining are as follows, and we will be going into detail about them.

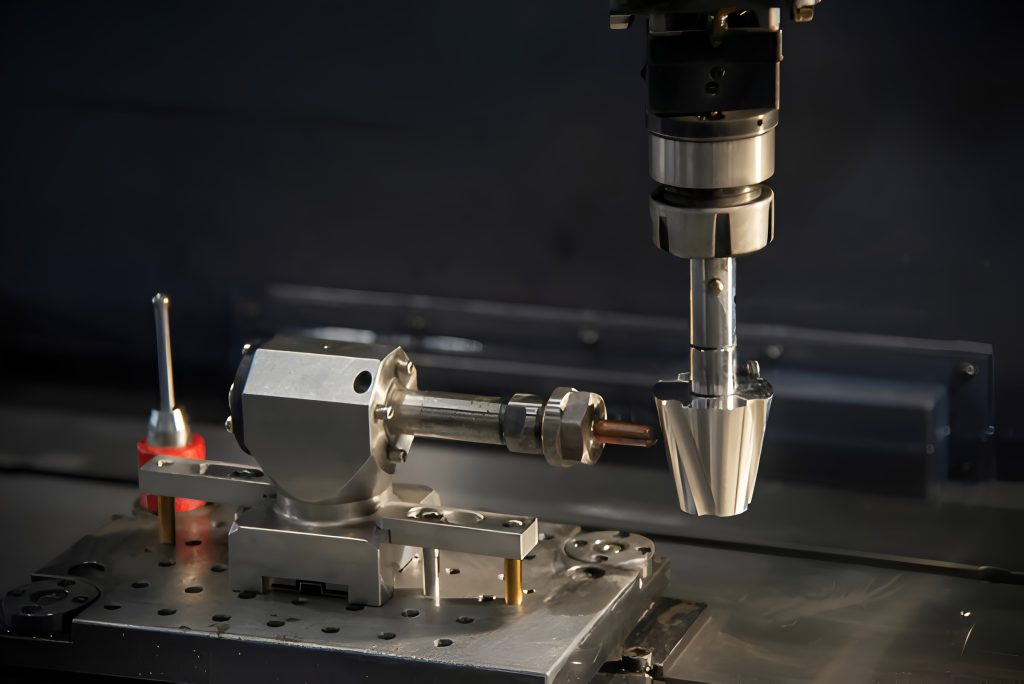

Sinker EDM is among the oldest models of electrical discharge machining. It is mostly used to make complex holes or blind holes in a workpiece. The workpiece is filled with dielectric fluid in which a shaped electrode, usually graphite or copper, is lowered into it. Some sparks digest the material by etching a cavity that is similar to the shape of the electrode.

The mechanism is more similar to a ram immersing into the work, such that 3D complex structures are generated. One does wear the electrode, and sometimes requires different roughing and finishing electrodes. Sinker EDM is best suited for molds, dies, deep ribs, and elaborate aerospace or jewelry parts.

Wire EDM is employed in cutting exact 2D or 3D contours of the conductive materials. The electrode uses a thin piece of brass or copper wire that is continuously supplied by a spool. It traverses the workpiece in a manner like the bandsaw blade through the workpiece immersed in water, and controls the path using upper and lower diamond guides.

Wire EDM offers high precision, close tolerances, and a thin kerf. It can cut up intricate shapes and has stack cutting capabilities on thin sheets. It is often employed in tool and die manufacture, medical equipment, aerospace, and electronics manufacturing due to nearly no tool wear.

Hole Drilling EDM is an application used to drill small deep holes under high aspect ratios. It operates on a rotating hollow tube electrode composed of copper or brass, and a dielectric fluid is flushed through its center to clean up the debris.

The technique is appropriate when drilling hard materials, producing burr free holes. Hole Drilling EDM is commonly used to create cooling slots in turbine blades, fuel injector nozzles, medical instruments, and pilot holes for threading in wire EDM.

The following are some of the applications of Electrical Discharge Machining.

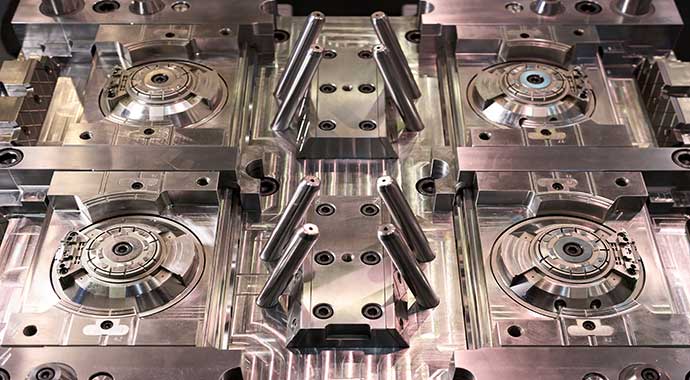

One of the most common uses of EDM is in manufacturing tools and dies, where it is preferred over other techniques due to its capability to produce complex cavities, sharp corners, and fine finishes. EDM is ideal for making molds used in plastic injection molding, die casting, and forging. It also manufactures fine dies and punches to use in stamping.

The aerospace industry also uses EDM to fabricate cooling holes and turbine engine impellers of hard superalloys. EDM is also used to machine fine details in lightweight structural components made from high-strength alloys.

EDM plays a crucial role in producing small, precise surgical instruments and custom implants. EDM is especially effective for machining biocompatible materials used in dental prosthetics, pacemakers, and orthopedic components.

EDM plays a very crucial role in manufacturing gentle and delicate surgical equipment and personal implants. EDM is particularly very useful for machining biocompatible materials in dentistry, implants, pacemakers, and orthopedics, where high temperatures must be avoided.

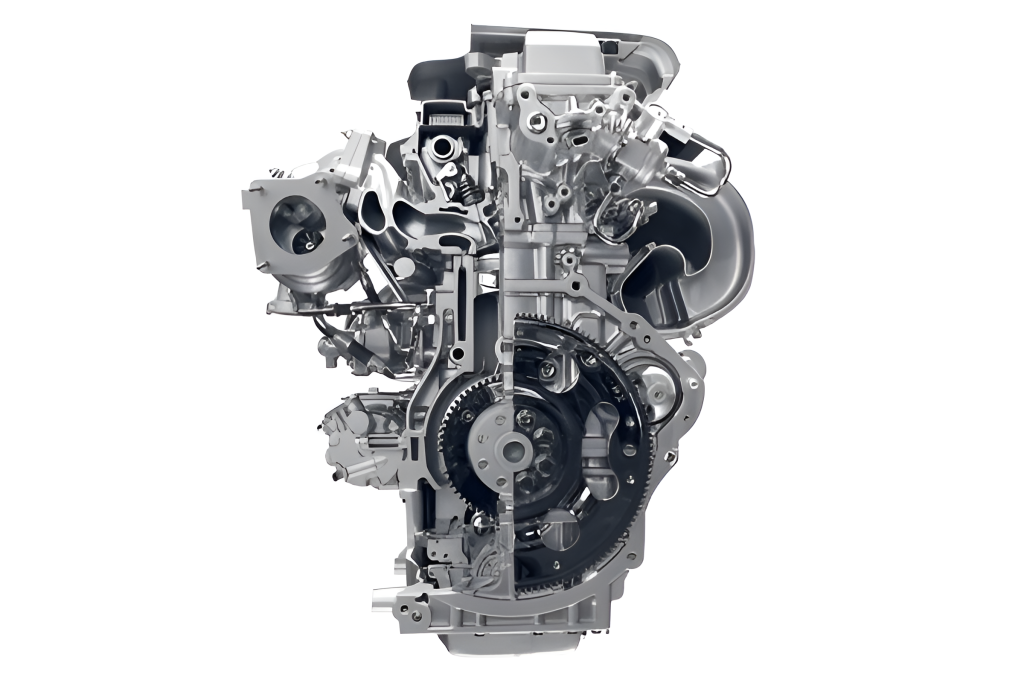

Automotive uses involve the production of fancy engine components such as fuel injectors, nozzles, and valve seats. EDM can also assist in quick prototyping of parts that need tight tolerances and intricate designs in the engineering of motorsport.

EDM is a widely used application in the production of small, elaborate connectors and micro-components in electronics. The accuracy enables it to make complex characteristics necessary in micro-electromechanical systems (MEMS).

EDM is useful for removing broken tools without damaging the workpieces. It is also used when making fine slots and machining hardened parts that would otherwise deform following heat treatment.

The following are some of the pros of Electrical Discharge Machining.

EDM can machine any conductive, hard, or soft material. This suitability is good when dealing with hardened tool steels, titanium, and superalloys. It does not use any mechanical force and does not distort or crack the parts.

EDM can create complex, irregular shapes, internal features, and sharp internal corners. It also fits quite well when making narrow slots and deep holes, which have high aspect ratios that conventional methods strive to achieve.

With the non-contact process, the surfaces are burr-free and thus finishing is reduced. Using the ability of precise control of parameters, EDM could offer mirror-like surfaces, and could provide close hold-tolerances, down to +/-0.0002" in many cases.

In wire EDM, a continuously fed wire is used, so tool geometry remains unaffected by wear. Sinker EDM does involve electrode wear, but modern machines and materials significantly reduce it, resulting in lower tooling costs.

The EDM machines have a very high degree of automation, enabling them to work long hours, especially the Wire EDM machine, which has auto-threading. The process offers exceptional repeatability, creating similar parts within a narrow tolerance.

Since EDM uses no cutting force, it is suitable for thin-walled or fragile parts. The fixturing needs are also easier since they do not have mechanical stress or weight that could alter and affect the workpiece.

The following are some of the key challenges and considerations of Electrical Discharge Machining.

EDM only applies to conductive materials. Plastics, most ceramics, and composites are non-conductive and are unsuitable for this process.

The rate of material removal with EDM is low compared with milling or turning. This may increase the cycle times, particularly when cutting large amounts or deep patterns.

Sinker EDM also drains electrodes over time, resulting in more tooling costs and complexity. It is also possible to leave a recast layer and a heat-affected zone (HAZ), which in critical components may require subsequent processing.

EDM machines and other consumable items, like electrodes and dielectric fluids, are also expensive. It is also important to flush the dielectric fluid to eliminate debris and guarantee good-quality and stable machining.

The wire and spark gap of Wire EDM prevent sharp internal corners. Absolute internal square corners can never be realised, although very tight radii can be obtained.

The following are some of the key practices employed in Electrical Discharge Machining.

The EDM entails high voltages. Always make certain that connections are well secured, guarded properly, and only qualified people are permitted to do maintenance. The use of flammable dielectric fluids poses a high risk to fire safety.

The EDM process releases fumes and vapors, requiring good ventilation and, in some cases, respiratory protection. Dielectric fluids can be irritating, so operators should wear gloves and eye protection and follow all handling guidelines.

The fumes and vapours generated during the EDM process necessitate good ventilation and respiratory protection in some instances. Dielectric fluids are irritating and should be handled using gloves, eye protection, and all handling procedures should be adhered to.

Always avoid the no-go interlocks and do not operate the machine when the covers are off. Even though you have EDM as a non-contact technique, the workpiece should always be secured to avoid any movement or accidents.

Operators should wear ear protection, safety glasses, and prescribed garments. Wear tight-fitting clothes or jewelry that can become tangled in the moving section, even though there is little mechanical movement in EDM.

No person is supposed to work with an EDM machine without an in-depth explanation of using the particular machine. Safe and efficient operation requires understanding the process, controls, and emergency procedures.

EDM (Electrical Discharge Machining) demonstrates how innovative modern manufacturing can be—offering solutions where traditional machining falls short. Its ability to cut any electrically conductive material, regardless of hardness, while achieving complex geometries and high precision without mechanical force, makes it a critical process across industries. From the intricate cavities produced by die-sinking EDM to the ultra-precise cuts of wire EDM and the fast drilling of micro-holes, each EDM method plays a unique role in today’s advanced manufacturing.

While EDM may involve lower cutting speeds and higher setup costs, its unmatched design flexibility, material versatility, and superior surface finish often make it the most cost-effective solution for high-precision components. At ApexRapid, we offer expert EDM machining services to help you realize tight-tolerance, intricate parts with reliability and efficiency.

The following are some of the frequently asked questions regarding Electrical Discharge Machining.

A1: No, EDM can do machining of only electrically conductive materials. These are metals (steel, aluminum, brass, copper, titanium, super alloys), carbides, and certain graphite compounds. EDM can not be used to cut non-conductive materials such as most plastics, ceramics, and wood.

A2: The largest benefit is that EDM can machine very hard and exotic electrically conductive materials (e.g., hardened tool steels, tungsten carbide, Inconel) and is unaffected by the hardness of these materials. In contrast to conventional machining, EDM makes use of no mechanical force, and as such there is no tool wear due to hardness, no mechanical contact stress on the workpiece and no burr generation.

A3: Sinker EDM can produce very sharp internal corners that nearly approach perfection based only on the spark gap and the integrity of the electrode. In Wire EDM, however, some minimum radius can never be exceeded as there will always be a small corner radius during the process, even in the case of a perfectly sharp internal corner, since the wire has a radius (and also the spark gap). Nevertheless, Wire EDM can produce by far a smaller internal radius than that of conventional milling.

A4: Dielectric fluid (it is usually deionized water or special oil) performs several of the most important functions:

A5: In general, not really. EDM material removal rate (MRR) is lower compared to the traditional machining processes, such as milling or turning. Removal of large volumes of material by EDM can be time-consuming, hence costly. It is cost-effective in that it can attain very high levels of precision, complex geometries, and the hard materials of machines, which are difficult or impossible to accomplish with faster processes.