You’re building parts that can’t afford to fail. Maybe it’s a drone housing, a machine bracket, or a heat sink. Whatever it is, it sees wear, heat, or moisture.

Now you’re deciding how to finish it. Type II anodizing works when looks matter and wear is low. Type III steps in when the part takes a beating. Wrong choice? You’ll get premature wear, corrosion, or field complaints.

You don’t want to overpay and underprotect. That’s where this comparison helps. It breaks down the use cases, performance, and trade-offs. No fluff, just what works, where, and why.

You don’t design for failure, but bare aluminum invites it. Without a surface finish, parts corrode fast. Even light use can leave dents or scratches.

Surface finishing changes how your parts behave. It adds resistance to wear, heat, and moisture. More importantly, it makes the surface reliable under stress. That matters when performance and safety are on the line.

Think about outdoor enclosures or sliding parts. Without protection, they degrade in months, not years. One study showed anodized parts last 10x longer. That’s less downtime, fewer replacements, and lower warranty claims.

You have likely seen Type II anodizing in everyday products. It appears on items like camera housings, electronics, panels, and even kitchen tools. It gives aluminum a smooth, colored finish and a basic level of protection.

Type II anodizing uses a sulfuric acid bath and electric current. This process creates a thin oxide layer on the aluminum surface. That layer grows into the metal and becomes part of it. The typical coating thickness ranges from 0.0002 inches to 0.001 inches.

You can dye the surface after anodizing. That makes Type II a top choice when appearance matters. It also helps resist mild corrosion and light wear. But this finish is not built for heavy-duty or high-friction use.

Type II is reliable for indoor products or non-critical parts. It keeps your components looking clean while extending their lifespan in low-stress environments. If your goal is color, appearance, and some resistance, this option works well.

You want an attractive protectant finish. Type II anodizing provides you with a smooth, colorful corrosion corrosion-resistant surface. It is commonly used on many daily aluminum components. And the reasons why it works well with you are as follows.

Type II coating forms a high-strength oxide layer. This coating inhibits rust and damage on the surface. It is perfect for moisturized or slightly exposed outdoor parts. You will obtain a good quality protection that is not very expensive.

Using Type II anodizing, you may include beautiful colors. It takes dyes of various hues, bright reds to dark blues. This assists you in branding your parts or just makes them appear good. Easy customization is provided through color choices.

This anodizing technique consumes less material and time. It maintains low costs of production on your side. You will not be paying more and getting heavy-duty coatings when you do not require them. It is good in terms of the balance between price and quality.

Type II offers fairly good surface hardness. It is not susceptible to light scratches and day-to-day wear. It is perfect for indoor or low-friction parts. It is simply not designed for severe abrasion.

What Are the Steps Involved in Applying Type II Anodizing

You would like to know how Type II anodizing is applied. The procedure is cool yet simple. All the steps are the preparation of your aluminum to a long-lasting, beautiful finish. The following is how it works.

The first step entails cleaning the aluminum part. This eliminates dirt, grease, and oils, which may destroy the finish. You could employ alkaline cleaners or an ultrasonic bath. Even coating and improved adhesion are guaranteed by a clean surface.

Then the part is etched. This action takes off a thin layer of metals and levels the surface. Brightening can be done after etching. Brightening produces a reflective appearance to aluminum. These steps influence the appearance and quality of the coating in the end.

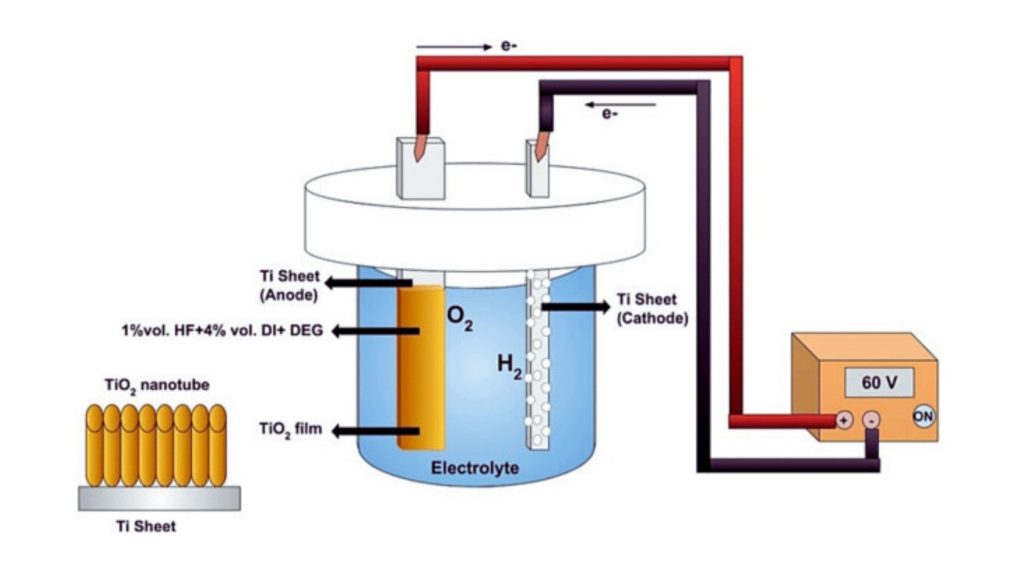

The next step is now the transferring of the part to the anodizing tank. It is placed in a bath of sulfuric acid in which an electric current is passed through it. The existing forces compel oxygen to combine with aluminum, and this creates a thin coating of oxide. This layer does not develop on top of the metal only.

Lastly, sealing is done to cover the oxide layer by covering the anodized section. You may close it up with hot water or steam. This seals small pores in the coating, which enhances corrosion resistance. You occasionally put in dyes prior to sealing coloring.

You want durable surface protection, right? Type II anodizing gives a thin, protective oxide layer. It’s the most common anodizing type used across industries. It forms a strong barrier against corrosion and wear.

This anodizing suits aluminum parts exposed to moderate stress. Think architectural panels, consumer electronics, or automotive trims. It adds aesthetic value, too, thanks to its ability to accept dyes easily.

Using Type II means you get corrosion resistance without heavy costs. It usually produces an oxide thickness between 0.0001 and 0.001 inches. This keeps parts lightweight yet durable, perfect for industrial needs.

Type II anodizing balances cost and performance perfectly. It doesn’t require expensive equipment or extended processing times. So, your production runs stay efficient and affordable.

You also gain flexibility in finish options. The oxide layer can be dyed vibrant colors or left natural. This flexibility makes Type II ideal for decorative and functional applications alike.

Industries like aerospace, automotive, and electronics rely on Type II. That’s because it protects parts in moderate environments without adding bulk. The surface hardness also improves, reducing scratches and surface wear.

If you need heavy-duty protection, skip Type II. It won’t withstand severe abrasion or chemical exposure well. In those cases, Type III or hard anodizing works better.

Also, if your part faces constant friction, Type II might wear down faster. Consider other coatings or anodizing types with thicker oxide layers for better durability.

Type III anodizing is a heavy-duty surface treatment. It forms a thick, hard oxide layer on aluminum parts. This layer is much thicker than Type II, usually between 0.001 and 0.003 inches.

This thicker coating makes your parts extremely resistant to wear and corrosion. Industries use Type III when durability is non-negotiable. It’s often called hard anodizing because of its toughness.

The process involves lower temperatures and longer treatment times. This creates a dense, hard surface ideal for harsh environments. Type III anodized parts handle abrasion, impact, and chemicals better than Type II.

You can pick type III when parts face heavy use or rough conditions. Think aerospace components, heavy machinery, or automotive engine parts. The hard coating reduces maintenance and extends lifespan.

Type III anodizing also improves surface hardness up to 60-70 Rockwell C. That means it can resist scratches and dents far better than softer coatings. Plus, it provides excellent electrical insulation and thermal stability.

This type of anodizing adds real value by cutting downtime and replacement costs. It’s perfect for parts that need long-lasting protection without adding much weight.

Type III forms a thicker, denser oxide layer. It is less porous than Type II; thus, it is more sealed to moisture and chemicals. The advantage is that you are provided with better protection at the increased costs of the process and lead time.

The end appearance is dull and less colorful than Type II, which is frequently dyed. However, at the industrial level, functionality prevails over looks. The roughness of Type III makes it the material of choice where failure is not an option.

Type III coating gives you better protection. Its thick, hard coat protects components in harsh environments. That is, your equipment will have a longer life and will work more efficiently.

The coating enhances resistance to corrosion and wear. Industries that require durability prefer using it as well. What are the main benefits you will see? Let us divide them.

Type III coating deals with great friction and rubbing. It avoids damage to the surfaces due to frequent use. This assists components in maintaining their form and functionality.

There is less wear and tear; hence, no frequent repairs. That conserves time and money on your operations. It’s ideal with machinery and moving components.

The coating is moisture and chemical-resistant. This stops rust and corrosion from eating away at your parts. You have equipment that lasts longer and is dependable.

It is suitable in marine, chemical, and industrial atmospheres. Hence, your components remain safeguarded in severe environments.

Type III hardens aluminum to a depth of 70 Rockwell C. This implies that the coating is more resistant to scratches and dents. Your parts remain in good shape and in good condition.

Increased hardness also implies reduced damage to the surface when handling or transporting. That minimises downtimes and maintenance expenses.

A thick oxide layer provides electrical insulation. This prevents electrical damage to sensitive components. It's useful in electronic and aerospace parts.

The insulation is also useful in the management of heat. Thus, your parts are safe to use at different temperatures.

Type III anodizing is an electrically and acid-based aluminum protection. The operation forms a tough, hard coating over the metal. So, how does it work? Let us find out step by step.

You start by cleaning the aluminum. The coating can be prevented to stick by dirt or oils. You may employ degreasing or chemical cleaning.

The clean surfaces contribute towards making the oxide layer uniform. This is an essential step to effective long-term protection.

Then you put the part in a bath of sulfuric acid. The acid assists in initiating the reaction that increases the oxide layer. This bath remains extremely cold, almost at freezing point.

Cold enables the oxide layer to remain dense and hard. It reduces the reaction rate, so the coating becomes thick and hard.

When you switch on the power, the electricity will pass through the acid. The oxide coating is formed by the formation of oxygen on the surface of aluminum.

The current is then tightly regulated to prevent overheating. This control assists in the even building of the layer and eliminates damage.

Oxide layer develops inwards and outwards. This bonding renders the coating extremely strong and tough.

The type III coatings are very thick compared to other types of anodizing. That is the thickness that gives it that heavy-duty protection.

Sealing the coating is done after anodizing. Typically, small pores on the oxide layer are sealed by hot water or steam.

Sealing prevents the entry of moisture. This procedure enhances resistance to corrosion and increases the life of the coating.

Lastly, you check the pieces in terms of thickness and hardness. This will guarantee you the coating that fits your needs.

Testing helps avoid weak spots or defects that could cause early failure.

You need numbers, not just opinions. Every surface finish offers different strengths. And each one affects how your part survives in the field.

Use this table when selecting for durability, thickness, or environment. These aren’t just specs — they help you predict performance. Make smarter choices before parts hit production.

| Property | Type II Anodizing | Type III Anodizing (Hard Coat) |

| Coating Thickness | 0.0002" to 0.001" | 0.001" to 0.004" |

| Hardness (Knoop) | 200–400 | 400–600+ |

| Corrosion Resistance (Salt Spray) | Up to 336 hours (with seal) | 1,000+ hours (unsealed or sealed) |

| Color Options | Wide range (dyed) | Limited (gray, black, dark bronze) |

| Wear Resistance | Moderate | High |

| Electrical Insulation | Moderate | High |

| Typical Use Case | Decorative or light industrial | Aerospace, defense, heavy-duty |

| Cost Per Square Inch (avg.) | Lower | Higher |

You don’t always need the strongest coat. But you always need the right one. Use these values to match the finish to the real-world demands your part will face.

Type III anodizing gives you tough, long-lasting protection. It builds a thick, hard oxide layer that resists wear, corrosion, and scratches. This makes it perfect for heavy-duty industrial parts.

The process uses cold sulfuric acid baths and electric current to grow the coating. Careful cleaning, controlled conditions, and sealing ensure the best quality finish.

You’ll choose Type III when parts face harsh environments or constant friction. Its benefits include strong wear resistance, excellent corrosion protection, and electrical insulation.

Type III anodizing extends part life and lowers maintenance costs, making it ideal when durability matters. Apex Rapid provides professional hard anodizing to enhance your CNC parts—Contact us to get started

Type III anodizing is used to protect aluminum parts that need heavy-duty wear and corrosion resistance. It’s common in aerospace, automotive, and industrial machinery.

The coating is usually between 0.001 and 0.003 inches thick. This thick layer makes the surface very hard and durable.

Yes, it creates a dense oxide layer that blocks moisture and chemicals. This helps prevent rust and extends the part’s life.

It’s harder to dye Type III coatings because they are thicker and less porous. Usually, the finish is left natural and matte for industrial uses.