The sheet metal duct fabrication process plays a big role in HVAC systems. You need durable, rust-resistant metal sheets like galvanized steel. You cut these sheets precisely to make sure all parts fit well. Cutting uses tools like shears or lasers for clean edges.

Next, you shape the metal sheets by bending and forming. Using press brakes or hand tools, you create the ducts’ curves and angles. Good bending keeps the metal strong and helps ducts connect tightly. This makes sure air flows smoothly without leaks.

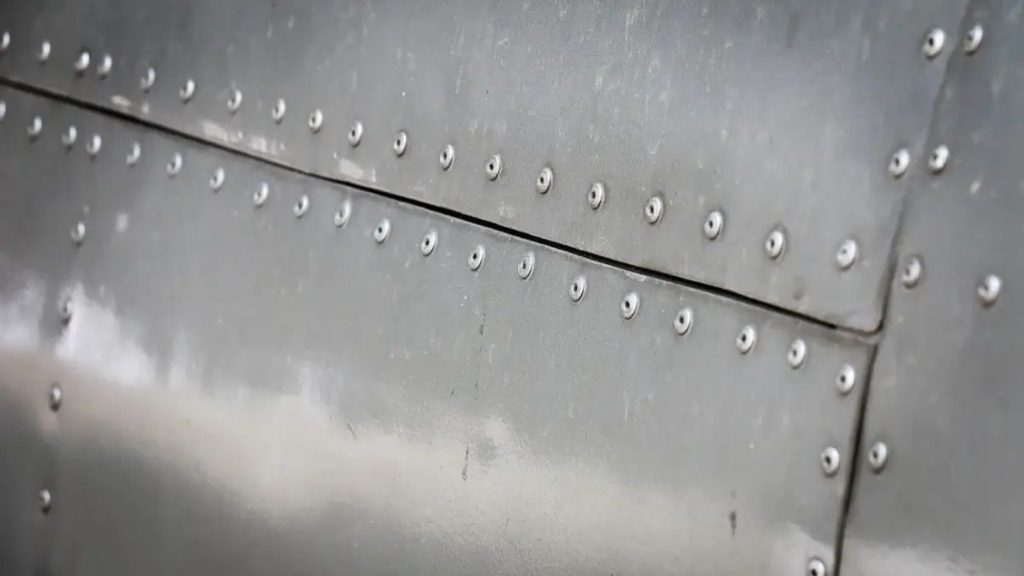

Finally, you join all duct pieces using spot welding or rivets. Sealing seams prevents air from escaping and lowers energy loss. After assembly, you inspect the ducts carefully. This ensures they meet quality and performance standards before installation.

HVAC sheet metal duct fabrication means making metal ducts for heating, ventilation, and air conditioning systems. You start with flat metal sheets and cut, bend, and join them into ducts. These ducts carry air throughout buildings to keep spaces comfortable.

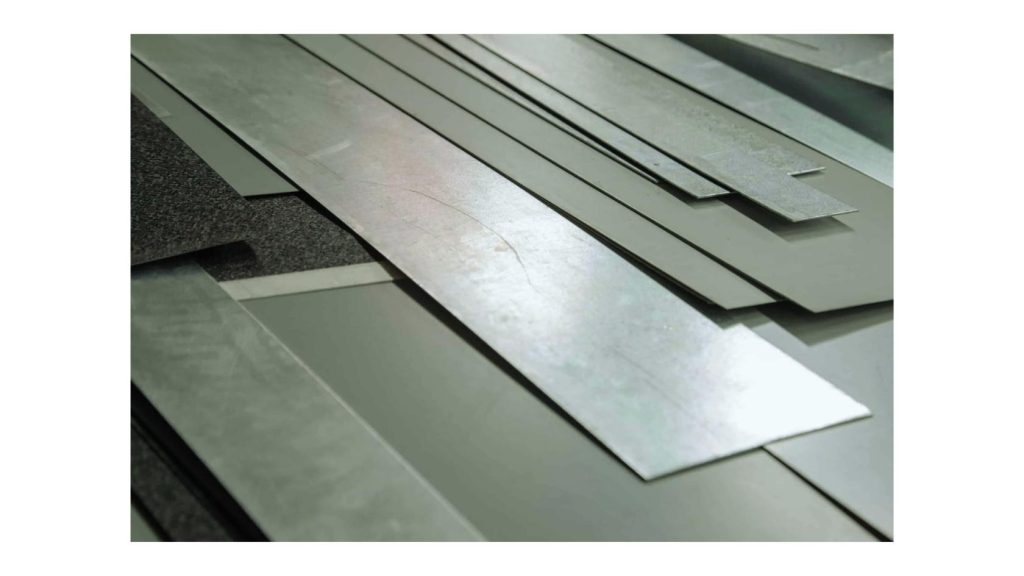

The process uses materials like galvanized steel or aluminum because they resist rust and last longer. You shape the metal to fit the design and size needed for airflow. Good fabrication makes sure the ducts fit tightly and work efficiently.

In short, HVAC sheet metal duct fabrication turns raw metal into parts that move air safely and quietly. It is a critical step to build reliable and energy-efficient HVAC systems.

The process of HVAC fabrication of sheet metal ducts consists of a number of accurate steps. You begin with unprocessed metal sheets, and you transform them into sections of duct that just slide together and efficiently carry air. Every step influences the strength, fit, and performance of the duct. Doing the right process will save you time and guarantee quality.

The primary steps you take in sheet metal duct fabrication are the following.

It starts with the correct metal selection. Galvanized steel is popular because it is rust-resistant. Aluminum weighs less and is not strong. The decision you make will be based on the budget and requirements of the system.

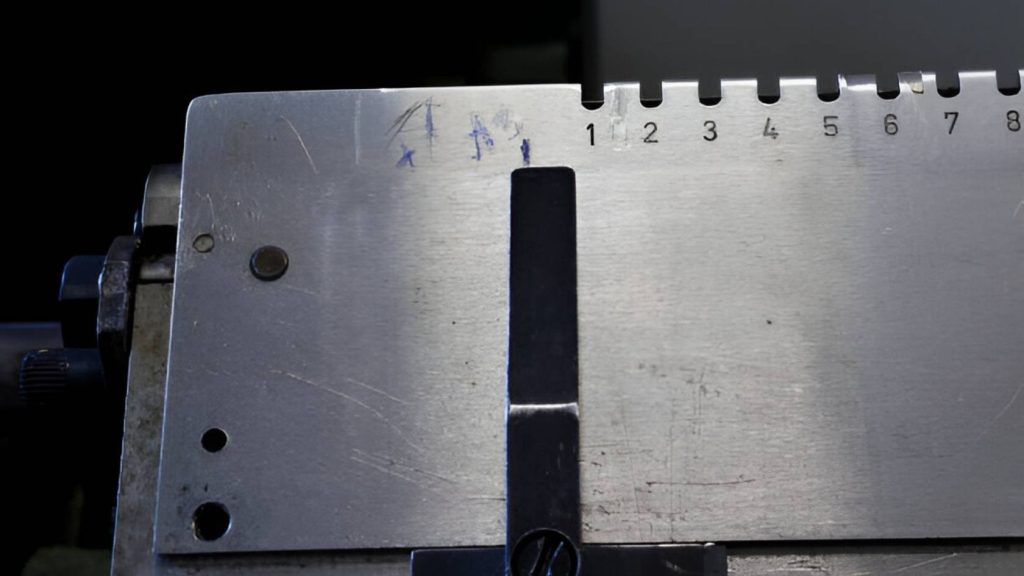

You then cut the metal sheets to precise sizes. You work with shears, lasers, or plasma cutters. Accurate cuttings facilitate the fitment of parts and minimize wastage.

You mark the metal sheet before bending. This gives you directions on where to continue folding and cutting. Legible marking avoids errors and wastage of time in the process of forming.

You bend the metal, on marked lines, with a brake press or by hand tools. The correct bending forming the shape of the duct leaves the metal strong. Here you must not crack or warp.

You make edges ready to join by cutting them down or moulding them. Smooth edges assist in forming tight and secure joints. This is a critical step towards leak prevention.

You join duct sections by spot welding, riveting or screws. All the techniques keep the pieces firmly in place. Proper joining makes the duct air-tight and robust.

You seal seams with special tapes or mastic compounds to prevent leaks of air. You may occasionally put insulation to minimize noise and loss of energy. When sealed properly, the systems become efficient.

Lastly, you inspect the ducts regarding their defects, fit, and quality of seal. Early inspection allows picking up problems before installation. It makes sure that the ducts will not underperform in the HVAC system.

HVAC duct design is not just a shape drawing. Airflow, durability, installation, and cost should be considered at the very beginning. An intelligent design saves you nightmares on fabrication and installation. It also enhances the performance and long life of the system. Suppose we take a closer look at the main aspects you should concentrate on during the design of HVAC sheet metal ducts.

You have to size ducts to the needs of the airflow. Too large ducts are a waste of space and material. Too small ducts will create noise and decrease the airflow. Size the airflow volume and velocity to provide a balance between performance and efficiency.

Select materials according to the strength, resistance to corrosion, and cost. Durability is galvanized steel. Aluminum is portable and simpler to work with, although it might not be suitable in every surrounding. Think about the place of installation and the needs of the system.

Construct joints in a way that reduces air leaks. Overlapping seams should be used with correct sealing tapes or mastic. Well-sealed joints will enhance the conservation of energy and avoid unwanted drafts. Allow ready access to seams, inspection, and maintenance.

Choose the thickness of walls to resist air pressure and mechanical stresses. Thin-skinned walls are economical in cost and weight, but can be dented or vibrate. The additional thickness of the walls makes them stronger, yet more expensive and heavier. Strike the balance that applies to your application.

In your design, consider having insulation to minimize heat loss and noise. The thickness of insulation is dependent on the climate and the location of the duct. Properly insulated ducts can hold the energy charges at bay and enhance interior comfort.

Design ducts that are easy to handle and install. Stay away from complicated shapes that need special equipment or additional manpower. Standard fittings and modular sections accelerate installation and minimise errors.

Make sure that your design complies with the local building codes and HVAC requirements. The compliance assures safety, performance of the system, and simplified approvals. Follow the evolution of laws to prevent the redesign that can cost a lot.

The HVAC duct fabrication needs exacting methods to bend, cut, combine, and seal sheet metal. Any of the approaches guarantees that your ducts are fitted, effective, and durable. So, what are these techniques essential for? Let us find out.

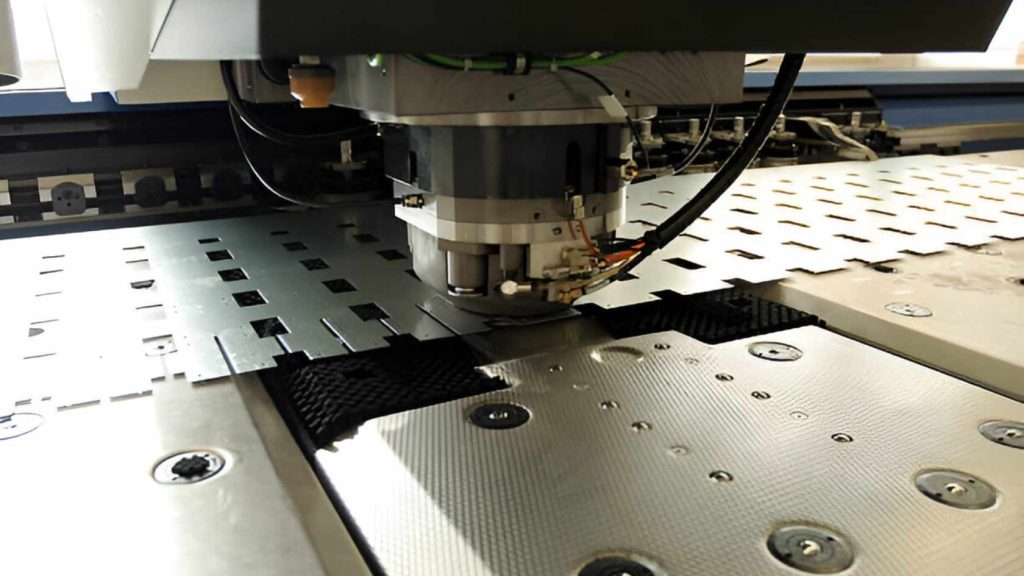

The initial process you undertake is shearing to chop huge metal sheets into manageable sizes. You have mechanical or hydraulic shears, which are operated like giant scissors and cut straight lines fast. The technique gives neat edges and does not bend or warp metal. In correct shearing, wastage is minimized, and all the pieces fit accurately during assembly.

Notching cuts away little parts of sheet edges, usually at corners or junctions. This enables duct sections to overlap or fit together. Notching tools or machines are used by you to make accurate cuts without destroying the remaining part of the sheet. Notching can be useful, in particular when making duct transitions or other complicated shapes where close fits are important.

The curving provides the flat metal sheets with a three-dimensional appearance. You either put the sheet on a press brake or use hand tools to bend the sheet along a certain line. The bending should also be done in a good, controlled fashion so as not to crack or make the metal weak. It is by proper bending that creates the angles and curves ducts require to allow free flowing air and ease in installation.

Punching makes holes or lugs to screws, rivets, or airflow openings. The metal is fast and precisely pushed through using hydraulic or mechanical punch machines. Punching is quicker than drilling and leaves a neater hole, particularly when you want a lot of similar holes. Punching assists in making sheets ready to be assembled quickly and accurately.

Lock forming Lock forms folds and locks the edges of the sheet to attach pieces without welding or fasteners. This is a usual method in case of rectangular ducts and produces powerful seams that are fitted. Lock-formed seams are airtight, time-saving, and minimize air leaks. It even enhances the structural strength of the duct.

Welding consists of joining metal pieces by melting the edges. Spot welding is quick on sheet metal and joins small areas. The seam welding process produces continuous, air-tight joints on seams. Welding creates tough, permanent joints that ensure ducts do not leak or fall apart, making it durable and giving it performance.

Riveting is a form of fastening metal sheets together using tiny metal pins known as rivets. You drill or punch holes and push rivets through the holes. Riveting comes in handy in instances where welding cannot be applied or when you are interested in being able to disassemble at a later stage. It forms strong connections, which keep ducts airtight and airtight.

The last procedure is sealing to close the gaps or seams. You put on special tapes, mastics, or gaskets around joints to prevent air leakage. Proper sealing enhances energy conservation, lessens the noise level, and maintains the HVAC system balanced. It plays an imperative role in the performance of the system and indoor comfort.

The ducts made of sheet metal can withstand wear and tear compared to most materials. They are not easily dented, corroded, or scratched by external objects. This longevity equates to fewer repairs and a longer life for the systems.

You can cut and form sheet metal to the specifications of your project. This permits non-standard duct sizes and intricate layouts. Accurate fabrication means easy flow of air and minimizes problems during installation.

When well fabricated, sheet metal offers airtight joints. This reduces the amount of air leaks, which allows your HVAC system to be more efficient. Well-designed ducts reduce energy cost and enhance interior comfort.

Unlike plastics or flexible ducts, metal does not burn or release toxic fumes. This concludes that sheet metal is safer in buildings and, in most cases, a fire code requirement. It provides an important safety measure for HVAC.

Sheet metal can be recycled completely (100 percent). Fabrication of scrap metal can be recycled, and waste can be minimized. Recyclable materials assist you in achieving the green building standards and reduce the environmental impact.

The sheet metal fabrication requires specialized tools and workers. Metal itself is more expensive than the alternatives, such as flexible ducts. Collectively, this increases project outlays.

Compared to lightweight materials, metal ducts are difficult to move or install because they are heavier. This makes the work more labor-intensive, and it might require additional support in buildings.

Metallic ducts may contribute to the increase of airflow or HVAC equipment noise. This, when not well insulated or designed, may result in noisy systems that may annoy the occupants of the building.

Unless painted or otherwise sealed and taken care of, sheet metal may rust, particularly in damp or rainy climates. Corrosion decreases both the life of ducts and the performance of the system.

The fabrication of sheet metal through cutting, bending, welding, and sealing needs accuracy. Errors in manufacture may lead to leakages or fitting issues. It requires time and carefulness.

Sheet metal fabrication is a vital part of modern HVAC systems. It allows you to create strong, custom-fit ducts that last for years and support high-efficiency airflow. From cutting and bending to welding and sealing, every step ensures your ductwork performs well and fits your design. While it requires skilled labor and carries some upfront cost, its benefits—like durability, safety, and precision—make it the top choice for commercial and residential HVAC systems.

Understanding the techniques, design rules, and pros and cons helps you make smart decisions in both planning and fabrication. If done right, sheet metal HVAC ducts deliver consistent comfort, energy savings, and long-term reliability.

Here at ApexRapid, we produce high-quality, durable, and precise sheet metal components. Need HVAC duct work, Industrial enclosures, or custom components? We help you make it happen - quickly and correctly.

We work with good metals such as galvanized steel, aluminum, and stainless steel. We have cutting, bending, and punching machines that are very precise, and thus your parts will always fit as they are supposed to. There is no need to worry about delays and untidy work; we work clean, tight, and on time.

We accompany you throughout the course with our team. You deliver your design to us, and we assist in preparing everything so that production can go on smoothly. We exist to help with your project, iron out issues at the development stage, and provide components you can rely on.

Q1. How long does it take to fabricate HVAC sheet metal ducts?

It depends on the size and complexity of the job. Small projects may take a day or two, while large systems can take a week or more.

Q2. Can sheet metal ducts be customized for tight spaces?

Yes, they can be fully customized. You can shape and size them to fit unusual layouts, small rooms, or tight mechanical areas.

Q3. What tools are used to make sheet metal ducts?

Fabricators use shears, press brakes, punches, and welding machines. These tools cut, bend, and assemble the metal into exact shapes.

Q4. Are there building codes for sheet metal HVAC ducts?

Yes. Most local and national codes require specific materials, sealing methods, and fire ratings. The following code ensures safety and performance.

Q5. Can old sheet metal ducts be repaired or reused?

In many cases, yes. If the metal is still solid, you can patch leaks, reseal joints, or resize ducts. However, badly rusted or damaged ducts should be replaced.