Sometimes, you do not need 1000s of parts. You may need a small batch to test a new design or meet a short-term demand. That is where low-volume injection molding comes in. It helps you make quality plastic parts in smaller quantities without high costs.

This method is useful when your design might change, or you want to avoid waste. It is also a good choice if you need parts quickly and want to stay flexible. Many industries use it, like medical, electronics, and aerospace, where precision and speed are more important than mass production.

Low-volume molding gives you control over cost, time, and quality. It is a smart step between making a prototype and going into full production.

Low volume Injection Molding

The low volume injection molding is not limited to small runs. It is a feasible option when accuracy, speed, and cost are a triple bottom line. The decision to use this method will be based on the stage of the lifecycle of your project, risk tolerance, and product complexity.

It is the best method when making the transition between a prototype and full-scale production. You would require effective components of end-use materials. At this point, you have no intention of investing in full tooling. It allows you the time to scale on form, fit, and functionality.

It can also be used in custom or special products where demand is not very high but steady. In these situations, it would not be possible to construct a huge steel mould. An aluminium or hybrid mould can be of high quality to ensure repeatability while being of low cost.

The other application is in preliminary product validation. Shorter tool lead times can be produced with low-volume moulds. This implies that product developers can stay abreast of beta user feedback, regulatory feedback, or field test feedback without having to stall development or spending excessive money on tools that may change.

This is suited to industries such as aerospace, medical equipment, and electronics, where any batch might require a small design change. Even complex geometries and tight tolerances can be done in short runs with simple production-grade resins when you have the right supplier.

Plastic Pellets for Injection Molding

The cost and tool life are directly influenced by material selection. In the low volume moulding, you need to consider the behaviour of the resin. Other materials deteriorate fast due to repeated thermal cycling. The others wear too much soft tooling.

Typically, ABS is selected on the basis of dimensional stability. It does not produce sink marks or warping in intricate geometries. It shrinks at a moderate rate, which is useful for aluminium tooling. Another thing you obtain is good surface quality, and little polishing is needed.

Other good choices include polycarbonate, which is good in terms of clarity and strength. It does not have an end-use brittle impact. It smoothly flows with low clamp pressures, and this is useful in short-run cycles.

Polypropylene is an excellent substitute when flexibility is a concern. It does not get tired or bend after long use. You do not get cracking problems that are present in stiffer plastics.

Consider glass-filled nylon in parts that have to support a load. The reinforcement enhances the mechanical properties very well. However, this also enhances the abrasion of the tools. To increase the tool life with filled resins, use coatings on cavities.

Different materials will act in different ways with respect to the thickness of the wall and the location of the gate. Shrinkage and flow rate testing must always be performed before production. This is so that the mould produces correct parts in each cycle.

You have to compromise between processability, part functionality, and mould cost. This consideration of selection eliminates downstream problems of testing and use.

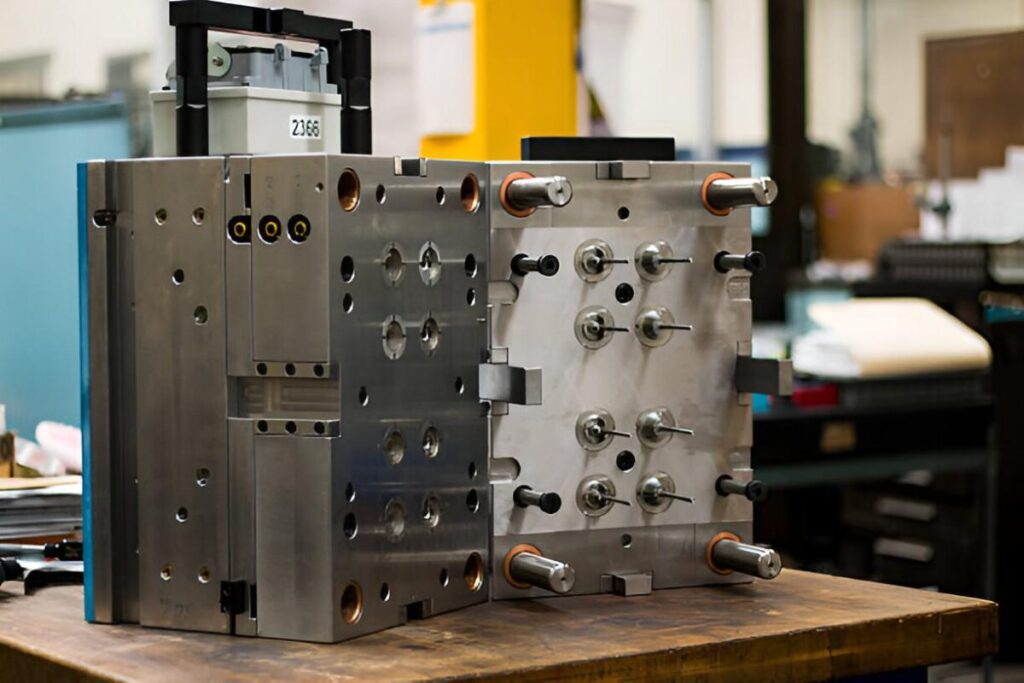

Eight Cavity Injection Mold Tool

The use of tooling is crucial when short batches are in use because any imperfection results in delaying or scrapping the product. You should come up with tools that are flexible and repeatable.

The low-volume requirements are accommodated by soft tooling, which may be aluminium or P20 steel. Aluminium is cheaper to manufacture, and it also cuts faster. However, it must be more strictly managed in terms of temperature when it is being operated. A change in dimension due to even small amounts of thermal expansion changes the dimensions of parts promptly.

The correct angles of draft have to be added to all the vertical faces. In the absence of this, parts stick and deform in the process of ejection. The normal range is between one and three degrees, and it depends on the resin.

In the tool cavities, venting needs to be provided on deep pockets. During injection, the gases trapped result in the burn marks and short shots. Such faults can be avoided by using micro-vents with a size of 0.02 millimeters.

Adjust features by using the interchangeable insets. Inserts allow the option to change logos, text, or fitment areas without replacing the tools. This minimizes downtime and allows for quick iteration.

Short cycles need cooling channels that are well-placed. Conformal cooling should be used to achieve uniform temperature. Repeatability between cycles is also enhanced due to consistent cooling that limits warping.

At last, we have to consider the gate design and placement. Gates that are smaller than they should be are also pressurizing, and gates that are too big are scarred. Functional areas are optimized and do not cause weld lines due to balanced gating.

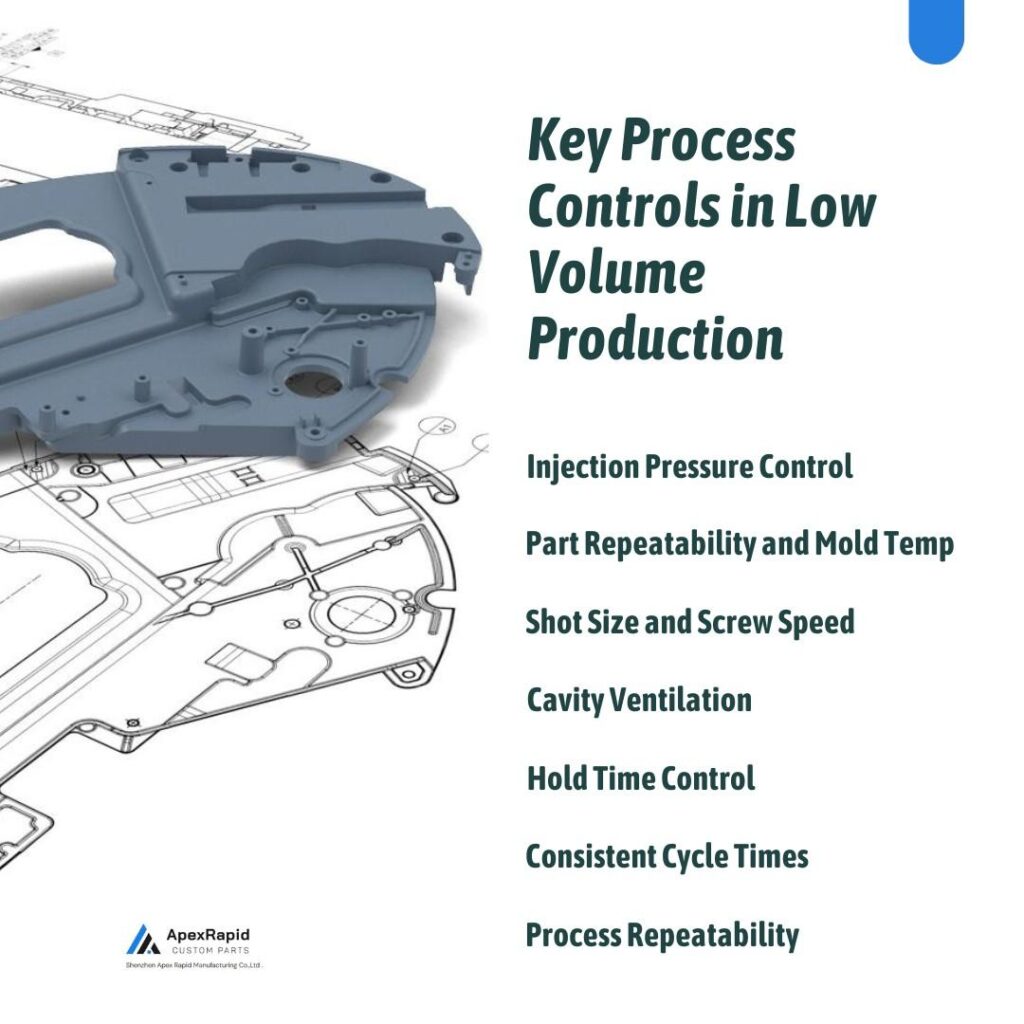

Process Controls in Low Volume Production

In short runs, the injection process has to be controlled. There is not much time to cater to or refine output. Each of the cycles should initially give high-quality parts.

The injection pressure has to be maintained over the same shot. In low-volume production, any change in pressure tends to be caused by material inconsistency or heat variation of the surroundings. This can be monitored in real time to prevent sink marks and warping.

Part repeatability is also critical when it comes to mould temperature. Aluminium moulds take less time to heat and cool, unlike the high-volume steel tools. You have to adjust the thermal range to match the resin's characteristics. The material can deteriorate by overheating, under-heating, and changes in fill rate and surface finish.

The size of shots and the speed of screws should be given special attention. A general-purpose machine is common in smaller runs. This is not always optimised to be precise in metering. Short-shot control of the machine requires you to calibrate the machine to prevent flash and short fills.

There must be ventilation in the cavity. The full venting systems may not be part of low-volume tools. It causes air entrapment and bad parts. Such considerations can be done by adding micro-vents and designing the gates well to ensure there are air escape ways.

Another thing that is ignored in short production is hold time. The pressure must be held at a point where a shrinkage is avoided, but not one that will result in over-packing. This equilibrium maintains the parts' dimensional properness and soundness in structure.

The cycle times need to be the same for all parts. Otherwise, you will lose part quality or tolerance if one cycle is different. The ability to keep track of pressure, temperature, time, and so forth due to digital pressure, temperature, and time sensors contributes to the stability of the process.

Repeatable control is the first step of precision in low-volume projects. Control of the product quality as a result of limited runs is aided by tight windows in the process.

The identification of uniformity in short-run injection molding requires customized quality measures. Reduced unit loss is achieved because a defective unit will mean a larger loss of the units in the smaller batch. Here, we are discussing how you have managed to keep product integrity without stretching resources.

All the resin batches ought to be traceable. You have small amounts of work, so it is important to monitor the blends or additives. Keep a record of the time taken to dry materials, the temperature, and exposure to humidity. This has a direct effect on the melt flow and the mechanical strength.

Different types of the same kind of polymer can change shrinkage rates even with a minute difference. Every batch of deliveries should be recorded and matched with a unique production ID. That will prevent the situation where the performance in parts of the trial and the end deliveries will not match.

Projects with low volume are usually in favor of prototyping or functional trials. This necessitates the relevance of dimensional accuracy. The key features should be inspected using a digital calliper or CMM during first article runs. Check against the tolerance of CAD models at the frequency dependent on the complexity of the part.

In the case of the parts that have inserts or overmoulded parts, carry out inline verification. Minor errors will be detrimental when left uncorrected. In the case of aluminium tools, the offsets of shrinkages should be taken into account per cavity section. Measure in the warm-up cycles to stabilise.

Cosmetic quality is not irrelevant in the short run. The parts can be sold to early customers or undergo regulatory testing. Surface defects such as flow lines, splay, or small flash need to be managed carefully.

Employ regular sources of light in order to point out the flaws. Compare the batches under controlled lighting in case there is a need to match the colour. Provide visual benchmarks when communicating results to the customers or design engineers.

In places where relevant, carry out pull test, impact, or tensile validation. In short runs, full destructive testing may not be performed, but you can perform fast tests on smaller numbers to prove the core strength.

Injection Molding Thermoplastic Machine

It is also necessary to select the appropriate collaborator for the short-run moulding. The supplier has an impact on cost, lead time, and part consistency. At a low level, errors can be noticed more easily. The technical capacity of the supplier, its way of working, and adaptability are the factors that should be assessed at the initial phase of work.

A good supplier knows the distinction between high and low volume tooling. Inquire into their past short-term projects. Have they ever used pilot tools, bridge tooling, or test-market parts?

Experienced suppliers that are capable of working with early-stage production are aware of how to assist in design changes, quick turn, and controlled tolerance requirements. They can also forecast problems with shrinkage of resin, gatin,g, or uniformity of the walls when they require a few hundred parts only.

The largest cost up front is tooling. Enquire whether the supplier will also provide aluminium tools, soft steel tools, and modular inserts. These are cheaper and time-saving than hardened steel ones.

There is also a need to evaluate their material support base. Are they able to procure low-volume resins in engineering? Do they provide mould flow simulation or material testing? The choice of resin influences the thermal resistance, strength, compliance, and flexibility; in this respect, it is essential.

Small volume is not small standards. They are asked whether they carry out dimensional checks, visual inspection, and batch documentation. Good suppliers offer traceability even in the short run.

This is significant to the controlled sectors such as medical, electronics, and vehicles. In the event your product is joining a regulated supply chain, a request for their certification is necessary. IATF 16949, ISO 9001, or ISO 13485 imply process control even with small batches.

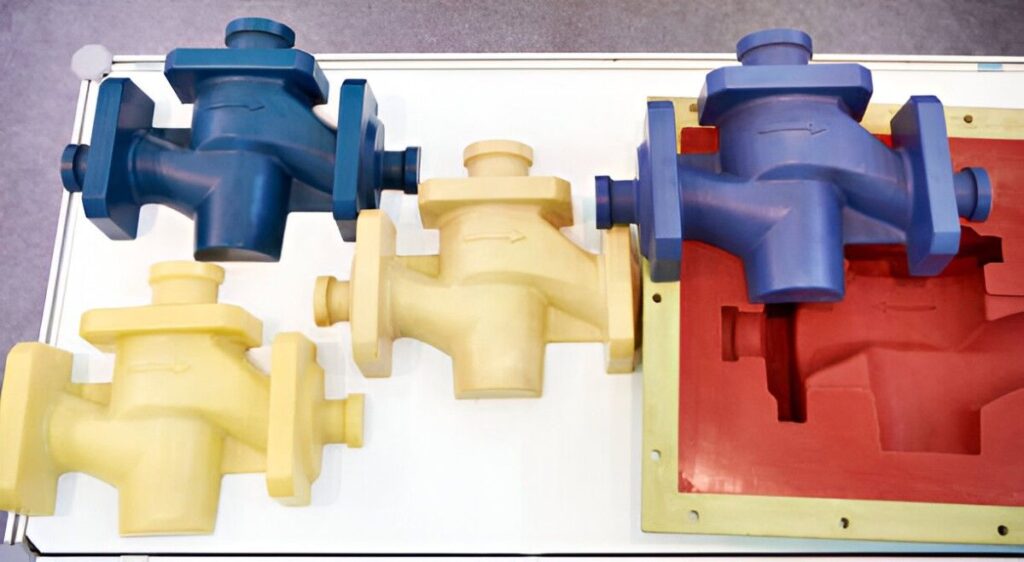

Low Volume Injection Molded Pipe Connectors

Trial orders should be tried before making an order. Request the supplier to make a few parts of the same tool. This demonstrates their real-world tolerances, the quality of their finish, and delivery reliability.

Take these sections to test fit, functionality, and the reaction of the users. It also makes scaling confident. If you want to go to medium and high volumes in the future, simulate how the supplier can support design changes, tool updates, and post-moulding processes such as printing or ultrasonic welding.

Low and high volume injection molding are not just separated by quantity. Each serves different stages of a product’s lifecycle and comes with trade-offs in tooling, speed, cost, and flexibility. Understanding these core differences will help you make better sourcing and production decisions.

The cheaper tooling materials, such as aluminum, are used in low-volume molding, which is less demanding. Such molds grow obsolete quickly and are perfect when the product is still in a development stage. They permit the adjustments to be made easily and have short lead times.

Molding is performed in large quantities, and the molds are made of durable, hardened steel. The tools are more expensive to acquire but are more supportive of larger production batches, and there is little maintenance. They are efficiency-oriented and not flexibility-oriented.

Short-run moulding makes it possible to develop the tools and launch production faster. It can be used to perform early testing in the market, product sampling, or seasonal runs. You can modify the features of the design even after the initial production.

The big volume molding takes a longer preparation cycle. Once tooling has been completed, changes will not be easy and will be costly. It is most appropriate when there is a tried and tested product design that will last over a number of years.

The low volume runs are run at low initial investment and higher cost per part. Such is okay when quantities are small and what is wanted is market entry or testing, and not cost effectiveness.

Start-up of high-volume runs is capital-intensive. Nevertheless, the unit price goes down considerably with the rise in volume. This model is applicable in long-term supply chains and high-demand applications.

Low volume processes tend to encompass hands-on inspection and a flexible criterion regarding quality. This is aimed at improving and perfecting the part that is under early-stage development.

High volume molding is fully based on automation and strict quality follow-ups. The cycle incorporates inspection processes, and thus every part in the process is tested and found to be within specification. It is robust, highly repeatable, and scalable

| Feature | Low Volume Injection Molding | High Volume Injection Molding |

| Mold Material | Aluminum or soft steel | Hardened steel |

| Tooling Cost | Low to moderate | High |

| Lead Time | Fast | Longer |

| Flexibility | High (designs can be changed) | Low (requires finalized designs) |

| Cost per Unit | Higher | Lower (at scale) |

Low-volume injection molding is a smart choice when it comes to fewer parts, fast changes, and flexible designs. It helps you reduce waste, lower costs early on, and allows you to test products before scaling. This method suits growing businesses and companies that make custom products. It gives you more control over design updates without waiting months. When compared to high volume molding, it’s more about speed and flexibility than mass output. Knowing the difference helps you plan better and avoid large upfront costs.

Q1: What is considered a low-volume run in injection molding?

A low-volume run typically ranges from a few hundred to around 10,000 parts. It depends on the material, design, and mold life expectancy.

Q2: Can I still get good-quality parts with low volume molding?

Yes, many low-volume services use precise equipment and quality checks. The main difference appears in scalability and cost per part, not quality.

Q3: Is aluminum tooling reliable for production use?

Aluminum tooling is durable enough for short runs and prototyping. It is ideal when you expect design changes or limited part demand.

Q4: How do I decide between low and high volume molding?

Consider your budget, timeline, and part demand. If you're testing the market or refining your design, low volume is ideal. For stable, high-demand products, high volume makes more financial sense.