CNC stands for “Computer Numerical Control.” This computer software-based process regulates machine tools through precise and repeatable operations. G-code represents machine-readable codes that function as a control system to guide movement and timing operations while deciding material removal choices in CNC systems. The system guarantees to meet every part identically to the original design with outstanding conformity.

CNC machines manage multiple operations, including drilling, milling, and turning. These are extremely flexible in manufacturing processes. These machines operate on various materials, such as metals and plastics, to serve the automotive industry, aerospace sector, and medical device manufacturers.

Compared to manual machining techniques, CNC provides higher accuracy and allows the production of repeatable, identical parts. The advancement of techniques drives the production of complex and exact components, thus becoming vital for present-day manufacturing needs. The focus of CNC machining depends on precise manufacturing, yet sometimes one does not require large quantities of parts. That’s where low volume CNC machining comes in. Let’s discuss how this approach can benefit your manufacturing project.

The production of smaller part quantities than traditional mass manufacturing defines the concept of “Low volume”. The number of produced units usually falls within the range of 10 to 500. The manufacturing process leads to decreased cost while maintaining the production of high-quality components. It works best for experimental purposes and markets requiring restricted product quantities.

Although it meets short-term requirements. The production technology serves two main purposes: prototype development and custom ordering, as well as product assessment. The main goal is to produce faster and more adaptable outputs rather than focusing on large quantities. You can modify design specifications between production runs. So, it minimizes time wasted on later revisions of your work.

In addition, the process achieves tight tolerances and clean finishes. The production of small batch size parts does not lead to diminished product quality. It provides unique parts within your desired time frame, regardless of time and budget constraints. This approach keeps your project focused and efficient.

Mass Scale CNC Machining

Mass production proves beneficial only when all production requirements match its standards. However, your manufacturing operations may require fewer than 1000s of identical parts. Your operation demands adaptability rather than a huge amount of production. Low volume CNC machining provides the ideal solution for such requirements. Let’s investigate how low-volume production achieves such goals.

The establishment of tooling equipment requires a significant duration for mass production operations. Preparing your machines and fixtures can take many hours of work before production begins. In contrast, the setup process for Low volume machining operations becomes faster and easier. As a result, design transition does not cause substantial manufacturing delays. Moreover, the production system quickly adapts to changes in the market.

In mass manufacturing, the production cost is distributed evenly across 1000s of identical units. The expenses increase dramatically when producing 50 units. The process of low-volume production helps you avoid high expenses for tooling and mold requirements. Such a production method costs you only for the items you require.. This approach makes small production orders logical and cost-effective to manage.

Mass production schedules often delay fast market entry. It takes many weeks before the process of machining parts even begins. In contrast, the low-volume method makes it possible to receive parts within short periods. The fast product delivery time allows businesses to test products in different markets and refine their products for optimal results. You can also speed up your operations while remaining free from large-volume manufacturing obligations.

The production of large quantities results in storing thousands of finished parts. The material storage, along with monthly expenses, reduces available space. Instead, the low-volume manufacturing method delivers products only for the current requirement. It helps reduce inventory risks and lowers warehouse costs. By limiting space usage, you gain both flexibility and savings.

When you use mass production, you cannot achieve extensive product customization options. The tooling operations require modifications that are time-consuming and expensive. On the other hand, the low volume method lets you adjust the products existing between each production cycle. You can easily generate different product versions along with their variants. The ability to change production numbers easily works best for emerging industries and niche markets.

When businesses scale up production, they expose themselves to higher financial risks. A failed design means losing a large investment in stock. However, producing in small batches reduces waste caused by design mistakes.. You only purchase the required amount of product when needed. This control system helps companies minimize significant material waste.

The unique characteristics make low-volume CNC machining popular for various projects. It works best for prototype manufacturing, limited batch production, and product testing purposes. This method offers flexibility, quick production times, and reasonable pricing, making it an ideal choice for many businesses.

CNC machining accelerates prototype creation by quickly turning designs into tangible parts/products. Through this quick process, you can check the design with adjustments. This leads to improved product quality before launching into mass production. Fast production progress occurs when you use this method to convert your ideas into tangible products.

Running small projects with traditional approaches often leads to high costs and unnecessary waste. Low-volume CNC machining serves as a solution by lowering production expenses and cutting down material waste. Since you’re producing fewer parts, setup takes less time and resources. This solution serves professional manufacturers who want to test their designs for large-scale production but have not reached that point.

Low-volume machining methods let you test real market demand before scaling up. Creating small batch production enables you to determine market response from customers. The high demand level enables you to increase your production capacity. But if demand falls short, you avoid wasting money on overproduction.

With its extensive versatility, low-volume CNC machining serves multiple industries in the market. It’s ideal for applications that demand precision, even when production volumes are small. The key to industrial innovation relies heavily on low volume machining applications across automotive fields, aerospace businesses and medical creation, and consumer product development.

Engineers rely on CNC machines to create functional, test-ready parts. The development of prototypes through this process makes testing possible before commencing final production runs. It gives fast, accurate results, helping you assess product performance early on.

Startups and small businesses often don’t need massive production volumes. Short-run product manufacturing requires affordable solutions, which are provided by low-volume CNC machining systems. It produces high-quality results when dealing with both small parts production and limited product series.

The production method serves as a temporary solution that links prototype development to commercial-scale manufacturing. This approach provides companies with an opportunity to assess market demand using less risky methods.

Low-volume CNC machining offers unique advantages that make it a smart choice for many projects. Despite its benefits, it has its limitations, too. Let’s walk you through both sides together.

| Benefits | Drawbacks |

| Faster turnaround time | Higher cost per part |

| Minimal material waste | Longer setup time per batch |

| Easy design changes | Limited scalability for large demand |

| No expensive tooling required | Less suitable for mass production |

| Ideal for prototyping and testing | Higher labor cost per part |

| Great for custom, niche parts | Limited automation potential |

| Lower upfront investment | Not optimal for very simple parts |

| Supports faster design iteration | Process adjustments affect unit economics |

Selecting the right material is crucial for low-volume CNC machining. The material needs to be compatible with the machining process and provide the desired strength, durability, and aesthetic finish. Whether you're working with metals or plastics, CNC machining offers a wide range of material options.

Metal Fabrication

The manufacturing industries typically use aluminum, steel, and titanium metals. Aluminum has become a market favorite because of its excellent machining properties. It features low-weight characteristics. While steel serves as a strong material that demonstrates excellent durability attributes. The specific tasks that require high-performance features rely on titanium. Different industries find their needs for product specifications fully satisfied by the pre-established traits of metals.

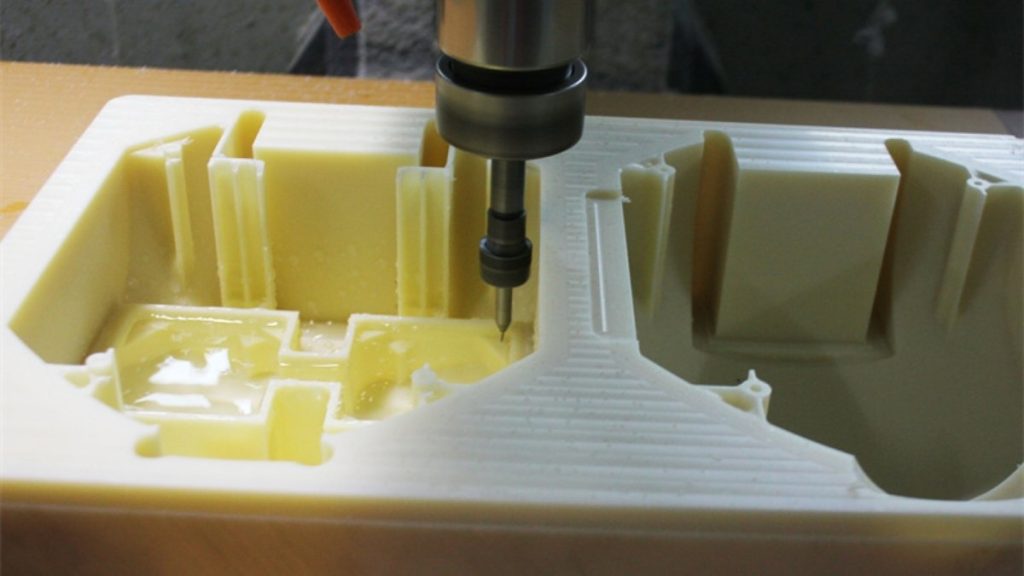

Plastic CNC Machining

Manufacturers use ABS and Nylon as well as Polycarbonate plastics during CNC production of low-volume products. These offer a combination of lightweight nature and easy machineability, and versatile characteristics. Plastics find application in industry mainly due to their economic advantages when producing consumer goods, medical equipment, and aerospace materials. Plastics serve as CNC machine materials since they adapt well to produce intricate forms.

Choosing the right partner for your low-volume CNC machining project is crucial to achieving the desired outcomes. Look for a provider who can deliver high-quality work, meet your deadlines, and offer competitive pricing.

Precision is non-negotiable in CNC machining operations. That’s why strong quality control is imperative. Choose a shop with proven precision abilities, as your parts must meet strict tolerance requirements. Inquire about their procedures for quality assurance and examination protocols, like whether they follow ISO standards or not. A reliable shop will always offer premium components. These will not only exhibit zero defects but also adhere to your technical requirements.

The cost/pricing of low-volume CNC projects depends on various determinants. It is established by multiple factors like quantity, part complexity, and turnaround. Let’s take a glance at these parameters.

The essential elements for cost consideration include initial expenses devoted to setup operations and coding protocols. A producer needs to evaluate production expenses, even though mass production setup fees do not apply to low-volume machining operations. Programming duration and machine setup time directly affect the total cost of your parts.

The total production costs rise when manufacturing operations need either costly raw materials or highly exacting precision standards. Your design needs precise tolerances, thus driving up production expenses because the product requires complex manufacturing methods and enhanced precision.

Don’t forget the extras. The project expenses rise as per post-machining needs. These include anodizing, painting, and polishing services. The project financial plan requires inclusion of all additional procedures.

ApexRapid is your trusted partner for low-volume CNC machining. We provide high-precision parts with fast lead times, often in just 1 day. From prototypes to short runs, our facility follows strict quality roles, ond our services are compliant to ISO 9001:2015-certified standards.

We serve industries like aerospace, medical, electronics, and automotive. With over 50 materials and 20+ finishes, every part meets your exact specifications. Need assembly or surface finishing? We’ve got you covered.

Let’s build your next project faster, easier, and with unmatched precision. Get an instant quote now at ApexRapid.