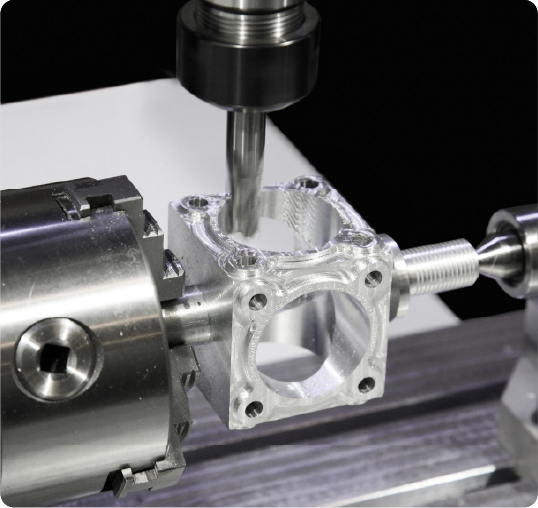

Rapid prototyping at ApexRapid transforms conceptual designs into tangible models swiftly and efficiently. Utilizing cutting-edge technologies such as CNC machining, injection molding, 3D printing, and vacuum casting, we offer fast turnaround times, with prototypes typically completed and delivered within 1 to 3 working days. This rapid approach allows engineers and designers to validate their ideas early in the development cycle, providing an invaluable opportunity for testing, feedback, and refinement.

Our services include CNC machining, injection molding, sheet metal fabrication, 3D printing, and vacuum casting, ensuring versatile solutions for various project requirements.

Experience rapid prototype delivery that accelerates your product development cycle, enabling quick evaluation and iteration.

CNC Milling: 4000×1500×600 mm

CNC Turning: 200×500 mm

1-3 Working Days

0.001 inches

| Type | Advantages | Disadvantages |

| Rapid CNC Prototyping | High precision and suitability for a wide range of materials. Ideal for producing functional and durable parts, often ready in just 1 day. | Higher costs and longer lead times than some additive manufacturing processes, particularly for complex geometries. |

| Rapid Prototype Injection Molding | Excellent for creating durable and consistent parts quickly, suitable for extensive testing and high-volume production. | High upfront costs for molds may not be economical for small quantities or initial prototypes. |

| Rapid Sheet Metal Prototyping | Offers fast turnaround for flat parts, ideal for prototypes that need to assess fit and form in their final material state. | Limited complexity, making this method less suitable for intricate designs that demand high detail and functionality. |

| Rapid 3D Prototyping | Extremely fast and cost-effective, allowing for complex geometries that would be challenging to achieve with traditional methods. | Material properties may not always match those of parts made through traditional manufacturing, and resolution can vary by technology. |

| Rapid Vacuum Casting | Allows for quick production of high-quality, detailed replicas, ideal for small to medium quantities with the precision of injection-molded parts. | Generally better suited for non-functional prototypes or visual models, as material properties may limit their applications. |