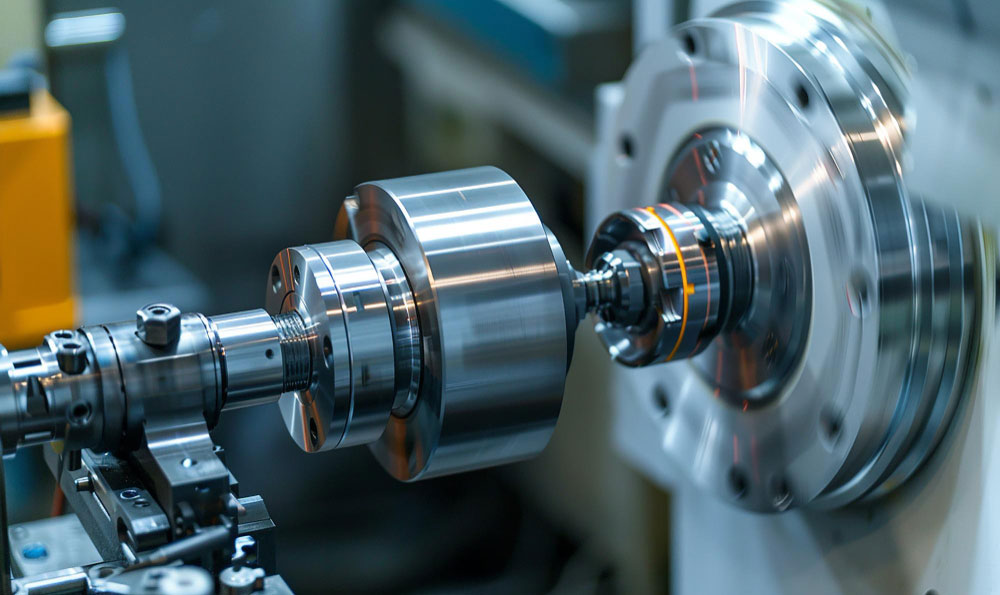

In the world of CNC machining, producing a part isn't just about shaping metal or plastic with precision and speed. Beyond the cutting tools and G-code lies an equally critical aspect of manufacturing: surface finishing. The right surface finish can enhance a part's appearance, improve its resistance to wear and corrosion, and even impact its functionality. But with a plethora of finishing techniques available, how do you choose the one that best suits your application?

This comprehensive guide delves into the various surface finishing options in CNC machining, their benefits, and how to select the optimal method for your specific needs.

Surface finishing is more than just an aesthetic enhancement; it's a vital step that can influence a part's performance and longevity. The finish can affect:

Recognizing these factors is the first step toward mastering surface finishing in CNC machining. For more details on different finishing options, visit our surface finishes page.

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, and corrosion-resistant anodic oxide finish. Commonly used on aluminum, it enhances surface hardness and allows for dyeing in various colors.

Plating involves depositing a thin layer of metal onto the surface of a part. Techniques include electroplating (using electrical current) and electroless plating (chemical process).

This dry finishing process involves applying a free-flowing powder that is then cured under heat to form a hard finish.

Polishing smooths the surface of a part to a shine by using abrasive materials.

This technique propels fine glass beads at high pressure to clean or finish a surface.

Passivation enhances the corrosion resistance of stainless steel by removing surface contaminants.

Choosing the optimal surface finishing technique involves considering several factors:

Not all finishes are suitable for every material. For instance, anodizing is primarily used for aluminum, while passivation is specific to stainless steel.

The visual aspect can be crucial. Polishing and powder coating offer different aesthetic outcomes. Choose a finish that aligns with your product's visual requirements.

Some finishing processes are more expensive or time-consuming than others. Balancing the project's budget and timeline against the benefits of the finish is essential.

If you're unsure which finish is right for your application, contact us for expert advice.

Surface finishing is a critical aspect of CNC machining that can significantly impact the performance, durability, and appearance of your parts. By understanding the various finishing options and carefully considering the specific needs of your application, you can select the most suitable technique to achieve optimal results.

Whether you're looking to enhance corrosion resistance, improve wear properties, or simply make your product stand out visually, the right surface finish is key. Take the time to explore your options, consult with experts, and make informed decisions to unlock superior performance in your CNC machined components.