You’ve likely seen chrome plating on car parts, tools/equipment, or hardware. It’s more than just a shiny finish. It protects components from corrosion and improves their performance. Besides, chrome plating adds strength, resists corrosion, and improves wear resistance. If you're working with metal, you need to know what chrome can do.

In this guide, you’ll learn how it works, where it’s used, and why industries trust it. Whether you're restoring parts or planning production, these facts will help you make the right call.

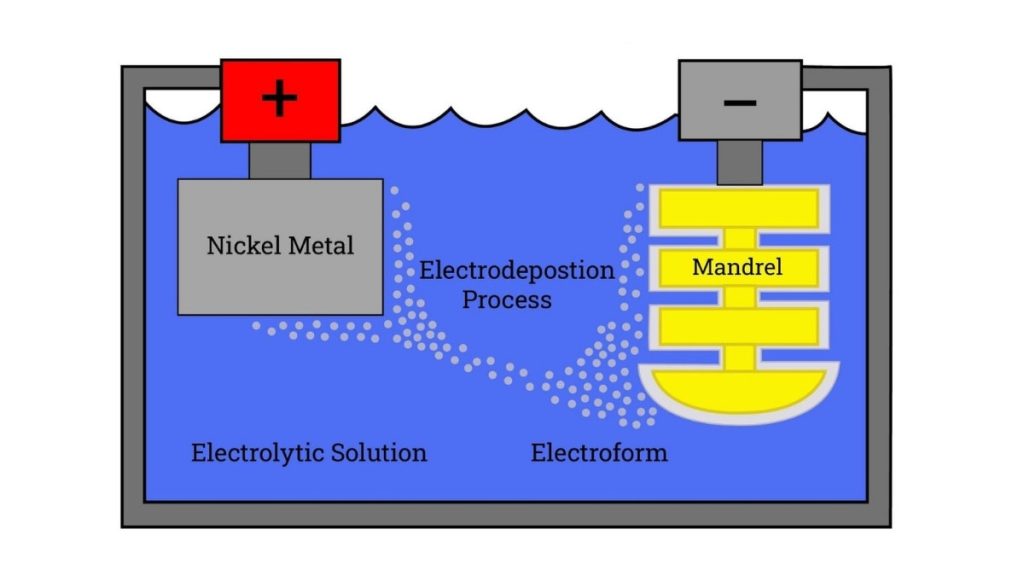

The purpose of chrome plating metal is to enhance part’s outer layer. A base metal obtains a thin layer of chromium through an electroplating process. It applies an electric current to join chrome to the part's surface.

The result? A hard, shiny surface emerges, which allows the part to resist rust, wear, and damage. Chrome plating creates parts that develop a uniform reflective surface with a mirror effect. The process is mainly used for its performance and appearance benefits.

Chrome plating appears across vehicles and industrial equipment, tools, automotive parts, and various appliances. Metal parts benefit from it by gaining appearance enhancement as well as extended product lifespan. Choosing Chrome is wise when you need excellent performance and a high-gloss appearance.

Several procedural steps lead to the transformation of basic metal materials into durable parts with polished chrome coatings. Let’s take a look at all these steps;

The initial step requires cleaning the metal surface. Rust or oil, and any foreign dirt will damage the final appearance. The outcome of chrome adhesion and strength depends on having an immaculate base. The treatment choice depends on the part condition between solvents and ultrasonic cleaning, and abrasives.

All existing paint and coating materials need stripping before proceeding. There are two approaches to removing coatings, including grinding and chemical exposure. Ahead of application, you obtain an untainted surface that allows you to work directly.

The pre-treatment step reveals all areas that may need attention for plating purposes.

The metal requires activation before the plating operation. The application of acid or low electric energy opens the surface for treatment. This step improves chrome bonding.

Once the chrome layer application is complete, peeling or flaking of the material surface is prevented.

The electroplating process fixes a thin chrome layer across the metal surface. The length of time and the amount of voltage determine how thick the applied layer will become.

The process of achieving even coating depends on maintaining the optimum chemical mix and proper bath temperature levels.

This step involves rinsing the part with water, free from chemical contaminants. The water rinsing procedure removes any residual chemicals as it simultaneously cools down the surface. It makes the item ready for concluding tests.

Failure to rinse the part results in remaining chemicals, which will affect the finish quality.

The inspection process requires you to examine the part for any imperfections and uneven surface areas. You will polish the chrome until achieving a mirror-like reflection if required. The part appears clean and operates optimally after this stage.

Surface smoothness as well as light reflectivity increases during the final polishing process.

Many factors determine the strength and quality, smoothness, and durability of your finish. Here are the most common aspects;

Your outcome heavily relies on the condition of your base material being free from blemishes as well as smooth in appearance. Cracks, rust, marks, and dents may disrupt the chrome surface appearance.

Achieving a proper mix composition for the chrome bath mixture is essential. An inappropriate amount of any chemical component in the solution will result in ruined chrome coatings. Therefore, a balanced mix solution leads to uniform plating distribution and solid chemical bonds.

The plating process depends on maintaining a constant solution temperature for optimal performance. If the temperature is high or low, the layer doesn’t form properly.

A continuous check of heat levels must be performed throughout the entire operation.

The speed of chrome layer accumulation depends on the electric current. Surface burns occur when the current levels are too high, while weak coverage results from low current levels. The voltage selection must consider part size and desired thickness.

Chrome layer thickness increases proportionally to the duration of time when parts remain in the bath solution. An extended period in the solution has the potential to lead to defects forming. The plating duration must correspond correctly with your project requirements.

The process requires three crucial stages, which include plating, followed by rinsing, and then polishing. Failure to perform post-treatment can lead to stains and rough surface areas. A suitable final layer both strengthens and provides gloss to your product.

Among the available chrome plating types, you have multiple options to select from. All these types present their unique combination of strength and appearance, and protective qualities. Your selection of choice relies on matching the requirements of your parts.

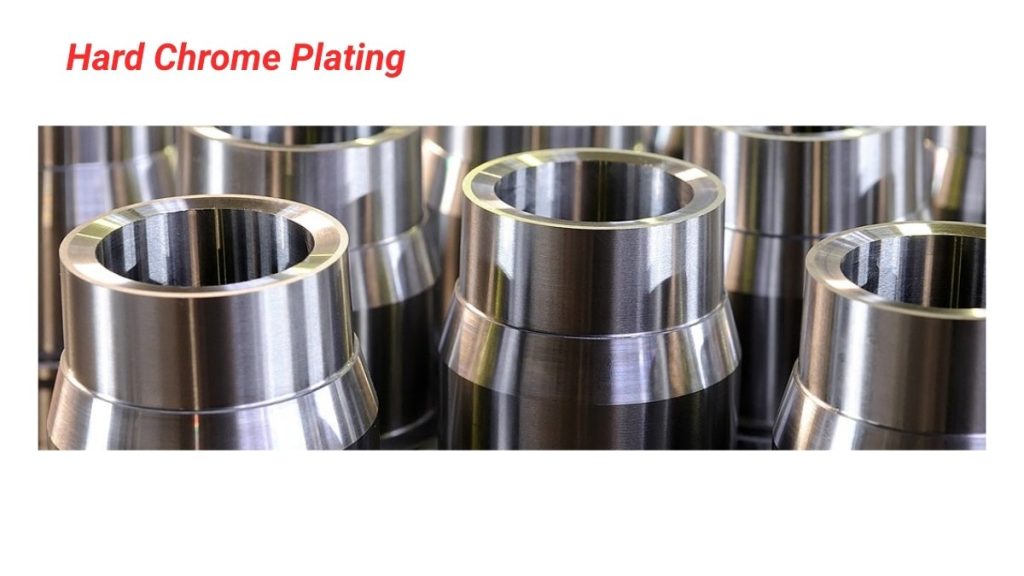

The key benefit of hard chrome plating emerges through its exceptional strength rather than its visual appeal. It develops a thick chrome coating, which ranges from 20 to 100 microns in thickness. The plating material exists to endure severe usage conditions, so it functions nicely on industrial equipment and engine components alongside hydraulic equipment. Although it appears dull, the material stands out because of its excellent durability.

Decorative chrome plating creates sleek reflective surfaces that resemble mirrors. It entails a thin chrome layer with a thickness of under 0.5 microns spreading across nickel base material. Basic types of decorative chrome coatings are present on vehicle bumpers, bikes, kitchen fixtures, and furniture.

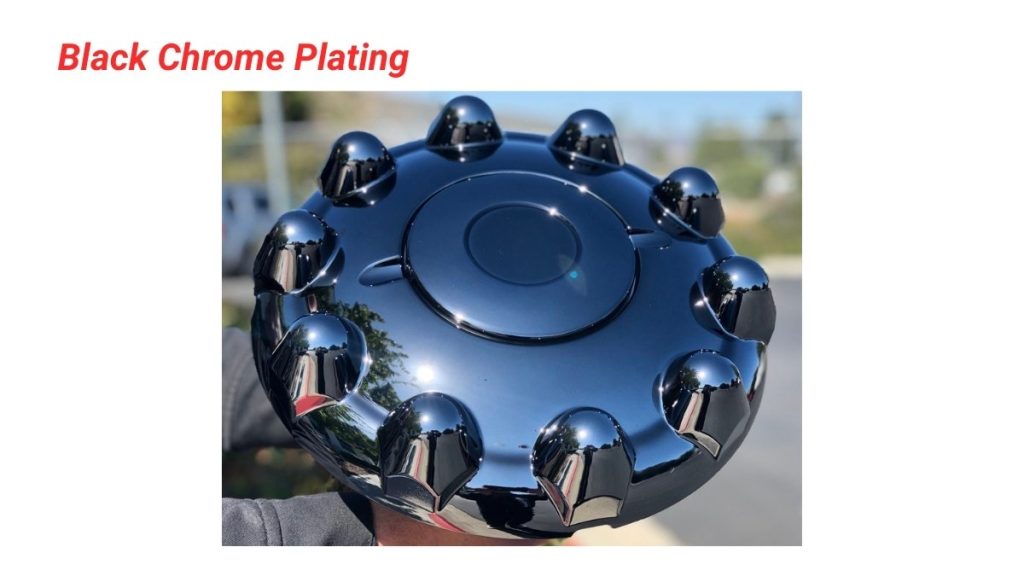

Black chrome plate materials provide a visible dark appearance that may present satin or matte finishes. It is produced through the blending of chrome, nickel, and metallic elements during plating procedures. The black chrome finishing combination eliminates glare while providing an upscale aspect. It finds common use across optics and aerospace fields and luxury product markets. The plating gives both corrosion resistance along reduced light reflection while bringing its special look to the table.

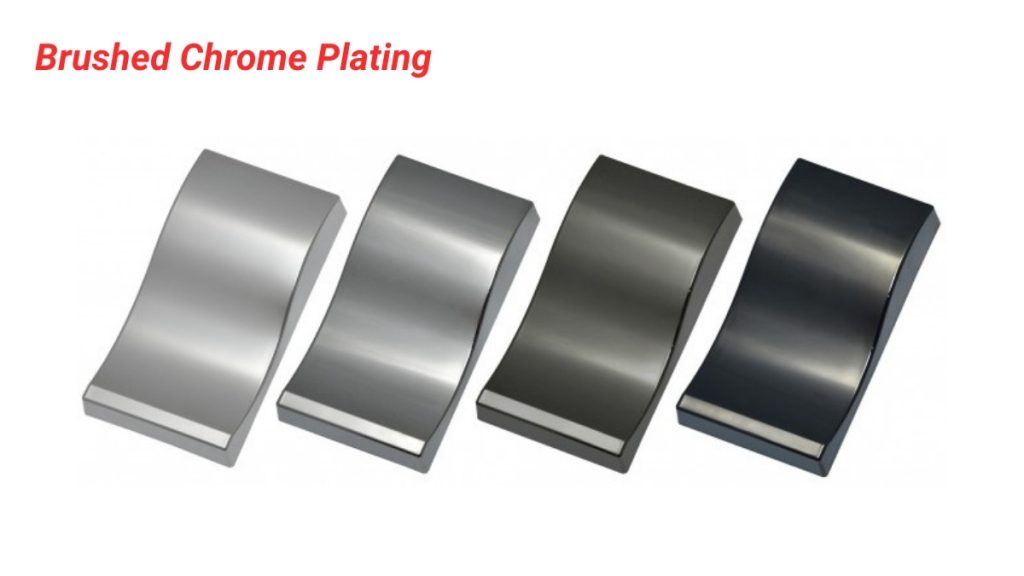

Parts that receive brushed chrome treatment appear with a soft textured surface finish. The surface preparation involves mechanical brushing for generating delicate lines that develop into a satin finish before plating takes place. It provides better concealed fingerprints and smaller scratch protection than polished chrome does.

The plating application suits appliance structures, automotive interior parts, and hand instruments that require attractive performance. The surface appearance remains contemporary without producing excessive reflection.

The surface of satin chrome material exhibits a soft velvety texture, which reflects minimal light. This plating surface maintains an attractive look that sits between glossy reflections and flat matte finishes, which works nicely in buildings across commercial and domestic, and business sectors. Users can identify satin chrome plating by observing it on door handles and kitchen equipment, along with light fixtures. The solution gives both acceptable protection against wear and corrosion.

Chrome plating presents value beyond its attractive appearance. Metal surfaces receive three major benefits from it because it strengthens components and protects them from damage, and creates endurance.

Chrome plating establishes a powerful defense that shields objects from rust while blocking moisture. It shields metal from chemicals, water, and air. The material functions optimally in challenging environmental conditions as well as outdoor areas.

The metal surface gains strength through the application of chrome plating. The surface of chrome-plated objects features high resistance to scratches and dents as well and abrasions. It enables tool applications as well as engine applications, and serves moving component in their operation. Heavy use duration becomes longer during operation.

The plating produces a smooth with reflective properties, and an upscale appearance. Your choice between shiny chrome and flat black finish makes any surface more noticeable. Chrome plating enhances the attractive value of vehicles, appliances, and consumer goods.

The application of chrome requires minimal maintenance. The uniform textured surface resists the accumulation of dirt, which makes the material easier to keep clean. The material stands strong against both tarnishing and fading. The material requires minimal cleaning work both inside and outside.

A chrome plating layer extends the longevity of components by reducing wear and damage. The protective layer shields essential components from persistent movement and heat exposure, as well as chemical substances. The plating reduces the need for replacements while cutting down downtime. So, it proves to be a long-term cost saver.

Despite the benefits of chrome plating, it also comes with several difficulties to consider. These includes;

Chrome plating creates adverse effects to the environment. Hexavalent chromium serves as a toxic hazardous material for chrome plating that develops dangerous properties when personnel handle it improperly. Waste management and disposal of chrome-plated materials becomes risky to the environment unless cautious procedures are followed. Safety standards must be achieved according to existing regulations.

The total expenses associated with chrome plating rise significantly. The expense typically increases as the volume of parts processed increases during plating operations. Higher expenses resulting from chrome plating mainly stem from equipment costs together with material expenses and labor costs. Other coating alternatives remain more affordable for businesses with minimal funds so chrome plating becomes impractical as a solution for them.

Chrome plating improves metal hardness, yet it creates brittleness as one of its effects. The outer chrome material becomes vulnerable to damage when it sustains heavy strikes and stressful conditions. Equipment exposed to high-pressure situations and high-impact conditions can cause damage to the protective chrome layer.

Chrome plating demands minimal care to maintain its appearance and operational efficiency. However, it requires proper maintenance for its effectiveness and to persist. The plating layer remains vulnerable to scratching since contact with rough surfaces is likely to cause damage. Repairing damaged plating proves to be expensive because it becomes challenging to fix.

The process of chrome plating succeeds only when specific types of metals are used. The best results from chrome plating occur when using steel and aluminum materials. The chrome plating on certain materials does not result in a solid bond with the base metal, so it becomes less durable and shows unevenness.

Chrome plating enables industries to benefit from three primary advantages that improve durability and resist corrosion, and deliver better wear performance. Here are the primary applications:

Chrome plating exists in specific automotive applications, including car bumpers and wheel rims, as well as trim sections. Engine components remain the main target group for this process application. The glossy finish Chrome plating delivers an enhanced appearance by creating an attractive aesthetic for vehicles.

Industrial machines usually have chrome on hydraulic rods and pistons. It aids in material hardness and resistance against wear in these systems. The plating operation implements friction reduction that leads to better operational efficiency. It minimizes the maintainance requirements and decreases the machinery's operating costs for longer periods.

Turbine blades, landing gear receive chrome plating treatments in aerospace applications. This process improves component strength, resistance to fatigue, and corrosion. The properties serve critical functions when used on components that encounter both harsh temperatures and substantial mechanical stress. The reliability of aerospace components under harsh conditions results from their chrome plating process.

Chrome plating serves as an application for electronic products, which include smartphones and laptops. The finish delivers a reflective surface with protection from surface damage and wear. Through plating, the products achieve better durability, which maintains their visual appearance. Also, such protection shields objects from corrosive elements and natural environmental harm.

The application of chrome dominates the production of furniture knobs and handles. This coating produces a shiny finish that stays bright because it does not tarnish. Chrome plating both enhances the durability of decorative items and lets them resist regular wear and tear. Chrome plating enhances office and home furniture by producing decorative effects with useful properties.

Manufacturers use chrome plating to protect marine hardware elements, which include propellers as well as railings. The layer shields metal components from developing rust because of saltwater contact. It serves as a friction reducer and improves water-based performance. The marine environment cannot damage chrome-plated hardware because it extends longevity while preserving the surface quality.

Chrome plating operates as a unique manufacturing process because it strengthens metal components while improving their surface appearance and making them resistant to corrosion within automotive industries, alongside aerospace sectors and industrial machine manufacturing. The process of chrome plating contains serious environmental hazards because toxic hexavalent chromium materials are released into the air and water systems, and soil if chemical waste disposal is not properly controlled. The plating process leads to environmental contamination because of dangerous substances and significant electrical power requirements. The necessity to comply with complete safety and environmental standards during chrome plating becomes vital due to the associated risks.

ApexRapid provides businesses with high-quality, environmentally aware solutions to perform chrome plating operations. The company delivers specialized plating expertise, so they maintain precise service while utilizing environmentally conscious techniques to safeguard your products.