CNC machining bronze is a reliable way to create durable and reliable parts. Bronze is popular for its strength, corrosion resistance, and uniform finish. With CNC machining, you can obtain complex shapes and maintain the exact measurements.

The method works well for bronze prototypes and large production runs. Bronze’s stability under cutting tools allows for consistent, repeatable results. It’s often selected for mechanical components, electrical fittings, and marine hardware.

The process uses computer-controlled tools to guide every cut. This ensures accuracy while reducing the chance of errors and wasted material. You also get a clean surface finish without heavy post-processing.

CNC machining bronze is also an economical process. It combines the metal’s natural strength with precision. Whether for custom designs or industrial needs, the results remain dependable and consistent.

Bronze Machining

Bronze machining means shaping bronze metal into parts using cutting tools. It involves removing material to create the desired shape and size. This process can include turning, milling, drilling, or grinding.

Because bronze is strong but soft enough to cut easily, it works well with many machining techniques. Machining bronze produces parts with a good surface finish and accurate dimensions.

Bronze machining is used to make items like bearings, gears, and decorative pieces. It is common in industries that need reliable, long-lasting metal parts.

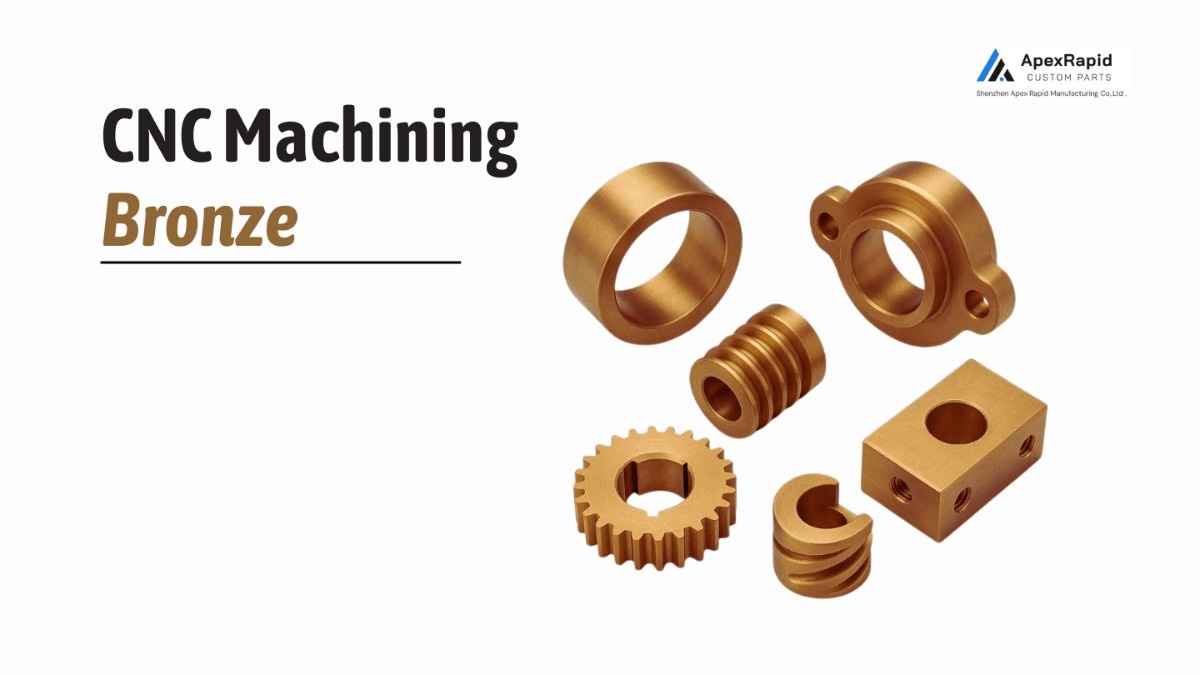

Bronze Machined Parts

The initial process is choosing an appropriate bronze grade. It must be best suited to your intended application. The various grades possess special qualities; thus, the right selection of the right type guarantees the final part has the required strength and durability.

Then get the bronze stock at hand after cutting it to size. This will reduce the machining time and materials wastage. Accuracy is also increased by initially using the accurate size of stocks.

Third, fix the CNC machine with the right cutting tool compatible with bronze. Applying the right tools would minimise wear and give a smoother surface finish.

Then give accurate instructions to the machine. Proper CAD/CAM programming should be done to specify a tight tolerance so that there is no mistake when performing the machining.

Keep an eye on cutting speeds and feed during the machining process. Modifying all these settings helps combat overheating and damage to tools, which enhances part quality.

Lastly, check the completed parts for quality and size. You can use measuring tools to ensure that the components do not exceed the specifications desired.

Bronze is a versatile metal that responds well to various machining methods. Choosing the correct technique depends on the part’s complexity, size, and the finish required. The following methods are commonly used to shape bronze parts accurately and efficiently.

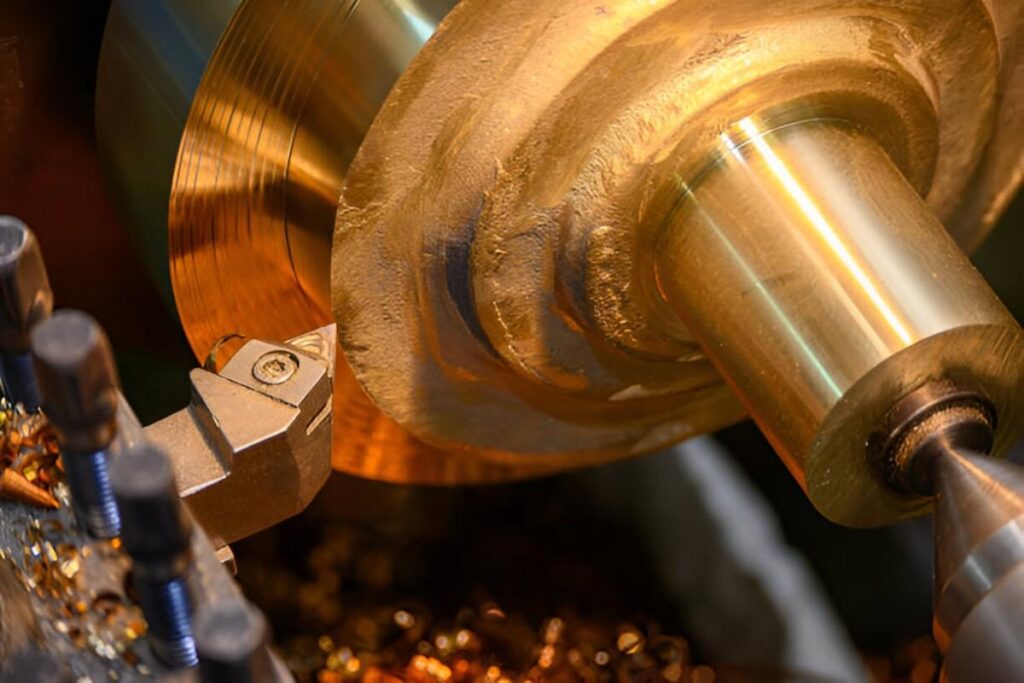

Bronze Turning

Turning is the rotation of a piece of bronze against a cutting tool to shape the outer area. It is popular in manufacturing cylindrical components, such as bushings, shafts, and valve components. Turning can provide smooth finishing and accurate diameters necessary for parts that are made to fit each other tightly.

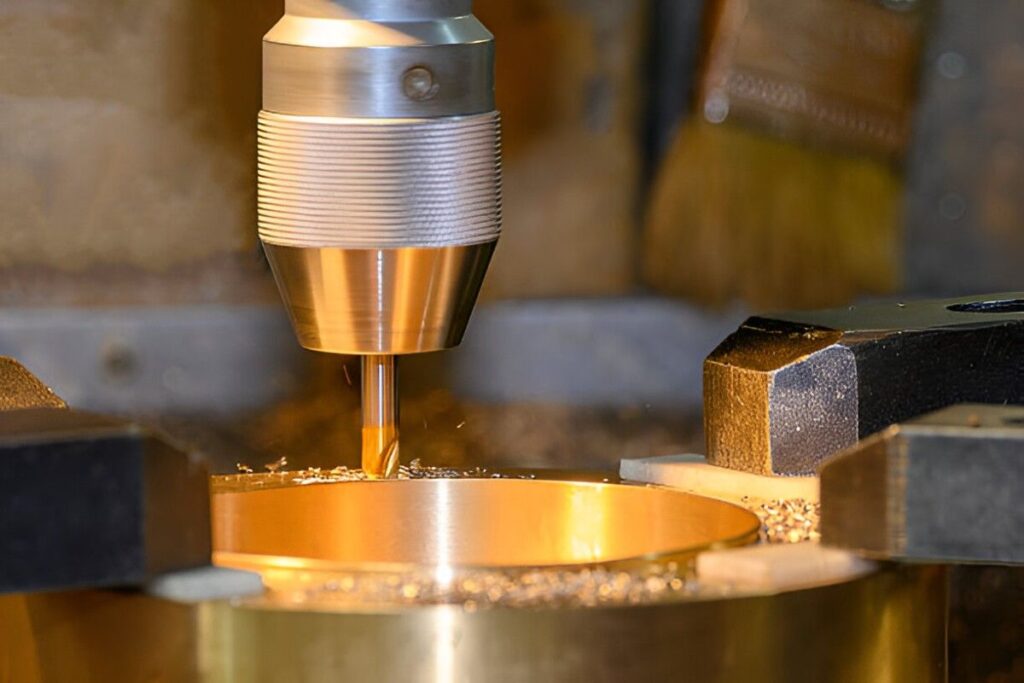

Bronze CNC Milling

Milling is the process of employing a rotating cutter to cut away pieces of bronze and create smooth surfaces or elaborate curves. It is suitable for use in components like brackets, flanges, and machinery custom components. Milling enables manufacturers to make detailed designs and slots required during assembly.

CNC Bronze Drilling

Drilling is the process of precision drilling bronze pieces with a rotating drill bit. This is required to manufacture fittings, connecting pieces of the pipes, mounting plates, and the hole size and location matter in the assembly and fastening of parts.

Grinding finishes and smooths out bronze objects and surfaces with an abrasive wheel. It is usually performed after other machining operations to give the parts close tolerances and a polished appearance. Gears and bearings are precision parts whose contact surfaces must be smooth, hence the importance of grinding.

Bronze Bushings

Boring increases or perfects holes of bronze parts into precise sizes. The components made with this technique include bushings, valve seats, and bearing housings, where the internal diameter has to be controlled precisely. Boring enhances the fit and eliminates friction in moving assemblies.

Machined Bronze Parts for Irrigation Systems

Threading makes cuts of screw threads on or in bronze pieces. This enables the parts to be fitted together by using bolts or screws. Threads are used to create shafts, pipe fittings, and fasteners that go into machinery and plumbing applications.

Broaching: with a broaching tool, which is a toothed tool, material is removed to form keyways, splines, or special grooves. Such a method is significant for components that require internal forms, such as pulleys, gear hubs, and couplings. Broaching provides close and repeatable internal features.

After machining, bronze parts often need surface finishing to improve durability, function, and appearance. Finishing removes tool marks and ensures parts meet required smoothness and wear resistance standards.

Polishing removes little scratches and unevenness in the surface. It has produced surface roughness (Ra) of 0.1 - 0.2 micrometres, providing a shiny finish. Part of the decorative hardware and electrical contacts, especially those with low friction, are polished bronze.

Sandblasting is an abrasive process that passes particles through a machine to clean and lightly roughen the surface. The process typically achieves a value of Ra between 1.0 and 3.0 micrometres. It pretreats bronze surfaces to be coated or painted and enhances adhesion.

Buffing is the last polishing stage; it helps smooth the surface and add shine. It can reduce the Ra to less than 0.1 micrometres. Jewellery and precision instruments are buffed bronze, essential for performance and appearance.

Electroplated Bronze Parts

Electroplating adds a thin layer (usually nickel or chrome) of metal to the surface to reduce corrosion and increase wear life. Average plating is about 5.25 micrometres. Plumbing parts and automotive bronze parts are commonly finished in this way.

Patina is a chemical process of applying a protective layer of colour to bronze. The process not only adds aesthetic value but also retards corrosion. It is usually used on pieces of art and architectural bronze.

Lacquering involves putting a clear coat on bronze to prevent environmental corrosion and deterioration. The lacquer is, as a rule, 10-30 micrometres thick. Lacquer is used to preserve the natural appearance of metal and is widely used as a furniture finish.

Bronze comes in several alloy types, each with unique features that affect how it machines. Choosing the right alloy is essential for meeting strength, corrosion resistance, and finish requirements. Here are standard bronze alloys used in machining.

Phosphor bronze consists of copper, tin, and minute phosphorus. It is renowned for being tough and wear-resistant. This alloy can be machined well and can make parts such as bearings, springs, and gears, which are supposed to be durable.

Aluminum bronze contains copper, aluminum, and low levels of iron or nickel. It has better resistance to corrosion and strength, particularly in a marine environment. It machines easily and finds use in valve components, marine hardware, and heavy-duty fittings.

Silicon bronze is a blend of copper and silicon, and minor proportions of other metals. It is a good machine (though easy to work with), and it takes a smooth finish. It is a standard alloy used in decorations, electrical terminals, and art.

Copper, zinc, and manganese are used in manganese bronze. It is highly stiff and wear- and corrosion-resistant. The alloy can be used in heavy machinery components, gears, and propellers of ships, but it is hard and requires sharp tools.

Copper and tin are the significant constituents of bronze. It possesses excellent corrosion resistance and average strength. It is readily machined and is applied to bushings, bearings, and small mechanical parts.

Threaded Bronze Bushings

Bronze can be CNC machined to deliver accurate and repeatable performance. The computerized process limits human intervention and gives close-tolerance parts. This is necessary where precision is needed in parts like the gears and bearings.

Bronze is machinable and therefore easy to machine as opposed to hard metals. This reduces the wear and tear of the tools, reduces the machining time, and makes production quicker and more economical. CNC machines can work with complicated shapes, enabling them to design versatile types of products.

Bronze parts are reliable and corrosion-resistant, and hence suitable for harsh conditions. CNC machining maintains these qualities since it does not destroy the material and leaves clean cuts.

Repeatability is also enhanced with the help of CNC automation. One can manufacture large quantities of the same parts with the same quality. This assists businesses in meeting deadlines and ensuring the standards of the products..

Key Benefits at a Glance:

CNC machining Bronze is a reliable process, but it has some challenges you need to consider. Knowing these helps avoid costly mistakes and keeps production smooth.

Other forms of bronze, such as aluminum and manganese bronze, are more complex and wear out cutting tools earlier. This implies that tools must be replaced frequently, a factor that can reduce work speed and raise costs. This effect can be minimized by using good cutting tools, but this will not be eliminated.

When your bronze component has a lot of small details or intricate shapes, machining time increases, and it involves additional programming and close machine control, which leads to increased expenses. CNC is effective with simple shapes, whereas very complex parts may be more readily produced by alternative processes such as casting.

Size limits most CNC machines. Large pieces of bronze might not be accommodated in standard machines. Manufacturers use forging or casting when parts are larger than these dimensions to obtain an initial shape that can be machined.

Machining results in minor scratches and roughness on the bronzes. When your component requires an impeccable finish, you often have to polish or grind it once it has been machined. These additional processes increase time and cost but are necessary for parts entering areas of view and/or high wear.

Machining also generates heat that may influence the tool's length and the part's finish. Heat can easily bring up coloring on the surface or warping when not controlled within fluids or at correct speeds. These issues require careful process control to avert them..

Several technical factors must be carefully controlled to achieve optimal results in bronze CNC machining. These considerations impact tool life, surface finish, dimensional accuracy, and overall efficiency.

Machinability and mechanical properties of different bronze grades are different. As an illustration, phosphor bronze is strong and easily machined with a tensile strength of about 550 MPa. In contrast, aluminum bronze has greater corrosion resistance and hardness as high as 300 HB, but is more difficult to cut. Selection of the proper alloy aids in establishing proper cutting parameters and tooling.

Apply carbide tooling with sharp edges and suitable coverings like TiAlN or TiCN. Such a coating lowers friction and enhances heat resistance. When machining bronze, tool geometry must prefer large rake angles (i.e, 10-15 degrees) to deliver less cutting force and better chip evacuation.

Normal cutting speeds of bronze would be between 100-200 meters per minute, and the tool would depend on the alloy. Milling ranges in feed rates are about 0.05 to 0.25 mm/tooth. To avoid tool wear, complex alloys like manganese bronze may require slower speeds and feeds.

Coolant is fundamental to managing heat production and enhancing the surface's finishing. Good lubricity and heat dissipation compounds that are water-soluble are recommended. Coolant should be applied directly to the cutting area, using flood or high-pressure systems to stabilize the cutting environment.

Bearing or sealing surfaces are commonly bronze parts that require surface roughness (Ra) less than 0.8 micrometers. This might need the additional machining process of grinding or polishing the workpiece. Close dimensional accuracy (to 0.01 mm) can be accomplished via CNC, but must be controlled.

CNC Machining of bronze parts gives you strong and accurate components. Picking the correct type of bronze and using the right tools makes a big difference. It’s essential to control speeds and cooling to avoid tool wear and get a good finish. Some parts may need extra polishing after machining to look and work their best. Knowing these details helps avoid common problems and keeps your project on track.

Apexrapid knows how to handle bronze CNC machining well. We have skilled operators and good machines to deliver quality parts on time. No matter your project size, they focus on getting it right the first time.

If you want reliable bronze machining without stress, contact Apexrapid today. We’re ready to help you with fast, accurate, cost-effective CNC machining solutions.