Wire EDM gives you extreme precision when cutting tight profiles in hardened materials. It’s commonly used for molds, aerospace components, and medical parts where accuracy matters most. Because there’s no cutting force, you can achieve fine details without deflection.

Most machines hold tolerances between ±0.0002" and ±0.001". The final accuracy depends on multiple factors, including machine condition, wire type, flushing setup, and part geometry. Even shop temperature plays a role in how stable your cuts stay over long runs. When tolerances are realistic, your process stays efficient without compromising precision.

Tight Tolerance EDM Machining

The Wire EDM Tolerance cannot be based only on the specification of the machine. The final cut is influenced by your setup, environment, and material. Having a clue on what to control provides you with a better grip, repeatable tolerances without production slowdown.

EDM machines are not all the same. The sophisticated types employ linear drives and glass scales, and thermal compensation. These systems are more consistent concerning long jobs. Even the best machines, however, do drift out of calibration. Regular tests, backlash testing, and updating of software keep the accuracy at its maximum.

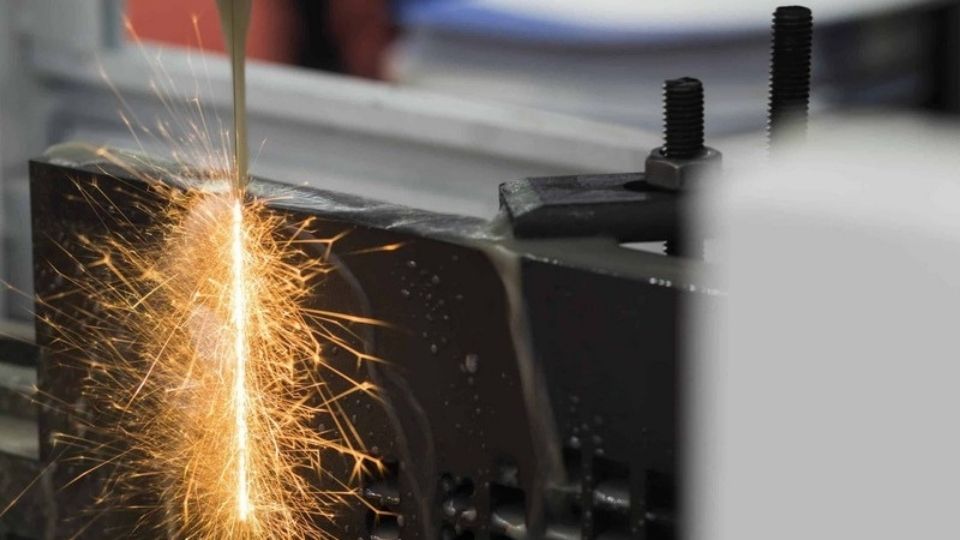

Wire EDM Spark

Spark control and cut accuracy are directly influenced by wire type. Most jobs will use standard brass, but to minimize wear and hold tighter tolerances, higher-grade coated wires are used. The size of the diameter also counts. Micro wires are smaller and cut finer detail, but are more susceptible to breaking on lifting tall sections or over-deflection in deep holes.

Constant tension of the wire makes a proper spark gap. When the tension is low, the wire tends to bow, thereby causing the sidewalls to taper or curve. Over-tension also causes cracks and uneven kerf width. Auto machines vary the feed rate with tension dynamically, whereas a manual setup requires fine-tuning per part.

The clean-up of debris by flushing stabilizes the spark gap. Poor flushing results in nonlinear wear and drift. The position of nozzles is equally important, as either misaligned or damage will cause edge defects and tapers. Before each job, there is a check on the nozzles and the dialing in of the pressure depending on part size and geometry.

Tolerances are able to be moved by even small changes in temperature. Machine/microscopic expansion of EDM machines occurs with heat, particularly when burns are extended. Temperature in shops, coolant temperature, and stability of dielectric fluid are factors. Thermal drift can be reduced by the use of climate-controlled environments, which enhances consistency.

Unstable or loose setups cause vibration and movements when cutting. This destroys tolerances--in tall or thin pieces. Secure parts holding them tightly using precision vises, clamps, or magnetic holders. Soft jaws and support plates can contribute to minimizing the distortion of fragile beauty lines or edges

Each of the parts does not require the same level of precision. Most machining processes can be harnessed to hold tolerances tighter than in Wire EDM, but tightening the tolerance to the max will cost in time and money. Once you match your specs to the application, the job is efficient, and it does not compromise quality.

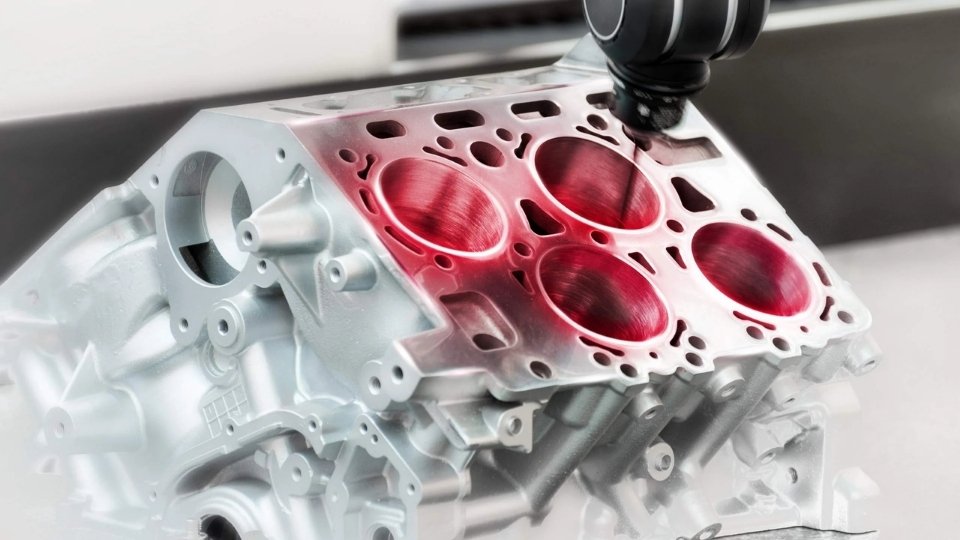

EDM Machining Aerospace & Defence Parts

Such components have tolerances which are frequently demanding to within a micro-inch, like 0.0002". Such minor details as turbine slots, fuel injector ports, or sensor housings need to be specified to the very nut and bolt in terms of safety and performance. These jobs normally have high-end EDMs with temperature control and the capability of fine-wires.

EDM Machining In Medical Sector

Alongside fit, the surface finish and shape of the edges are also imperative. Tolerances are in the range of between plus or minus 0.0003 inch and 0.0005 inch, depending on the part. Coated wire and skim pass are common on surgical instruments used in surgery, implants, and micro-components to meet the final specification.

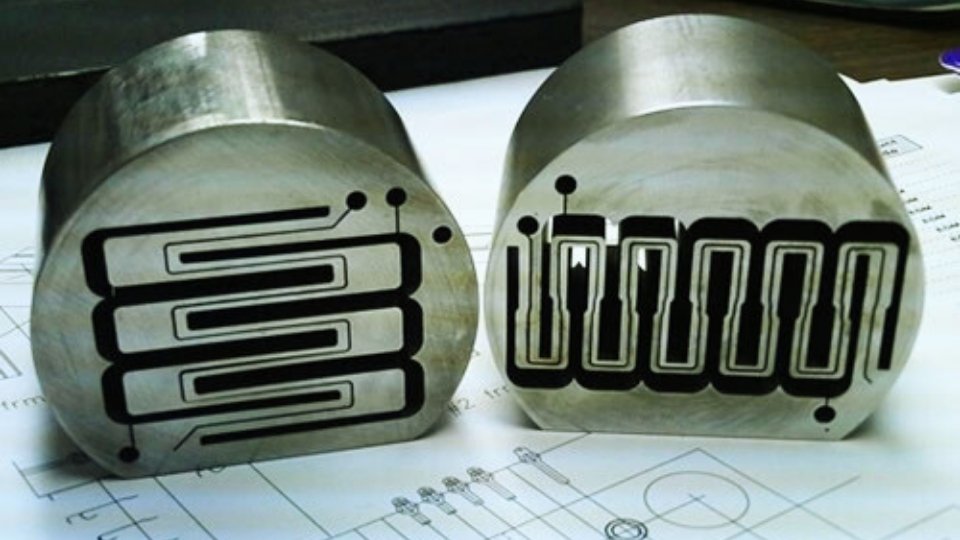

EDM Mold Machining

Mold parts tend to be in the range of +/-0.0005 to 0.001". It is emphasized that the compatibility between the cavity and the core is. The taper and sharpness of the corners are important. In this case, repeatability can be much more significant than ultra-close specs.

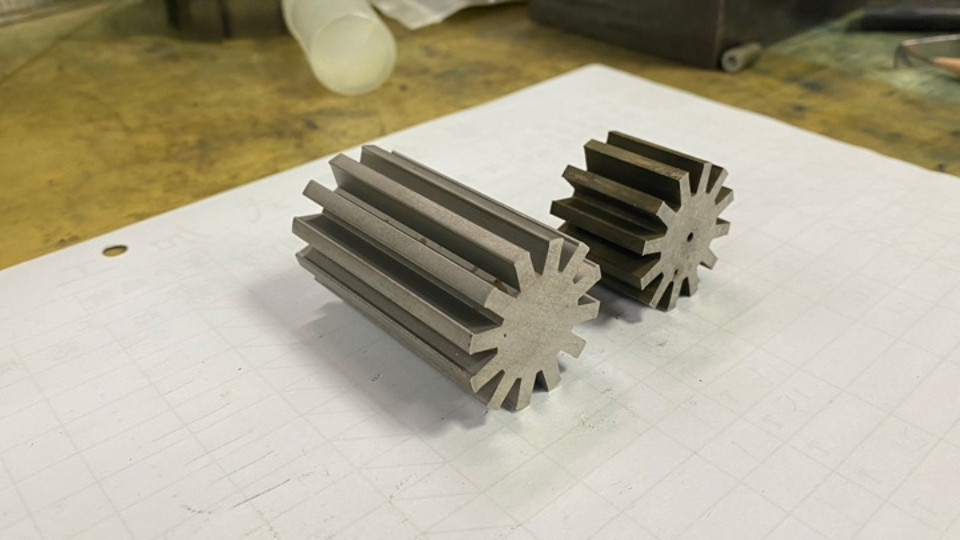

EDM Cut Tolerance Machined Parts

In industrial applications, for many jobs, the tolerance of +/- 0.001 is adequate, such as that of brackets, housings, or form tools. Here, the EDM is frequently utilized when other conventional machining methods cannot be applied to achieve certain features or internal corners.

Maintaining the close EDM tolerances is not all about the machine. It needs proper arrangement, planning, and a controlled process. Some targeted changes can be used to streamline indicators to improve results without spending superfluous time or making it more complicated.

The rough passes de-materialize fast, yet they are not to spec. Each skim brings the edge to a higher fit, decreases the amount of overburden, and shrinks the final dimension. To work in the ultra-precision degree, 2-5 skim passes are used. The power settings should be adapted according to each pass so as to reduce wear and enhance accuracy.

Tolerance is influenced by thermal drift. Even the smallest alterations of 1 to 2 °F may lead to dimensional changes in the course of extended burns. Operate a machine in an area maintained at a moderate climate, and observe the temperature of the dielectric fluid. It is also advisable not to run high-precision jobs directly following a warmup or significant changeover.

Not every wire is identical when it comes to cutting it. Use plain brass for ordinary work, and change to zinc-coated or diffused wire for high precision or minute work. These wires minimize wear as well as enhance surface integrity, particularly on small radii and shallower corners.

Tolerances are destroyed by part movement. Apply hard, no-vibration mountings with micrometre precision-fixturing. Hold the thin or tall features to prevent wire deflection or move over during flushing. After you place your pieces, check integrity before the initial cut; little mistakes add up quickly.

What you can not measure cannot be managed. Checking EDM tolerances should involve accurate machinery and appropriate inspection planning. The appropriate method of choice will rely on the geometry of parts, desired tolerance, and equipment available.

CMM Machine Inspecting Part Geometry

The standard of inspection of the high-precision parts is done using CMMs. They provide sub-micron resolution as well as can measure complicated 3D features. Check them to make a final verification of dies, mold inserts, or other aerospace parts in which each dimension matters.

The instruments are effective when used in terms of profile checks and fine features. Vision systems store the part outlines and make a comparison to CAD models. Optical comparators provide instant response to angles, radii, and contour shape, which are perfect when inspecting quick tests on flat or 2D parts.

Micrometer Measuring EDM Machined Part

In the case of the simpler features, manual tools can remain viable. Flatness, width, and hole diameters are checked on micrometers and bore gages. Pin gages verify the size of the small holes or slot widths where there is limited access to the CMM. Never make use of uncalibrated tools or in an uncontrolled environment.

The fit and performance depend upon the surface finish. Measure the Ra values using profilometers, in particular, following numerous skim passes. Sharp edges or burr free finishes are areas that can be checked visually through a magnification device.

You have to know the limits of your machine, but you have to have a repeatable system. These measures assist you in the tightening of tolerances, cutting of scrap, and achieving predictable results, even on complicated parts.

Test a scrap part to run a tolerance test, then cut production parts. Use what you have got set up, same material, same height, same wire. Measure the results and compare them with your spec. This provides you with a real-world baseline, and not machine data.

Do not disregard the conditions in the room. During long burns, drift occurs by changing the temperature or humidity of the shop. Put in place temperature monitors. In case required, the high-precision EDMs should be isolated in climate climate-controlled cell. Final dimensions can be altered even by a 2 o F swing.

Metal moves on clamping. Do not over-tighten or press the part into a square. Use soft jaws or ground parallels. Thin or tall parts should be preloaded with care, and enough expansion room should be provided when cutting long. No stress is set up, which means more precise cuts.

Minimise part stress by planning your cut sequence. Do not prematurely isolate thin features; they will shift as internal stresses relax. Cut reliefs and complete tight-tolerance areas as the last ones. Take bulk off in roughing passes, and skim on fine settings.

It is not only irritating when wires break frequently; this is an indication of instability. Every cut is broken, and changes the path of your cut, and can cause tolerance changes. In case of an increase in breaks, verify the tension settings, power, or flushing. Wire stability = tolerance stability.

When you get a winning setup, take a note of it. The type of log wire, power settings, the number of passes, fluid pressure, and ambient conditions. This is your starting point when it comes to repetitive parts. A written arrangement decreases trial and error and enhances repeatability.

Despite the best practices, you will have to deal with barriers that present challenges to close tolerances. By early detection of such issues, you will be able to troubleshoot easily and maintain parts in spec.

During cutting, the wire wears out unevenly and resulting in a variation in kerf. This impacts accuracy and finish. Change spools of wires regularly, and think of coated wires that will last longer and make similar cuts.

Machines and parts get hot and expand with time. Taper or drift can be caused by long runs without a break or bad temperature control. Long jobs should be divided into parts, and the fluid temperature must be observed.

Inappropriate flushing results in the accumulation of debris, uncontrolled sparking, and unpredictable cutting. This lowers the quality of surfaces and dimensional precision. The nozzle position and pressure should be adjusted to ensure that the dielectric smoothly flows.

When the part moves in the process of cutting, tolerances are out the window. This is usual in thin, tall, or complicated parts. Make any movement minimal by using rigid fixtures and vibration dampeners.

Over-aggressive power will result in excessive overburn and enlarged kerfs. On the other hand, insufficient power will slow down cutting and might break the wire. Refine power according to material, thickness, and finish needs.

Accurate cuts can do nothing when it comes to measurement. False tolerance readings may be a result of calibration errors, the use of the wrong tools, or unstable inspection conditions. Periodically check tools and examine them in conditions of control.

Tactics beyond the basics can smarten up any process-driven improvement of EDM tolerance. Such sophisticated techniques assist you in driving accuracy at a time when efficiency remains high.

Monitor the frequency of sparks, vibration of wires, and flushing pressure in real time by means of sensors and software. The early warning that is given on the anomalies will allow you to change the parameters before you lose the tolerance during the cut.

Some contemporary EDM controls have thermal compensation, which automatically adjusts the coordinates as the machine heats. This saves dimensional drift without having to intervene manually, particularly on long or complex parts.

With very minute details, use ultra-thin wire (less than 0.010") to cut a finer kerf and sharper edge. This enhances the tolerance in micro-features, but they need to be very careful of their tensions and power.

The voltage of the spark gap should be adjusted carefully with each pass. Small spark gaps minimise overcut, but they wear out the wire. This trade-off of the settings enhances dimensional control and surface finish.

On 5-axis wire EDMs, offset the wire path with programmed offsets of the wire path to accommodate predicted taper or heat distortion. This is a preventive measure that leads to more vertical walls and fewer variances in sizes.

When working with materials that have the tendency to develop residual stress, perform post-cut heat treatment on the material to avoid this. This removes stresses internally and gives the part dimension stability before final machining or assembly.

Maintenance of your Wire EDM is the key to consistent, tight tolerances. Preventive health care also saves on downtimes and prevents latent problems that compromise accuracy.

Wires guides get worn out and filled with debris. Cleaning and inspection regularly is the only way that the wires will not become misaligned and start to wander, and this will directly affect the control of the dimensions.

Filtered dielectrics, which are clogged or dirty, decrease the efficiency of the flushing action and the stability of sparks. Routine change of filters according to the advice of the manufacturer keeps the fluid clean and uniform.

Wire movements are accurate under the guidance of servo motors. Due to time, backlash and wear might be created. Check and fine-tune servo parts to ensure trouble-free and precise movement of wires.

The schedule of lubricating all moving parts (linear guides and ball screws) must be followed. Wear would be less, and the precision of the machinery would be retained through good lubrication.

Other than the filtration, the conductivity and temperature of the dielectric fluid should be periodically checked. The fluid should be changed before it goes bad in order to prevent instabilities in the process from occurring on tolerances.

Carry out extensive calibration of machine axes, tensioning of the wire, and alignment. Record the results using certified calibration tools as a way of monitoring the health of the machine over time.

Follow these targeted actions and steer clear of common mistakes to keep your EDM process accurate and efficient.

1. Confirm Setup Alignment Before Cutting

Re-check your machine settings. Any deviation causes the final dimensions. Install precise tools to help in making sure the wire path and the workpiece are in the right position.

2. Skim Critical Features with Multiple Passes

Take a few fine finishing strokes instead of one deep cut. This lowers overburn and enhances surface finish, maintaining tight tolerances in place.

3. Keep Dielectric Fluid Clean.

Check the clarity of fluid and filtration regularly. Contaminated or dirty fluid destabilizes the spark and results in unstable cuts.

4. Environmental Temperature should be Strictly Controlled

Regulate the temperatures of the ambiance and the machine. Thermal variations lead to expansion and contraction, and this disrupts your tolerances in long cycles.

5. Record and Analyse Process Data

Maintain the records of the cutting parameters and inspection outcomes in detail. Use trends to find out what works best by material and part design.

6. Train Operators on Techniques of Precision

Train your operators about the nuances of setup, maintenance procedures, and signs of incipient problems to avoid the loss of tolerance in advance.

1. Skipping Baseline Test Cuts

Do not make production without test cuts. Baseline measures indicate whether the settings that you have are yielding the needed accuracy so that you do not make expensive errors later.

2. Over-Clamping Workpieces

Thin or delicate parts may be distorted by the application of excessive clamping force. Fasten in securely with gentle force that will not cause stress to alter the final dimension.

3. Running Long Cuts without Stopping

Do not have long runs without breaks. Heat accumulation during continuous cutting may lead to thermal drift and dimensional errors.

4. Forgetting about Regular Maintenance Works

The lack of cleaning guides, the change of filters, and the calibration of your machine will slowly reduce precision. The main point in maintaining tight tolerances is preventive maintenance.

5. Operating on One-Size-Fits-All Settings

The parameters of different materials and geometries should be different. Indiscriminate use of the same power, speed, and type of wire lowers accuracy and raises scrap.

6. Overlooking Inspection Environment Control

Unstable inspection conditions are the sources of measurement errors. Humidity, temperature, and vibration should be controlled during part verification to be able to obtain reliable results.

This article has covered: