You probably handle metal every day. Figuring out which one holds up best isn’t always easy. Choosing the wrong metal can mean wasted time, extra costs, or even safety issues. So knowing how strong each metal is matters—a lot.

That’s why a metal strength chart is so handy. It’s like a quick cheat sheet that tells you what metals can handle tough jobs and which ones might crack under pressure. Instead of guessing, you get the facts to pick the right material the first time.

In your work, this knowledge saves headaches. Whether you’re fixing a machine, building something new, or just figuring out what metal fits your needs, understanding strength means better results and fewer surprises. Let’s break it down so you can choose smart and get it right.

Not all of the terms on a metal strength chart will be easy to understand at first. Below physical terms are must to understand. These let you choose the right type of metal for your work.

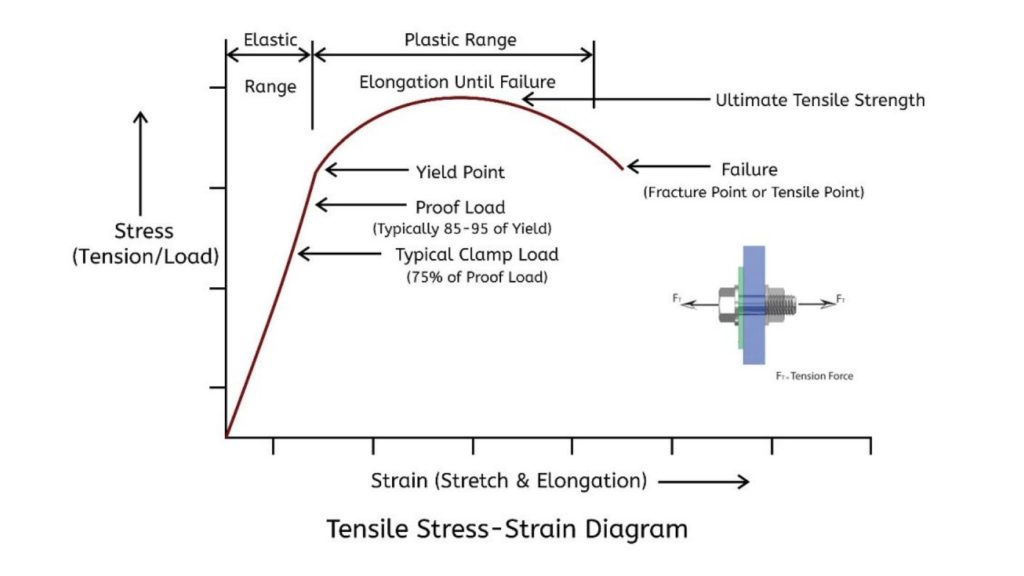

Tensile strength shows you how much force a metal can resist before it tears apart. Stretch a metal wire until it breaks; that is tensile strength.

If your project requires stretching or pulling metal, this number tells you if the metal is strong enough to resist breaking.

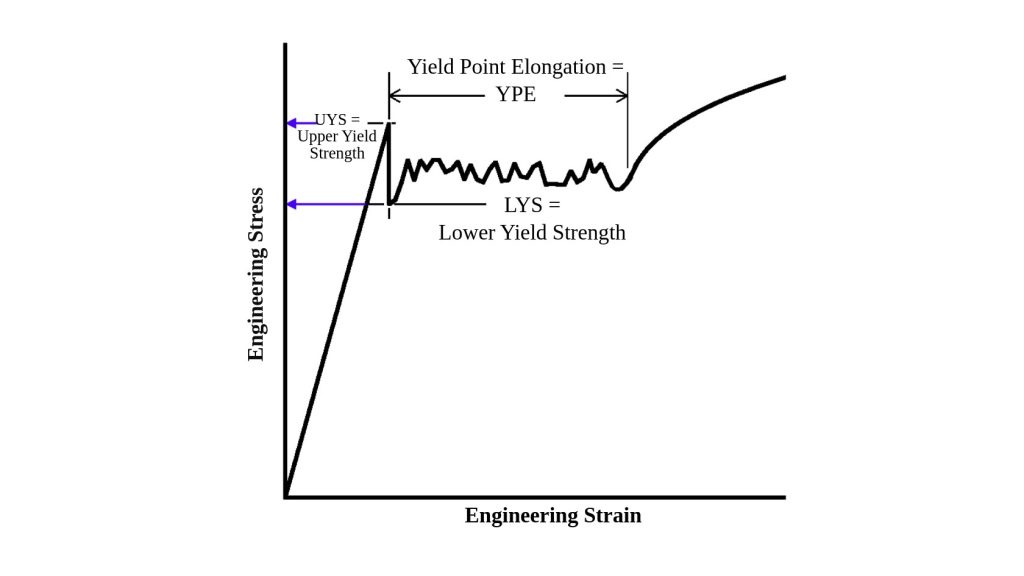

The strength of a metal is said to be its yield strength, which means the metal has bent or changed shape but not broken. See it as an indicator that something may go wrong in the future.

When your metal might face pressure or weight that could bend it, this shows you the point where it could bend too far.

The resistance of a metal to scratches and dents is what is called hardness. The power is not in the strength of the metal inside, but in how sturdy the outer surface keeps its shape.

If parts made of metal rub or are hit, they last better if they are hard.

Picking the right metal begins with being familiar with some basics. Different metals are strong in their own ways, and knowing those distinctions allows you to pick what you need. This is a look at some frequent metals, what they are, and how relevant their strength is.

Many fields depend on steel. It is tough and able to handle lots of weight without bending or breaking. The tensile strength of steel changes based on its type; for example, mild steel has about 400 MPa, and high-strength alloys have more than 2,000 MPa.

For projects where durability is important, such as building frames, parts for vehicles, and heavy machines, steel is usually used first. It is not expensive, people can get it easily, and it works well under stress. Any project will be reliable if steel is used to withstand tough and harsh conditions.

Though aluminum is lighter than steel, it is still a tough option. Softer alloys have a tensile strength of about 70 MPa, whereas stronger grades can be up to 700 MPa. That is why aluminum is often found in airplanes, bicycles, and electronics which need to be strong and light.

Since it is light and doesn’t corrode, aluminum is often used for boats, docks, and outdoor equipment. To lose weight without losing a lot of your strength, go for aluminum.

Their tensile strength, which gives clues about their strength, is usually under 300 MPa. There are more benefits that they contribute:

Copper is very good at conducting electricity and heat. Wiring and plumbing are simple with conduit. Brass, which is made of copper and zinc, is easy to machine and does not corrode easily. Valves, decorative fixtures, and musical instruments may include both types.

Some call titanium the superhero among metals. It has the strength of steel, but is much lighter because its tensile strength is often higher than 1,000 MPa. It holds up without rusting, and it stands up to high temperatures and pressures.

Because titanium is light but very strong, it is used in aerospace, implant devices, and top-quality sports gear. It is more expensive, though, if your project needs wonderful results, titanium is worth the extra expense..

Here’s a comprehensive and practical Metal Strength Chart table showing common metals and key strength properties. This chart can help you quickly compare metals for your projects:

| Metal | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (Brinell) | Density (g/cm³) | Corrosion Resistance | Common Uses |

| Carbon Steel | 370 – 700 | 250 – 600 | 120 – 200 | 7.85 | Low (prone to rust) | Construction, tools, automotive |

| Stainless Steel | 480 – 750 | 250 – 520 | 150 – 300 | 7.75 | High (excellent corrosion resistance) | Kitchenware, medical instruments, marine |

| Aluminum (6061) | 310 – 350 | 275 – 300 | 95 – 120 | 2.70 | Moderate (good outdoors resistance) | Aerospace, automotive, frames |

| Titanium (Grade 5) | 900 – 1000 | 830 – 880 | 330 – 370 | 4.43 | Very High (excellent corrosion resistance) | Aerospace, medical implants, sports equipment |

| Copper | 210 – 370 | 70 – 350 | 35 – 110 | 8.96 | High (resists corrosion well) | Electrical wiring, plumbing |

| Brass | 300 – 550 | 200 – 350 | 55 – 200 | 8.50 | Moderate (resists corrosion) | Decorative items, valves, fittings |

| Cast Iron | 150 – 300 | 100 – 250 | 150 – 250 | 7.20 | Moderate (can rust without coating) | Engine blocks, pipes, and machinery |

| Magnesium Alloy | 200 – 350 | 150 – 250 | 60 – 110 | 1.74 | Low (corrodes easily) | Lightweight frames, electronics |

| Nickel Alloy | 550 – 1400 | 350 – 1100 | 200 – 450 | 8.90 | Very High (used in harsh environments) | Aerospace, power plants, chemical processing |

Picking the right metal isn’t just about numbers—it’s about what your project needs. Here are some easy tips to help you decide.

Focus on: How heavy or tough will the loads be that I need to handle with this metal? If there is a lot of stress put on the object, go for strong metals, for example, steel or titanium.

When something has to be light, such as a bike frame, aluminum helps because it is both strong and light.

Will the metal face exposure be outside, close to water, or face high temperatures? In the case of yes, pick rust- and corrosion-resistant materials such as aluminum or stainless steel. If exposed to high heat, the metal should continue to be strong at that temperature.

When your piece will be rubbed or stressed many times, use metals that have both good hardness and resistance to repeated use. What that means is your metal will stand up to corrosion and shock better.

Also, ask yourself if it’s possible to coat your jewellery to make it last longer.

In some cases, using the toughest material isn’t the right decision when it is costly or scarce. Make sure your workouts work well with the equipment you own.

Many people prefer steel since it is cheap and plentiful compared to titanium, which gets expensive. Check that the kind of metal you choose matches your budget and schedule for the project.

If you are in doubt, test just a little bit at first. Check if your project’s conditions affect the metal, such as its bending, getting scratched, or rusting..

Understanding metal strength means more than just numbers. Real tests reveal how metals behave in everyday use. Here are several important metal strength tests you might not know about—and why they matter.

The compression test pushes a metal sample until it deforms or crushes. This test is crucial for materials used in columns, supports, or anything that bears a heavy weight.

If your project involves squeezing forces or heavy loads, the compression test shows whether the metal will hold or fail.

The bend test bends a metal piece until it cracks or breaks. This test tells you how flexible the metal is and how much it can take before it snaps.

This is important for parts that will be shaped during manufacturing or will face bending forces in use.

Creep testing measures how a metal slowly deforms over time under constant stress, especially at high temperatures. Think of metals in engines or turbines that run hot and under pressure for years.

Knowing creep behavior helps pick metals that won’t slowly stretch or fail after long use.

Corrosion testing exposes metals to moisture, salt, or chemicals to see how fast they rust or weaken. This test is key for metals used outdoors, near saltwater, or in harsh environments.

It helps you choose metals that will last, not just look good at first.

The torsion test twists a metal piece to see how much torque it can take before it breaks or deforms. This test matters for shafts, screws, or any part that twists during use.

If your metal part needs to resist twisting forces, the torsion test results are critical.

While hardness tests check surface strength, impact toughness tests measure how well a metal absorbs sudden forces without cracking.

This test mimics real-world impacts like dropping or hitting and helps pick metals that can take a beating without failing.

Receiving test results is only the opening step. You see the real benefit when you interpret what the numbers mean in your project. These are some ways to look at these in practical use.

For example, you are putting together a metal structure that is supposed to hold a lot of weight. Interest yourself in the numbers describing stress and strain in steel. If these properties are strong, the metal will not break under heavy stress.

For a part that must bend, such as a spring, aim for metals that can stretch slightly. It helps make certain you don’t go with something too weak.

Even if it looks good on paper, metal could be very difficult to work with in construction or manufacturing. A typical example is when very hard metals, when dropped or shocked, may fracture or crack.

Assess the tools you use and the way you do things in your workshop. Some applications might be better solved with a slightly soft metal, which cuts down both time and costs.

When your project will be exposed to the elements, make sure the test considers these kinds of changes. Something that did well in testing can fail after being used in the environment.

Testing metals in similar conditions allows you to choose the right ones and avoid problems later.

Check fatigue tests if the metal will see frequent daily movement or flexing. If a part breaks soon after it is used thousands of times, it is not useful.

Based on the test results, arrange inspections or change parts to stop them from breaking. Using this way of thinking helps operations work smoothly and safely.

Often, the material itself is tough enough, but the coating needs additional strength. Looking at the test results can steer you toward coatings that stop rust or make the surface harder.

Applying a protective coating helps your metal survive longer and still keep its main properties.

Using test results in real project circumstances helps you come up with smarter and more realistic decisions. You should understand the financial side and how it affects your normal operations and outcomes.

Metal strength charts are super helpful when you’re trying to pick the right metal. They show you how tough, strong, or flexible a metal is, and how well it will hold up over time. Whether you’re building something big or small, knowing these details means you won’t end up with metal that bends, breaks, or rusts too soon.

But don’t just go for the strongest metal on the chart. Think about how heavy it is, where you’ll use it, and how it reacts to heat or water. Combining these factors with the chart helps you make the smartest choice for your project. When you know what the numbers mean, you save time, money without frustration.

Q1. What exactly is tensile strength?

Tensile strength tells you how much pulling force a metal can handle before it snaps. It’s important to know if your part will be stretched or pulled.

Q2. How is yield strength different from tensile strength?

Yield strength is when the metal starts to bend or change shape, but hasn’t broken yet. Tensile strength is the breaking point. Yield strength helps you know how flexible the metal is under pressure.

Q3. Which metals are usually the strongest?

Titanium and some nickel alloys are known for being very strong while still not too heavy. Steel is also strong and widely used.

Q4. How does weather or moisture affect metal strength?

Water and rust can weaken some metals over time, especially steel. Metals like aluminum and stainless steel resist rust better, so they’re better for outdoor use.

Q5. Can I trust metal strength charts alone?

Charts give you a good idea, but actual performance depends on how the metal is made and used. Testing the metal in your specific situation is the safest way to know for sure.