Aluminium is a preferred material choice for early-stage prototyping. You can benefit from its excellent strength-to-weight ratio and machinability. It allows you to build functional parts with production-level geometry.

Aluminium prototypes support structural, thermal, and mechanical testing. You can validate form and fit without switching materials later. This helps speed up development and reduces design risk early.

Aluminium also responds well to machining and sheet forming. You can create parts using CNC cutting, bending, or turning. This makes it ideal for fast, accurate prototype fabrication. Explore more about aluminum prototyping in this guide.

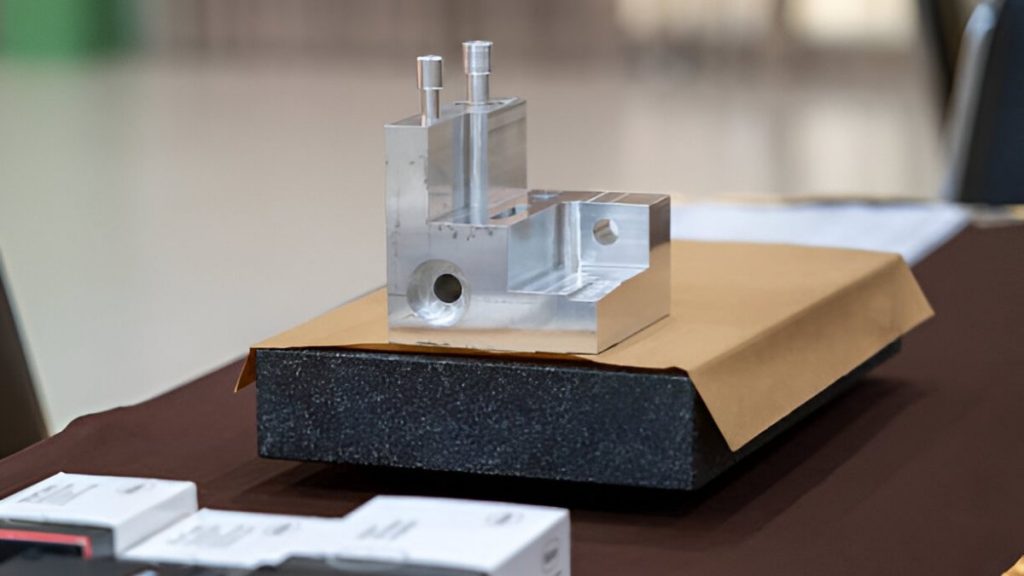

CNC Machined Aluminum Prototype

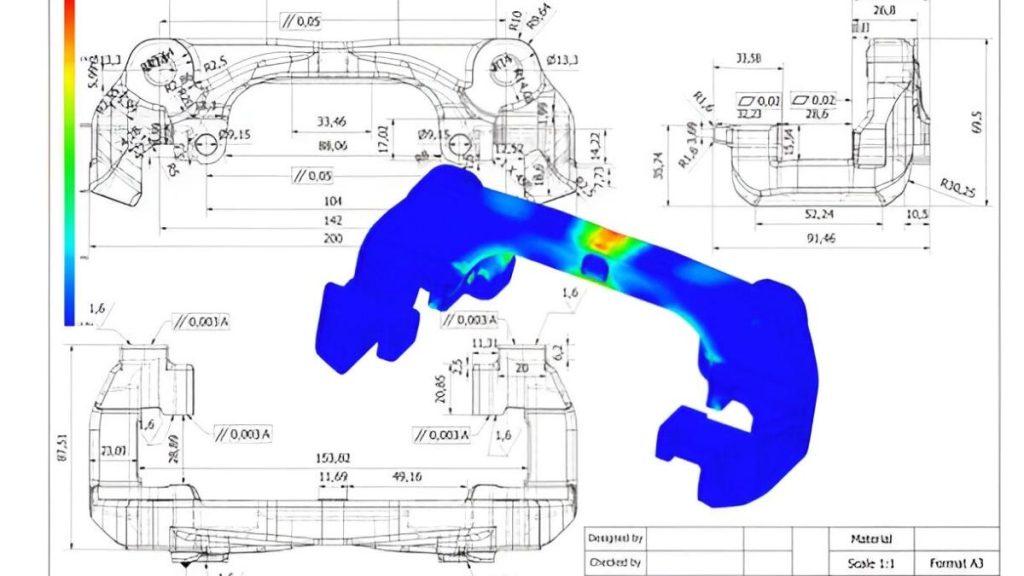

Aluminium prototypes require careful planning from concept to output. The process involves a sequence of precise technical steps. Each stage supports dimensional accuracy and functional validation.

Start by identifying how the prototype will function. Consider load, temperature, and physical fit constraints. This step guides alloy and process selection.

Prototype 3D Illustration

Create a detailed 3D model for its fabrication. Include features like bends, cut-outs, and thickness. Use defined tolerances based on process capability.

Match your design to a practical fabrication method. CNC machining works best for blocks, forming suits of flat designs. Always consider material form and wall limits.

Choose clean aluminium stock that meets your model’s size. Calibrate tools and secure workholding before any cuts begin. Proper setup avoids early dimensional variation.

Cut or part-bend based on the model. Use correct feed rates and tool paths. Avoid overheating and edge tearing during operations.

Insert fasteners where required by your design. Confirm alignment before tightening. Moreover, use the right press force for PEM or rivet hardware.

Inspect hole positions, bend angles, and surface finish. Check functional clearances and mounting features. Address deviations before moving to testing.

Aluminium prototyping is done using machining as a choice method. It provides close tolerances, good finishing, and quick delivery. Some of the most important processes in aluminium prototype manufacturing are given below.

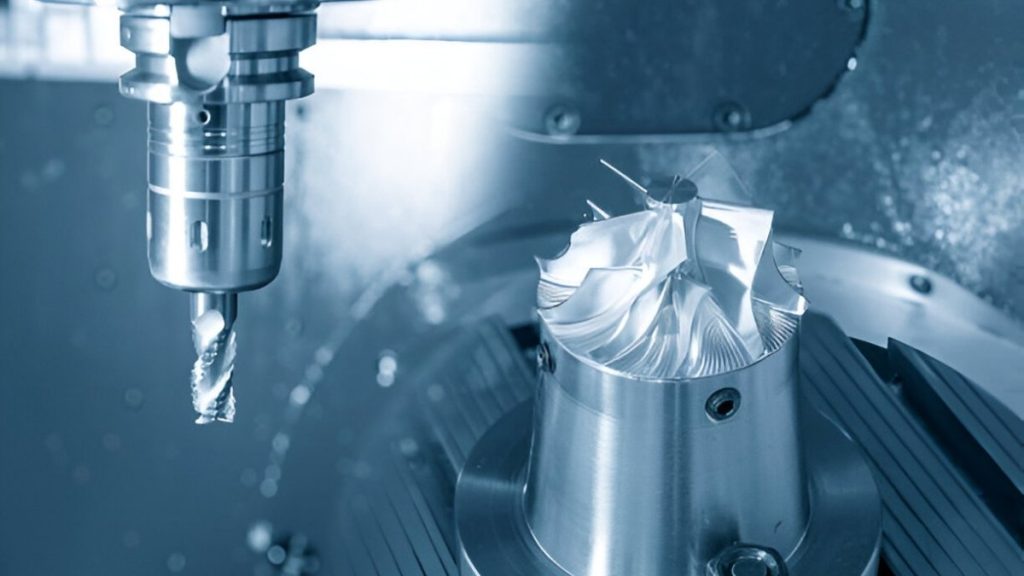

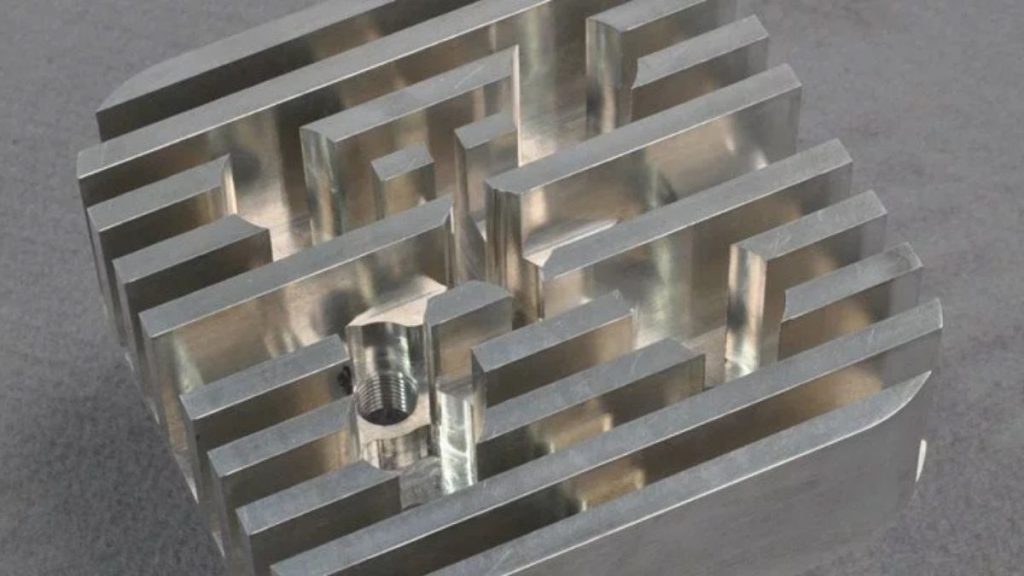

Aluminum CNC Milling

CNC milling removes a solid aluminium block. Faces, pockets, slots, and holes may be machined accurately through milling. The procedure facilitates complicated lines and abrupt changes.

Multi-axis milling machines offer greater accessibility and reduced setup time. Coated carbide tools should have less wear and heat. Tool life and the surface quality depend on coolant flow.

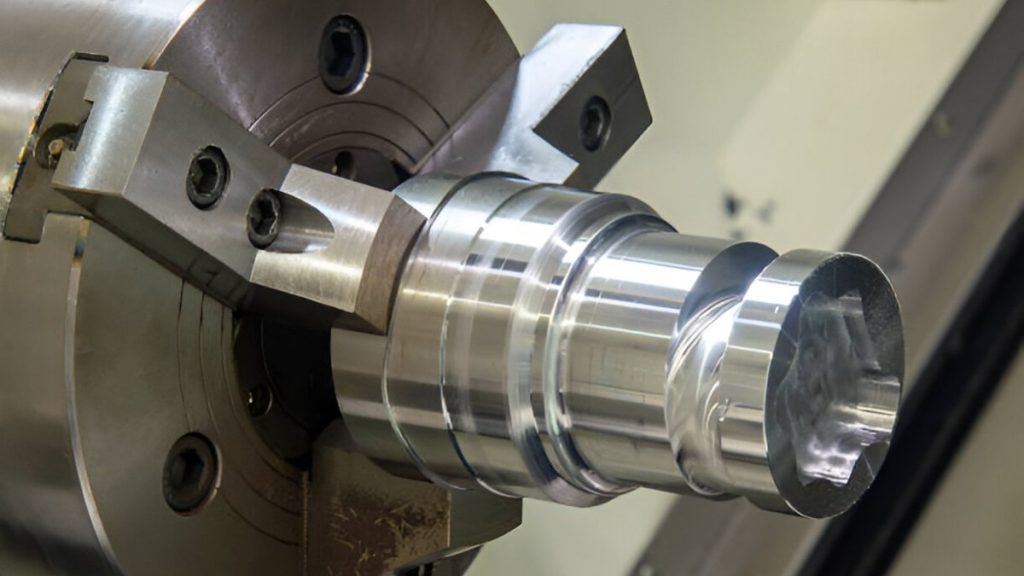

CNC Turning Aluminum

Turning is a fast process. It helps make round or cylindrical aluminium components. You also work rotating the workpiece and cutting material against a fixed tool. This fits shafts, connectors, and ring parts.

Lathe setups that are well-maintained allow tight concentricity. The surface finish is controlled by the tool sharpness and the spindle speed. Put chamfers and threads right in the same cycle.

Threading Hole In Aluminum Profile

Drilling makes accurate fastener holes and features. You can use standard twist drills or step drills. The depth and diameter of holes should be specified.

Tapping makes threads within holes that are already made. You can choose hard or soft taps against the part geometry. Deformation should be avoided by controlling the speed and lubrication.

CNC Aluminum Reaming

Reaming improves the roundness of the hole and makes it dimensionally tighter. You use it post-drilling to fine-tune the quality of fit. It is suitable for dowel, pin, or bearing fits.

On the other hand, boring is used to enlarge and straighten up the internal diameters of machined parts. In high precision, do single-point tools or boring heads. These two techniques improve the repeatability in small clearances.

After machining, you can use surface finishing to increase the part's functionality. The process of deburring gets rid of sharp edges that are left by the tools. Brushing produces a smooth directional grain of cosmetics.

Electrical insulation or protection against corrosion may be performed by Anodizing. Dimensional tolerances are to be maintained to assemble correctly, and surface treatments should be avoided to this end. Well-prepared, clean surfaces increase the finish adhesion.

Aluminium has practical and mechanical benefits in the development of a prototype. It offers speed, accuracy, and consistency of material when testing. The following are the five major advantages that are applicable to the engineering cases.

Aluminium cuts quicker than most of the engineering metals. You decrease cycle time, and you do not lose dimensional control. There are short lead times, which enhance development.

It is also soft, and this reduces the wear of the tools operating. This leads to smoother finishes and fewer corrections in the process.

Aluminium provides great strength as compared to its weight. You are able to test parts that have to bear weight without too much mass. This suits enclosures, brackets, and support frames.

Prototypes that are lighter are better in terms of handling when inspecting as well as during fit checks. They also lower the danger in manual assembly tests.

Aluminium carries heat conductively and electrically. You apply this property in thermal paths and electronic housings. Prototypes act almost similarly to end-of-production items.

This assists you in checking thermal flow, shielding, or grounding at the early stages. It makes sure that there is a correct result in the operation tests.

Aluminium does not change its shape when it comes to high precision machining. When needed, you are able to have tolerances of less than plus or minus 0.05 mm. The quality of the surface does not change during milling or turning.

The material is non-distortive and. resists the formation of burrs. This enables the direct test of press fits, sealing points, and mounting faces.

Selecting the correct aluminium grade is critical during prototyping. Each alloy offers unique strength, formability, and thermal response. Below are the most widely used grades in prototype manufacturing.

Aluminium 6061 Alloy Rods

6061 is the optimum alloy choice for prototypes. It gives balanced strength, corrosion resistance, and excellent machinability. It responds well to anodising and basic coatings.

You typically use 6061 for structural frames, brackets, and housings. It supports both milling and turning operations with reliable finish quality.

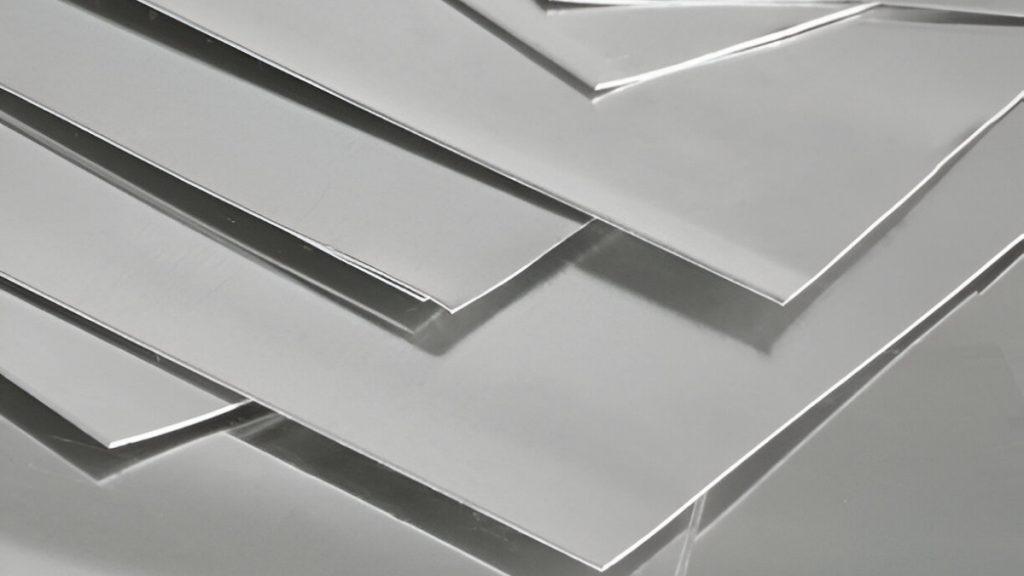

Aluminum 5052 Stacked Sheet Stock

5052 offers superior bendability and fatigue resistance. You use it in sheet form for folded and formed parts. It handles tight bends without cracking or surface stress.

This grade is ideal for enclosures, panels, and mounting plates. It also performs well in marine or high-humidity environments.

Aluminum 7075 Machined Prototype

7075 provides high strength and rigidity for critical parts. You use it where structural loads or precision alignment matter. It machines cleanly but requires sharp tooling.

Common parts include aerospace fixtures, arms, and high-load supports. However, it offers less corrosion resistance than 6061 or 5052.

Aluminum 2024 Alloy Prototype

2024 will perform well in fatigue resistance and mechanical stability. It’s often used where part stress varies under load. You must protect it with surface coatings due to its lower corrosion resistance.

This grade suits aerospace clips, brackets, and test mounts. However, you need to machine it with caution to avoid edge deformation.

5083 is known for excellent marine and chemical resistance. You can choose it for prototypes in harsh and corrosive settings. It performs best in non-heat-treated applications.

Typical parts include sealed housings, marine brackets, and protective covers. Its strength and weldability are also useful for structural prototypes.

Aluminium prototypes find application in industries where they are needed for quick iteration, dimensional accuracy, and functionality testing. These industries depend on aluminium owing to its performance, flexibility, and affordability at the initial stages of design.

Aluminum Aerospace Prototyping

You validate the lightweight structure components, using aluminium, in the aerospace industry. Examples of prototypes are houses of sensors, frames of a drone, and assemblies of brackets. These components have to be at the highest limit in terms of weight and dimensions.

Grades like aluminum 7075 and 2024 are popular due to their strength. Prototypes allow engineers to perform a check on the stability of parts before it is ready to be committed to production-grade assemblies.

ALuminum Automotive Prototypes

Modern vehicles and cars use aluminium prototypes in the enclosure and chassis. You can make suspension arms, heat shields, and mount brackets of 6061 or 5052. These diligently assist in testing clearances and systems alignment in advance.

Aluminium is used in the platforms of electric vehicles as prototypes of battery housing. These components are checked in terms of strength, sealing, and cooling.

Aluminum Traumatology and Orthopedic Implant

During the medical design, aluminium can be used to make a clean and accurate prototype in medical or testing equipment. You can manufacture machine enclosures, rail mounts, and test fixtures out of 6061. Here, smoothness and close tolerance are needed.

The anodized aluminium parts are used to simulate the sterilized medical components or coated ones. Testing of these prototypes in clinical conditions is made possible.

High heat-sensitive electronics often have aluminium prototypes. You machine your enclosures, your display frames, and your connector plates. These make it possible to do early thermal validation and fit testing with small layouts.

These parts are used to perform the visual and structural reviews by the consumer hardware companies. The finishing processes are to give an illusion of how the final product will look in order to allow the user to check.

The design of automation systems uses the assistance of aluminium, which supports functional tests. You construct checkpoints, backup weapons, mounts, and sensors. Such prototypes assist in the testing of layout, movement, and accuracy of alignment.

Such grades as 6061 or 5083 are good for mechanical assemblies. Prototypes are checked as machined to fit confirmed and final production runs are carried out.

Designing aluminium prototypes requires more than basic geometry. You must account for material-specific behaviours that affect function and production. Below are key design challenges engineers often face.

Aluminium is softer than steel and distorts under pressure. Thin walls may bend or vibrate during milling passes. You must control tool speed and fixturing force carefully.

Unsupported surfaces risk edge deflection and uneven cuts. Design thicker cross-sections or add temporary supports when needed.

Thin structures are subject to deformity by heating and mechanical loads. The maximum spindle speed causes localised heat in small areas. This has an undesirable impact on the hole diameter and flatness.

In order to prevent that, apply uniform wall thickness throughout the modeled object. Minimize unsupported lengths and use restrictive tolerances.

Threads that are made of aluminium can be stripped easier as compared to those of harder metals. Fine threads do not have the integrity of being repeatedly torqued or pushed out of line. Areas that have a high load usually require thread inserts.

The holes that were tapped had the least thread engagement lengths. In repetitive fastening applications, stainless helicoils or rivet nuts should be used.

Milling aluminium produces a sharp burr on to cut edges. Scratches are also attained easily in the handling or even in post-machining procedures. Such concerns include fit, seal, and appearance.

Do not drag pieces on hard-working surfaces. Make deburring processes and think over protective coatings following inspections.

Surface treatments add thickness that affects fit. Anodising may add up to twenty-five microns per surface. Powder coating builds even more in confined zones.

Update tolerances in critical dimensions to reflect coating build-up. Mask functional surfaces where interference may occur.

Aluminium prototypes provide a fast and effective path to product validation. You benefit from accurate machining, excellent strength-to-weight balance, and flexible fabrication. These advantages support both functional testing and early design evaluation.

To ensure success, you must plan each step carefully. Material grade, feature geometry, and coating behaviour directly affect performance. Even small design oversights can introduce tolerance issues or surface defects.

When done correctly, aluminium prototyping delivers consistent, test-ready components. It helps you reduce lead times, identify design flaws early, and prepare for scalable production. This makes it a preferred option across engineering sectors.

Q1: What is the recommended bend radius for 5052 aluminium?

Use a radius equal to one times the material thickness. This prevents surface cracking and ensures clean, repeatable bends.

Q2: How can I reduce vibration during thin-wall machining?

Use high-speed tools with reduced axial load. Secure the part firmly and avoid unsupported walls during finishing cuts.

Q3: Can aluminium prototypes hold press-fit components reliably?

Yes, but you must maintain strict diameter control. Undersized holes or sharp edges may deform under press load.

Q4: What surface preparation is required before anodising?

All machining marks and oils must be removed. A fine mechanical or chemical polish helps maintain uniform anodising layers.

Q5. How do I control flatness after CNC machining?

Minimise heat buildup and use a symmetrical layout. Avoid deep pockets and thin floors that release internal stress.

Q6. Is it possible to combine sheet and billet aluminium?

Yes, but joint design must accommodate thickness differences. Use rivets, mechanical fasteners, or adhesive bonding where needed.