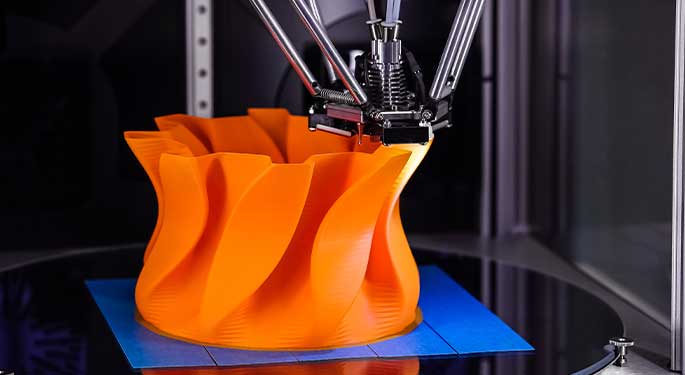

In product development, rapid prototyping is essential for turning ideas into reality quickly. 3D printing technology is leading this change with continuous improvements that are changing how industries design, test, and manufacture products. Here, we explore the latest 3D printing innovations and their impact on various fields.

Modern 3D printers can now use multiple materials in a single print, allowing for more complex and functional prototypes. For example, combining rigid plastics with flexible parts creates prototypes that better reflect the final product’s properties.

This makes prototypes more accurate for testing, such as creating durable and flexible car parts in the automotive industry.

Learn more about multi-material 3D printing capabilities at Apex Rapid.

New high-speed 3D printing methods like CLIP and HSS cut down production times without losing quality.

Quicker printing means faster development cycles, crucial for industries like aerospace where time-to-market is important.

Advances in 3D printing have improved accuracy to the micron level and enhanced surface finishes with techniques like laser polishing.

Higher precision ensures prototypes closely match final products, essential for electronics and medical devices that require exact specifications.

The variety of 3D printing materials has grown to include metals, ceramics, and bio-compatible substances, offering properties like strength and heat resistance.

A wider material range allows for specialized prototypes, such as medical models or custom implants in the healthcare sector.

Advanced CAD software and AI optimize designs, predict failures, and suggest material improvements.

This speeds up design processes and improves prototype quality, benefiting industries like consumer electronics with better-performing products.

Eco-friendly materials like biodegradable plastics and recycled composites are now available, along with energy-efficient printers.

Sustainable practices reduce environmental impact and meet corporate social responsibility goals, particularly in automotive and aerospace sectors.

Hybrid systems that use both 3D printing and CNC machining create complex and precise parts in one setup.

These systems allow for intricate designs and high precision, reducing costs and lead times in industries like aerospace.

On-demand 3D printing enables manufacturing closer to the end-user, minimizing inventory and shipping times.

This flexibility is useful in fashion, where designers can produce custom accessories tailored to individual preferences quickly.

Automated post-processing techniques ensure consistent and high-quality prototypes with smooth finishes and reliable performance.

High-quality prototypes are ready for presentations and testing, enhancing confidence in their appearance and functionality, especially in consumer electronics.

Cloud-based 3D printing platforms allow teams to share designs and collaborate in real-time, improving efficiency.

Global teams can work together seamlessly, ensuring prototypes meet diverse standards and market needs, as seen in the automotive industry.

3D printing innovations are revolutionizing rapid prototyping by offering faster, more precise, and versatile solutions. From multi-material printing to sustainable practices and smart software, these advancements help industries speed up development, cut costs, and improve prototype quality.

Embracing these technologies positions businesses to lead in their fields, driving the next wave of product innovation with confidence and creativity. Whether in aerospace, automotive, electronics, or other precision-dependent industries, staying updated with 3D printing advancements is key to maintaining a competitive edge and continuous improvement in design and manufacturing.

For more information about advanced 3D printing services or to discuss your project, contact Apex Rapid today.