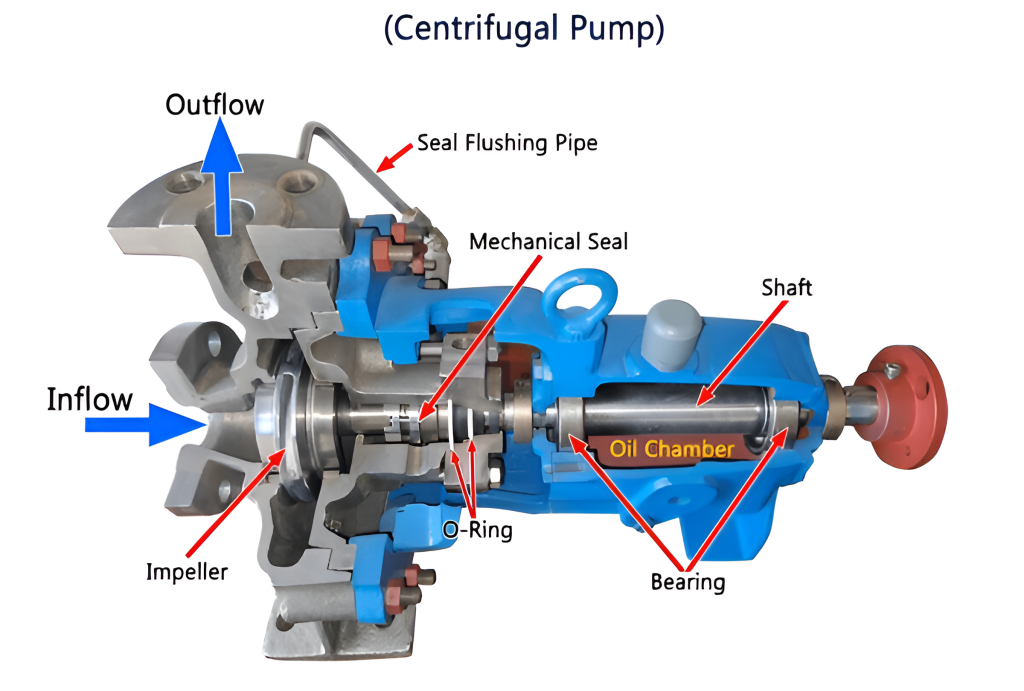

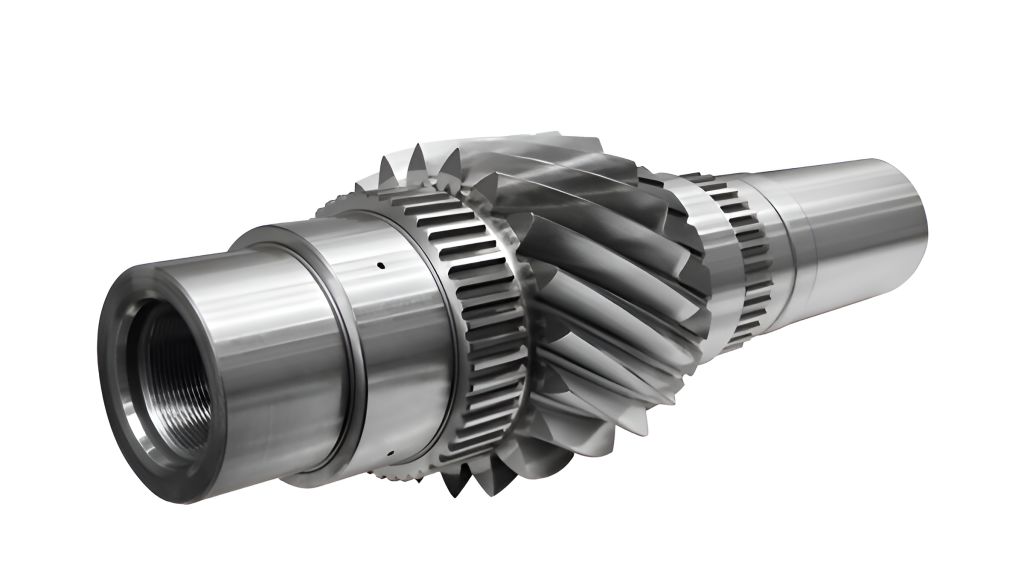

Every mechanical system employs shafts, which transmit power, bear rotating parts, and enable movement in a wide variety of applications, including engines, landing gears, industrial equipment, and medical equipment.

The ability of these systems to perform, as well as their life span and efficiency, hinges directly on the accuracy of their shafts. Gross deviation of straightness, roundness, or concentricity can cause excessive vibration, premature wear, and catastrophic failure, and even minor variations (less than one per cent) may cause serious difficulties. Here, CNC (Computer Numerical Control) machining is a must-have technology. Utilizing the immeasurable levels of control, precision, and a sophisticated role of processes, CNC machining maintains high levels of shaft production accuracy, which is essential for the highly stressed performance needs in today's applications.

The accuracy of a shaft is most imperative, since it has a direct dependence on:

Inequality in a rotating shaft causes vibration, noise, early breakdown, and inefficiency in the system.

Misalignment or out-of-roundness exposes bearings to excessive and unnecessary strain, resulting in their premature failure.

Backlash, poor power transmission efficiency, and high power losses in geared systems can occur when inaccurate shafts are used.

Shafts have tight tolerances that allow them to fit in mating components with ease, hence facilitating mass production and maintenance.

An Accurate shaft is a key to a reliable and lasting mechanical system.

CNC machining will have the controlled atmosphere and technical sophistication necessary to achieve such accuracy. CNC machines repeat very closely to instructions programmed into the controller, unlike manual machine shaft production, which is highly subject to introducing human error.

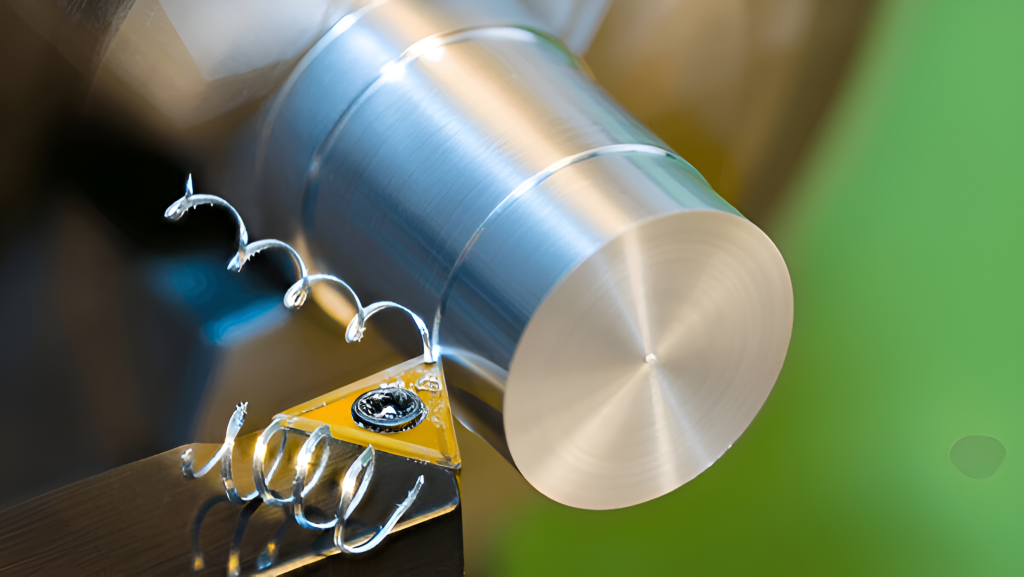

The machining of long, slender pieces tends to have shafts, and these types of workpieces specifically have their own set of challenges, which may gravely affect the accuracy unless it is carefully addressed. CNC machining characteristics provide effective tools for addressing these natural challenges.

Long, sharp shafts naturally have a low rigidity. On a machined cut, the cutting forces, together with gravity and even the weight of the shaft itself, can cause the shaft to bend or deflect out of the direction of the cutting, resulting in a variation of diameter, taper, or an hourglass/barrel out the length of the shaft. This becomes especially an issue in turning processes where the force is parallel to the axis of the shaft.

Deflection may easily degenerate into vibrations or chatter, a self-resonant oscillation of the tooling with the work. Surface finish is poor, tool wear is rapid, noise is produced, and there is poor dimensional accuracy (e.g., a polygon rather than round).

The process of machining (because of cutting action and friction) creates heat, which results in the expansion of both the workpiece and machine components. The part shrinks as it cools. Otherwise, this thermal cycling may cause severe dimensional errors.

Long and stringy chips produced during turning operations can wrap around the workpiece or the tool, causing scratches on the surface, recutting of chips, and even tool breakage, all of which reduce accuracy and finish.

In addition to mitigating routine problems, specific CNC solutions are implemented to uphold shaft accuracy to the highest standards.

The stability of the piece of work is polar.

Typically holding one half of a shaft (3-Jaw) and typically holding one end of a shaft (4-Jaw), the power chucks are identical to other chucks in every aspect except that they exert constant clamp force.

A better concentricity and clamp to accept a smaller diameter shaft, particularly where the through hole is necessary.

Necessary to bear long shafts between the headstock and tailstock with assured concentricity and freedom of deflection.

As argued, they are essential when the shaft is long and slender since they help counter incidences at the bends and vibrations.

More complex shaft forms or unusual materials may require custom fixtures to hold and support the shaft with clamping.

The direct contact with the material is the cutting tool.

Sharp, suitable carbide or ceramic inserts utilizing an ideal material and process coating (roughing, finishing) must be used.

Coming up with the best inserts, rake, and nose radius with the chip breaker that suits the material and the type of finish required.

The shorter the tool is projected beyond its holder, the more rigidity is maximized, and the deflection and vibrations are reduced.

Setting the tool length and diameter with tool preservers or on-machine probing results in accurate tool length and diameter, eliminating manual setup errors.

The last pass has no depth of cut. This enables the tool to recover (or spring back) any residual deflection, refining a hidden finish to the dimension and surface roughness, without additional material removal.

The machine brain plays an important role.

Giving precise and accurate feedback as to axis positions, enabling fine movements to be taken.

Real-time feedback on the true tool position and commanded position, check any deviations, and correct for them.

Involves software correction of common machine errors such as backlash correction in between machine actions, discrepancies in the lead screws, and thermal expansion of machine parts.

Look-Ahead Functionality: The controller’s “looks ahead” in the program to predict the next movements, enabling smoother acceleration/deceleration, and continuous movement, which lowers the vibrations and gives a better surface finish.

On a more sophisticated machine, it is possible to monitor the cutting forces and change the machine parameters (speed, feed) on the fly so that the cutting conditions remain optimal

Beyond having coolant, a stable thermal environment is important.

Temperature variations are not useful as the structure of the machine itself will move in and out under normal conditions, potentially interfering with accuracy. High-precision work is best done in a place that maintains climate control.

Systems maintain the temperature of the coolants to prevent thermal shock on the workpiece.

To achieve precision, parts could be rough-machined, left to normalize to ambient temperature, and finish-machined.

Being accurate is one thing, but it's another to show this fact. Advanced metrology is well integrated with CNC machining.

There is on-machine measurement, where many CNC machines have touch probes that can measure workpiece features (e.g., diameter, length, runout) directly on the machine during or after machining.

The machine can automatically adjust tool offsets or work offsets based on measurement results and offset changes to compensate for tool wear or material variations.

Temporal checking without removing the part from the machine, decreasing the setup time, and reducing re-fixturing errors.

Early warning that trends are in place or there are deviations in accuracy.

Accuracy is ensured after machining with the help of very accurate measuring instruments.

Include measurably precise equipment that contains touch probes or laser scanners, which complete a survey of complicated shapes and dimensions with their CAD models. Essential to check GD&T callouts.

Transfer the profile of a shaft, magnified using optical comparators, to a screen to be compared to a tolerance overlay. Appropriate for inspecting the profiles, lengths, and angles.

Special optical or optical-tactile systems that precisely and quickly measure all characteristics of a shaft (diameters, lengths, runouts, straightness, and form errors)

Basic checking of dimensions, but they are not as accurate as a CMM or shaft-specific measuring tools.

A dial indicator and Runout gauge can be used to measure the runout (total indicator reading, TIR) of a shaft during rotation, and are used to check its concentricity and its straightness.

Special-purpose instruments to measure deviations in perfect roundness.

GD&T is a language that can be identified as symbolic and shown in engineering drawings, specifying the geometric tolerances that are allowed as aspect tolerances of features. In the case of shafts:

GD&T ensures that manufacturers review the necessary features of critical components of the products, ensuring precision and creating a fully functional assembly.

The selection of material greatly affects the machinability and the final accuracy of a shaft.

Economical, common, good strength. Machinability is good; long shafts should be avoided to avoid deflection.

Alloy steels are stronger, harder, and more wear-resistant. They may be harder to machine due to their hardness, and cutting parameters, and a very robust machine is needed to maintain accuracy. Heat treatment may be pre- or post-machining, and EDM is frequently a post-heat-treat feature.

High corrosion resistance and variable machinability. Certain grades (such as 303) are free-machining, others (such as 304, 316) are gummy and subject to work hardening, requiring special tools and settings to avoid surface finish destruction and preserve accuracy.

The alloys are lightweight, and their machinability is good. Isolated when lighter-duty shafts are used, or during a prototype phase. The cutting forces tend to be low, which eases the ability to achieve high precision, but the thermal expansion of the material cannot be ignored.

Good strength-to-weight ratio, good corrosion resistance. Extremely difficult to machine because of its low thermal conductivity and chemical reactivity. Needs rigid setups, unique apparatus, and low cutting rates to sustain correctness and avert wear of the accessories.

High Temperature strength and high corrosion resistance. Very difficult to machine. Highly rigid CNC machines' operation and high-level controls are essential to any chance at precision.

CNC machining is the ultimate solution to fulfilling the intricate requirements of the correct production of shafts. With every detail of the procedure meticulously regulated, including the rigid machine construction and safe workholding along with optimized toolpaths and modern feedback systems, it practically eliminates problems such as deflection, vibration, and thermal distortion. This enables consistent manufacture of shafts to sub-micron tolerances, fine surface finishes, and geometries. To achieve such accuracy is not optional in modern high-performance mechanical systems. The automation and level of control that CNC machining allows also make shaft production a repeatable, reliable, and high-quality exercise, the basis of innovation and performance within any such industry that relies on rotating parts.

A1: Low rigidity leads to long shaft deflection or vibration, resulting in diameter uncertainties or a bad finish. With firm structures, impact-free rests, and optimized settings, CNC machines can lower this.

A2: It has steady supports that span the length of the shaft and avoid deflections and vibrations. This will also guarantee uniform diameters, finer surface finish, and higher tool life.

A3: Coolant eliminates heat, avoids thermal distortion, minimizes friction, and assists in the removal of chips--important towards dimensional accuracy and surface quality.

A4: Roughing is used to remove material, semi-finishing is used to reduce stress, and finishing using light cuts to achieve an accurate size and finish, and reducing error and deflection.

A5: Runout is concerned with how the shaft moves away from its true rotation. CNC reduces this to the minimum by the use of precise spindles, rigid workholding, accurate tools, and applicable cutting forces.