These days, CNC machining and 3D printing are the two technologies used in plastic manufacturing. Each has its strengths, and so both are ideal for certain applications, budgets, timelines, and design requirements. Whether you are prototyping, whipping up some functional parts, or moving to production, picking the right method is worth it.

This guide compares CNC machining and 3D printing for plastic parts on a moderate scale. We help you dive deep into material properties, costs, and mechanical performance to make an informed decision. These decisions will depend on your project goals and the right way to understand the basic processes.

The plastic workpiece material undergoes removal through CNC (Computer Numerical Control) machinery. It uses numerous tools, including end mills, lathes, and drills. The tools operate under computer software instructions that stem from automated 3D model information.

Manual machining surpasses the standards of tolerances and repeatability, so CNC produces results to a ±0.025 millimeters precision range. Engineering applications that need structurally reliable components with dimensionally stable requirements receive consistently accurate parts from this workflow.

CNC machining benefits primarily the aerospace field, automotive, robotics industries, and the medical device sector. It is mainly due to the importance of structural reliability.

Here are some materials and their applications we can use in CNC machining;

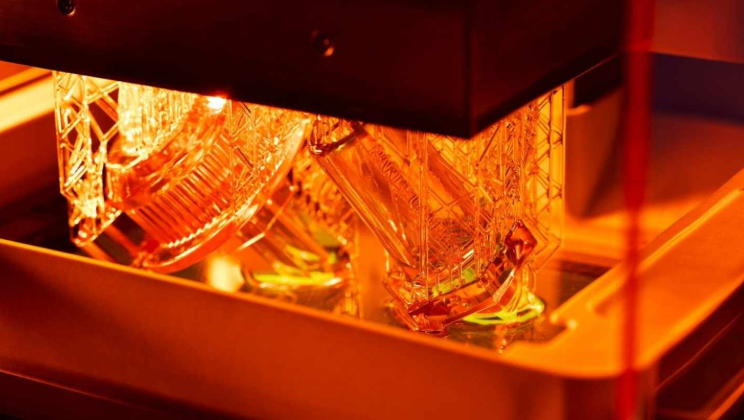

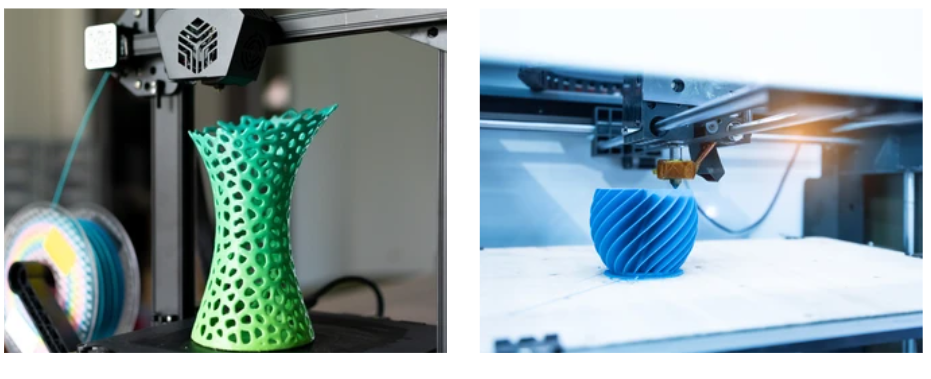

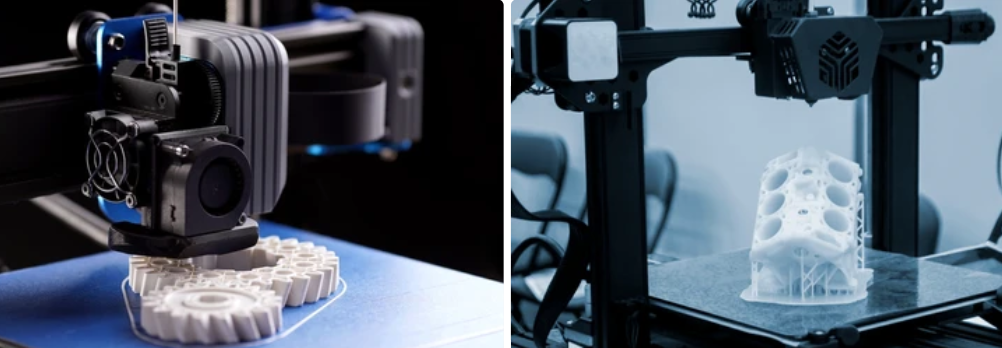

Additive manufacturing, or 3D printing, is the process of building material layer by layer based on a computer-aided design 3D CAD model. Whereas 3D printing only adds material where it is important, subtractive methods waste the vast majority of the material and have limited geometric freedom.

This is especially apt for small to medium volume runs TO optimize different applications in industries, i.e., consumer products, medical devices, and architecture.

With this capability, 3D printing allows for designs that integrate internal channels, lattice structures, and organic shapes, often at much faster iteration cycles and with less investment in tooling.

Let’s discuss the whole CNC machining operation in detail.

First, a 3D digital model of the part using CAD software such as SolidWorks, AutoCAD, or Fusion 360. Here, it covers the final parts’ dimensions, tolerances, and surface specifications of the final part.

Second, the CAD file is imported into a CAM (Computer Aided Manufacturing) software, where the design is translated into machine-readable toolpaths. The paths cut by the cutting tools depend on these tool paths.

The desired mechanical properties of strength, temperature resistance, and chemical durability preclude an appropriate plastic block, or 'workpiece', or 'stock'. Popular options include ABS, Nylon, Polycarbonate, PEEK, and Delrin (POM).

A CNC machine, such as a mill, lathe, or router, secures the workpiece. The machine obediently follows the programmed toolpaths to cut, mill, drill, or bore the material extremely precisely. For complex parts, we usually use multi-axis machines (three-axis, 4 axis, or 5 axis).

Secondary processes are performed to better functionalize or finish the product after machining. Deburring (removing sharp edges) or polishing, threading, engraving, or special surface treatment applications are all part of it.

The following is the step-by-step process of 3D printing;

Starting with design, this part is designed in CAD software. The final design is exported in a format that can be used for 3D printing (for example, STL or OBJ files). In these files, the geometry data rebuilds the model physically.

After that, we cut the model into thin horizontal sections with slicing software such as Cura, PrusaSlicer, or PreForm. In addition, the program generates code for the printer to follow the instructions regarding the movement, extrusion rate, temperature, layer height, and speed.

3D printer reads the G-code, which controls the order of any printing object, one layer at a time. The technology used determines the actual process.

As soon as the part is printed, the part is cleaned and polished.

FDM and SLA need to support the removal of temporary support structures.

Combining 3D printing and CNC machining can improve the end-use performance and development speed in modern manufacturing workflows. The hybrid approach relies on the strengths of each process where they’re strongest.

Different manufacturing methods can result in mechanical performance that varies when the part is made of the same material. The following comparison is direct between the key properties for one common plastic used in both CNC and 3D printing: ABS.

| Property | CNC Machined ABS | 3D Printed ABS (FDM) |

| Tensile Strength | ~40 MPa | ~25 MPa |

| Impact Resistance | High | Moderate |

| Compression Strength | Strong | Weaker due to layers |

| Dimensional Accuracy | ±0.025 mm | ±0.1 mm |

So, deciding on which plastic manufacturing method to put into plastic. It should take your project’s technical needs, budget, preferred material, and scalability into account. CNC machining and 3D printing each have their strengths, but the best choice will be different depending on your particular objectives.

Solid plastic blocks are cut into CNC parts to ensure that they have the same material properties everywhere. This uniformity means that they are excellent for use as structural load-bearing parts. On the other hand, parts printed in 3D are constructed in layers, with weaker strength across layers (anisotropy) that makes them less appropriate for hostile stress scenarios.

CNC machining ensures that little or no distortion has occurred to the material structure, so it can offer higher tensile strength. Such components require high durability and performance, and 3D printing is a better choice. The typical 3D parts are weaker, especially on the vertical axis. We can improve them with the print orientation and the use of advanced materials.

The strength of 3D printing is a fast turnaround, perfect for prototypes with shorter turnaround times and custom components. It has no setup, just slice and print it. CNC machining requires more preparation work (toolpath programming included). So, it can be and yet can be faster for larger batch runs when it’s set up.

3D printing is cheap and flexible for low-volume production (1–100 parts). With the volume increasing (100…10,000+), CNC machining becomes more efficient because the per-part setup costs are spread over many parts, thus lowering the actual cost per part.

Engineering plastics from the CNC family support high-performance and filled materials. On the other hand, whereas for 3D printing, materials more limited set is used, industrial printers come with stronger options, such as nylon, PEEK, and ULTEM, and better performance.

One of the 3D printing, advantages is the low upfront costs. It’s best suited for prototypes and small batches. At the scale, CNC has higher initial costs due to tooling and programming, but better economics. For parts to be repeated, this is a smart choice.

Automated and multi-axis CNC machining is very efficient at scale due to its automation, and CNC machining scales well with production. 3D printing is much less attractive at scale for mass production for several reasons, such as slow build times and low printer throughput; however, for more info on this subject, please see this blog post.

Two widely used manufacturing technologies are great for different purposes: CNC Machining and 3D Printing. 3D printing is a free, rapid prototyping, flexible process, while CNC is subtractive, precise, and strong. Here's a quick comparison:

| Feature | CNC Machining | 3D Printing |

| Process Type | Subtractive (removes material) | Additive (builds layer by layer) |

| Material Options | Metals, plastics, wood, and composites | Plastics, resins, metals (limited types) |

| Precision | Very high | Moderate to high (depends on printer type) |

| Surface Finish | Smooth, professional finish | Often requires post-processing |

| Complex Geometry | Limited by tool access | Excellent for complex/intricate shapes |

| Speed | Fast for simple parts | Slower, especially for large objects |

| Cost Efficiency | Better for bulk production | Better for prototyping and custom pieces |

| Waste | More material waste | Minimal waste |

| Setup Cost | High initial setup | Lower initial investment |

| Durability | Strong, especially with metal | Depends on the material (often less strong) |

3D printed part mechanical strength is not solely determined by the material but also greatly governed by the print method. The result can be quite sensitive to several variables.

However, CNC machining has some trade-offs in achieving high-performance results. It is important to understand its strengths and limitations of manufacturing needs.

3D printing democratizes manufacturing through its fast, cheap, and flexible fabrication. Its only issue is if there is widespread use of this (or any) language in high-performance applications. Let’s discuss its pros and cons, both to get a better idea.

CNC cut machining and 3D printing help in a broad swath of industries. They have different applications due to different advantages, like speed, precision, and design flexibility. Below are some typical use cases for which each process is optimal:

The choice of CNC machining vs. 3D printing is based on your project’s importance: size, price, budget, speed, or geometry. Whereas CNC machining is especially suited for producing high-performance, functional parts with very tight tolerances, 3D printing loves fast and cheap prototyping and geometrically complicated parts.

In most cases, the best of both worlds is achieved by following a hybrid workflow that combines both processes at different steps. If you can understand your material, performance needs, and production volume, you should be able to choose between one or the other.

1. Is CNC machining more costly than 3D printing?

The upfront CNC costs are higher, given setup and tooling, but it is economical for medium to large volumes.

2. Is CNC or 3D printing better for prototyping?

Early-stage prototyping is typically faster and cheaper in 3D printing, especially for visual models.

3. Can a 3D print hold up to the strength of a CNC part?

Not usually. The CNC parts have a uniform structure, so they are stronger.

4. Can you provide the material best suited for durable plastic parts?

The first choice of material is PEEK and Nylon, both strong and performant, but the material choice depends on the application.

5. Can I switch from developing on a 3D printer to a CNC mill?

Absolutely. ApexRapid often begins many workflows with 3D printed prototypes and testing & production with CNC.

6. Which would give a better surface finish?

CNC parts usually come out smoother, but are often ready to use. 3D printed parts might require post-processing.