Now, modern manufacturing is powered by Computer Numerical Control (CNC) machining. It benefits from CNC machining for aerospace, automotive, medical device, consumer electronics, and other applications. For instance, if you’re a product designer, engineer, entrepreneur, or student, you should understand the fundamentals of CNC machining to design and manufacture high-quality components, optimize production time, and make cost-effective decisions.

Here in this guide, we will talk about what CNC machining is, the types, working principles, materials and finishes, design considerations, and practical insights that you can take advantage of for this powerful manufacturing process.

A subtractive manufacturing process, such as CNC machining, wherein a formed solid block (also called workpiece) is machined from a solid block (also called machined workpiece) by computer-controlled machines until a desired part is produced. A CAD (Computer Aided Design) model gets preprogrammed software, mostly a G-code, that helps guide the process.

CNC systems automate the control of machinery using digital instructions for high precision and consistency, even in complex geometries. Drilling, milling, turning, and grinding are common operations.

CNC machining consists of several processes specialized for specific materials, dimensions, and precision needs. These operations, i.e., milling, turning, EDM, and laser cutting, help make precise parts. Here, you can decide the best technique for your project using different strengths and techniques.

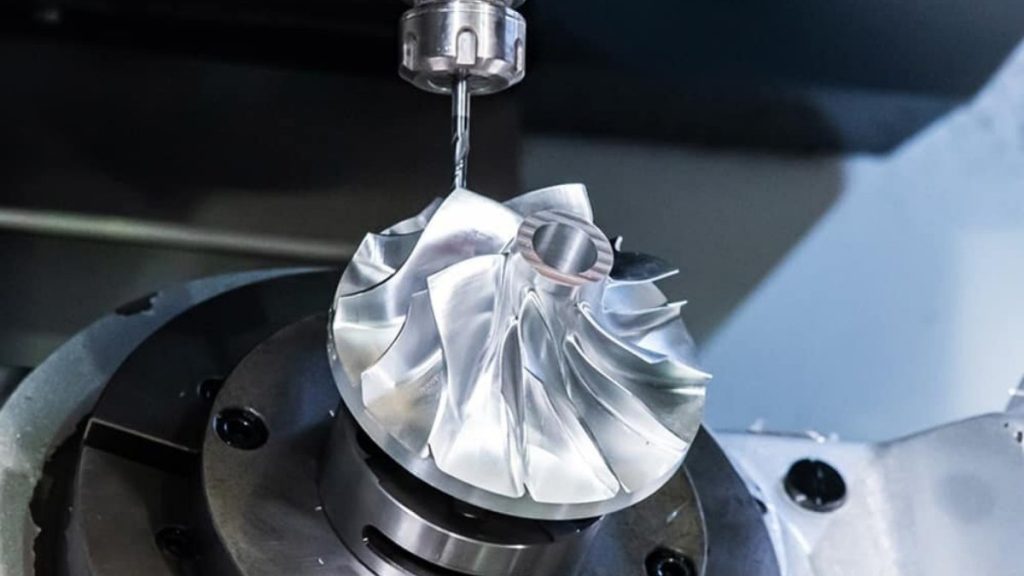

CNC milling is an operation that enables cutting tools to be rotated to remove material from a fixed workpiece. It is widely used to produce flat surfaces, slots, pockets, and complex 3D geometries. We can operate milling machines on several axes, varying from 3 to 5 axes, i.e., multi-axis, intricate machining. The versatility of milling allows it to be used for prototype and production use in virtually any industry. They have been found most useful for parts requiring fine detail or close tolerances.

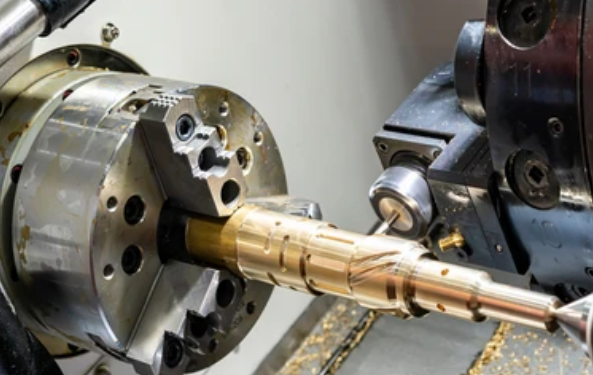

The machining process in which the workpiece rotates and a stationary cutting tool shapes it is known as CNC Turning. The advantage of this method is that the parts thus produced are round or cylindrical, such as rods, pins, pulleys, and bushings. However, a single setup on lathes can perform such things as facing, threading, and grooving. Milling is usually faster and less costly than for symmetrical designs. These industries can be automotive, aerospace, and mechanical components.

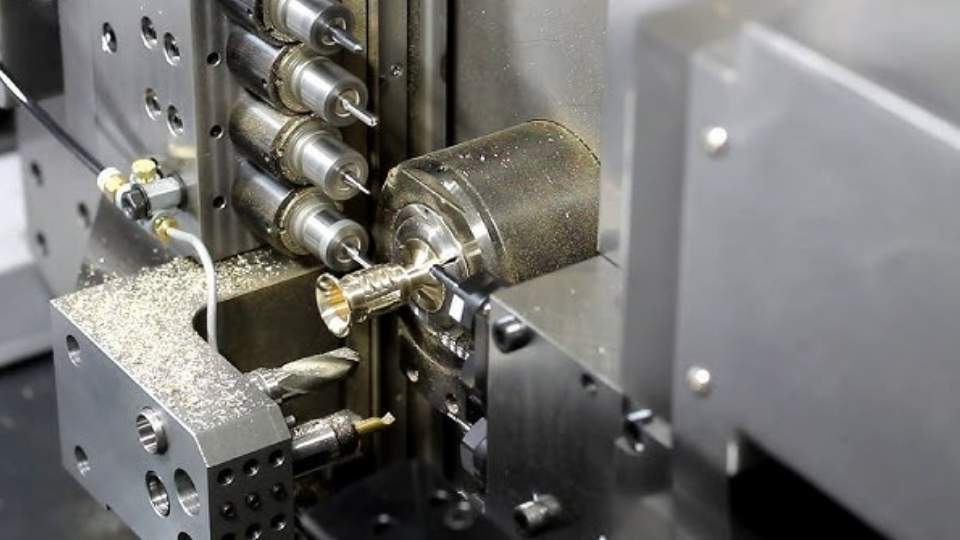

CNC drilling is an incredible process for making precision round holes in a material using drill bits that go vertically into the material. Most commonly, it is integrated into milling machines or is done on dedicated CNC drill presses. It will help you make fastener holes, tapped holes, and countersinks with the desired depth and spacing. As an essential operation, it is usually combined with other machining techniques. Drilling multiple holes simultaneously can be done in an automated multi-spud setup, increasing its efficiency.

In CNC grinding, small amounts of material are removed in smooth surface finishes using a rotating abrasive wheel. It is better for precision components and working on hardened metals. After machining, we can refine the tools, dyes, and parts using these Grinding Machines. The final part in this process must have the requested surface quality and geometric accuracy. CNC grinders can produce fine enclosed patterns on metal surfaces as well.

EDM is a nonconventional machining method to remove material using electrical discharges between the electrode and the work surface. It’s great for making detailed shapes, narrow slots, and internal cavities in materials such as titanium and tool steels. Various types of EDM exist, i.e., wire EDM and sinker EDM, which are applicable in different applications. Since there is no direct contact, EDM can machine delicate orthin-walled components. It’s widely used in die making, aerospace, and medical industries.

They help cut through metals or plastics precisely. Here, we use an ionized gas jet for laser cutting. They are mainly utilized for sheet material cutting with 2D profile shapes. They're speedy processors, have a clean edge, and produce less waste. They’re perfect for use in signage, brackets, and enclosures. Although this is not traditional subtractive. Besides this, they are useful in CNC fabrication as milling tools.

CNC machines work with designing parts in CAD software, programming, machine setup, and execution. Here, we process the material using a step workflow, and the machine reads coded instructions to cut, drill, or shape out material with high precision. Finally, we make sure the final part fits the quality and dimensional requirements, using post-processing and inspection to

Here, CAD (Computer Aided Design) software helps generate a precise 2D or 3D model. It is a digital blueprint of the part’s dimensions, geometry, and critical features. In addition, tolerances, material type, and surface finishes are criteria for the design. The more well-designed it is, the more accurate it is. When all is finalized, a CAD file can be made ready to be processed for the next stage.

In the CAM (Computer Aided Manufacturing) phase, the CAD model is imported into CAM software to plan the tool path. It will decide what operations to perform and what tools we should use, and this software helps with it. Then, it translates those instructions into G-code, the CNC machine's universal programming language. Reducing machining times, avoiding tool collisions, and improving part accuracy is made easier with efficient CAM programming. This one bridges the gap between what is designed and what is produced.

The operator will secure the workpiece on the machine bed or chuck and prepare the CNC machine. Drills, end mills, and inserts displace and calibrate. The proper setup would require workpiece alignment, setting the origin (zero point), and the machine. This is an important step that drives dimensional accuracy and repeatability. This typically leads to part failure or machine damage.

During the execution phase, the CNC machine starts working with the G code instructions, cutting the material one layer at a time. Normally, the machine does all this automatically, i.e., feed rate, spindle speed, and tool movement. But you can check it using the operator before starting a job. The coolants will help dissipate heat and extend tool life. Besides this, the real-time sensors will help monitor the tools and machine performance. Here, we refine the material to the end part with high precision and speed.

The part may be subjected to several different steps, i.e., deburring, sanding, polishing, anodizing, or painting. These steps depend upon what the part will be used for. They all help increase aesthetics, functionality, and sometimes mechanical properties such as corrosion resistance or wear resistance.

In this case, parts need tight tolerances or high surface finish requirements, and extra functions like grinding or lapping are done. It allows post-processing of that component so it would be ready or fit for production and meet the customer's expectations.

After the part, we inspect its quality for measurement and test it against the design specifications. The dimensions are verified using tools like calipers, micrometers, or Coordinate Measuring Machines (CMMs). For part use, it may be necessary to check the surface finish, material hardness, and structural integrity. The inspection takes place to ensure that only the parts that are advanced to assembly or shipping are accurate and defect-free. It is an important step for quality assurance in manufacturing.

Are you interested in decreasing your CNC machining costs without sacrificing quality? Use this checklist:

CNC machining is used in nearly every industry to prototype, tool, and produce parts.

CNC machining is used to machine a wide range of materials, including metals and plastics, but each has its strengths, machine ability, durability, or cost. Common metals like steel, brass, and aluminum provide strength and precision, while plastics such as ABS and Delrin offer lightweight, cost-saving options. Part function, environment, and finish required dictate material choice.

| Material Category | Example Materials | Key Properties | Typical Applications | |

| Metals | ||||

| Aluminum | 6061, 7075 | Lightweight, corrosion-resistant, easy to machine, good strength-to-weight ratio | Aerospace parts, brackets, automotive components, housings | |

| Steel | 1018 (mild), 4140 (alloy), SS 304 | Strong, durable, good wear and heat resistance, versatile finishes | Shafts, gears, tooling, structural components | |

| Brass | C360 | Excellent machinability, corrosion resistance, electrically conductive, aesthetic | Plumbing fittings, decorative parts, electrical connectors | |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) | Very strong, lightweight, corrosion-resistant, biocompatible | Medical implants, aerospace parts, marine hardware | |

| Copper | C110 | Superb electrical and thermal conductivity, soft, ductile | Heat sinks, electrical wiring, contacts, radiators | |

| Plastics | ||||

| ABS | Acrylonitrile Butadiene Styrene | Impact-resistant, cost-effective, easy to machine, good surface finish | Prototypes, consumer electronics, enclosures, toys | |

| Nylon | PA6, PA66 | High strength, flexible, wear-resistant, absorbs moisture | Gears, bushings, rollers, structural parts | |

| POM (Delrin) | POM-H, POM-C | Low friction, high dimensional stability, easy to machine | Bearings, precision gears, automotive and mechanical parts | |

| PTFE | Teflon | Non-stick, chemical and heat resistant, low friction | Gaskets, seals, insulators, medical and chemical equipment | |

| Polycarbonate (PC) | Lexan | Transparent, impact-resistant, heat-resistant, durable | Machine guards, light diffusers, protective covers | |

| PVC | Polyvinyl Chloride | Chemically resistant, rigid, flame-retardant, weather-resistant | Piping, electrical insulation, fittings | |

| PEEK | Polyether Ether Ketone | High-performance, temperature and wear-resistant, chemically inert | Aerospace, medical implants, high-stress components | |

| HDPE | High-Density Polyethylene | Lightweight, chemical-resistant, flexible | Chemical tanks, food containers, industrial parts | |

| Acrylic | PMMA | Transparent, UV-resistant, good aesthetic properties | Displays, lenses, signs, light fixtures | |

Several factors are involved in choosing the right process.

Shown As-Machined: No additional finishing; may show tool marks.

We can optimize CNC machining designs to cut down costs. It will ultimately improve accuracy and shorten production time. Most importantly, deep cavities should be avoided, drills should be of standard size, and multiple setups should be avoided. Fillets on the interior corners and the use of tight tolerances only as needed will make machining easier.

It’s widely used for both prototyping and full-scale production thanks to its exceptional precision, speed, and consistency. Supporting a broad range of materials, it enables scalable manufacturing through automation, offers fast turnaround, and delivers excellent repeatability—making it a top choice across many industries.

CNC machining has a few restrictions, but it has several impressive aspects. High-volume runs are costly and wasteful since the process is subtractive and produces material waste. These can be design constraints, with challenges with undercuts and delicate materials high on the list.

CNC machining is one of the most reliable and versatile manufacturing technologies today. An industry go-to with its tight tolerances, smooth finishes, and broad selection of materials, it has applications in everything from aerospace to medical devices. The nuances (types, materials, design tips, cost strategy) can serve you well in designing a prototype or planning mass production.

CNC machining plays an important role as digital manufacturing evolves. It is getting better with bundling with automation, AI, and cloud computing to enable even more efficient operations.

1. How is CNC milling different from CNC turning?

CNC milling is similar to milling, except that the cutting tool orbits and removes material. Besides this, it is suitable for creating flat and complex 3D parts. The best for cylindrical shapes is CNC turning, where the workpiece itself becomes the spinning part while the stationary tool cuts it.

2. Should CNC machining be used to make low amounts?

CNC machining is the perfect prototype and medium-to-low volume production choice because it occurs quickly and with accuracy, without creating molds or dies.

3. Can plastics be CCNC-machined

Absolutely. ABS, nylon, polycarbonate, PTFE, and other plastics are CNC-machinable and suitable for industrial and consumer applications.

4. What are standard tolerances when machining the CNC?

Standard parts Tolerances are typically l ±0.005 inches (±0.127 mm) unless the part is critical.

5. What are the ways to cut down on CNC machining prices?

Use standard materials, do not make tight tolerances unless they are required, design for manufacturability from the very beginning, and consolidate the machining steps.