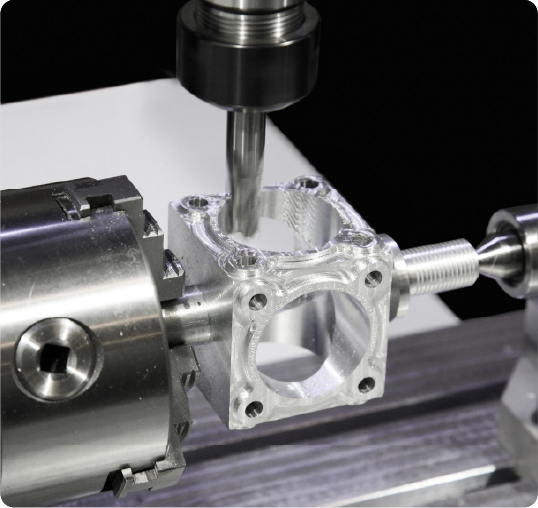

At ApexRapid, we specialize in on-demand manufacturing solutions that empower your business to adapt swiftly to changing market demands. Our state-of-the-art technology and advanced methodologies, including CNC machining and additive manufacturing, facilitate quick turnaround times, ensuring your prototypes and products are delivered as swiftly as within 1-3 working days.

Our expertise encompasses CNC machining, plastic injection molding, sheet metal fabrication, 3D printing, and vacuum casting.

Receive your prototypes and products swiftly, with lead times ranging from 1-3 working days, depending on complexity.

CNC Milling: 4000×1500×600 mm

CNC Turning: 200×500 mm

1-3 Working Days

0.001 inches

Kickstart your project by uploading your CAD files (e.g., STEP, SLDPRT, or IGES) through our intuitive online platform. We ensure a seamless transition to production with rapid verification and preparation of your designs.

Our team of manufacturing experts will reach out within 24 hours to provide a detailed quote tailored to your project needs, ensuring transparency and clarity around production costs and timelines.

Our advanced production and logistics systems ensure that your parts are delivered on schedule. Enjoy the flexibility of scheduled batch shipments or single deliveries, all backed by our commitment to quality and consistency.

| Type | Advantages | Disadvantages |

| Rapid CNC Prototyping | High precision and suitable for a wide range of materials. Ideal for producing functional and durable parts. Excellent surface finish and dimensional accuracy. | Higher costs and longer lead times than some additive manufacturing processes. Requires significant setup time for complex designs. |

| Rapid Prototype Injection Molding | Cost-effective for large production runs, offers excellent repeatability, and can handle complex geometries. Fast production of high-quality end-use parts. | Initial mold creation costs can be high. Not ideal for low volume production due to lead times in tooling. |

| Rapid Sheet Metal Prototyping | Versatile for a variety of applications, allows for quick modifications, and features high durability. Supports intricate designs and functions well with different materials. | Can be limited by the thickness of the sheet material and requires additional processing for certain features, which may add to the time and cost. |

| Rapid 3D Prototyping | Highly flexible and can create complex structures without needing tooling. Suitable for fast iterations and testing of designs before full scale production. | Build size limitations and surface finish may not meet all functional application requirements. Material properties can vary significantly based on the process used. |

| Rapid Vacuum Casting | Quick turnaround for small quantities, offers high detail, and is cost-effective for low-volume production. Good for producing flexible parts and prototypes. | May require additional finishing steps for aesthetic quality, and the longevity of the molds can be limited. Not suitable for high-volume production runs due to cycle time. |