Titanium alloys, such as Grade 5 (Ti-6Al-4V), are some of the most demanded materials in high-precision industries because of their high-strength weight ratio, resistance to corrosion, and biocompatible nature. The Grade 5 titanium is widely used in the aerospace, medical, energy, and motorsport industries as an alloy typically used when manufacturing a performance product is required.

But the titanium is notoriously hard to machine, despite its superior mechanical properties. CNC machining is a difficult task to perform due to the low thermal conductivity of the material, its strong chemical affinity to cutting tools, and the low modulus of elasticity. This paper focuses on the major properties of material, machining/cutting issues, and practical uses of Ti-6Al-4V in CNC conditions.

It is perhaps the best-known alpha-beta titanium alloy is titanium alloy Ti-6Al-4V (also known as Grade 5 titanium ). Grade 5 consists of titanium (90%), aluminum (6%), and vanadium (4%). It is by far the most frequently used titanium alloy in the world and forms more than 50 percent of titanium consumption.

Major Chemical Composition:

This alloy provides the best possible combination of lightweight, high strength, good oxidation resistance, and workability, which are characteristic of expensive parts that must show ultimate resistance to all types of stress, high temperatures, and the environment.

Let’s explore the physical properties of Titanium Grade-5

| Property | Value / Description |

| Tensile Strength | ~895–965 MPa (annealed); up to 1200 MPa (heat-treated) |

| Yield Strength | ~830–880 MPa |

| Density | ~4.43 g/cm³ (approximately 60% of steel) |

| Hardness | ~334 HV (Vickers Hardness) |

| Modulus of Elasticity | 110 GPa |

| Thermal Conductivity | ~6.7 W/m·K (relatively low—leads to heat buildup during machining) |

| Corrosion Resistance | Excellent (effective in marine and chemically aggressive environments) |

| Melting Point | ~1,660°C (3,020°F) |

Here are some of the major advantages of Titanium Grade -5 in CNC machining;

The strength-to-weight ratio of Ti-6Al-4V is one of the highest of all the structural metals, so manufacturers are able to lighten the parts without losing strength. This can make it suitable to use in aircraft parts, medical products implanted in the body, and also in the parts of motorsports where only performance and weight matter.

Grade 5 titanium develops a naturally stable layer of oxide that provides resistance to corrosion in severe conditions, i.e., marine and chemical environments. This qualifies it as being very applicable in offshore and biomedical, and chemical processing.

Ti-6Al-4V Ti-6Al-4V does not lose its mechanical properties at high temperatures, remaining reliable to perform to 400oC, and higher. The temperature resistance is critical to engine components, turbine parts, and aerospace applications, which have to face a high amount of heat.

The alloy is bio-compatible; it is also biologically non-reactive, non-toxic, and non-biologically hostile, thus being the best material used as an implant, surgical instruments, and dental pieces. It is bio-compatible, hence it will last long in the body.

Titanium grade 5 is very fatigue strength and wear resistant, and components can survive in harsh conditions with the possibility of cyclic loading. This strength minimizes breakages and life span in the challenging sectors.

The following are some challenges we can observe;

Titanium thermal conductivity is low, and hence, the heat is focused in the cutting area. This causes more rapid tool wear, formation of build-up edges, and a variable surface finish unless effectively cooled and routed.

Ti-6Al-4V will get hard during the machining process, especially when light cuts or dull tools are used. This makes cutting more resistant, and a subsequent pass is difficult, and the tool life decreases considerably.

At high temperatures, titanium reacts and welding to the cutting tool frequently occurs. This leads to galling and material accumulation on the tool edge, resulting in a reduction in accuracy and finish quality as well as reduced tool life.

As compared to steel and aluminum, titanium is more elastic because of its low modulus of elasticity. This creates springback when you cut, so it is more difficult to maintain tight tolerances, particularly in flexing or thin-walled components.

Titanium is a costly and tedious material to work with. Slow cutting speeds, significant tool wear, and consuming more controls to meet the requirement undermine the costs and material waste and require optimization to address the situation.

Titanium is manufactured in various grades, and each grade is made to meet a particular performance requirement. The simple comparison of Grade 5 (Ti-6Al-4V) to other popular titanium grades used in machining, aerospace, medical, and industrial applications is provided below.

| Grade | Type | Key Features | Common Uses |

| Grade 1 | Commercially Pure (CP) | Softest, most ductile, excellent corrosion resistance | Heat exchangers, marine, chemical processing |

| Grade 2 | CP Titanium | Best balance of strength, corrosion resistance, and weldability | Pressure vessels, implants, piping |

| Grade 3 | CP Titanium | Higher strength than Grade 2, lower ductility | Aerospace, structural parts |

| Grade 4 | CP Titanium | Strongest CP grade, less machinable | Medical tools, marine, heat exchangers |

| Grade 5 | Ti-6Al-4V | High strength, fatigue, and heat resistance, tough to machine | Aerospace, implants, motorsports |

| Grade 6 | Ti-5Al-2.5Sn | Creep resistance at high temperatures | Jet engines, elevated-temp parts |

| Grade 7 | CP + 0.15% Pd | Outstanding corrosion resistance in acids | Chemical plants, pollution systems |

| Grade 9 | Ti-3Al-2.5V | Moderate strength, excellent formability, and weldability | Aircraft tubing, bikes, and marine |

| Grade 12 | Ti-0.3Mo-0.8Ni | Good strength + excellent chemical resistance | Paper industry, chemical processing |

| Grade 23 | Ti-6Al-4V ELI | Purified version of Grade 5 for implants |

The following are the best practices;

Use hard (up-temperature), carbide-type tools with TiAlN or AlTiN plated can be used to cope with heat impact and low reactivity. Smoother chip flow and less cutting force should be achieved by the positive rake angle in tools. Use of HSS tools is not recommended because they do not last long.

Modest or slow speeds (3060 m/min) and feeds (0.050.3 mm/tooth ) must be used during machining to ensure that friction and heat are reduced to a minimum. Make sure the minimum depth of cut is not reached, in order to prevent hardening of the surface.

High-pressure through-tool coolant or flood coolant is highly needed in dissipating heat and flushing chips. MQL can also be effective on light-duty or finishing work. Dry cutting must be avoided as there are risks of overheating.

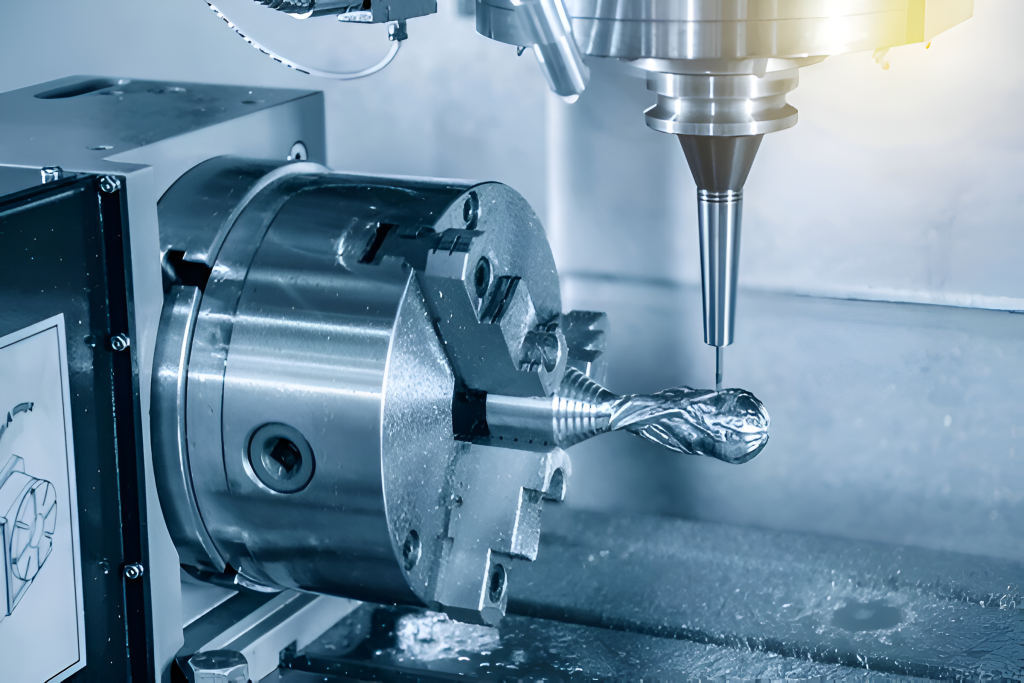

Use toolpaths such as adaptive clearing that keep the cutter engaged at all times. Trochoidal milling allows controlling the heat generation and chip load and minimizes tool wear. Avoid heat buildup and work hardening by minimizing tool dwell.

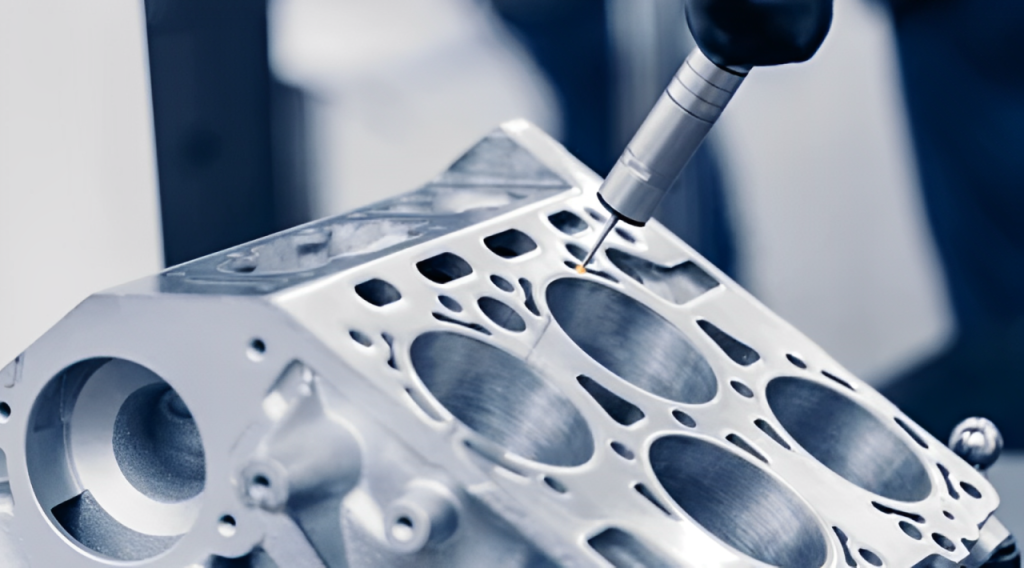

Let’s explore the different CNC operations we can apply to titanium grades.

The cylindrical titanium workpieces, such as shafts, orthopedic implants, and aerospace fasteners, are frequently shaped through turning. Titanium is elastic and sensitive to heat; thus, hard tooling, even feed and control of chips, is necessary to ensure precision and the surface finish.

Milling is well-suited to make any intricate shapes on parts that include structural aerospace parts and orthopedic implants. Tactics used to balance the heat, such as making trochoidal milling and adaptive toolpath, are crucial to work on titanium Grade 5.

Ti-6Al-4V can be drilled very badly because of chip buildup and heat buildup. Better chip evacuation is obtained by using coolant-through drills, peck drilling cycles, and sharp carbide tips, and tool wear and hole accuracy are kept down.

Titanium is difficult to tap due to the galling tendency of that material and poor thermal conductivity. Thread milling is sometimes the choice instead of conventional tapping because it offers more control of the chips, a smoother surface, and an impregnable thread.

The Wire Electrical Discharge Machining (EDM) cuts fine details and complex geometrical shapes made on titanium very efficiently. It saves tool wear problems, since it is operated by electrical erosion rather than mechanical force, and since it provides precision in thin or delicate regions.

Ti-6Al-4V parts require grinding and polishing to obtain medical-grade finishes or ultra-fine tolerances. The abrasive tools and the application of controlled pressure are done to prevent overheating, distortion, and damage to a surface, especially in surgical and dental parts.

Titanium parts that were machined are usually finished to enhance their appearance, wear tolerance, or bonding properties:

Machining of titanium is way too costly compared to either aluminum or steel due to:

Nevertheless, the sometimes high investment value is often justified by long-term performance advantages, particularly in the aerospace and medical areas.

Here are some of its applications;

| Property | Grade 5 Titanium | 6061 Aluminum | 304 Stainless Steel |

| Density (g/cm³) | 4.43 | 2.70 | 8.00 |

| Tensile Strength (MPa) | ~900 | ~310 | ~520 |

| Corrosion Resistance | Excellent | Good | Excellent |

| Machinability | Difficult | Easy | Moderate |

| Biocompatibility | Excellent | Poor | Good |

| Cost (material + machining) | High | Low | Moderate |

Grade 5 titanium (Ti-6Al-4V) is notoriously difficult to machine—but when strength, corrosion resistance, and lightweight durability are critical, few materials can match its performance. Whether used in medical implants or turbine blades, this alloy delivers reliable results in the most demanding environments.

Due to its work-hardening behavior and thermal properties, machining Grade 5 titanium requires specialized equipment, techniques, and experience. At ApexRapid, we provide advanced CNC machining services tailored to titanium alloys, ensuring high precision, tight tolerances, and consistent quality for mission-critical parts.

Q1: What makes titanium difficult to turn?

Titanium is thermally non-conductive, is easy to work hard, and reacts with cutting tools; hence the difficulty of cutting and tool wear.

Q2: Is Grade 5 titanium heat-treatable?

Yes. Ti-6Al-4V may be heat-treated to increase strength, but even in the annealed condition, it has high performance.

Q3: Which industries employ CNC-machined titanium?

Titanium parts are used in aerospace, medical, automotive, marine, energy, and industrial industries due to their strength and resistance to corrosion.

Q4: Which is the most suitable cutting tool for titanium?

The perfect ones are solid carbide, which have TiAlN or AlTiN coatings, since they maintain their heat and are durable.

Q5: Is titanium grade 5 biocompatible?

Yes. Ti-6Al-4V is not toxic and can be implanted into the human body on a long-term basis.