In the ever-evolving world of aerospace manufacturing, precision, reliability, and efficiency are paramount. The industry demands components that can withstand extreme conditions while maintaining the highest standards of safety and performance. Computer Numerical Control (CNC) machining has emerged as a critical technology in meeting these rigorous requirements. This article explores the pivotal role CNC machining plays in aerospace manufacturing, highlighting its benefits, applications, and impact on the industry's future.

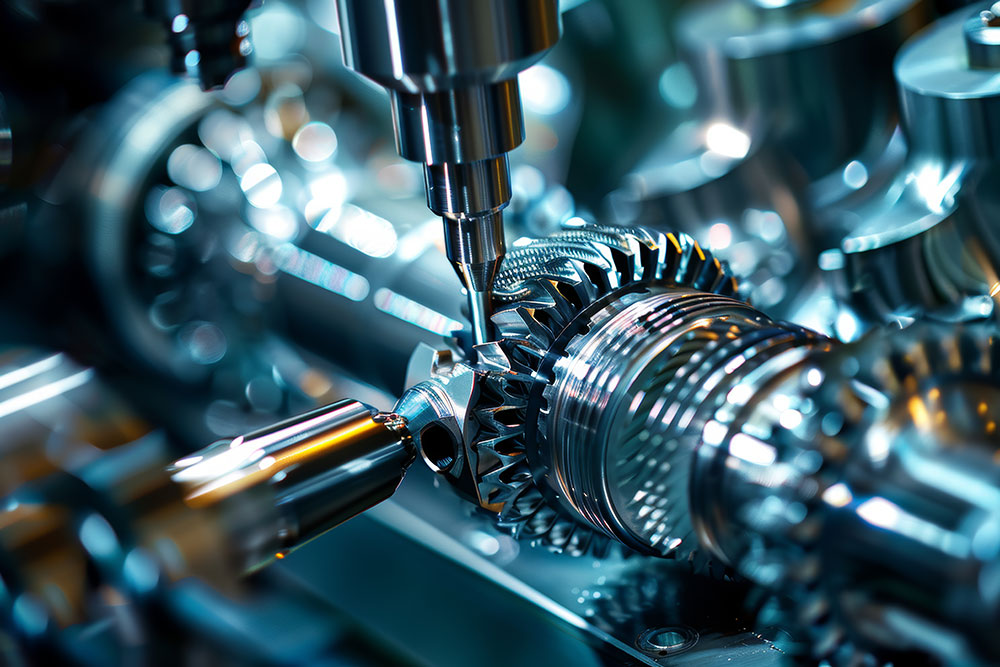

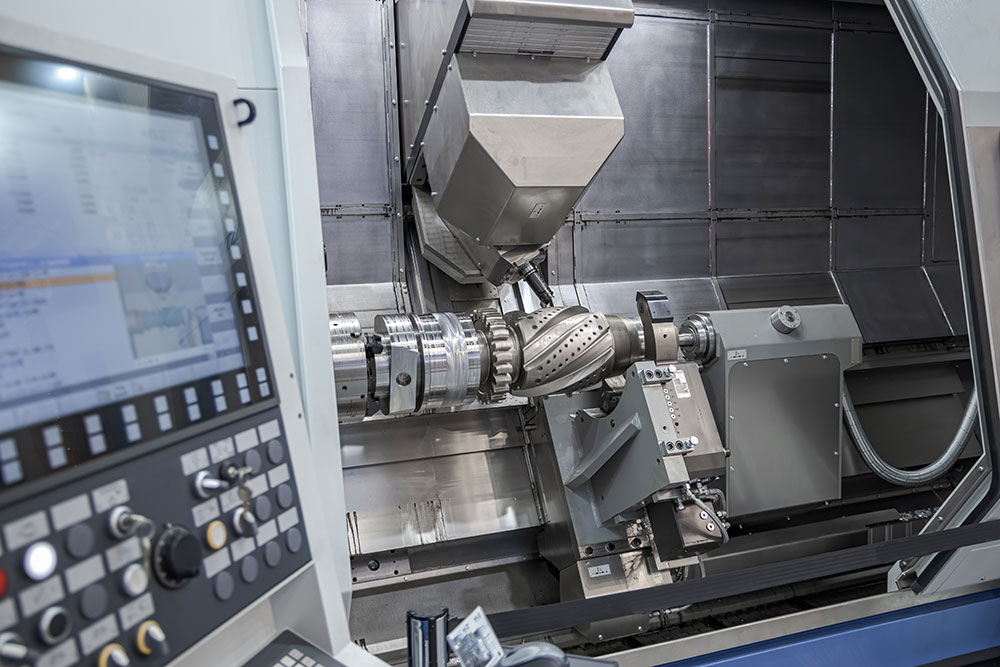

CNC machining is a manufacturing process that uses computerized controls to operate and manipulate machine tools. It removes layers from a workpiece to produce custom-designed parts with high precision. The technology encompasses various processes, including milling, turning, drilling, and grinding, all controlled by computer programs that dictate movement, speed, and coordination.

The aerospace industry deals with complex systems where even the smallest error can have significant consequences. Components must fit perfectly and function flawlessly under extreme temperatures, pressures, and stresses. Precision in manufacturing ensures that each part contributes to the overall safety and efficiency of an aircraft or spacecraft.

CNC machines can achieve tolerances as tight as ±0.0001 inches. This level of precision is crucial for aerospace components like engine parts, landing gear, and structural elements that must fit together seamlessly.

Aerospace components are often made from advanced materials like titanium, aluminum alloys, and composite materials. CNC machines are capable of handling these tough-to-machine materials, ensuring components meet the required strength-to-weight ratios.

Once a CNC program is set up, the machine can produce identical parts consistently. This repeatability is essential for mass-producing components that must meet stringent industry standards.

Modern aircraft and spacecraft designs often include complex shapes and intricate features. CNC machining allows for the creation of these complex geometries that would be challenging or impossible with manual machining.

CNC machining streamlines the production process, reducing the time from design to finished product. This efficiency is vital in an industry where time-to-market can impact competitiveness.

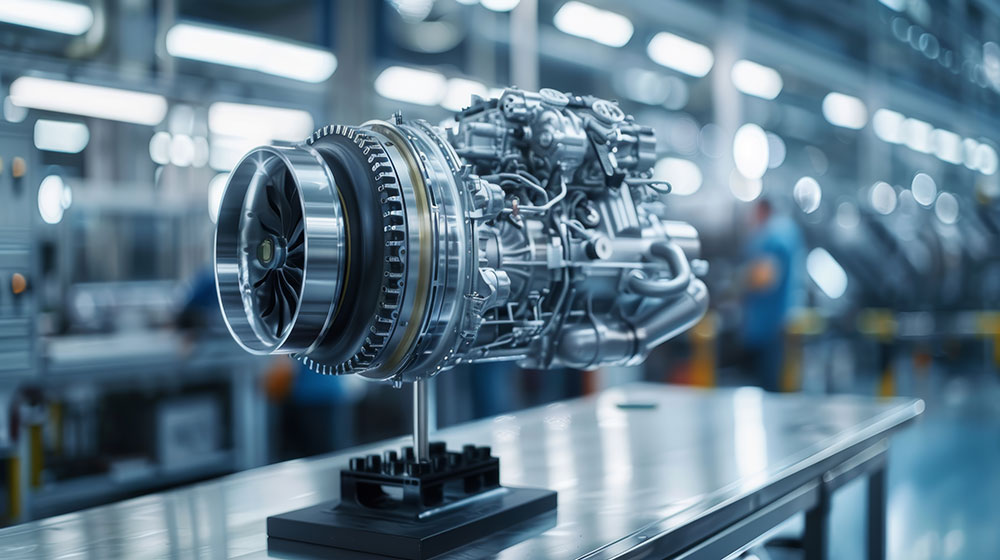

Aircraft engines consist of numerous precision parts like turbine blades, housings, and shafts. CNC machining ensures these components meet exact specifications to function efficiently under high stress and temperatures.

The airframe of an aircraft relies on structural components like ribs, spars, and bulkheads. CNC machines produce these parts with the necessary precision to ensure the structural integrity of the aircraft.

Sensitive instruments and avionics systems require housings and components that protect against environmental factors while allowing for precise operation. CNC machining produces parts that meet these critical requirements.

In research and development, rapid prototyping is essential. CNC machining allows engineers to create functional prototypes quickly, facilitating testing and refinement.

Space exploration demands components that can withstand extreme conditions. CNC machining produces parts for rockets, satellites, and space stations with the necessary durability and precision.

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) are integral to modern CNC machining. Engineers design components using CAD software, creating detailed 3D models. These models are then translated into CNC machine instructions via CAM software.

This integration offers several benefits:

Quality control is critical in aerospace manufacturing. CNC machining contributes to quality assurance through:

While CNC machining offers numerous advantages, it also presents challenges:

Advanced CNC machines require significant upfront investment. However, the long-term benefits of efficiency and precision often justify the cost.

Operating CNC machinery and programming requires specialized skills. Investing in training and retaining skilled operators is essential.

Regular maintenance is necessary to keep machines running optimally. Implementing a preventive maintenance schedule can minimize downtime.

The aerospace industry continues to push the boundaries of technology. CNC machining is evolving to meet new demands:

The adoption of 5-axis CNC machines allows for more complex machining in a single setup, improving efficiency and precision.

Integrating robotics with CNC machining enhances automation, reducing human intervention and increasing production speed.

Combining CNC machining with additive manufacturing (3D printing) opens new possibilities for creating complex parts with reduced material waste.

AI can optimize machining processes, predict maintenance needs, and enhance quality control through data analysis.

CNC machining plays a vital role in aerospace manufacturing by delivering the precision, reliability, and efficiency required in this demanding industry. Its ability to produce complex, high-quality components from advanced materials makes it indispensable. As technology advances, CNC machining will continue to evolve, integrating with other innovations to push the aerospace industry forward.

By embracing CNC machining and investing in its development, aerospace manufacturers can ensure they meet current challenges and are well-prepared for future advancements. The synergy between CNC technology and aerospace engineering not only propels the industry but also contributes to safer, more efficient air and space travel for all.